Burner for a gas turbine

A gas turbine and burner technology, applied in the direction of burners, combustion chambers, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

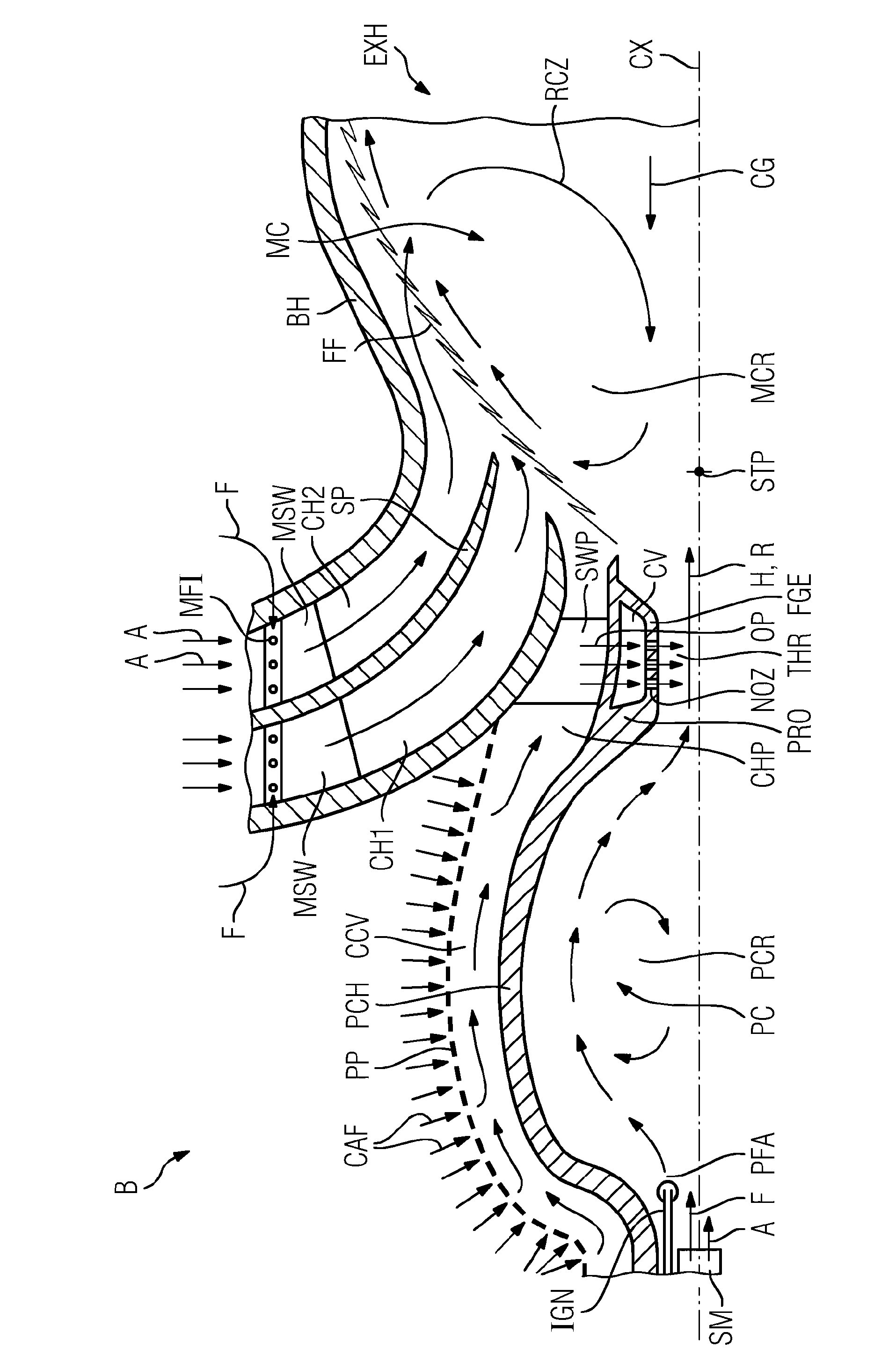

[0023] figure 1 A longitudinal section through a burner B according to the invention is shown. The burner B includes a pilot combustion chamber PC and a main combustion chamber MC. The pilot combustion chamber PC supplies a flow with heat H and R masses into the main combustion space MCR of the main combustion chamber MC.

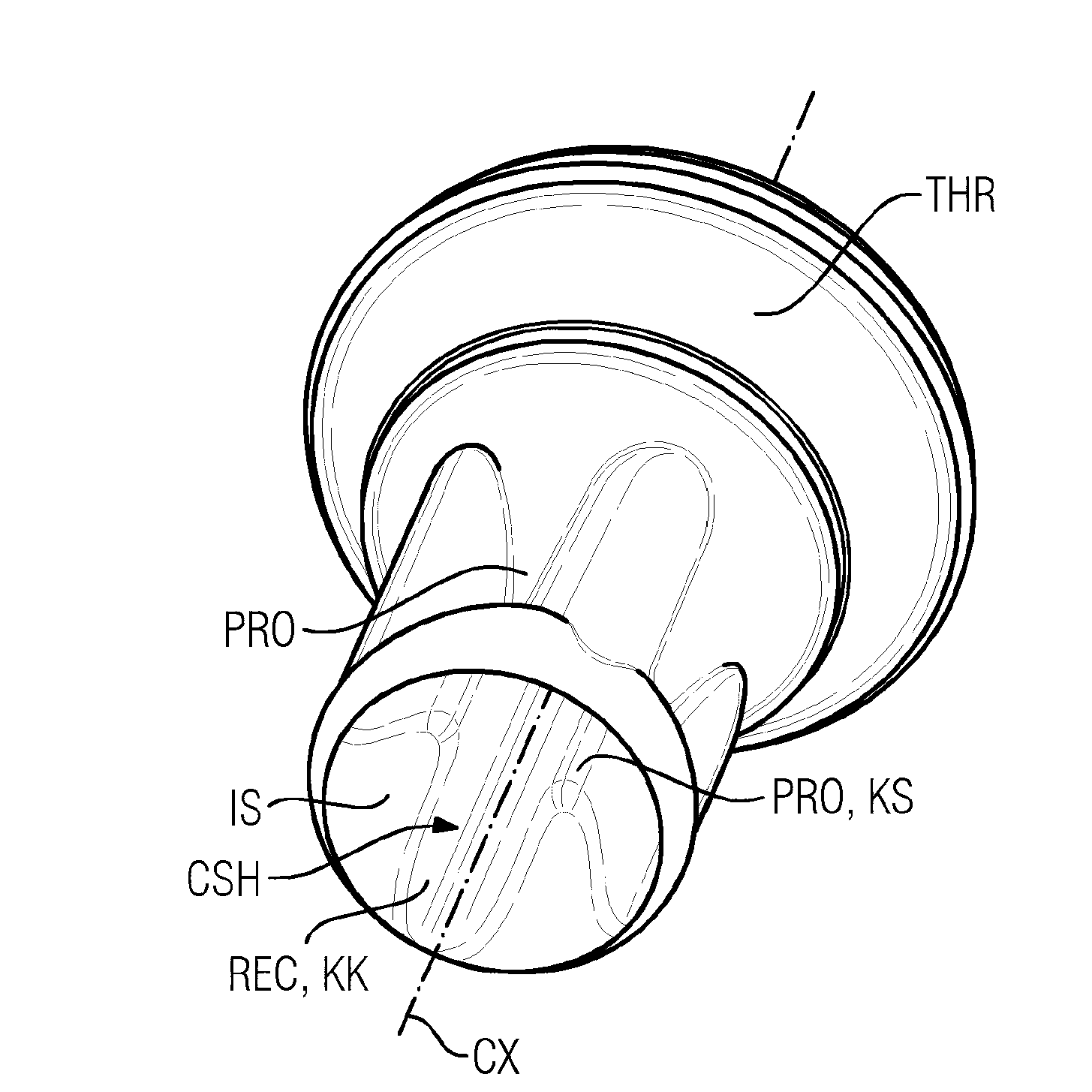

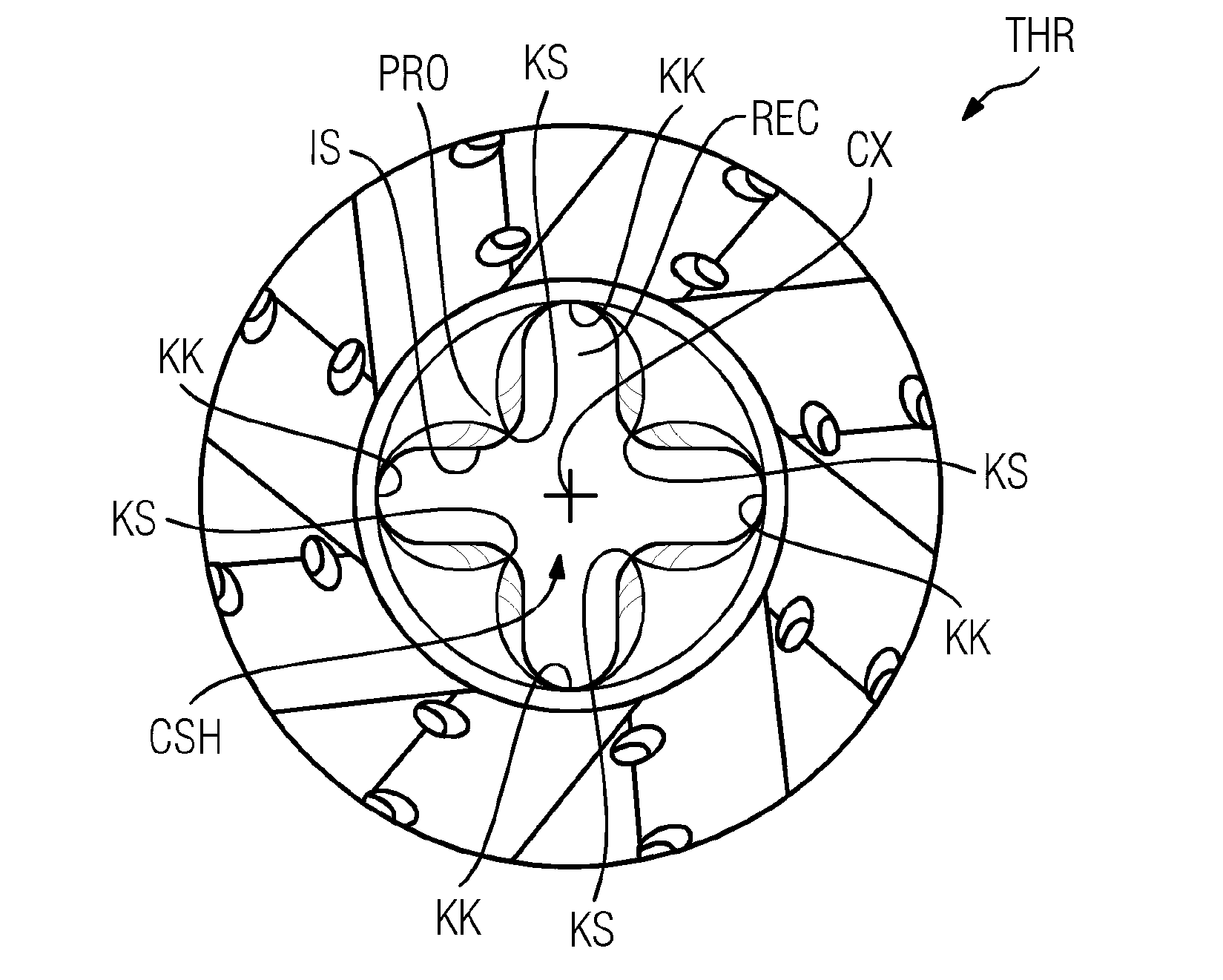

[0024] The main combustion chamber MC comprises a burner housing BH which encloses the main combustion space MCR and the air A and fuel F supplied to the main combustion space, and additionally in a manner not shown encloses the pilot Combustor PC. The pilot combustion chamber PC discharges heat H and radicals R through the throat THR into said main combustion space MCR. The burner axis CX is defined by a centerline extending in the direction of the main flow generated through said throat THR.

[0025] The supply of air A and fuel F into the main combustion space MCR is provided by two annular channels, namely a first channel CH1 and a second channel CH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com