Automobile antifreeze and preparation method thereof

A technology for automobiles and formulations, which is applied in the field of antifreeze for automobiles and its preparation, which can solve the problems of precipitation, uneconomical, low temperature resistance, etc., and achieve the effects of simple production process, extended service life, and strong low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Antifreeze for automobiles, the basic raw materials are dimethyl sulfoxide and deionized water, and the respective weight percentages are as follows:

[0028] Dimethyl sulfoxide 35%;

[0029] Water 50%.

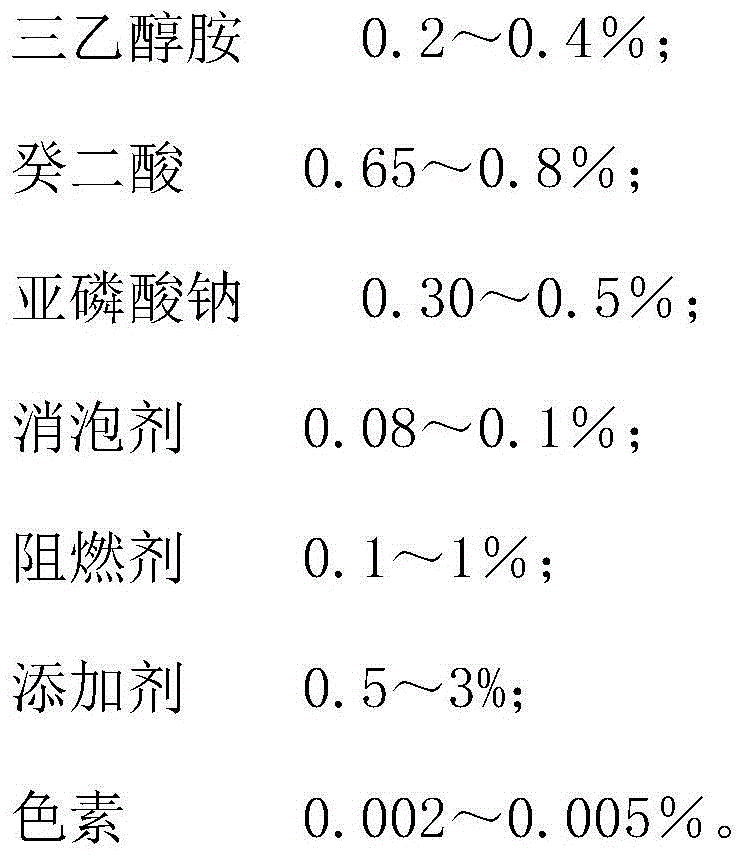

[0030] Described automobile antifreeze, take base raw material as 100% quality basis, the weight percent of other batching that adds is as follows:

[0031] Triethanolamine 0.2%;

[0032] Sebacic acid 0.65%;

[0033] Sodium phosphite 0.30%;

[0034] Defoamer 0.08%;

[0035] Flame retardant 0.1%;

[0036] Additive 0.5%;

[0037] Pigment 0.002%.

[0038] The preparation of the flame retardant: by weight, 1% ammonium dihydrogen phosphate, 1% potassium hypophosphite, and 1% sodium phosphite were added to 90% water respectively, stirred and heated to boiling, and kept for 20 minutes. Then cool to room temperature.

[0039] The water needs to be preheated to 50°C.

[0040] The water is deionized water.

[0041] The preparation method of described automobile antifr...

Embodiment 2

[0046] Antifreeze for automobiles, the basic raw materials are dimethyl sulfoxide and deionized water, and the respective weight percentages are as follows:

[0047] Dimethyl sulfoxide 45%;

[0048] Water 50%.

[0049] Described automobile antifreeze, take base raw material as 100% quality basis, the weight percent of other batching that adds is as follows:

[0050] Triethanolamine 0.2%;

[0051] Sebacic acid 0.8%;

[0052] Sodium phosphite 0.5%;

[0053] Defoamer 0.1%;

[0054] Flame retardant 1%;

[0055] Additives 3%;

[0056] Color 0.005%.

[0057] The preparation of the flame retardant: by weight, 3% ammonium dihydrogen phosphate, 3% potassium hypophosphite, and 4% sodium phosphite were added to 95% water respectively, stirred and heated to boiling, and kept for 20 minutes. Then cool to room temperature.

[0058] The water needs to be preheated to 50°C.

[0059] Described water is distilled water.

[0060] The preparation method of described automobile antifree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com