Polypropylene composite material for seamless instrument board and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials for seamless dashboards and its preparation, can solve the problems of large parts of seamless dashboards, tiger skin patterns and air marks, and affect the production capacity of enterprises. The effect of high rigidity-toughness balance and low-temperature impact, simple preparation method, and excellent injection molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0033] A polypropylene composite material for a seamless instrument panel and a preparation method thereof, specifically comprising the following steps:

[0034] (1) Add polypropylene, high-density polyethylene, polyolefin elastomer, talcum powder, antioxidant, light stabilizer, scratch-resistant agent, lubricant and toner to the high-speed mixer according to the formula ratio in Table 1. Mix at high speed in the mill for 5-10 minutes;

[0035] (2) Add the mixed material to the twin-screw extruder through the main feed to melt, extrude and granulate; wherein, the barrel temperature is 190-220°C, the screw speed is 300-500r / min, vacuum The degree is -0.04-0.1MPa;

[0036] (3) Put the material extruded by the twin-screw extruder into a drying oven at a drying temperature of 80-90°C for 2-4 hours to obtain a polypropylene composite material for a seamless instrument panel.

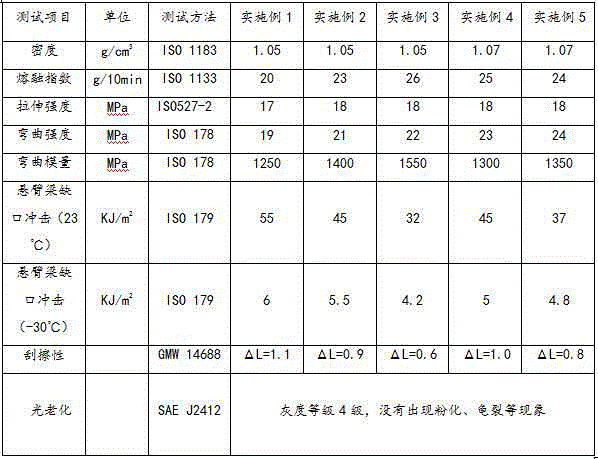

[0037] Wherein, the main performance indexes in Examples 1-5 are shown in Table 2.

[0038] Table I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com