Patents

Literature

32results about How to "Easily intrusive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

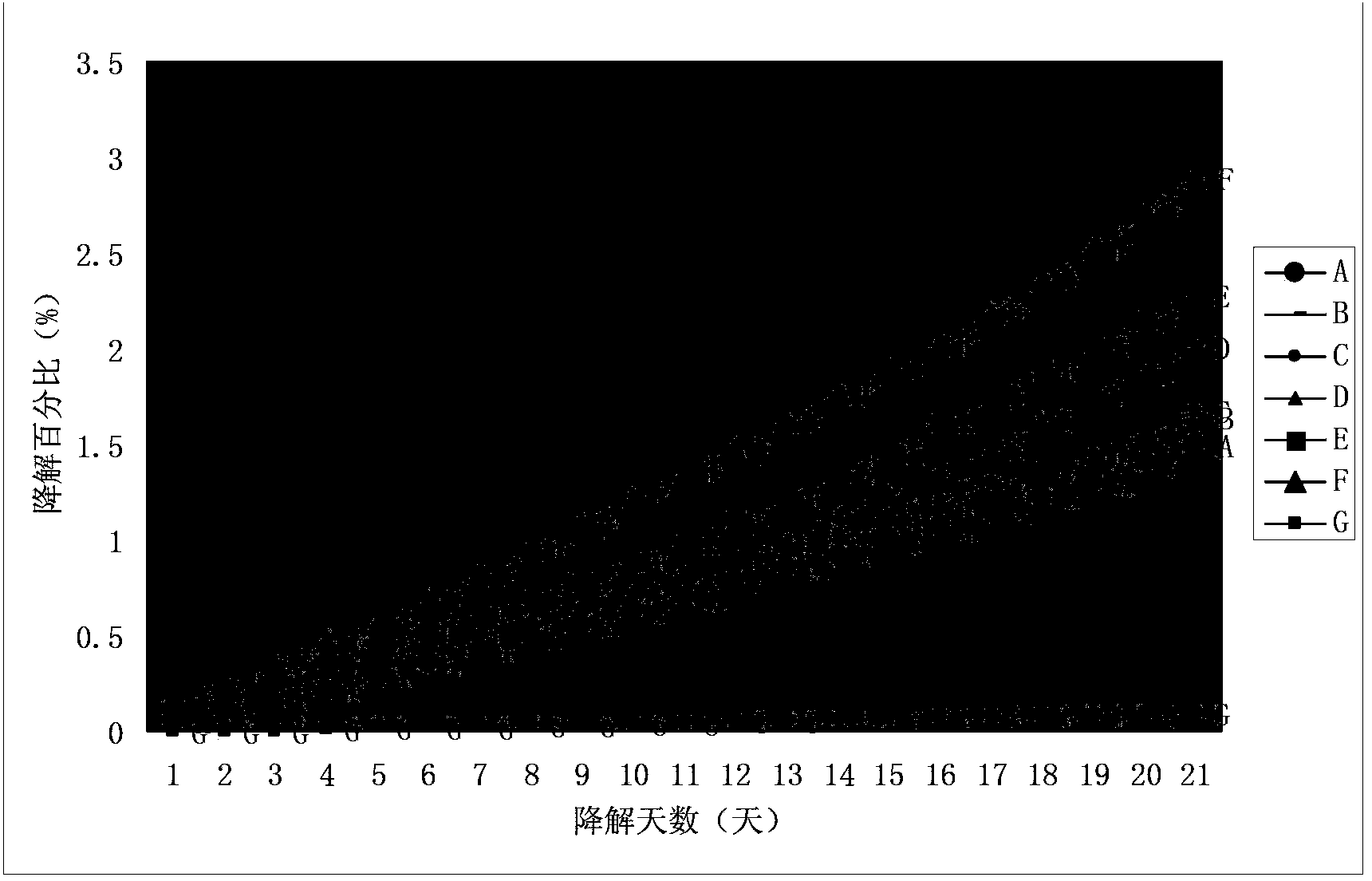

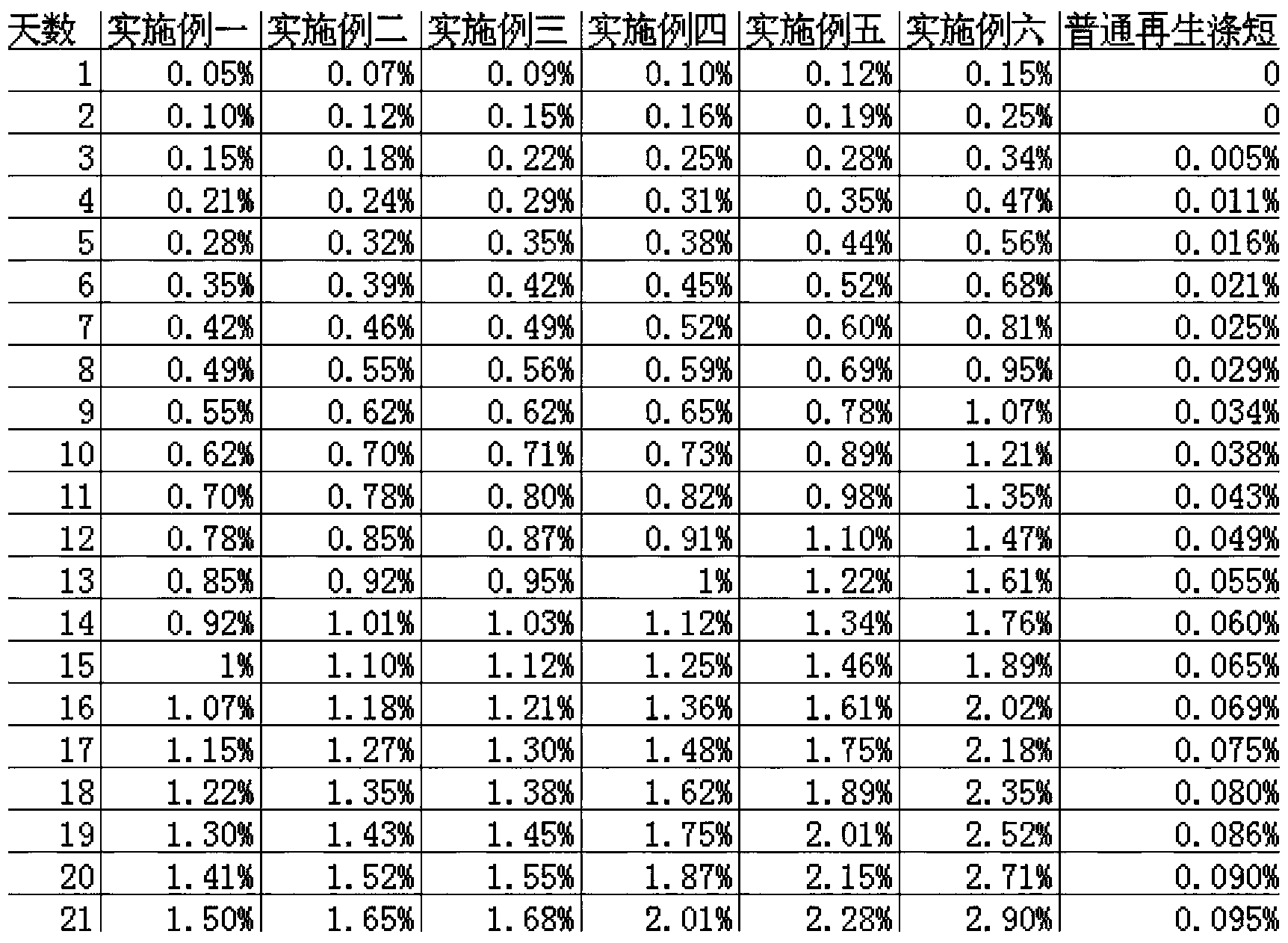

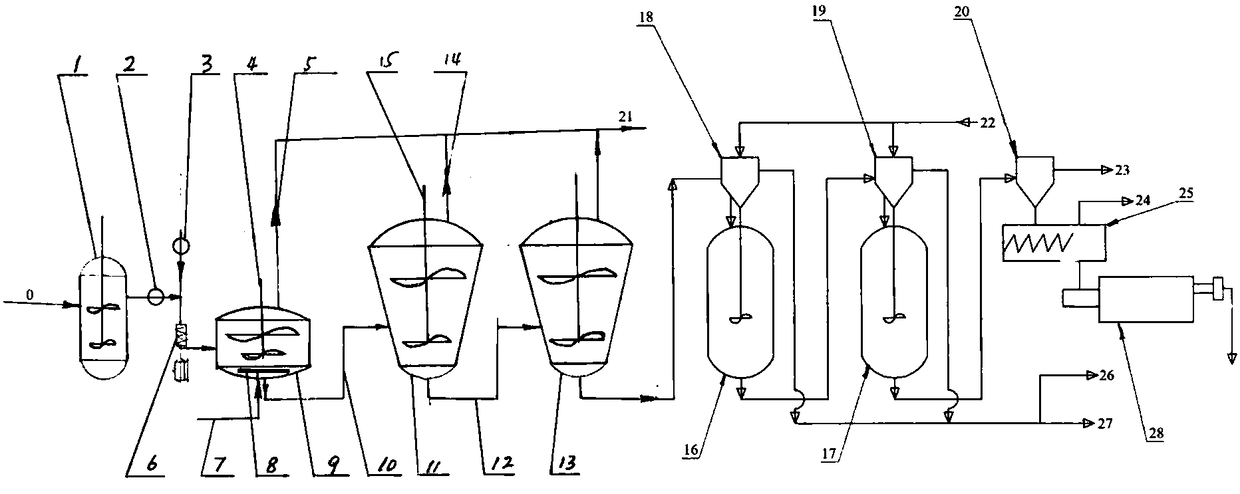

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276APrevent volatilizationBalanced moistureFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

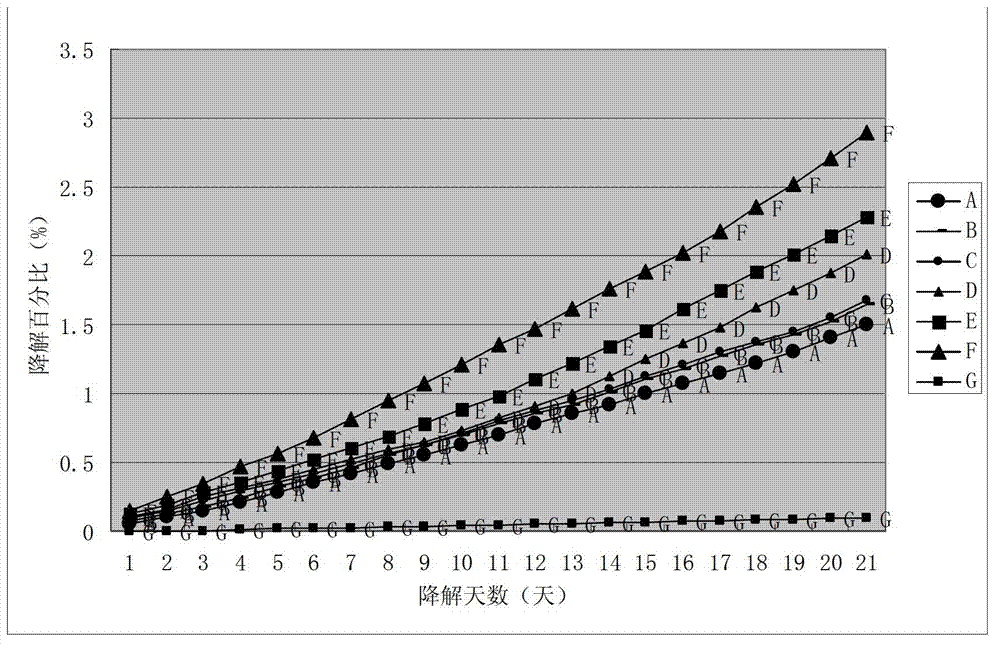

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

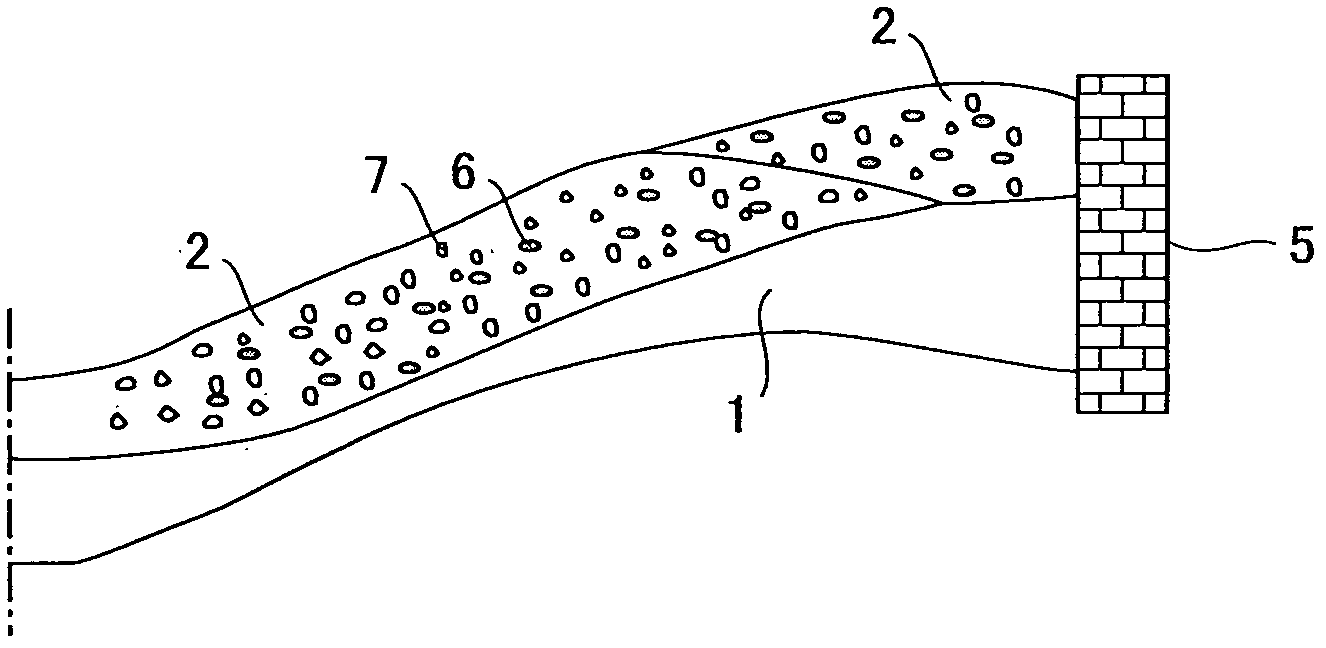

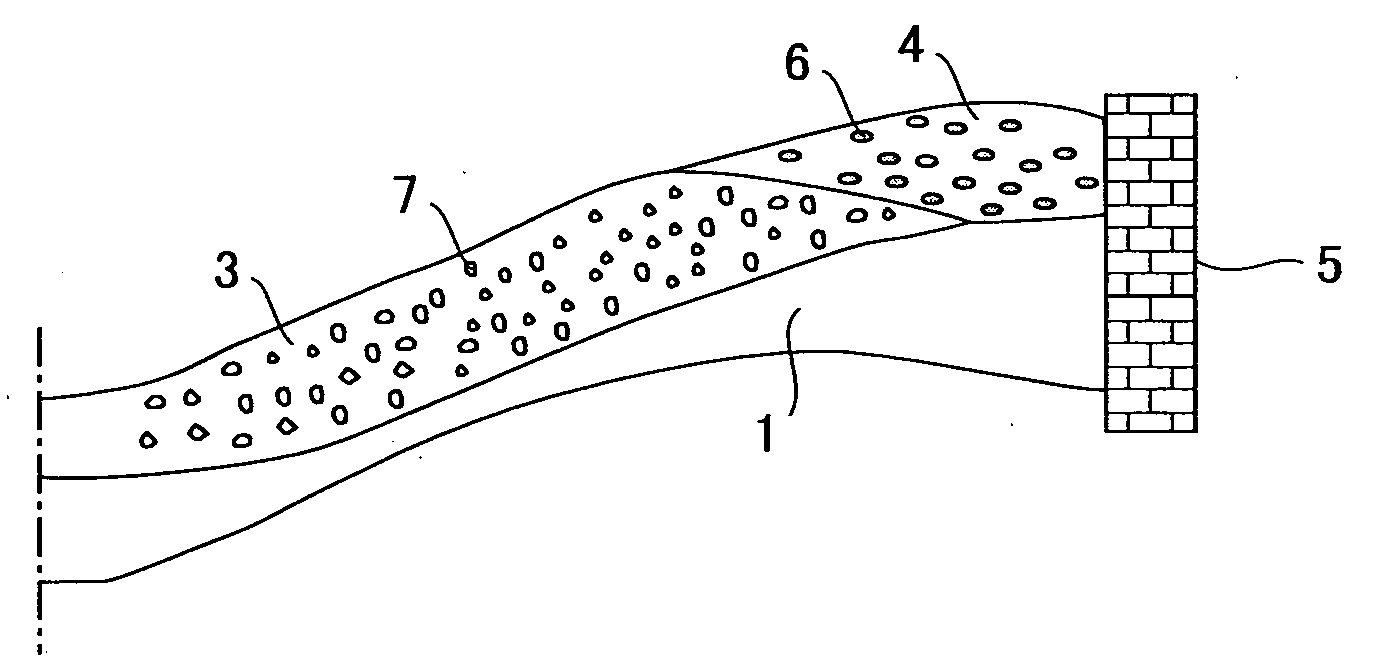

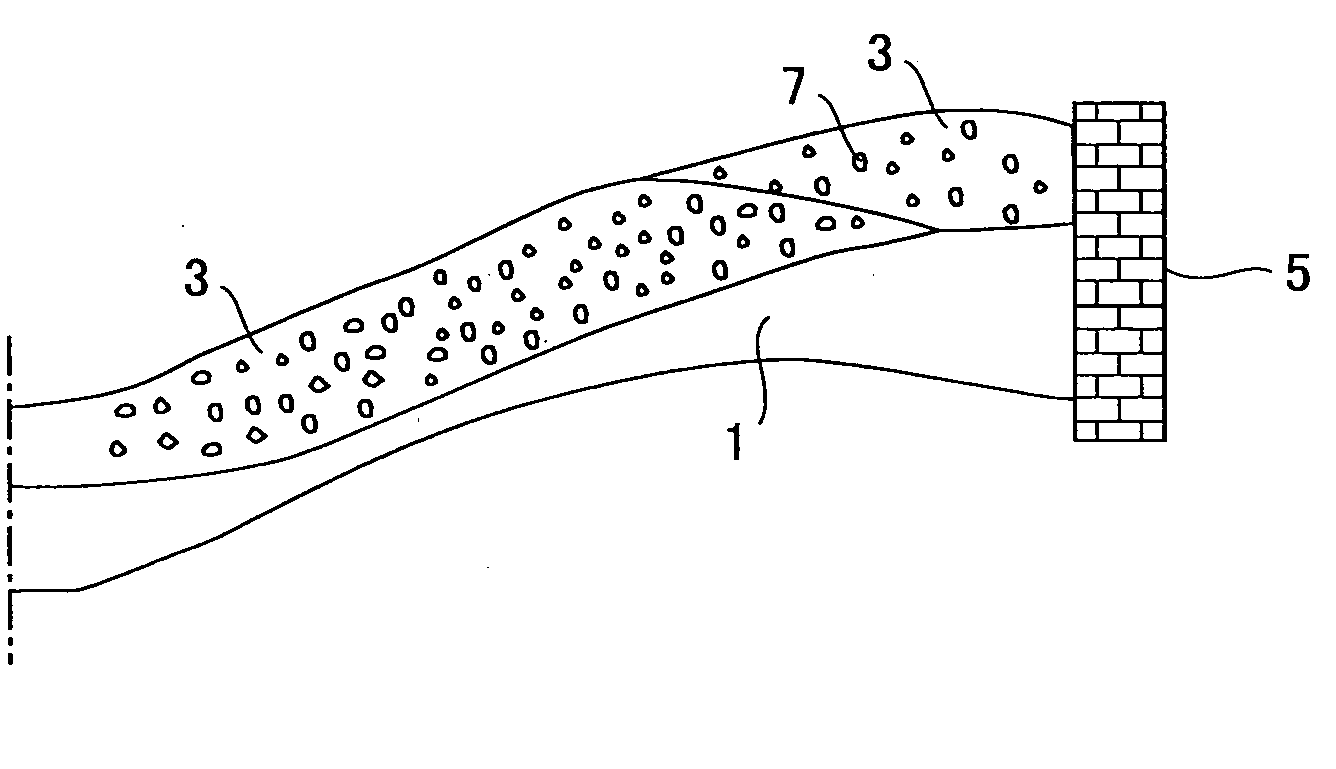

Method for updating deteriorated grassland bluegrass lawn at low cost in north

ActiveCN103931416ASolving the degenerative update puzzleReduce replacement costsHorticultureGrasslandBiology

The invention provides a method for updating a deteriorated grassland bluegrass lawn at low cost in the north. Weed control, pruning height control, lawn partition area and turf block size determination, rooting hastening with grass blocks soaked in pesticide, determination of the number of turf blocks planted in a community per square meter and planting positions, compacting, watering, sand covering, growth regulator application and other technologies are applied, on the basis of the natural rules of plant interspecific competition and the survival of the fittest, zoysia japonica can easily invade the deteriorated grassland bluegrass lawn due to strong creeping stems and the strong growing vigor and competitiveness, other grass seeds can hardly invade the lawn once the population of the zoysia japonica is formed, and therefore the aim of updating the deteriorated grassland bluegrass lawn at low cost is achieved. The effective method can be applied to the production practice of landscaping in a large area, can solve the problem of a deteriorated cool-season lawn, and can lower updating cost.

Owner:浙江知多多网络科技有限公司

Organic compound sewage dehydrating conditioning agent prepared from paper mill sludge and preparation method

InactiveCN106946438ATo achieve the effect of resource utilizationEasily biodegradableSludge treatment by de-watering/drying/thickeningEpoxyResource utilization

The invention discloses an organic compound sewage dehydrating conditioning agent prepared from paper mill sludge and a preparation method. The preparation method comprises the following steps: dissolving paper mill sludge with alkaline liquor, acidifying the filtrate with acid liquor, and filtering and drying the separated lignin to obtain lignin; preparing a chlorinated triethyl glycidyl ammonium monomer from epoxy chloropropane and triethylamine; dissolving the lignin with water and a sodium hydroxide solution, adding ammonium persulfate after heating, after stirring for activating, adding the chlorinated triethyl glycidyl ammonium monomer, and stirring the mixture to react to obtain a lignin quaternary ammonium salt product; and compounding the lignin quaternary ammonium salt product and cationic polyacrylamide in a weight ratio of (5-7.5): (0.015-0.03) to prepare the sewage dehydrating conditioning agent. The organic compound sewage dehydrating conditioning agent disclosed by the invention realizes resource utilization of paper mill sludge, obviously improves the sludge dehydrating property, and is small in dosage, and the feeding amount of polyacrylamide is reduced to a great extent, so that the resource utilization of follow-up sludge is facilitated.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Micro-emulsion for water base drilling fluid for blocking micro-cracks in shale stratums

InactiveCN105778873AReduce filtrate intrusionSlow pressure transmissionDrilling compositionBlock effectEmulsion

The invention relates to the field of chemical materials for oilfield exploration, and discloses a micro-emulsion for water base drilling fluid for blocking micro-cracks in shale stratums. The micro-emulsion is composed of the following components in percentage by weight: 35 to 55% of mineral oil, 4 to 8% of surfactant, 4 to 15% of co-surfactant, 1 to 2% of salt, 5 to 10% of nano stabilizer, 5 to 10% of nano dispersant, 0.3 to 0.5% of antifoaming agent, and the balance being water phase. The provided micro-emulsion can be diluted infinitely, and has the advantages of small particle size and stable properties. After long time storage, the quality is not changed, and layering does not happen. The micro-emulsion can be used as a drilling fluid processing agent and is capable of being directly added into drilling fluid on site; the properties of drilling fluid are not influenced, the filter loss of drilling fluid can be effectively reduced, the blocking effect is good, and moreover, the micro-emulsion has a good lubricating performance.

Owner:SINOPEC SHENGLI PETROLEUM ENG CO LTD DRILLING TECH RES INST

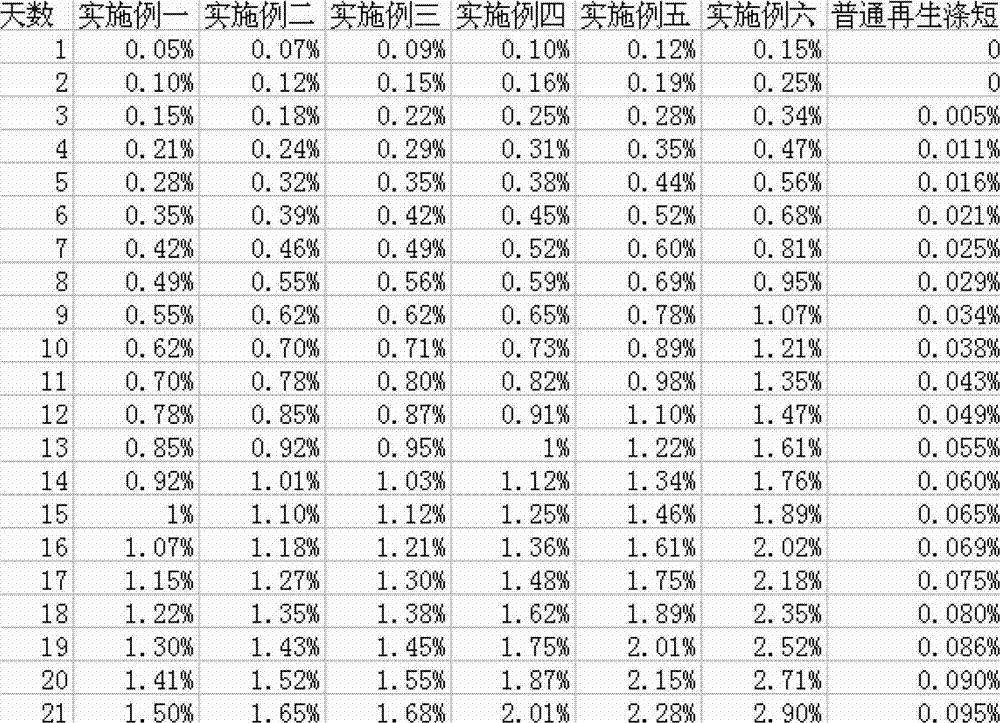

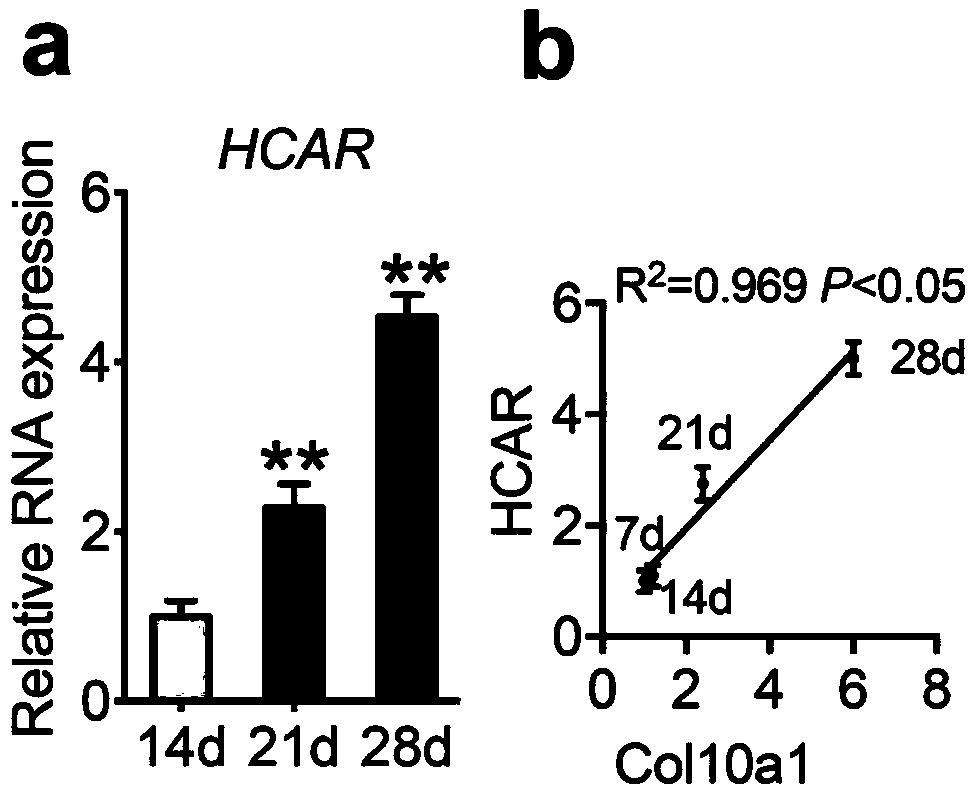

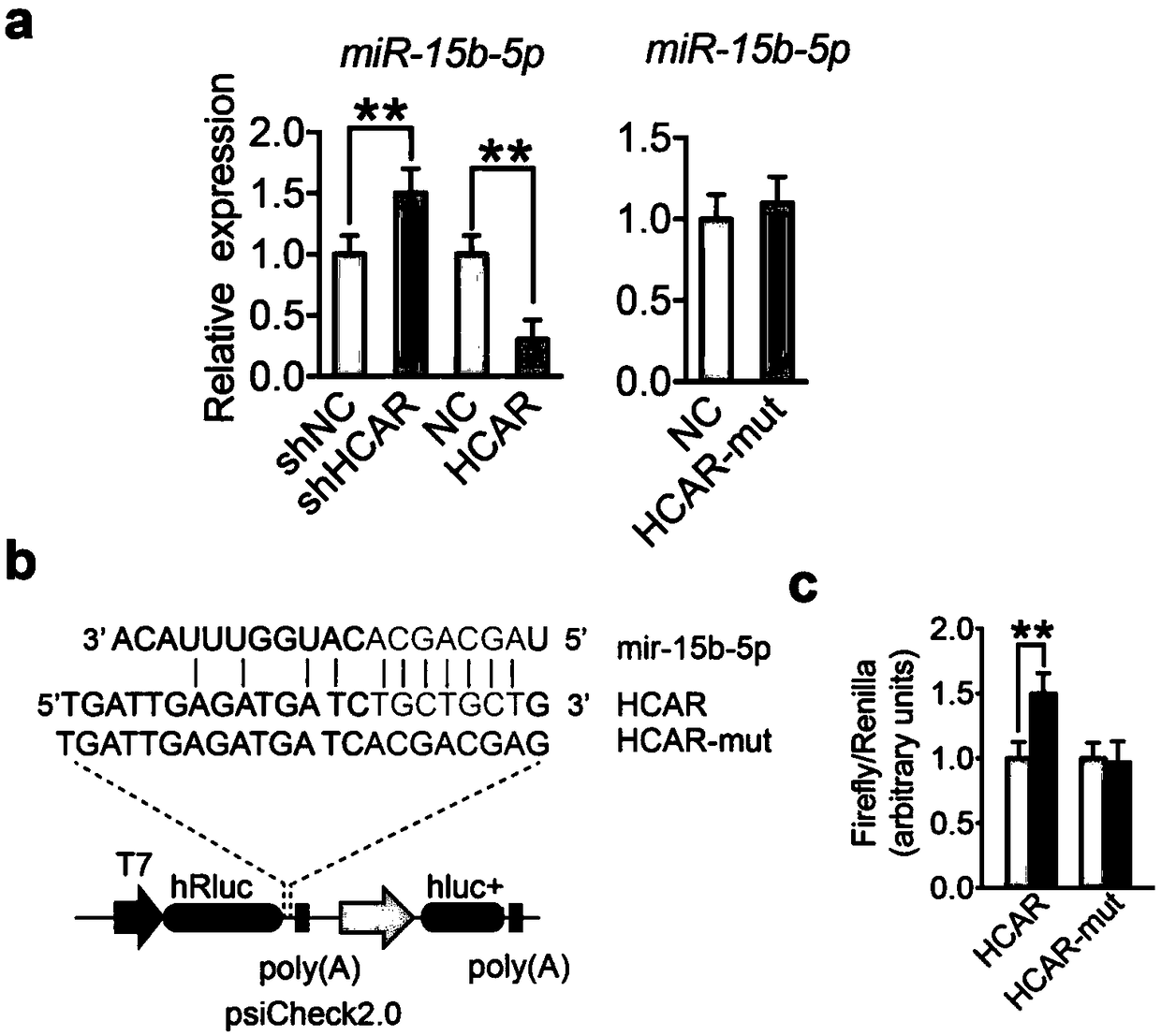

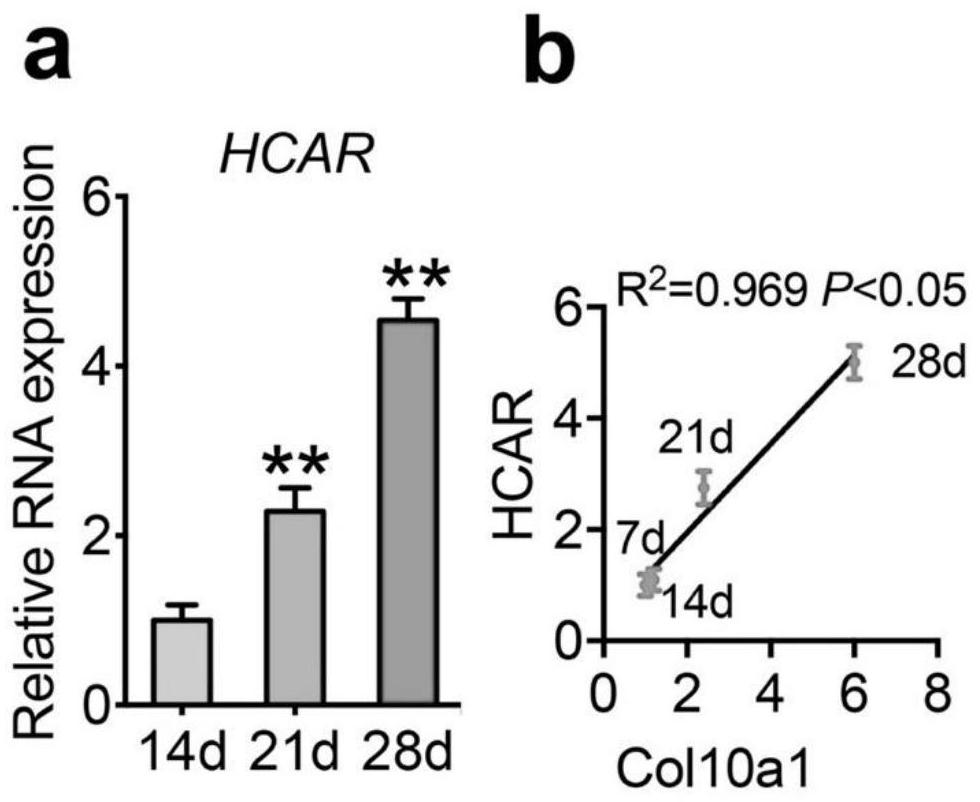

Application of long-chain non-coding RNA lnc-HCAR in preparation of bone repair system and bone repair system and preparation method thereof

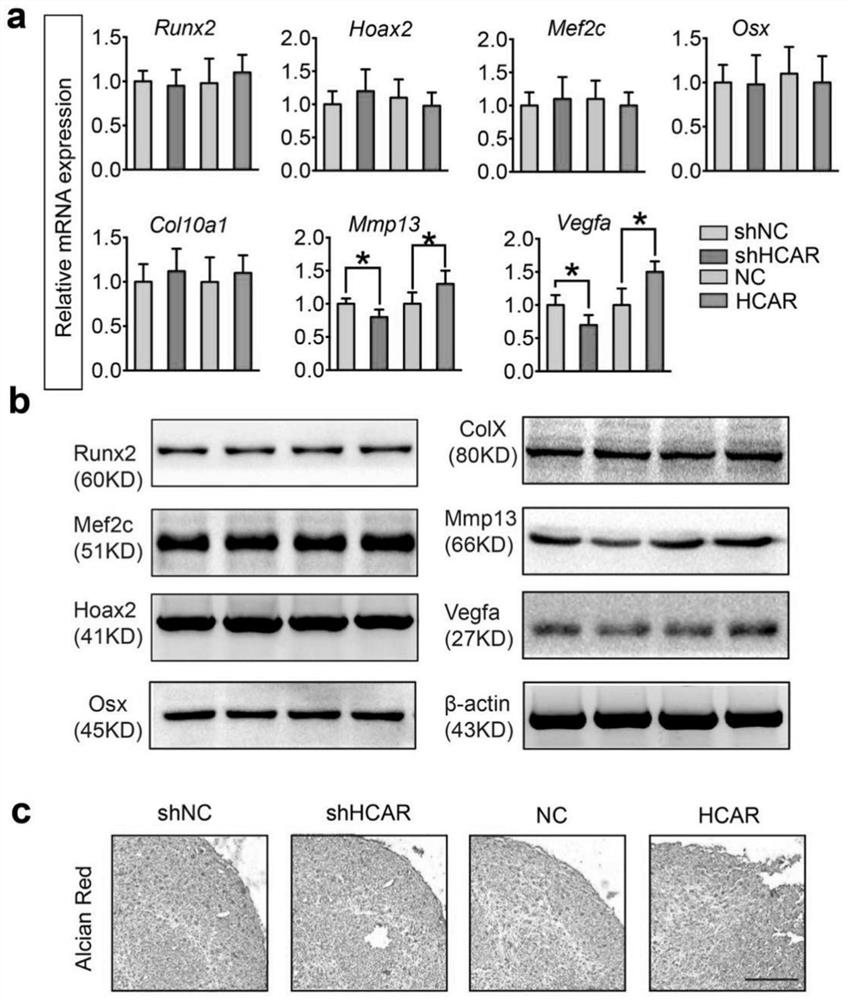

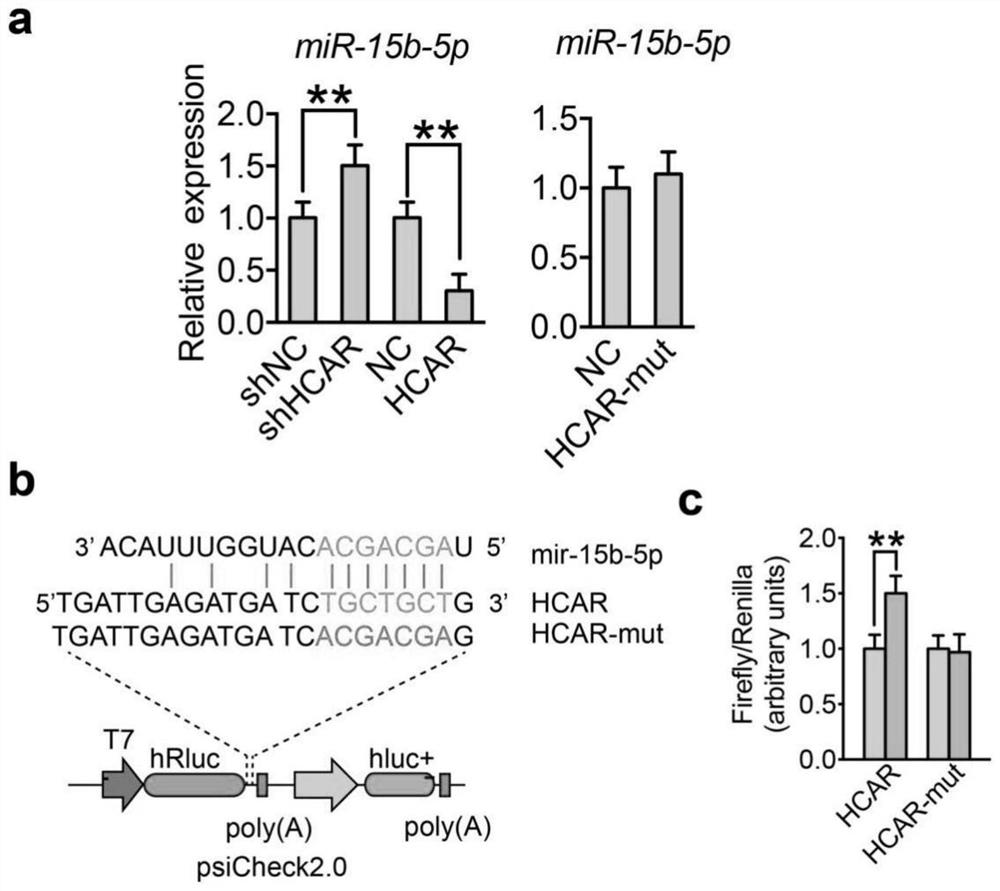

ActiveCN109224130AEasily intrusiveEasy to break intoGenetic material ingredientsSkeletal disorderEccentric hypertrophyGene delivery

The invention discloses application of long-chain non-coding RNA lnc-HCAR in preparation of bone repair system based on endochondral osteogenesis. The nucleotide sequence of the lnc-HCAR is SEQ ID NO.As shown in Fig. 1, the lnc-HCAR can promote the expression of Vegfa gene and Mmp13 gene, and can competitively bind to miR-15b-5p, thereby promoting hypertrophy of chondrocytes, promoting blood vessel formation in cartilage osteogenesis, and promoting Remodeling of the matrix in the cartilage osteogenesis. The bone repair system based on the long-chain non-coding RNA lnc-HCAR includes lnc-HCAR,gene delivery system, mesenchymal stem cells and porous bone scaffold materials. The invention has good application prospects in tissue engineering bone construction and bone defect repair.

Owner:ARMY MEDICAL UNIV

Dredged sludge curing agent as well as preparation method and use method thereof

InactiveCN111470751AEliminate bad effectsImprove stabilitySludge treatment by de-watering/drying/thickeningEnvironmental chemistryEnvironmental geology

The invention discloses a dredged sludge curing agent, a preparation method and a use method. The invention belongs to the technical field of environmental engineering. In the dredged sludge curing agent, the mass percent ratio of quartz tailings, iron ore tailings, carbide slag and 'coagulated stone' is (1-3.5): (1-3.5): (1-3.5): (1-3.5). The preparation method comprises the steps that the quartztailings, the iron ore tailings and the carbide slag are washed, dried, crushed and ground, the 'coagulated stone' is also ground and treated and then the materials are evenly mixed in proportion. The use method of the dredged sludge curing agent comprises the steps that dredged sludge and the added dredged sludge curing agent are stirred to be uniform in proportion, curing is achieved, the compressive strength can reach 60-82.6 KPa after the mixture is stacked in a normal-temperature and normal-pressure field for three days, and the pH of leachate ranges from 6.9 to 8.9. The dredged sludge curing agent adopts solid waste as a raw material, achieving an effect of treating waste with waste, and is wide in raw material source and low in cost. The cured dredged sludge is used as soil for road filling.

Owner:虞克夫

Process for enhancing extraction rate of ferulaic acid form plant stalks by steam explosion pretreatment

InactiveCN101311274AReduce the degree of polymerizationEasily intrusiveFermentationFiberSteam pressure

The invention belongs to the application field of biotechnology and particularly relates to a method for improving the extraction rate of ferulic acid in plant straws by steam explosion pretreatment. The method includes the following steps: the plant straws containing 10 to 25 percent of water are treated by steam explosion under the condition that the steam pressure is 0.9 to 1.9 MPa, and then the plant straws are air dried; with the synergistic effect of ferulic acid esterase and the degrading enzyme of lignocellulose material, the air dried plant straws processed by steam explosion is carried out zymohydrolysis to obtain the enzymolysis liquid of the ferulic acid. The steam explosion technology is clear and high efficient without pollution. Combined with enzymatic extraction, the method improves nine to twelve times of the release rate of the ferulic acid in the plant straws.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

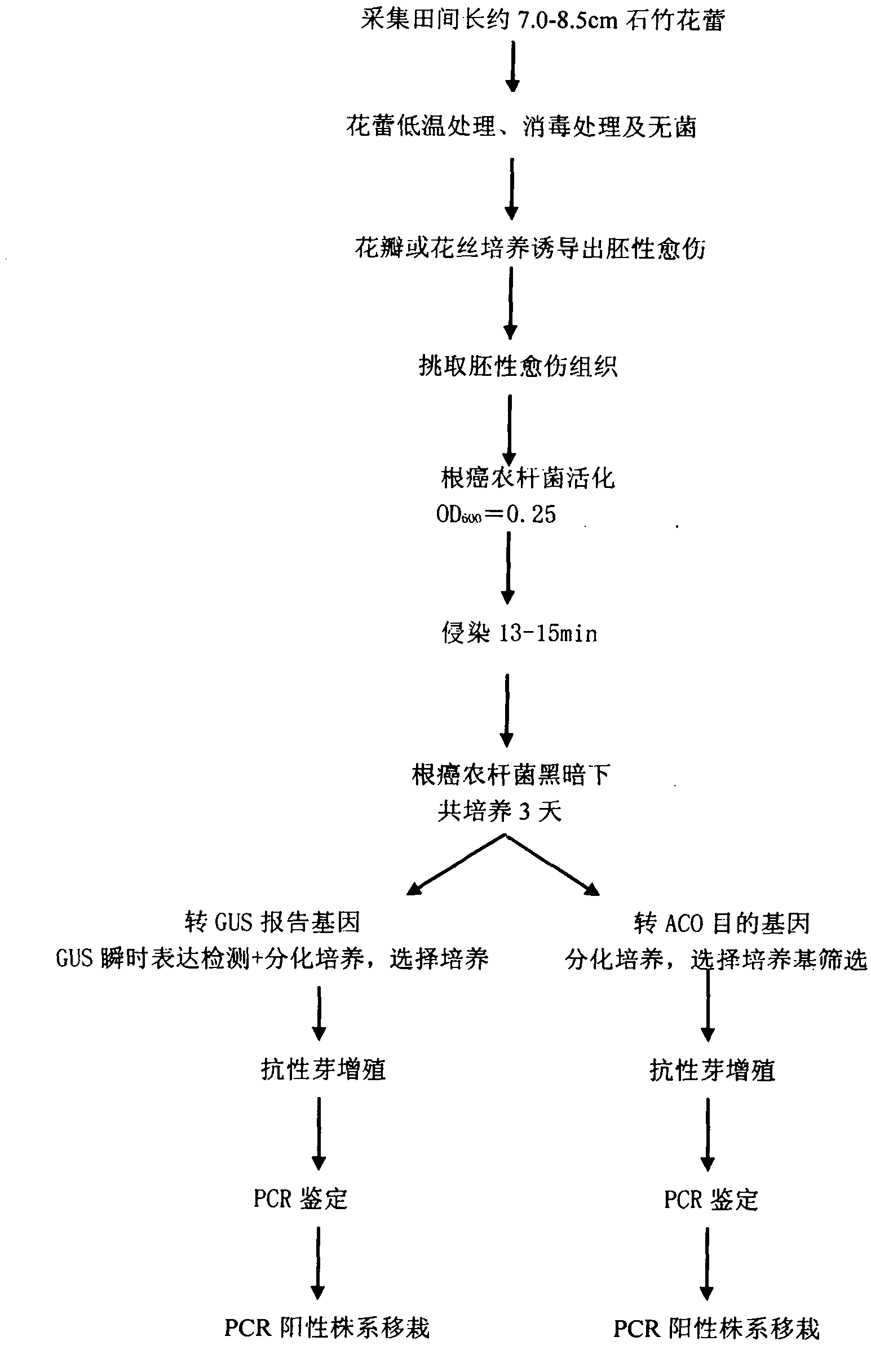

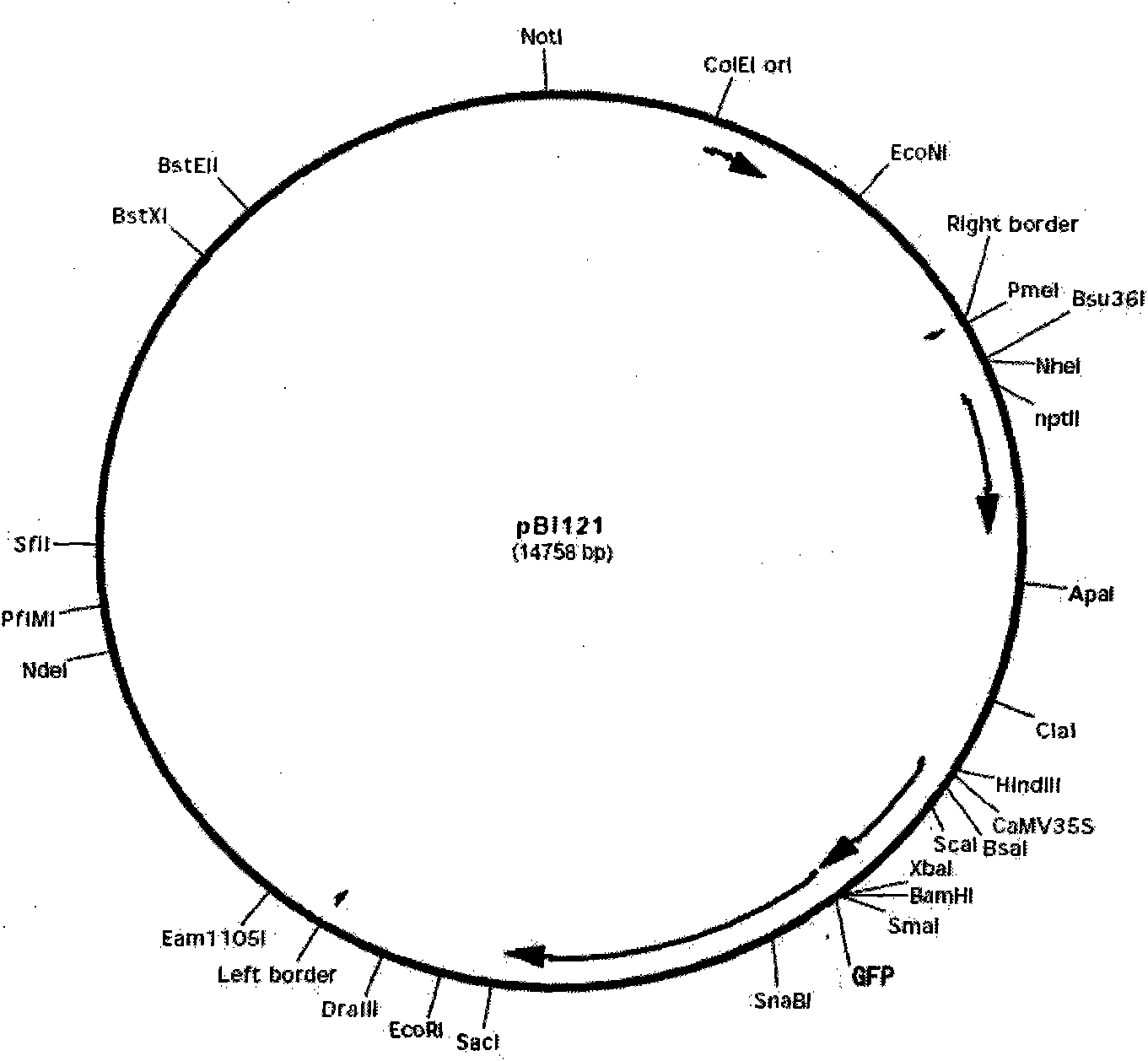

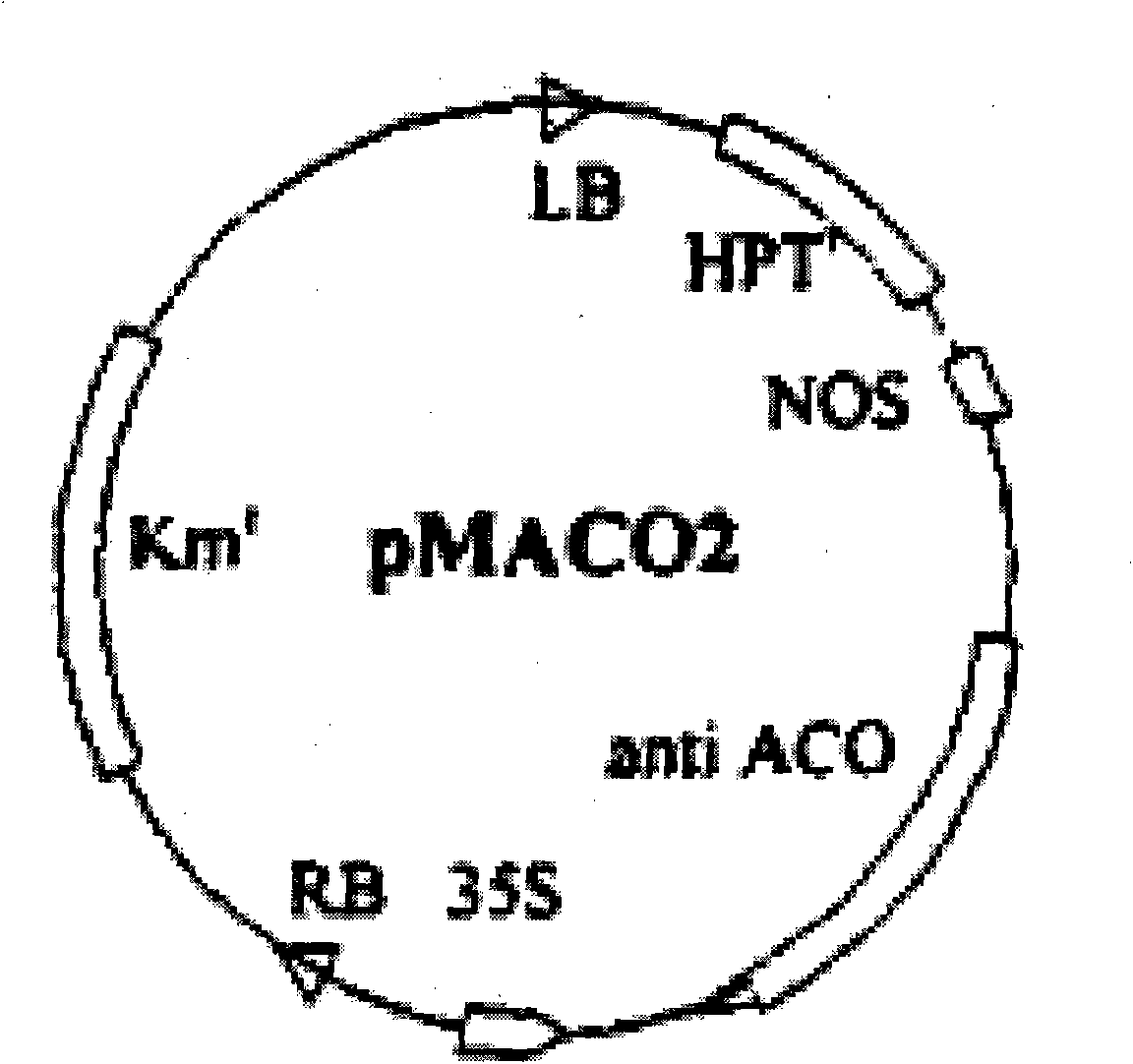

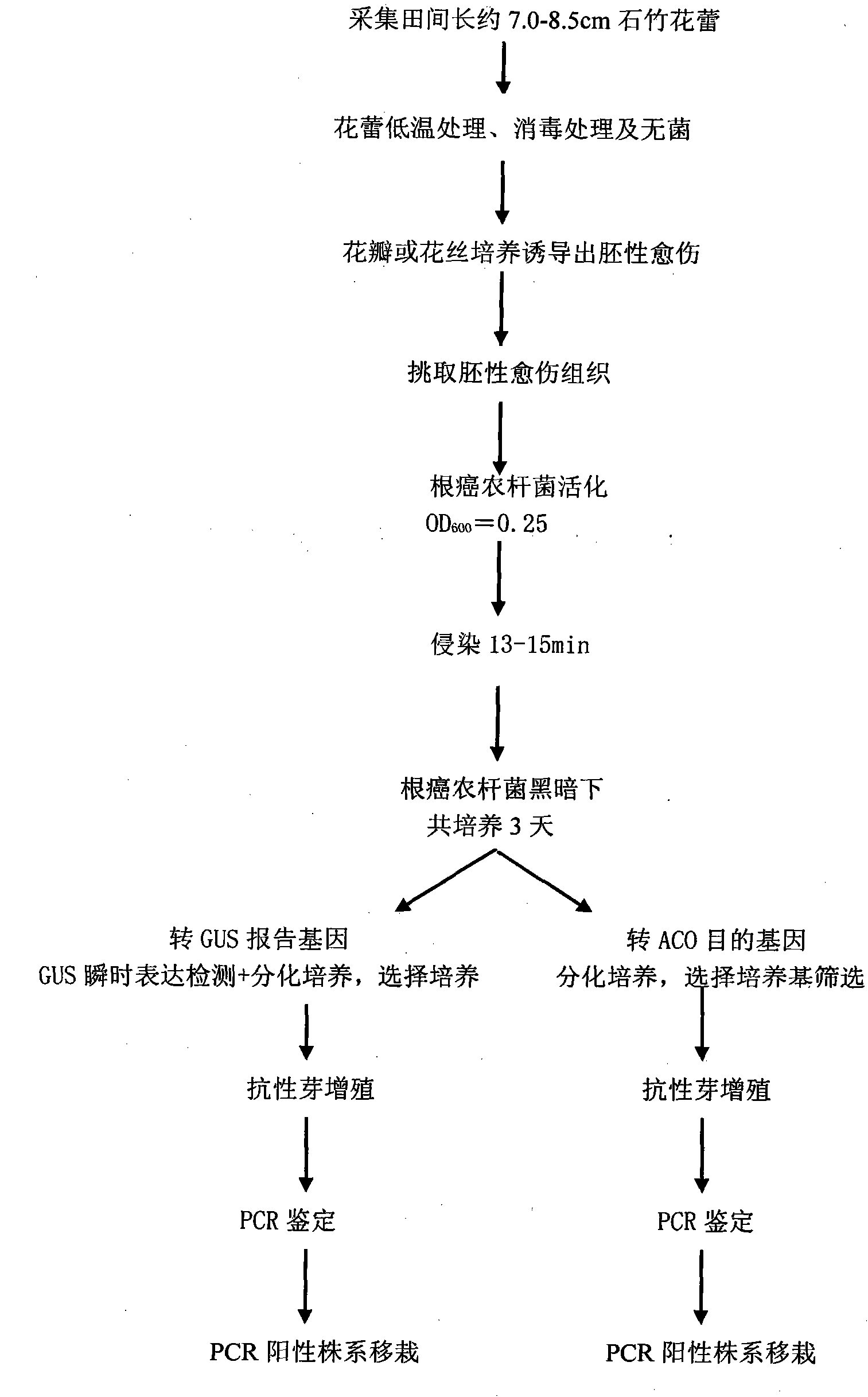

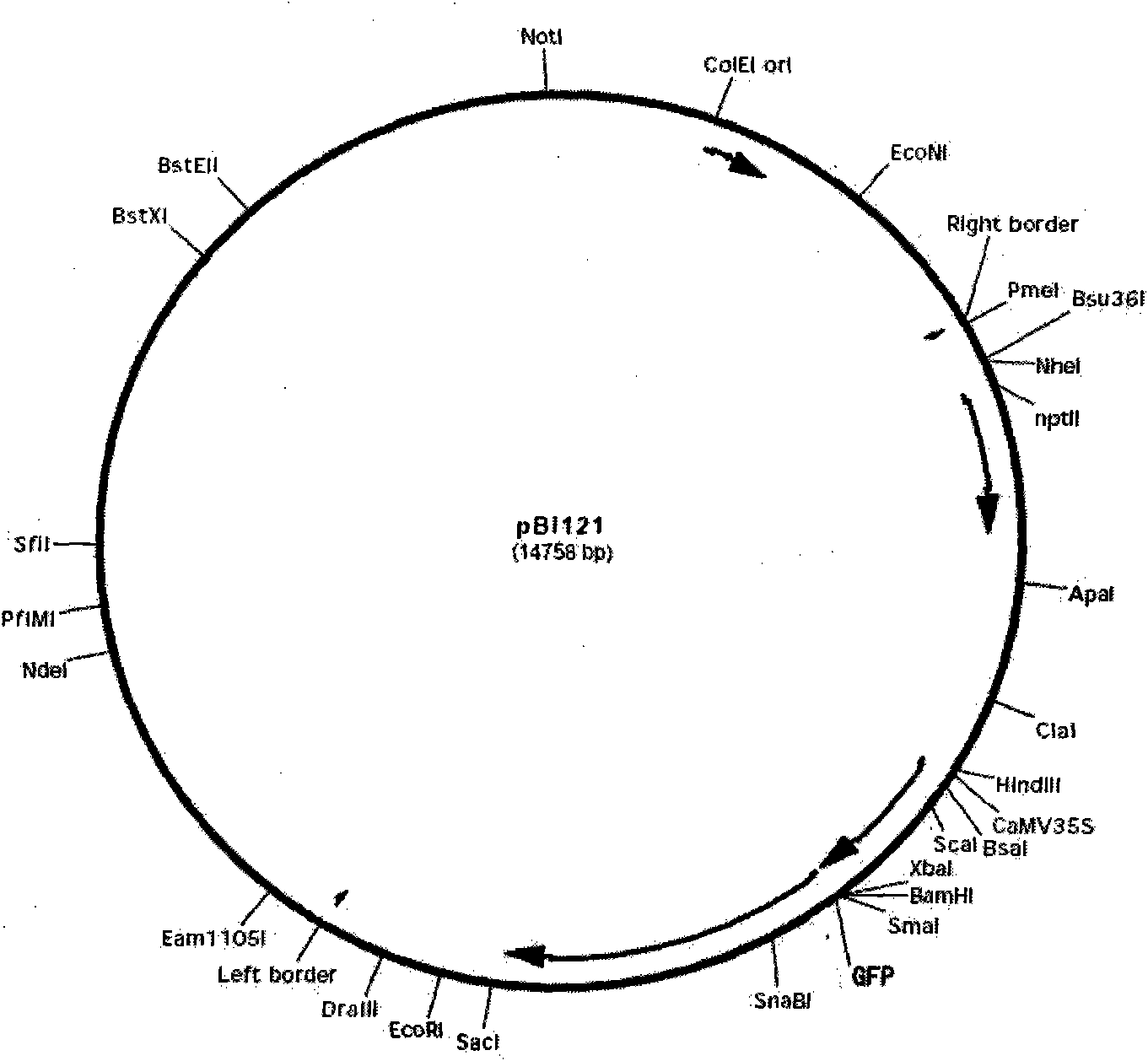

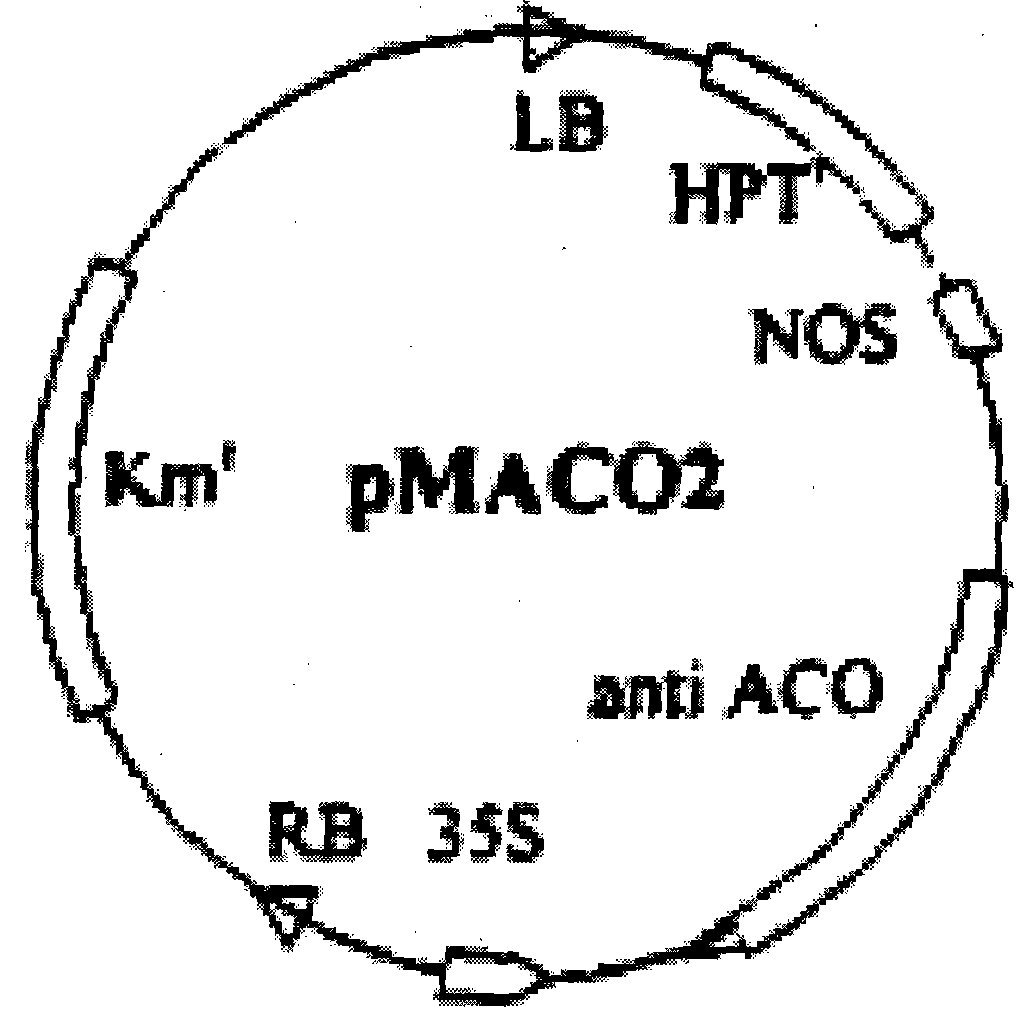

Method for culturing transgenic dianthus through agrobacterium-mediated embryogenic callus transformation

InactiveCN102604985AEasy to getEasy to proliferateHorticulture methodsPlant tissue cultureKanamycinGermplasm

The invention belongs to the field of ornamental plant transgenic technology, particularly relates to a method for culturing transgenic dianthus and more particularly discloses a method for culturing transgenic dianthus by taking agrobacterium-mediated embryogenic callus of the dianthus as a material. The method comprises the following steps of embryogenic callus induction, genetic transformation, screening and regeneration, GUS (glucuronidase) coloration detection and PCR (polymerase chain reaction) detection. The method is characterized in that the GUS report gene and the ACO target gene are introduced into the receptor which is the embryogenic callus of the ianthus through agrobacterium mediation, different factors affecting the embryogenic callus transformation are screened, kanamycin or hygromycin is used as a screening agent to screen the transformed embryogenic callus, and the screening is carried out through GUS coloration, PCR detection and other auxiliary methods to obtain the transgenic dianthus. The invention provides a novel technology platform for the innovation of the germplasm resources for the genetic transformation of the dianthus.

Owner:HUAZHONG AGRI UNIV

Composite PTA preparation method

InactiveCN108484887AEasily intrusiveEasy to spreadMonocomponent polyesters artificial filamentArtifical filament manufactureSlurryTitanium oxide

The invention relates to a composite PTA preparation method. The method comprises the following steps: 1) mixing zinc molybdate, cerium oxide, a fluorboric acid aqueous solution, graphene oxide, tin oxide and titanium oxide, and a perchloric acid aqueous solution and grinding a mixture, and then performing a hydro-thermal reaction and steps of filtering, calcining, plasma processing, and organosilicon modification to prepare composite age-proof powder; and 2) mixing acetic acid and water, adding a sodium hexametaphosphate aqueous solution and the composite age-proof powder obtained in the step1), and beating the materials for dispersing to obtain the composite age-proof agent, fusing the composite age-proof agent with crude terephthalic acid slurry, performing crystallization and solid-liquid separating, washing the material, and performing steps of drying, beating, and solid-liquid separating to obtain composite PTA. The prepared product has obvious age proof effect.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

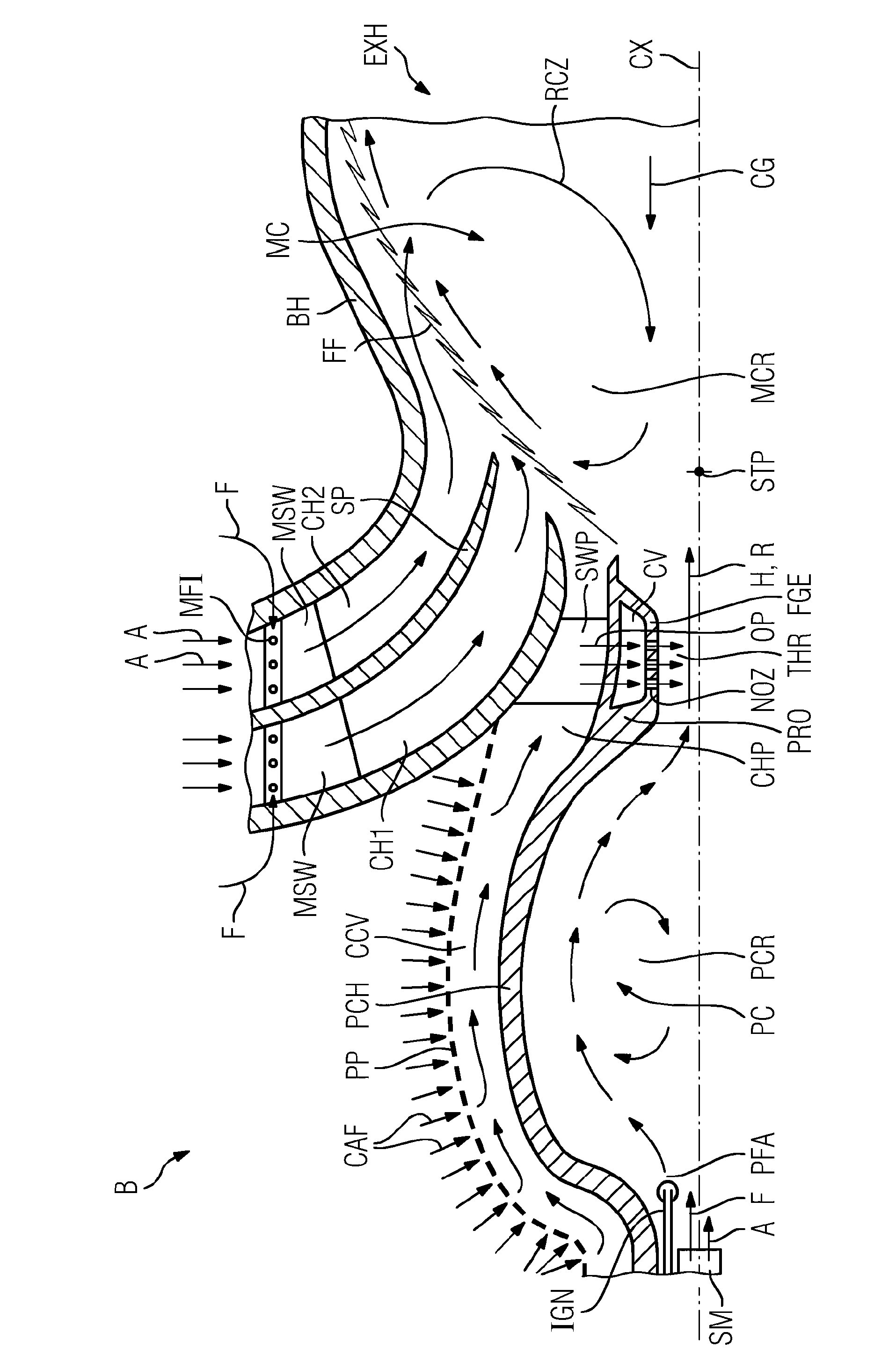

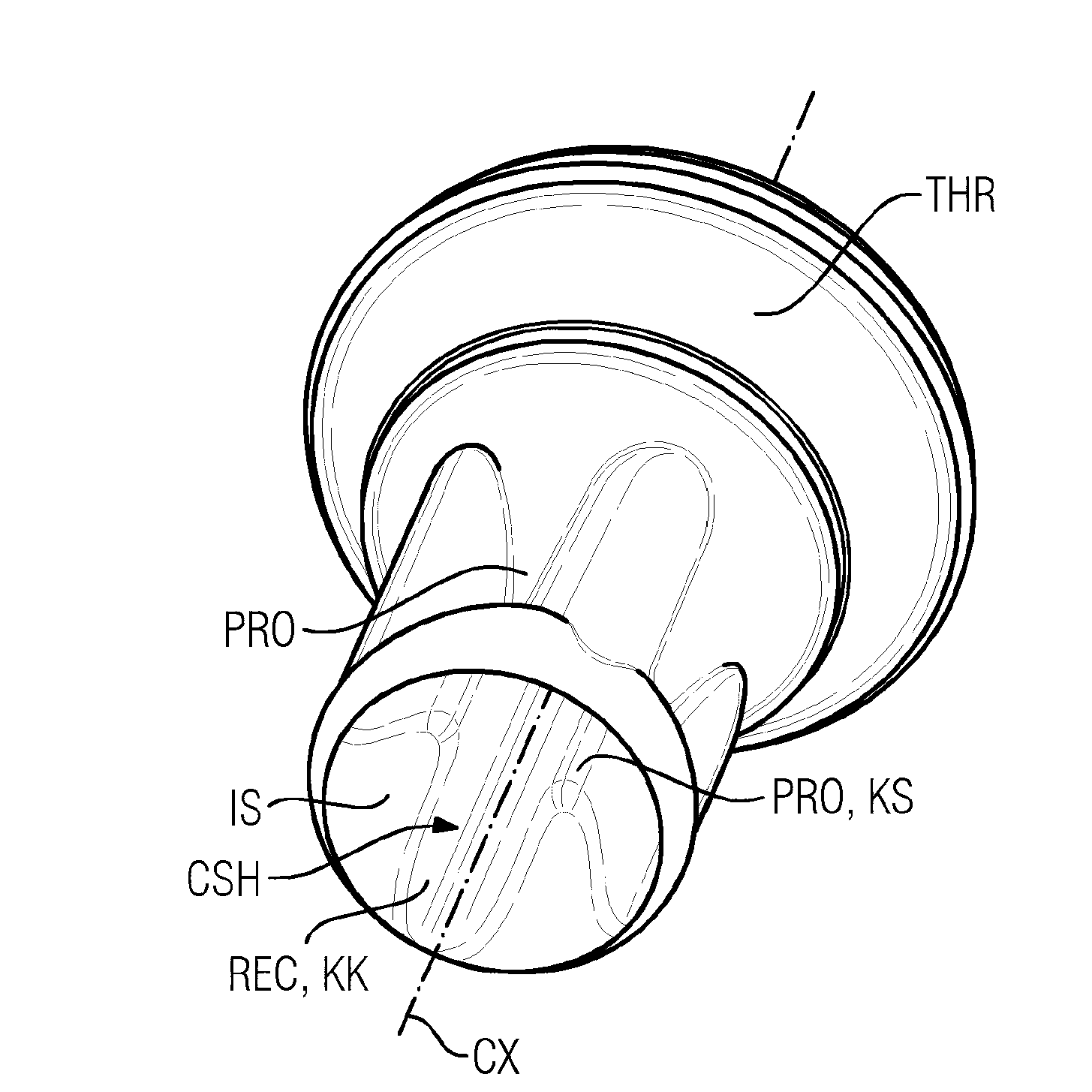

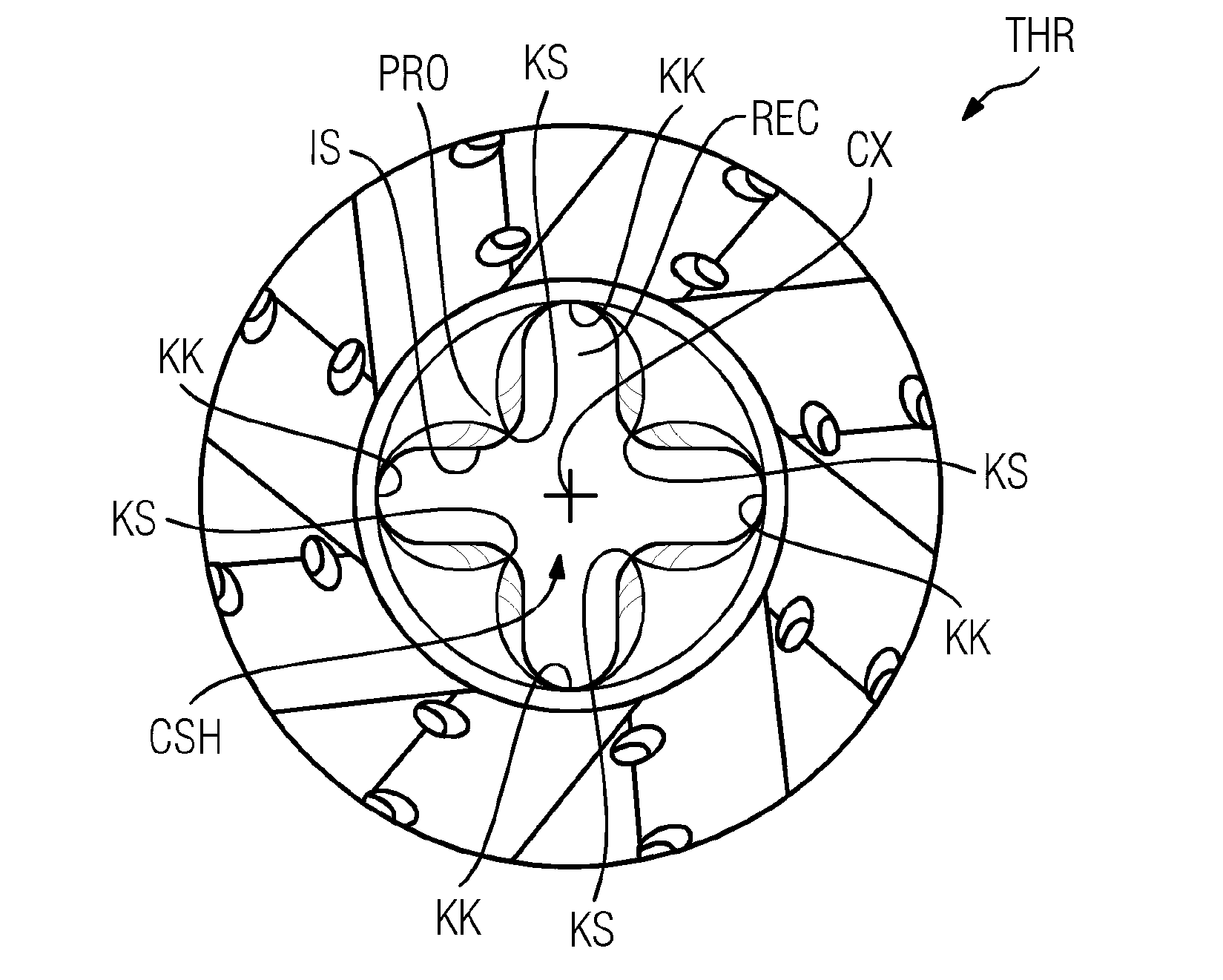

Burner for a gas turbine

InactiveCN103140714ASuppression of peripheral velocity componentsEasy jet penetrationBurnersContinuous combustion chamberCombustorCombustion chamber

The invention relates to a burner (B) for a gas turbine comprising a burner housing (BH) and a pilot combustor (PC) comprising a supply module (SM) providing pilot fuel (F) and pilot air (A) into pilot combustion room (PCR) being enclosed by a pilot combustor housing (PCH) comprising a tapered exit with a throat (THR) of a defined lengths into the resulting main flow direction, said throat (THR) discharging a concentration of radicals (R) and heat (H) generated in said pilot combustion room (PCR) into a main combustion room (MCR) enclosed by said burner housing (BH), wherein a burner axis (CS) is defined by a centre line of said throat (THR) extending in the direction of the resulting main flow through said throat (THR). To improve stability the invention proposes that the interior cross section area of said throat(THR) deviates from a circle by means of flow guiding elements (FGE) provided as protrusions (PRO) with a defined radial hight or as recesses (RCE) with a defined depth extending longitudinally along the direction of the burner axis (CX) to give the discharging flow a defined velocity distribution with regard to a circumferential direction.

Owner:SIEMENS AG

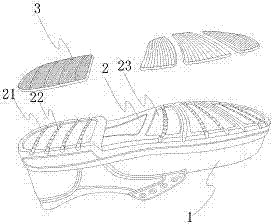

Waterproof and breathable shoes

Owner:FUJIAN DENGTAI TECH CO LTD

Preparation method of preposing-modified EG

InactiveCN108440743AEasy to interpenetrateEasily intrusiveFlame-proof filament manufactureMonocomponent polyesters artificial filamentButanediolAluminium

A preparation method of preposing-modified EG includes the following steps: 1) mixing a citric acid water solution with magnesium aluminate spinel, hydroxyapatite crystal whiskers and dawsonite crystal whiskers and performing a hydrothermal reaction, and grinding, filtering, calcining, washing and drying a product to prepare a preposing flame retarding modifier; 2) mixing ethylene glycol, propylene glycol, butanediol and a urea cosolvent with the preposing flame retarding modifier, magnesium oxide and aluminum oxide, and grinding, dispersing and filtering the mixture to obtain a preposing-modified EG mother liquid; and 3) spray-adding the preposing-modified EG mother liquid into EG to obtain the preposing-modified EG. The preposing-modified EG, when being used for preparing a synthetic material having flame retarding function, has durable flame retarding effect.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Differential p-xylene preparation method

InactiveCN108484889AEasy to interpenetrateEasily intrusiveMonocomponent polyesters artificial filamentArtifical filament manufactureBismuth vanadateSilver phosphate

The invention relates to a differential p-xylene preparation method. The method comprises the following steps: 1) mixing silver phosphate, bismuth vanadate, rutile titanium dioxide, white carbon blackand a fluosulfonic acid aqueous solution for a hydro-thermal reaction, and performing the steps of grinding, filtering, calcining, washing and drying on a mixture to obtain a special anti-aging agent; 2) employing p-xylene, acetic acid, o-xylene, acetamide and the special anti-aging agent obtained in the step 1); and 3) adding differential p-xylene mother liquor obtained in the step 2) in p-xylene in a spray form to prepare the differential p-xylene. The anti-aging function of a subsequent product prepared by the differential p-xylene can be obviously increased.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Preparation method of EG

The invention discloses a preparation method of EG. The preparation method comprises: mixing an oxalic acid solution, a hypochlorous acid solution, bismuth vanadate, graphene oxide, rutile type titanium oxide and hydrotalcite, carrying out a hydrothermal reaction, grinding, filtering, calcining, washing, and drying to prepare a special anti-aging agent for EG; mixing ethylene glycol, propylene glycol, glycerin, the obtained special anti-aging agent for EG, silica, mica powder and a potassium hydrogen phosphate dispersion liquid, grinding, dispersing, and filtering to prepare a differentiated EG mother liquor with anti-aging function; and adding the obtained spraying-like differentiated EG mother liquor to EG to prepare the deep-fused differentiated EG having anti-aging function. The product prepared through the method of the invention has excellent anti-aging function.

Owner:钱圣奎

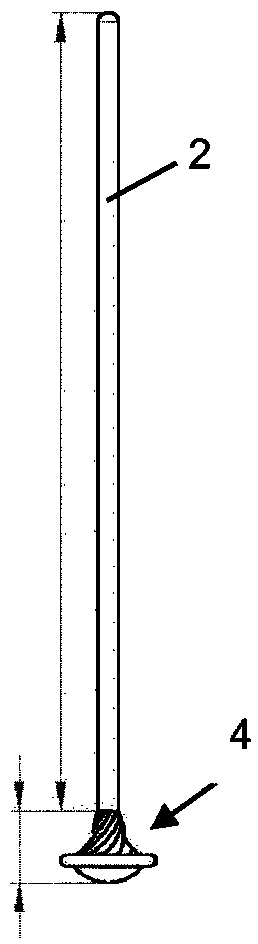

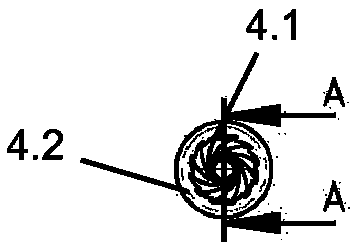

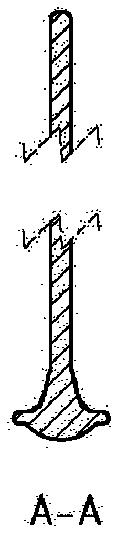

Surgical milling cutter

InactiveCN109475359AConvenient spacingSolve the lack of cooling capacityDiagnosticsSurgeryMilling cutterFlemming body

The invention relates to a surgical milling cutter which is designed to remove bone and / or cartilage tissue, comprising a shaft (2) which extends along a longitudinal axis, can rotate about same, andcan be releasably connected to a drive device and which has a proximal end that can be rotationally fixed to a drive unit and a distal end lying opposite the proximal end. A milling surface (4.1) which circumferentially surrounds the shaft (2) and extends on the distal end along the longitudinal axis of the shaft (2) is formed at the distal end, said milling surface protruding radially from the shaft and having a milling surface maximum radius R1. The aim of the invention is to prevent unwanted damage to delicate body structures. This is achieved by an atraumatic design in that a protective assembly is provided on the distal end. The protective assembly has a distal support surface and a protective assembly maximum radius R2 in order to form a protective ring (4.2) which surrounds the milling surface maximum radius R1 in a circular manner.

Owner:SKAJSTER FAMILIENSTIFTUNG

Welding method for welding polycrystalline diamond compacts (PDC) and tungsten carbide matrix by using silver solder

ActiveCN103008816BImprove welding qualityEasily intrusiveSoldering apparatusCruciblePolycrystalline diamond

The invention discloses a welding method for welding a polycrystalline diamond compact (PDC) and a tungsten carbide matrix by using a silver solder. The welding method comprises the following steps of: a. forming a hole with an internal diameter size larger than an external diameter size of the PDC on the tungsten carbide matrix; b. before welding, cleaning the PDC and the welding surface of the tungsten carbide matrix by using anhydrous ethanol with the volume concentration of 99.7%; c. smearing a silver brazing flux on the welding surface of the tungsten carbide matrix, heating the tungsten carbide matrix to 640-680 DEG C; putting the PDC in a crucible and adding the silver brazing flux, and heating to 640-680 DEG C; and d. adding the silver solder and the silver brazing flux between the welding surface of the tungsten carbide matrix and a substrate of the treated PDC, and heating the silver solder by oxygen-acetylene flame. The method has the advantages that the process is simple, the welding quality is improved, the compact shedding phenomenon caused by instable welding is avoided, the life of a PDC bit is prolonged, and the overall performance is improved.

Owner:CCDC PETROLEUM CORING TECH

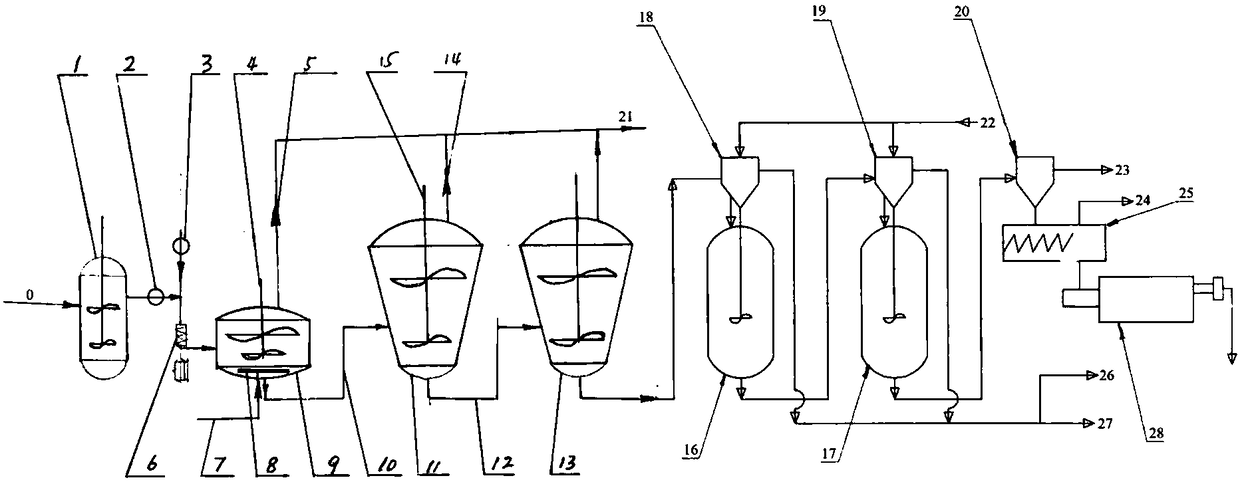

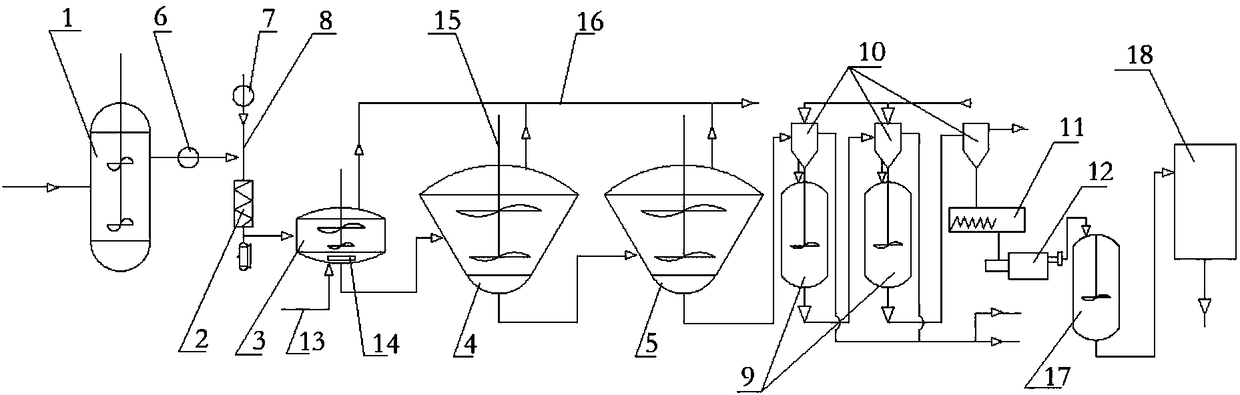

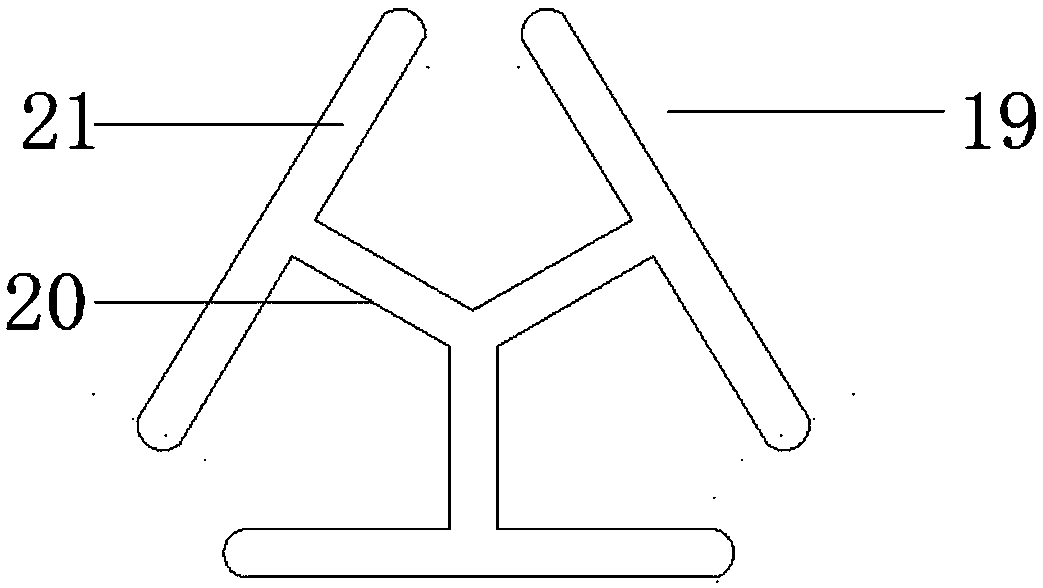

Production method and device of doping modified copolyester and profiled fiber

InactiveCN108301064AEasily intrusiveEasy to spreadHollow filament manufactureMelt spinning methodsPolymer scienceSlurry

The invention discloses a production method and device of doping modified copolyester and profiled fiber. A trifluoroacetic acid aqueous solution, a perchloric acid aqueous solution, Mg-Al hydrotalcite, silica whiskers, white carbon black and conductive mica powder are mixed in proportion and pretreated, doping modified powder is prepared and fused with CTA slurry, oxidation crystallization with adisc-shaped secondary oxidation crystallization kettle and crystallization with No.1 and No.2 frustum-shaped crystallization kettles are performed, hydrofining is performed, doping modified PTA is prepared, the doping modified PTA, ethylene glycol and PTA are subjected to copolycondensation, the doping modified copolyester is prepared, and the profiled fiber is prepared through melt spinning withan open spinneret orifice. The antistatic performance of polyester and polyester fiber is improved, moisture in the air can be absorbed, accumulated charges can be transferred timely, a flame retardant function is realized, the comprehensive performance of fiber is substantially improved, the use field of the fiber is broadened, the thermal rheological property of a polyester material is improved, melt spinning forming and drafting are facilitated, and the surface finish is substantially improved.

Owner:东南新材料(杭州)股份有限公司

Blast-furnace operation method

ActiveCN102471809BEnsure clearancePromote reductionBlast furnace detailsMaterials scienceBlast furnace

Coke layers and ore layers are formed in the blast furnace. The coke layer is formed of coke oven coke, and the ore layer is formed of iron coke, coke oven coke and ore. The mixing ratio of coke oven coke to the ore in the ore layer is 0.5% by mass or more. The stagnation of the gasification reaction of iron coke in the clad layer can be suppressed.

Owner:JFE STEEL CORP

Modification treatment technique for yield increase of hard culture medium mushroom

InactiveCN107459377AIncrease profitImprove qualityCalcareous fertilisersBioloigcal waste fertilisersCelluloseNutrition

During mushroom planting production, except for the demand for sufficient nutritional substances on a culture medium, mushroom sticks are required to have forming strength, air permeability, easy hypha invasion and the like. A mushroom culture medium comprises 70% or above of hard materials including cottonseed hull, oak chips, sawn timber chips and the like, which are compact in texture. The contents of such nutritional substances as cellulose protein and the like in the culture medium are high, and the produced mushroom is good in quality. In order to guarantee the air permeability, large-particle mixtures are generally used, and as the hard particles with compact textures lead to difficult core invasion of hyphae, the utilization ratio of raw materials is low. Explosion puffing equipment is utilized to perform puffing treatment on the hard culture medium to enable tissues to become loose and porous, so that large particles of the raw materials are maintained to guarantee the air permeability, the hyphae can easily invade the cores of the particles, and accordingly, the utilization ratio of the raw materials is improved. As cellulose substances are degraded, time for edible mushrooms to degrade the cellulose substances through self-metabolism is shortened, and carbon sources required for growth of the edible mushrooms are increased. Protein in the culture medium is subjected to denaturation, and part of protein is degraded into free amino acids, so that the edible mushroom culture medium is richer in nutrition, absorption and growth of the edible mushrooms are facilitated, particularly, in the early growth stage of the hyphae, owing to rich nutrition, the hyphae grow to be thick, accordingly, the mushroom quality is improved, the mushroom yield is increased, the production time is shortened, and economic benefits are improved.

Owner:HUBEI HAODA BIOLOGICAL TECH CO LTD

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276BPrevent volatilizationBalance internal stressFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

Method for preparing composite modified p-xylene

InactiveCN108359082AEasy to interpenetrateEasily intrusiveMonocomponent copolyesters artificial filamentArtifical filament manufactureALUMINUM PHOSPHATEChromium

The invention relates to a method for preparing composite modified p-xylene. The method comprises the following steps: 1) mixing aluminium hexafluorosilicate, phosphorus chlorate chromium, nickel oxide, a calcium phosphate whisker and trifluoroacetic acid aqueous solution, and a phosphofluoric acid aqueous solution, grinding a mixture and performing a hydro-thermal reaction, and performing steps of filtering, calcining, washing and drying to prepare a special-purpose antibacterial modifier; 2) mixing p-xylene, o-xylene, an acetamide cosolvent and the special-purpose antibacterial modifier obtained in the step 1), chromium aluminum phosphate, and white carbon black, dispersing the mixture, and filtering the mixture to prepare the composite modified p-xylene mother liquor; and 3) adding thecomposite modified p-xylene mother liquor obtained in the step 2) in p-xylene in a spray form to prepare the composite modified p-xylene. The composite modified p-xylene has excellent antibiosis function.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Preparation method of inorganic modified p-xylene

InactiveCN108484888AEasy to interpenetrateEasily intrusiveMonocomponent polyesters artificial filamentArtifical filament manufacturePotassiumSilver phosphate

The invention relates to a preparation method of inorganic modified p-xylene. The preparation method comprises the following steps: mixing zinc molybdate, silver phosphate, a hydrobromic acid solution, silica fume, montmorillonite, titanium oxide and a fluosulfonic acid solution, grinding a mixture, and performing a hydro-thermal reaction, and performing the steps of filtering, calcining, washingand drying on the mixture to obtain anti-aging powder; mixing p-xylene, acetic acid, m-xylene, an acetamide cosolvent, and the anti-aging powder, zinc oxide, and potassium hydrogen phosphate dispersion liquid, and performing grinding on a mixture, and dispersing and filtering the mixture to obtain the age-proof inorganic modified p-xylene mother liquor used for refinement; and 3) adding age-proofinorganic modified p-xylene mother liquor in p-xylene in a spray form to prepare the inorganic modified p-xylene. The inorganic modified p-xylene has good anti-aging function.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Preparation method of multifunctional micro-nano structure modified wood

InactiveCN114505935AGood modification effectEasy to modifyRadiation/waves wood treatmentWood treatment detailsCellulosePolymer science

The invention discloses a preparation method of multifunctional micro-nano structure modified wood, a modification solution A comprises the following components in parts by weight: 0.1-5 parts of a silane coupling agent, 1-20 parts of sodium silicate, 1-50 parts of furfuryl alcohol, 0.1-5 parts of a catalyst and 100 parts of deionized water, after a wood board is soaked in a soaking tank for a period of time, the modification solution A is absorbed by the wood board, and then the wood board is soaked in a soaking tank for a period of time; a proper amount of a modified solution B is added into a soaking tank, and through later-stage high-temperature drying, the modified solution absorbed to cell walls and cell gaps of the wood is promoted to be subjected to a cross-linking reaction with hydroxyl and carboxyl on the surface of lignocellulose of the wood to generate a micro-nano net structure, so that the mechanical structure of the wood is changed, and the mechanical property of the wood is improved. The hardness, the elastic modulus and the bending strength of the modified wood are remarkably improved.

Owner:深圳碳十四科技创新有限公司

Preparation method for differentiated EG

InactiveCN108456297AEasily intrusiveEasy to spreadMonocomponent polyesters artificial filamentArtifical filament manufactureFiltrationPotassium

Provided is a preparation method for differentiated EG. The method comprises the following steps that oxalic acid solution, hypochloric acid solution, pucherite, graphene oxide, zinc oxide, titanium dioxide top grade and hydrotalcite are mixed to be grinded after hydrothermal reaction is carried out, and filtration, calcination, washing and drying are carried out to prepare a special age resisterfor EG; ethylene glycol, propylene glycol, glycerinum, lactic acid, the obtained special age resister for EG, silicon dioxide, mica powder and potassium hydrogen phosphate dispersion liquid are mixedand grinded, then dispersion and filtration are carried out to prepare differentiated EG mother liquor with a function of ageing resistance; the obtained differentiated EG mother liquor is sprayed into the EG to prepare the differentiated EG fused deeply with the function of ageing resistance. The preparation method for the differentiated EG has the advantage that the differentiated EG prepared bythe above method has the good function of ageing resistance.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Method for preparing hybridized p-xylene

InactiveCN108341939AEasy to interpenetrateEasily intrusiveFlame-proof filament manufactureMonocomponent copolyesters artificial filamentPotassiumEthylamine

A method for preparing hybridized p-xylene comprises the steps of: mixing a fluorosulfonic acid solution and a fluorophosphoric acid solution with magnesium aluminate spinel, aluminum hydroxide whiskers and magnesium zinc spinel, performing a hydrothermal reaction, grinding, filtering, calcining, washing and drying to obtain a flame retardant hybridizer; mixing p-xylene, acetic acid, sodium hypophosphite, o-xylene, an ethylamine cosolvent, a potassium hydrogen phosphate dispersion, and the obtained flame retardant hybridizer, grinding, filtering and dispersing to obtain a hybridized p-xylene mother liquor; adding the obtained hybridized p-xylene mother liquor in a form of spraying into the p-xylene to prepare the hybridied p-xylene. The product prepared by the method has an excellent flameretardant function.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Method for updating deteriorated grassland bluegrass lawn at low cost in north

The invention provides a method for updating a deteriorated grassland bluegrass lawn at low cost in the north. Weed control, pruning height control, lawn partition area and turf block size determination, rooting hastening with grass blocks soaked in pesticide, determination of the number of turf blocks planted in a community per square meter and planting positions, compacting, watering, sand covering, growth regulator application and other technologies are applied, on the basis of the natural rules of plant interspecific competition and the survival of the fittest, zoysia japonica can easily invade the deteriorated grassland bluegrass lawn due to strong creeping stems and the strong growing vigor and competitiveness, other grass seeds can hardly invade the lawn once the population of the zoysia japonica is formed, and therefore the aim of updating the deteriorated grassland bluegrass lawn at low cost is achieved. The effective method can be applied to the production practice of landscaping in a large area, can solve the problem of a deteriorated cool-season lawn, and can lower updating cost.

Owner:浙江知多多网络科技有限公司

Environment-friendly cotton dyeing process based on fruit juice and environment-friendly cotton natural latex bra

PendingCN113073480AImprove securityEasily intrusiveBrassieresBiochemical treatment with enzymes/microorganismsColour fastnessAcetic acid

The invention discloses an environment-friendly cotton dyeing process based on fruit juice and an environment-friendly cotton natural latex bra, and relates to the technical field of printing and dyeing. The dyeing process comprises the following steps of S1, pretreatment; S2, dyeing; S3, washing and color fixing; and S4, drying and setting. During dyeing, fruit dye is adopted to dye an environment-friendly cotton fabric. The preparation process of the fruit dye comprises the following steps of A1, selecting fruits to be used, and cleaning the fruits; A2, crushing and grinding the fruits, adding water, performing mixing, controlling the temperature to be 50-80 DEG C, adding acetic acid for adjustment, controlling the temperature, and performing continuous stirring, wherein a mixture is vibrated through ultrasonic waves in the stirring process; and A3, filtering the mixture to obtain a filtrate and filter residues, and mixing the obtained filtrate with water to obtain the fruit dye. According to the invention, the cotton fabric is dyed based on the fruit juice dye, so that the pollution and harm caused by chemical dyeing are reduced, and the health and environmental friendliness of a bra fabric material are improved; and the dyeing effect of the fruit juice dye on the cotton fabric and the color fastness of the fabric are improved.

Owner:浙江普娜拉纺织科技有限公司

Application of long chain non-coding RNA lnc-HCAR in preparation of bone repair system and bone repair system and preparation method

ActiveCN109224130BEasily intrusiveEasy to break intoGenetic material ingredientsSkeletal disorderNucleotideBlood vessel

The invention discloses the application of long-chain non-coding RNA lnc-HCAR in preparing a bone repair system based on endochondral osteogenesis, the nucleotide sequence of the lnc-HCAR is shown in SEQ ID NO.1, and the lnc ‑HCAR can promote the expression of Vegfa gene and Mmp13 gene, and can competitively bind miR‑15b‑5p, thereby promoting hypertrophic differentiation of chondrocytes, promoting blood vessel formation in endochondral osteogenesis, and promoting matrix in endochondral osteogenesis remodel. The bone repair system based on long non-coding RNA lnc-HCAR includes lnc-HCAR, gene delivery system, mesenchymal stem cells and porous bone scaffold materials. The invention has good application prospects in tissue engineering bone construction and bone defect repair.

Owner:ARMY MEDICAL UNIV

Method for culturing transgenic dianthus through agrobacterium-mediated embryogenic callus transformation

InactiveCN102604985BEasy to getEasy to proliferateHorticulture methodsPlant tissue cultureKanamycinGermplasm

The invention belongs to the field of ornamental plant transgenic technology, particularly relates to a method for culturing transgenic dianthus and more particularly discloses a method for culturing transgenic dianthus by taking agrobacterium-mediated embryogenic callus of the dianthus as a material. The method comprises the following steps of embryogenic callus induction, genetic transformation, screening and regeneration, GUS (glucuronidase) coloration detection and PCR (polymerase chain reaction) detection. The method is characterized in that the GUS report gene and the ACO target gene are introduced into the receptor which is the embryogenic callus of the ianthus through agrobacterium mediation, different factors affecting the embryogenic callus transformation are screened, kanamycin or hygromycin is used as a screening agent to screen the transformed embryogenic callus, and the screening is carried out through GUS coloration, PCR detection and other auxiliary methods to obtain the transgenic dianthus. The invention provides a novel technology platform for the innovation of the germplasm resources for the genetic transformation of the dianthus.

Owner:HUAZHONG AGRI UNIV

Preparation method for differentiated PTA

InactiveCN108383986AEasy to interpenetrateEasily intrusiveOrganic compound preparationMonocomponent polyesters artificial filamentFiltrationSlurry

The invention provides a preparation method for differentiated pure terephthalic acid (PTA). The method comprises the following steps: (1) mixing bismuth molybdate, graphene oxide, a hypochlorous acidaqueous solution, zinc oxide, white carbon black, potassium titanate crystal whiskers and a hydrofluoric acid aqueous solution, performing grinding, performing a hydrothermal reaction, performing filtration, performing calcination, performing plasma treatment, and performing organic-silicone modification to obtain a special anti-aging agent; and (2) mixing acetic acid and water, then adding sodium hexametaphosphate aqueous solution, nickel fluoroborate, calcium tungstate and the special anti-aging agent obtained in the step (1), performing beating dispersion to obtain a special modifying liquid, fusing the special modifying liquid and crude terephthalic acid slurry, performing crystallization, performing solid-liquid separation, performing washing, performing drying, performing beating, performing solid-liquid separation, and performing hydrofining to prepare the differentiated PTA. According to the preparation method provided by the invention, the product prepared by the method has asignificant anti-aging effect.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com