Oxidation process of preparing wool keratin solution

A protein solution and oxidation technology, applied in the field of preparation of wool keratin solution, can solve the problems of high dissolving temperature, inability to maintain wool physical and chemical properties, low solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

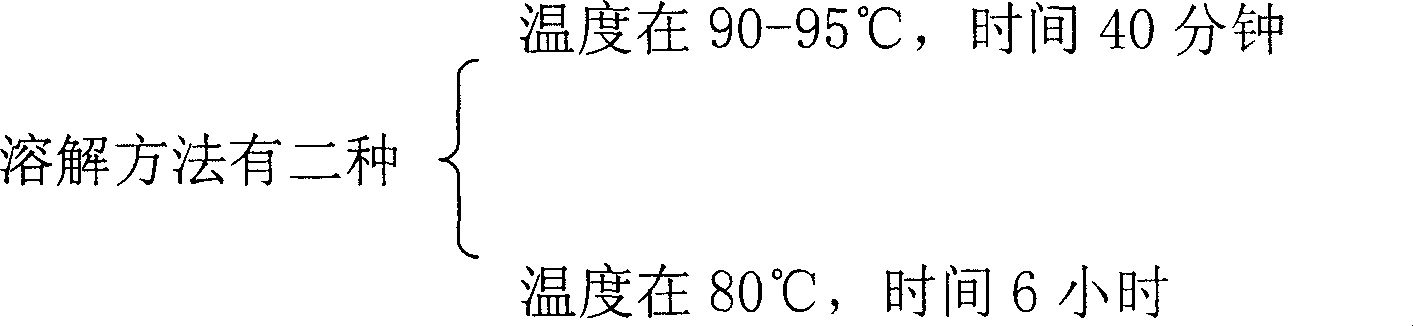

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: wool is washed with the sodium lauryl sulfate solution of concentration 4%, the bath ratio of wool and this solution is 1: 40, temperature 70 ℃, time 30min, and wash under the condition of stirring; H 2 o 2 Add urea under stirring, and H 2 o 2 The weight ratio of urea and urea is 3: 4, keep the temperature at 30 DEG C, stir and react for 1.5 hours to obtain urea hydrogen peroxide adduct; mix the urea hydrogen peroxide adduct obtained above with distilled water, and the process The weight ratio of urea hydrogen oxide adduct to distilled water is 1:1, and anionic surfactant is added under stirring state, under normal temperature state, stirring for 1 hour, a colorless transparent liquid is obtained; the colorless transparent liquid prepared above is put into Add the wool obtained above, the weight ratio of the liquid to the wool is 5: 1, keep stirring, and slowly heat up to 65°C, after 6 hours, a light yellow translucent liquid is obtained, and the insolub...

Embodiment 2

[0023] Embodiment 2: wool is washed with the sodium lauryl sulfate solution of concentration 4%, the bath ratio of wool and this solution is 1: 30, temperature 60 ℃, time 40min, and wash under the condition of stirring; H 2 o 2 Add urea under stirring, and H 2 o 2 The weight ratio of urea and urea is 3: 4, keep the temperature at 26 ° C, and stir for 1.5 hours to obtain urea hydrogen peroxide adduct; the above-mentioned urea hydrogen peroxide adduct prepared above is mixed with distilled water, and the process The weight ratio of urea hydrogen oxide adduct to distilled water is 14:10, and anionic surfactant is added under stirring state, under normal temperature state, stirring for 1 hour, a colorless transparent liquid is obtained; the colorless transparent liquid prepared above is put into Add the wool obtained above, the weight ratio of the liquid to the wool is 10:1, keep stirring, and slowly heat up to 70°C, after 5 hours, a light yellow translucent liquid is obtained, ...

Embodiment 3

[0024] Embodiment 3: wool is washed with the sodium lauryl sulfate solution of concentration 4%, the bath ratio of wool and this solution is 1: 50, temperature 68 ℃, time 40min, and wash under the condition of stirring; H 2 o 2 Add urea under stirring, and H 2 o 2 The weight ratio of urea and urea is 3: 4, keep the temperature at 30 DEG C, stir and react for 1.5 hours to obtain urea hydrogen peroxide adduct; mix the urea hydrogen peroxide adduct obtained above with distilled water, and the process The weight ratio of urea hydrogen oxide adduct to distilled water is 14:15, and an anionic surfactant is added under stirring state, under normal temperature state, stirring for 1 hour, a colorless transparent liquid is obtained; the colorless transparent liquid prepared above is put into Add the wool obtained above, the weight ratio of the liquid to the wool is 20: 1, keep stirring, and slowly heat up to 85°C, after 4 hours, a light yellow translucent liquid is obtained, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com