Composite PTA preparation method

A technology of aqueous solution and fluoboric acid, applied in the direction of single-component polyester rayon, etc., can solve the problems of insufficient synergistic effect, side reactions, and poor mutual fusion, so as to improve the overall function and quality effect, improve the dispersion and Compatibility, the effect of promoting the growth of oxide crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

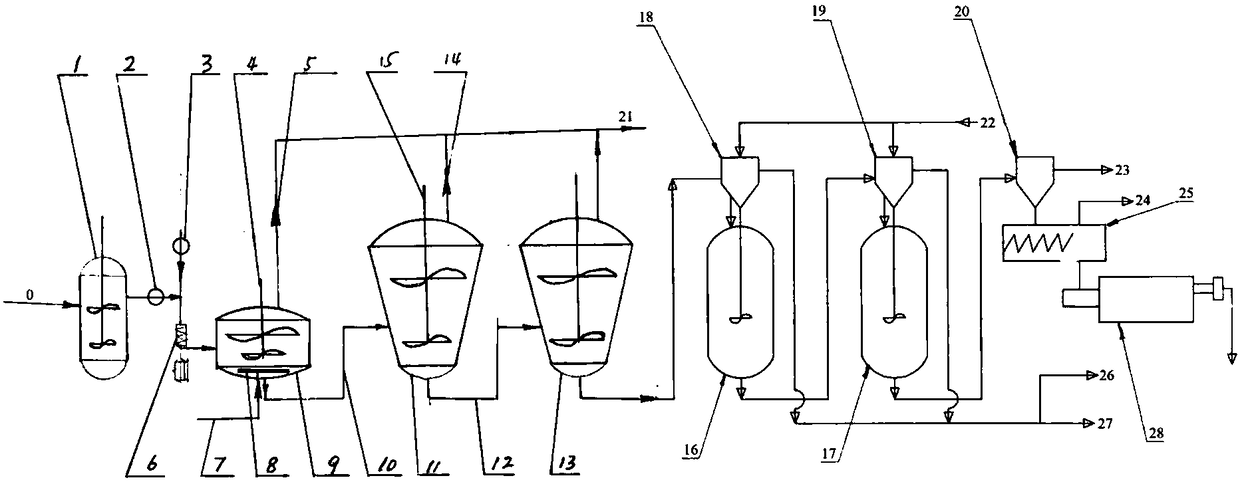

Image

Examples

Embodiment 1

[0065] A preparation method of composite PTA, comprising the steps of:

[0066] (1) By mass parts, 1.25 parts of zinc molybdate, 1.25 parts of cerium oxide, 6 parts of mass fraction are 20% fluoroboric acid aqueous solution, 0.5 parts of graphene oxide, 0.5 parts of tin oxide, 0.2 parts of Titanium oxide and 10 parts of perchloric acid aqueous solution with a mass fraction of 2% are fully mixed, ground at 50°C for 3 hours with a high-energy ball mill, and then moved to a hydrothermal reactor lined with titanium, and then heated at 190°C, 3MPa Down treatment for 7 hours, cooling and filtering, calcining at 525°C for 4.5 hours, cooling to room temperature, grinding in a ball mill for 3.5 hours, moving to a stirred plasma reactor, using nitrogen as a carrier gas at 45Pa, 65W power RF plasma treatment for 8 minutes, then added to 12.5 parts of 30% organic silicon ethanol solution, ultrasonically dispersed at 70°C for 2 hours, filtered, fully washed with absolute ethanol, then heat...

Embodiment 2

[0071] A preparation method of composite PTA, comprising the steps of:

[0072] (1) In parts by mass, 1 part of zinc molybdate, 1.5 parts of cerium oxide, 8 parts of mass fraction of 15% fluoroboric acid aqueous solution, 0.4 part of graphene oxide, 0.6 part of tin oxide, 0.3 part of Titanium oxide and 8 parts of perchloric acid aqueous solution with a mass fraction of 1% are fully mixed, ground at 55°C for 2 hours with a high-energy ball mill, and then moved to a hydrothermal reactor lined with titanium, and then heated at 200°C, 2MPa Down treatment for 8 hours, cooling and filtering, calcining at 530°C for 5 hours, cooling to room temperature, grinding in a ball mill for 3 hours, moving to a stirred plasma reactor, using nitrogen as a carrier gas, and performing radio frequency plasma at 40Pa and 80W power The body was treated for 6 minutes, and then added to 15 parts of ethanol solution of organic silicon with a mass fraction of 40%, ultrasonically dispersed at 80°C for 1 h...

Embodiment 3

[0077] A preparation method of composite PTA, comprising the steps of:

[0078] (1) In parts by mass, 1.5 parts of zinc molybdate, 1 part of cerium oxide, 4 parts of mass fraction of 30% fluoroboric acid aqueous solution, 0.6 parts of graphene oxide, 0.4 parts of tin oxide, 0.1 part of Titanium oxide and 12 parts of perchloric acid aqueous solution with a mass fraction of 2% are fully mixed, ground at 45°C for 4 hours with a high-energy ball mill, then moved to a hydrothermal reaction kettle lined with titanium, and then heated at 180°C, 4MPa Down treatment for 6 hours, cooling and filtering, calcining at 520°C for 4 hours, cooling to room temperature, grinding in a ball mill for 4 hours, moving to a stirred plasma reactor, using nitrogen as a carrier gas, and performing radio frequency plasma at 50Pa and 50W power The body was treated for 10 minutes, and then added to 10 parts of ethanol solution of organic silicon with a mass fraction of 20%, ultrasonically dispersed at 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com