Waterproof and breathable shoes

A waterproof, breathable, and air-permeable technology, which is applied to footwear, soles, clothing, etc., can solve the problems of insufficient ventilation performance, affect the aesthetics of shoes, and complex production processes, achieve good ventilation effects, and achieve waterproof and breathable effects. The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

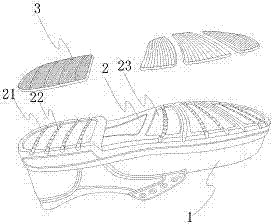

[0012] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to figure 1 , a waterproof and breathable shoe, comprising a shoe upper 1 and a sole 2, a shoe chamber for feet is formed between the upper 1 and the sole 2, the upper 1 and the sole 2 are integrally formed structures, the upper surface of the sole 2 and the There are a plurality of ventilation grooves 21 that run through the left and right side edges of the sole evenly distributed between the lower surfaces along its length direction. The upper surface of the sole 2 communicates with the ventilation groove 21 and the air hole 22 of the shoe cavity; further, the waterproof and breathable shoes also include a non-slip and wear-resistant rubber sheet 3, and the lower surface of the sole 2 corresponds to the heel and metatarsal parts of the human foot. An embedding groove 23 for accommodating an anti-slip and wear-resistant rubber sheet is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com