Ripening process for wheat aleurome layer content, and product thereof

A technology for wheat aleurone layer and contents, which is applied to the field of frying and curing technology for the contents of the wheat aleurone layer and its products, and can solve the problem that the content of the wheat aleurone layer is not perfected in the production process and cannot well control the wheat aleurone. The uniformity of the layer contents and the inability to retain nutrients well, so as to increase energy consumption and ensure the effect of physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

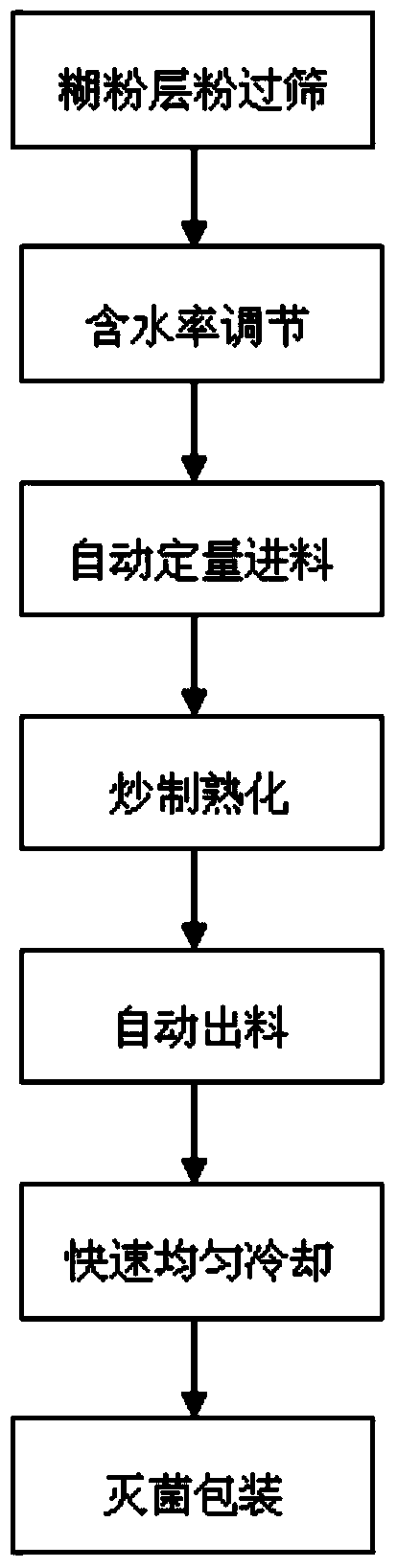

[0029] Sieving the contents of the wheat aleurone layer to screen out the contents of the wheat aleurone layer with an average particle size of less than 75 μm;

[0030] The moisture content of the content of the wheat aleurone layer should be controlled at less than 16%, and the low moisture content can avoid agglomeration and paste pan phenomenon during the ripening process;

[0031] Use the automatic quantitative feeding device to carry out automatic quantitative feeding to prevent dust and realize fully automatic and precise quantitative feeding;

[0032] When frying, the temperature should be precisely controlled below 143°C, and dehumidification equipment should be installed to remove a large amount of steam generated in the equipment during the curing process. If the dehumidification is not timely, the materials inside the equipment will agglomerate and stick to the wall, which may eventually lead to Unsmooth discharge and gelatinization of materials sticking to the wal...

Embodiment 2

[0038] Sieving the contents of the wheat aleurone layer to screen out the contents of the wheat aleurone layer with an average particle size of less than 50 μm;

[0039] The moisture content of the content of the wheat aleurone layer should be controlled at less than 16%, and the low moisture content can avoid agglomeration and paste pan phenomenon during the ripening process;

[0040] Use the automatic quantitative feeding device to carry out automatic quantitative feeding to prevent dust and realize fully automatic and precise quantitative feeding;

[0041] When frying, the temperature should be precisely controlled below 143°C, and dehumidification equipment should be installed to remove a large amount of steam generated in the equipment during the curing process. If the dehumidification is not timely, the materials inside the equipment will agglomerate and stick to the wall, which may eventually lead to Unsmooth discharge and gelatinization of materials sticking to the wal...

Embodiment 3

[0047] Sieving the contents of the wheat aleurone layer to screen out the contents of the wheat aleurone layer with an average particle size of less than 50 μm;

[0048] The moisture content of the wheat aleurone layer content should be controlled at less than 10%, and the low moisture content can avoid agglomeration and paste pan phenomenon during the ripening process;

[0049] Use the automatic quantitative feeding device to carry out automatic quantitative feeding to prevent dust and realize fully automatic and precise quantitative feeding;

[0050] When frying, the temperature should be precisely controlled below 143°C, and dehumidification equipment should be installed to remove a large amount of steam generated in the equipment during the curing process. If the dehumidification is not timely, the materials inside the equipment will agglomerate and stick to the wall, which may eventually lead to Unsmooth discharge and gelatinization of materials sticking to the wall, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com