Fire-retardant medium density fiberboard and preparation method thereof

A technology of fiberboard and medium density, which is applied in the field of flame-retardant medium-density fiberboard and its preparation. It can solve the problems that fiberboard is easy to absorb moisture, and the flame-retardant performance and environmental protection performance need to be improved, so as to achieve excellent flame-retardant effect and good matching synergy , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Preparation method one of modified MUF adhesive:

[0063] A. 100 parts of formaldehyde aqueous solution, 0.1 part and 0.3 part of amino-terminated hyperbranched polymer PAMAM whose mass concentration is 36.5wt% are 100 parts by weight, and 0.3 part of amino-terminated hyperbranched polymer PAMAM is put into the reactor, and the stirring is started; The active substance is sodium hydroxide, potassium hydroxide, calcium hydroxide, barium hydroxide or ammonia water;

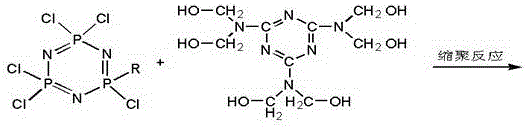

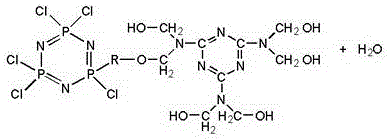

[0064] B. Add 1 part of hexachlorocyclotriphosphazene, heat up to 50°C, and when the temperature rises to 75°C by itself, add 35 parts of melamine, continue to heat up to 90°C, and react to obtain a preliminary polycondensate;

[0065] C. Add 40 parts of melamine to the above-mentioned preliminary polycondensate, and add 0.6 part of p-toluenesulfonamide to obtain the second polycondensate;

[0066] D. Add 20 parts of urea when the temperature of the second polycondensation product is lowered to 70°C, continu...

Embodiment 1

[0078] 12 parts of the modified MUF adhesive prepared by the modified MUF adhesive preparation method 1, 0.12 parts of ammonium chloride, 1.2 parts of paraffin emulsion (concentration 40%), Mg / Al-LDHs prepared by the flame retardant formula 1 (0.01 part of silane coupling agent modified) 12 parts, sprayed evenly on the surface of poplar fiber with spray gun and sieve in turn, after spraying, the fiber was paved, pre-pressed (pre-pressed pressure 3MPa), hot-pressed ( The three-stage curve of hot pressing pressure is 4.0MPa, 2.5MPa, 1.0MPa respectively, the hot pressing time is 60s / mm, and the temperature is 180°C). After cooling, the flame-retardant medium density fiberboard can be obtained, and the measured oxygen index is 34.2%.

Embodiment 2

[0080] 14 parts of modified MUF adhesive prepared by preparation method 2 of modified MUF adhesive, 0.14 part of ammonium chloride, 1.2 parts of paraffin emulsion (concentration 40%), Mg / Al-LDHs15 prepared by flame retardant formula 2 parts (modified by 0.01 part of silane coupling agent) are evenly sprayed on the surface of poplar fiber with a spray gun and a sieve in sequence. Pressure three-stage curve, respectively 4.0MPa, 2.5MPa, 1.0MPa, hot pressing time 60s / mm, temperature 190 ℃), cooling to obtain a flame-retardant medium density fiberboard, the measured oxygen index is 34.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com