Preparation method of biodegradable regenerated polyester staple fibers

A biodegradable and recycled polyester technology, applied in melt spinning, stretch spinning, melting of filament raw materials, etc., to achieve the effects of avoiding softening and sticking, reducing extrusion swell ratio, and ensuring biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

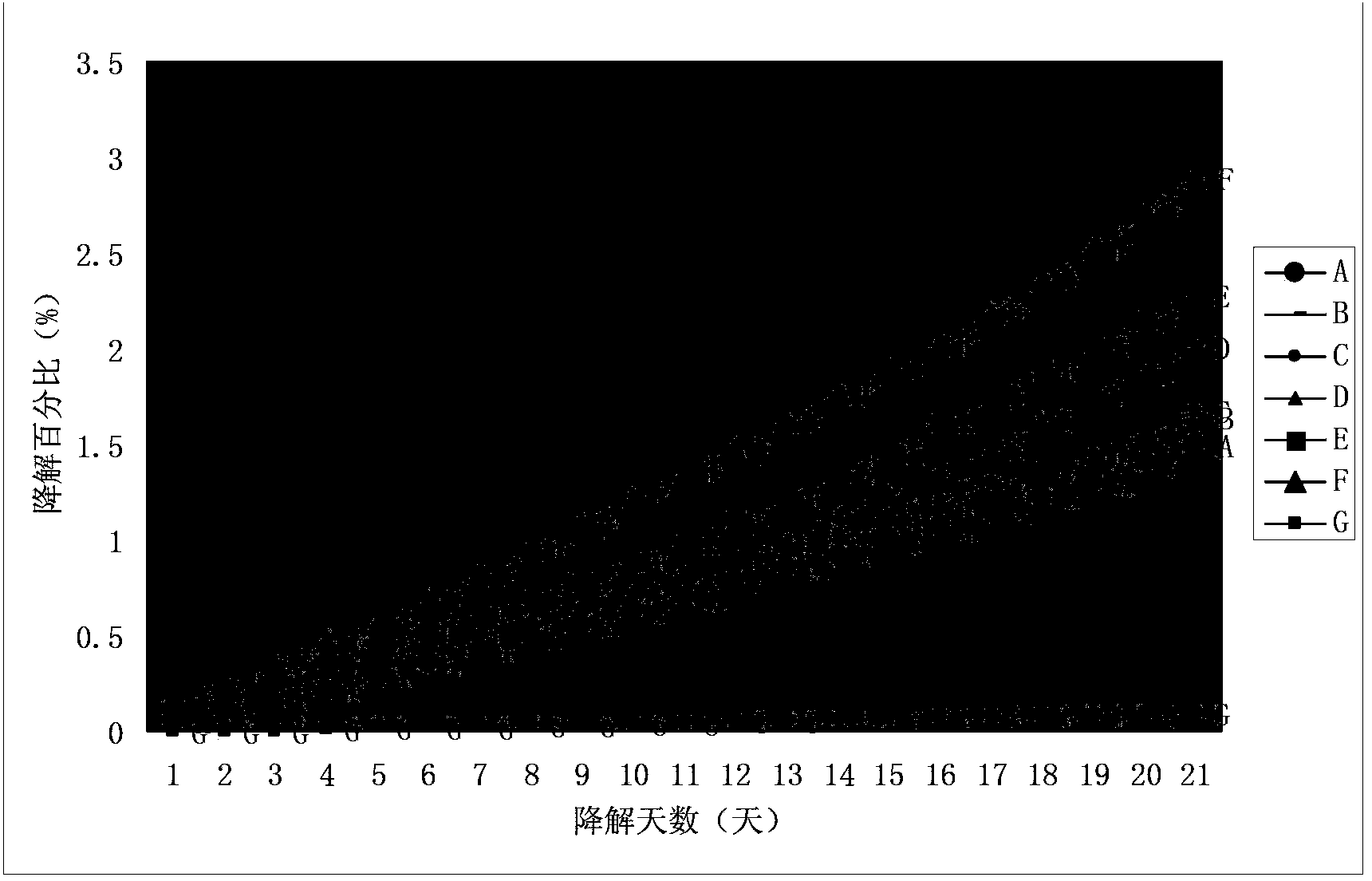

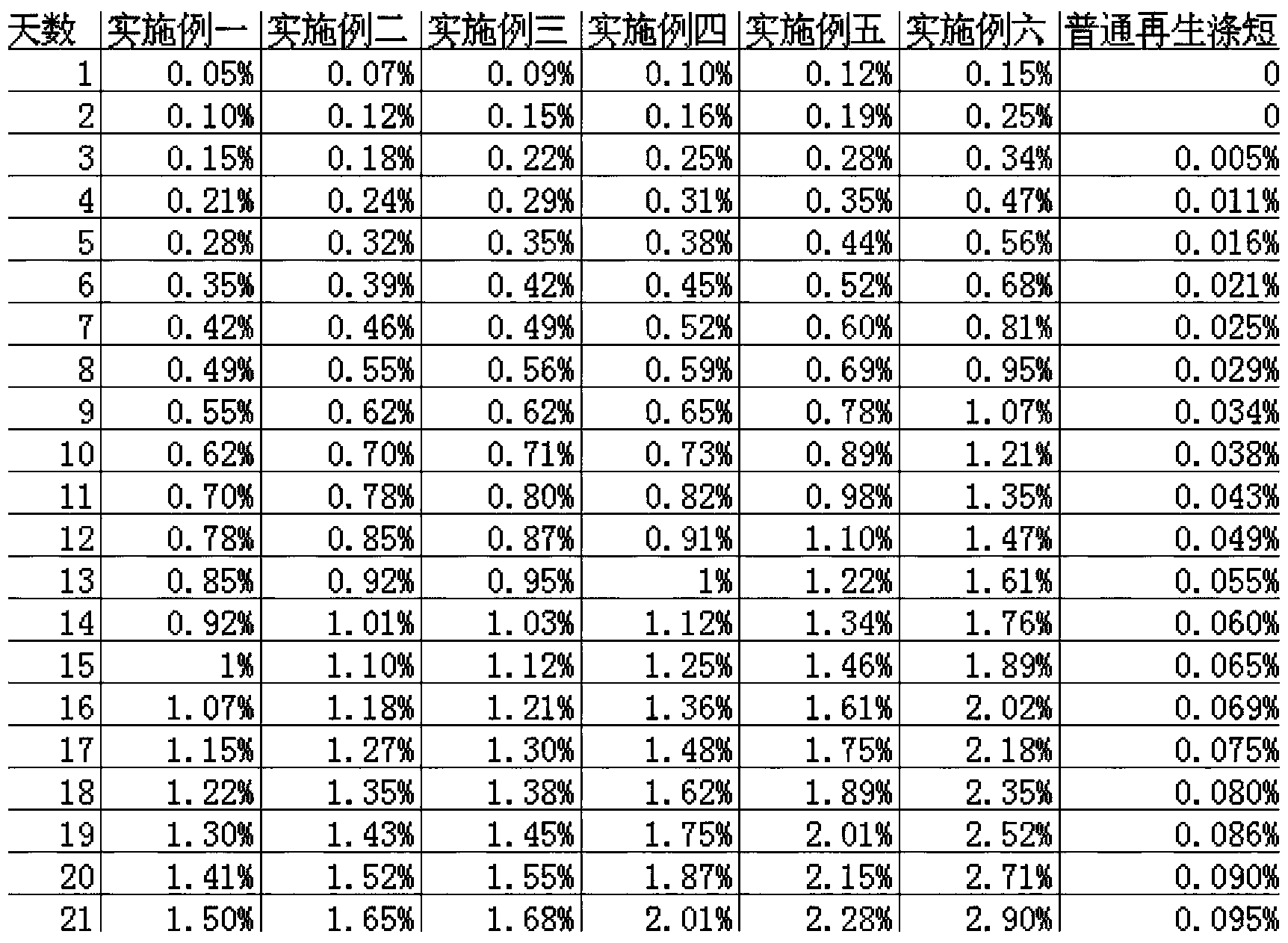

Examples

Embodiment 1

[0031] A kind of preparation method of biodegradable recycled polyester staple fiber of the present invention, realizes by following steps:

[0032] 1. 2150.4 kg of waste PET bottle flakes, 75 kg of friction material, 75 kg of foam material, 75 kg of plastic sheet and 0.6 kg of fluorescent whitening agent are used as raw materials for spinning; the melting point of waste PET bottle flakes is 260°C, and the viscosity is 0.72 dl / g, PVC content is 0.020wt%; friction material melting point is 255°C, viscosity is 0.64dl / g, PVC content is 0.028wt%; bubble material melting point is 253°C, viscosity is 0.60dl / g, PVC content is 0.025wt%; the melting point of the blister sheet is 258°C, the viscosity is 0.65dl / g, and the PVC content is 0.032wt%;

[0033] Among them, chemical fiber friction materials, foam materials and blister sheets can come from various PET wastes, such as polyester filament waste, staple fiber waste, polyester syringe waste, X-ray film waste, film waste, and melt fil...

Embodiment 2

[0042] A kind of preparation method of biodegradable recycled polyester staple fiber of the present invention, realizes by following steps:

[0043] 1. 1901.4 kg of waste PET bottle flakes, 150 kg of friction material, 150 kg of foam material, 150 kg of plastic sheet and 0.6 kg of fluorescent whitening agent are used as raw materials for spinning; the melting point of waste PET bottle flakes is 262°C and the viscosity is 0.75 dl / g, PVC content is 0.024wt%; friction material melting point is 255°C, viscosity is 0.65dl / g, PVC content is 0.026wt%; bubble material melting point is 254°C, viscosity is 0.62dl / g, PVC content is 0.020wt%; the melting point of the blister sheet is 260°C, the viscosity is 0.62dl / g, and the PVC content is 0.040wt%;

[0044] Among them, chemical fiber friction materials, foam materials, and blister sheets come from various PET wastes, including polyester filament waste, short fiber waste, polyester syringe waste, X-ray film waste, film waste, and melt fil...

Embodiment 3

[0053] A kind of preparation method of biodegradable recycled polyester staple fiber of the present invention, realizes by following steps:

[0054] 1. 1727.4 kg of waste PET bottle flakes, 200 kg of friction material, 200 kg of foam material, 200 kg of plastic sheet and 0.6 kg of fluorescent whitening agent are used as raw materials for spinning; the melting point of waste and old PET bottle flakes is 265°C and the viscosity is 0.78 dl / g, PVC content is 0.010wt%; friction material melting point is 255°C, viscosity is 0.62dl / g, PVC content is 0.025wt%; bubble material melting point is 256°C, viscosity is 0.65dl / g, PVC content is 0.020wt%; the melting point of the blister sheet is 260°C, the viscosity is 0.58dl / g, and the PVC content is 0.025wt%;

[0055] Among them, chemical fiber friction materials, foam materials, and blister sheets come from various PET wastes, such as polyester filament waste, staple fiber waste, polyester syringe waste, X-ray film waste, film waste, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com