Method for removing aluminum trichloride catalyst form petroleum resin by dry cleaning

A technology of aluminum trichloride and petroleum resin, applied in the field of petroleum resin synthesis, can solve the problems of environmental pollution, incomplete neutralization, affecting the physical and chemical properties of resin products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

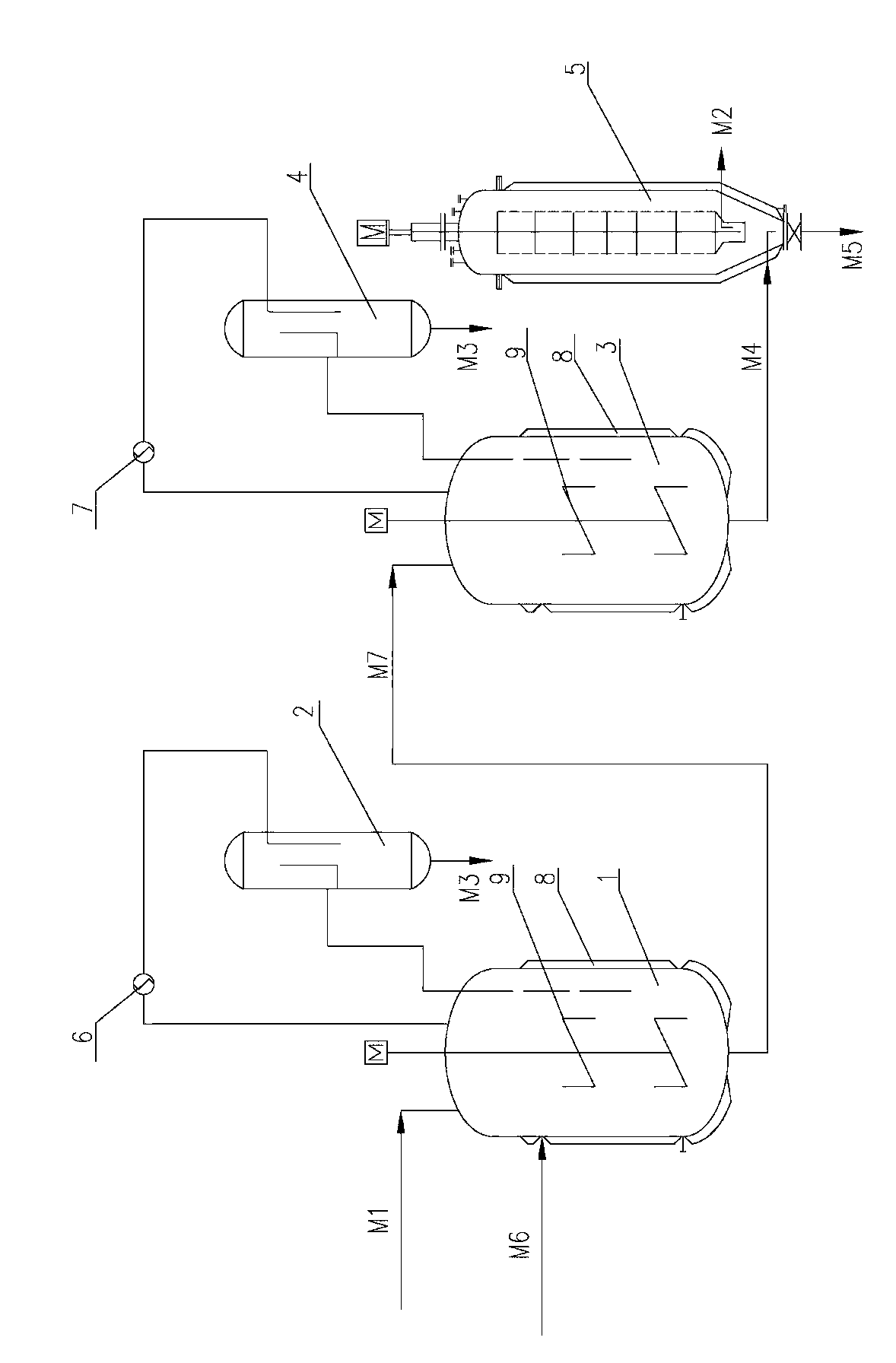

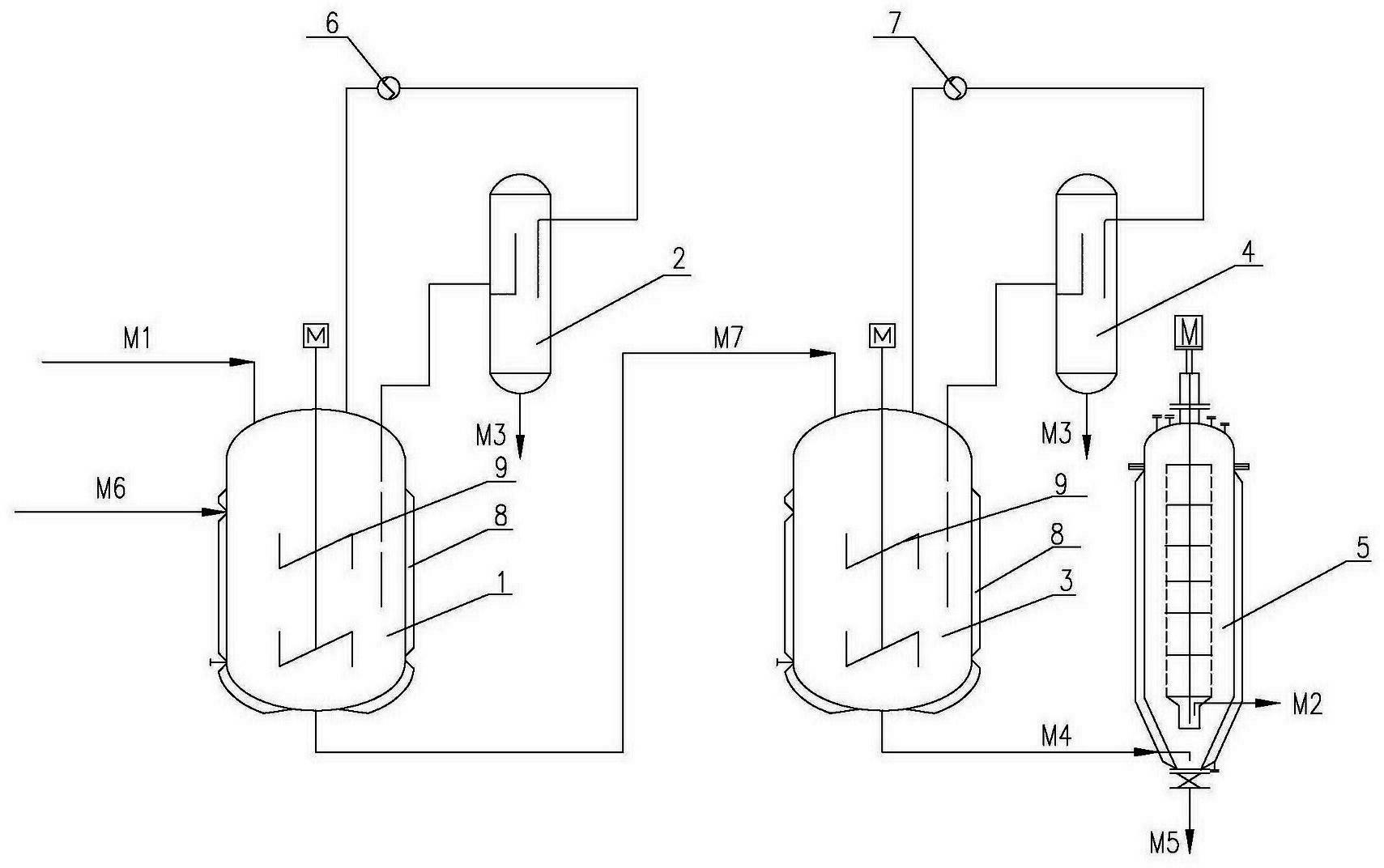

Method used

Image

Examples

experiment example

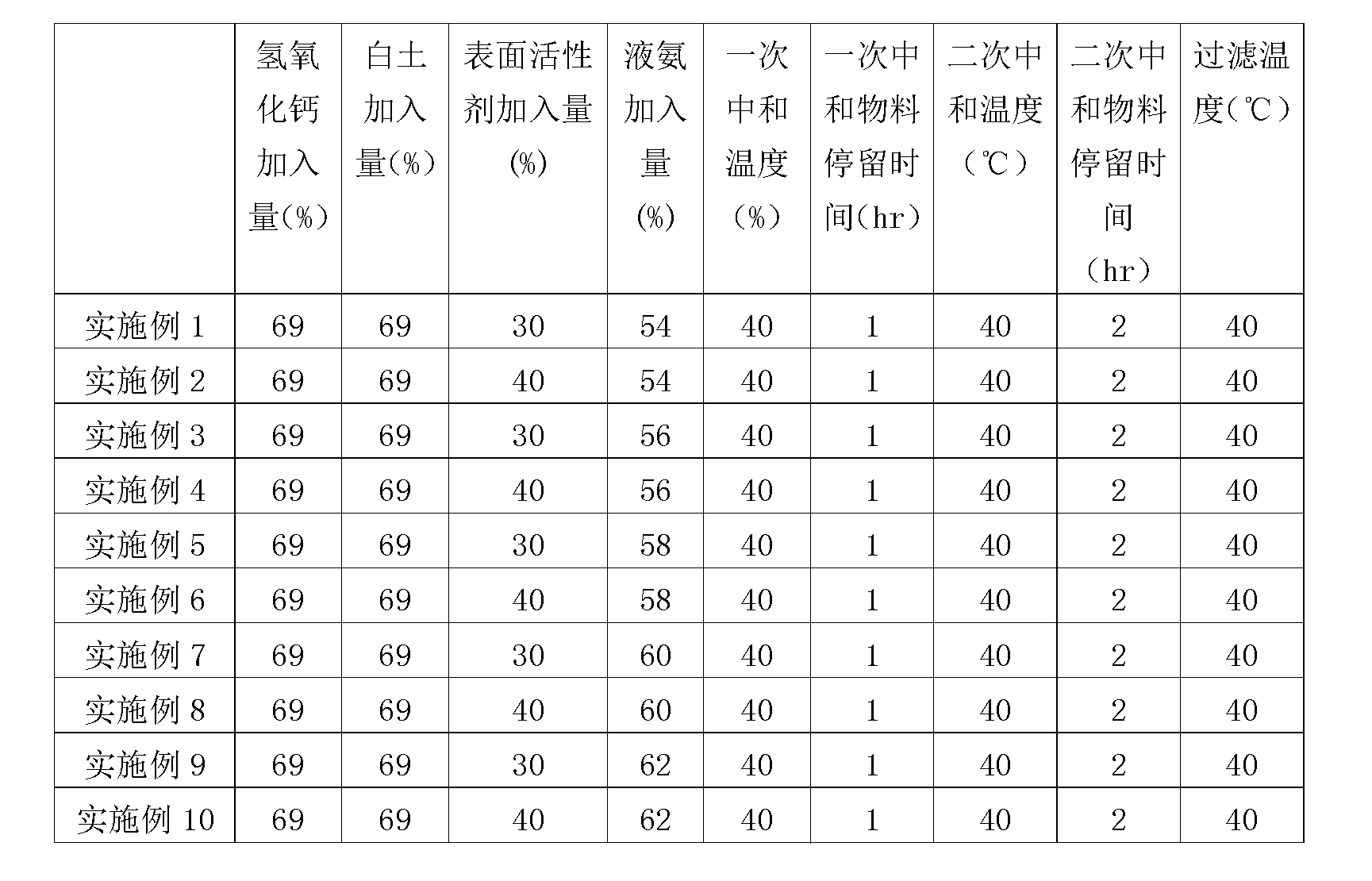

[0018] Experimental example: The polymerization raw material is piperylene, C5 solvent 1, C5 solvent 2, aluminum trichloride catalyst is added dropwise, the polymerization temperature is 60°C, the polymerization pressure is 0.2MPa, and the polymerization time is 3 hours. The plan is to remove the catalyst, distill off the solvent and unpolycarbonated carbon five, then pass through water vapor to distill off the residual solvent and oligomers, and finally add an appropriate amount of antioxidant to obtain the product. Analyze the produced petroleum resin, and the results are as follows surface:

[0019]

[0020] It can be seen from the above table that the color and ash content of the obtained petroleum resin have been greatly reduced, and the effect is very remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com