High weather resistant and flame-retardant cable

A flame-retardant cable, high weather resistance technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as cracks, damage, and damage to the structural integrity of cables, and achieve high phase change enthalpy, stability, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

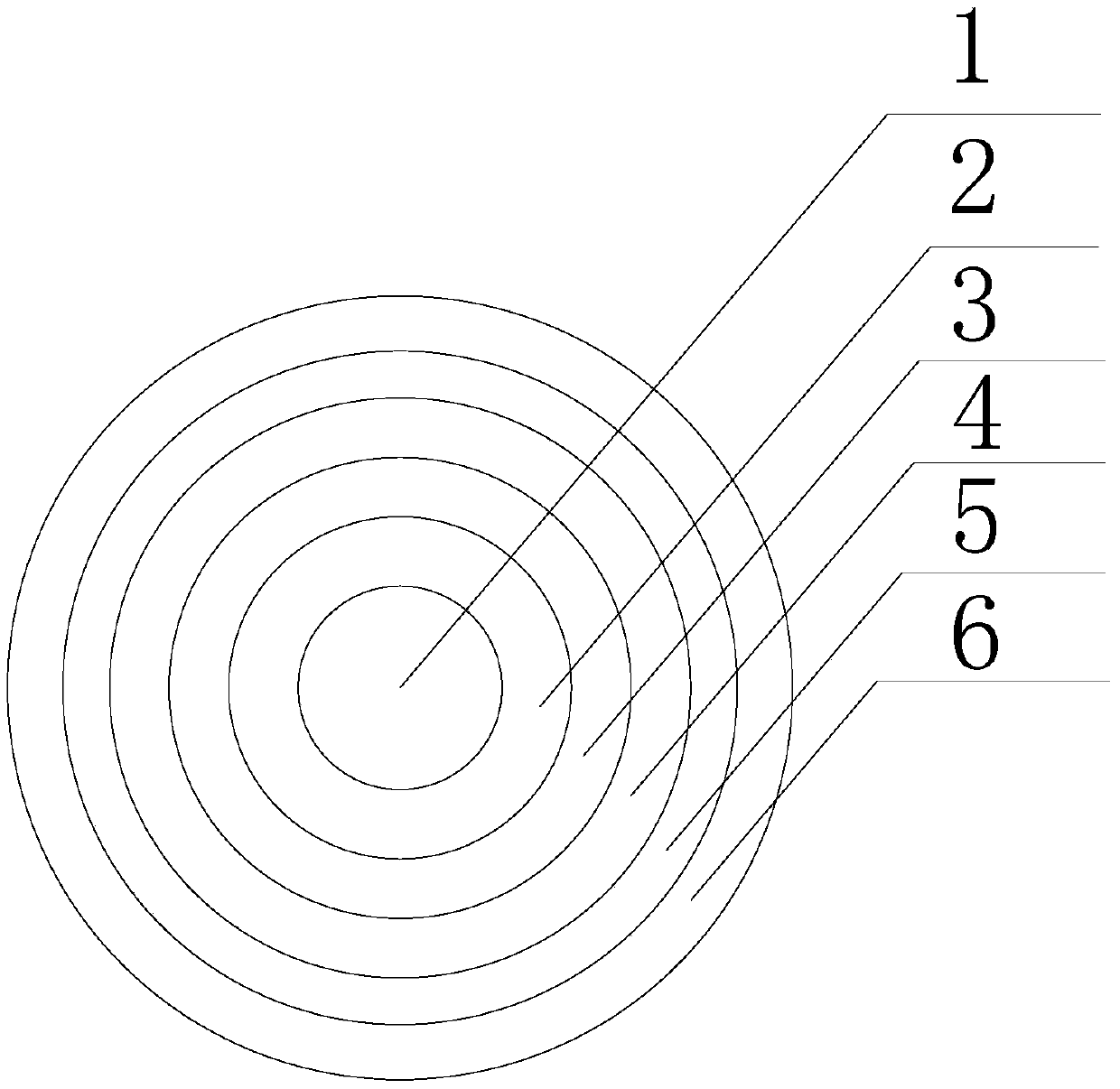

[0025] Such as figure 1 as shown, figure 1 It is a schematic diagram of the radial section structure of a high weather resistance and flame retardant cable proposed by the present invention.

[0026] refer to figure 1 , a high weather-resistant and flame-retardant cable proposed by the present invention, including a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, and a covering shielding layer The armor layer 5 of 4 and the outer sheath 6 covering the armor layer 5;

[0027] Wherein the raw material of outer sheath 6 comprises by weight: 48 parts of styrene-butadiene rubber, 25 parts of chloroprene rubber, 20 parts of natural rubber, 10 parts of phase change control microcapsules, 1.2 parts of sulfur powder, 1.6 parts of accelerator AA, 2.5 parts of agent MZ, 11 parts of hard clay, 6 parts of sepiolite, 8 parts of lanthanum oxide, 5 parts of mica powder, 3 parts...

Embodiment 2

[0034] A high weather-resistant and flame-retardant cable proposed by the present invention includes a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, and a covering shielding layer 4 The armor layer 5 and the outer sheath 6 covering the armor layer 5;

[0035]Wherein the raw material of outer sheath 6 comprises by weight: 45 parts of styrene-butadiene rubber, 27 parts of chloroprene rubber, 17 parts of natural rubber, 13 parts of phase change control microcapsules, 0.8 part of sulfur powder, 2.4 parts of accelerator AA, 2.8 parts of agent MZ, 8 parts of hard clay, 9 parts of sepiolite, 6 parts of lanthanum oxide, 7 parts of mica powder, 2.6 parts of monoalkoxy pyrophosphate titanate coupling agent, 2.8 parts of coconut oil, 3 parts of naphthenic oil, 6 parts of antimony trioxide, 3 parts of melamine, 6 parts of red phosphorus masterbatch, 5 parts of barium stearat...

Embodiment 3

[0042] A high weather-resistant and flame-retardant cable proposed by the present invention includes a conductor 1, an insulating layer 2 covering the conductor 1, a filling layer 3 covering the insulating layer 2, a shielding layer 4 covering the filling layer 3, and a covering shielding layer 4 The armor layer 5 and the outer sheath 6 covering the armor layer 5;

[0043] Wherein the raw material of outer sheath 6 comprises by weight: 47 parts of styrene-butadiene rubber, 25.5 parts of chloroprene rubber, 19 parts of natural rubber, 11 parts of phase change control microcapsules, 1.1 parts of sulfur powder, 1.7 parts of accelerator AA, 2.7 parts of agent MZ, 9 parts of hard clay, 8 parts of sepiolite, 6.5 parts of lanthanum oxide, 6 parts of mica powder, 2.7 parts of monoalkoxy pyrophosphate titanate coupling agent, 2.7 parts of coconut oil, 4 parts of naphthenic oil, 5 parts of antimony trioxide, 3.5 parts of melamine, 5.5 parts of red phosphorus masterbatch, 6 parts of bari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com