Blast-furnace operation method

A blast furnace operation and blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., to achieve the effects of reducing the ratio of reducing materials, promoting reduction, and improving ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

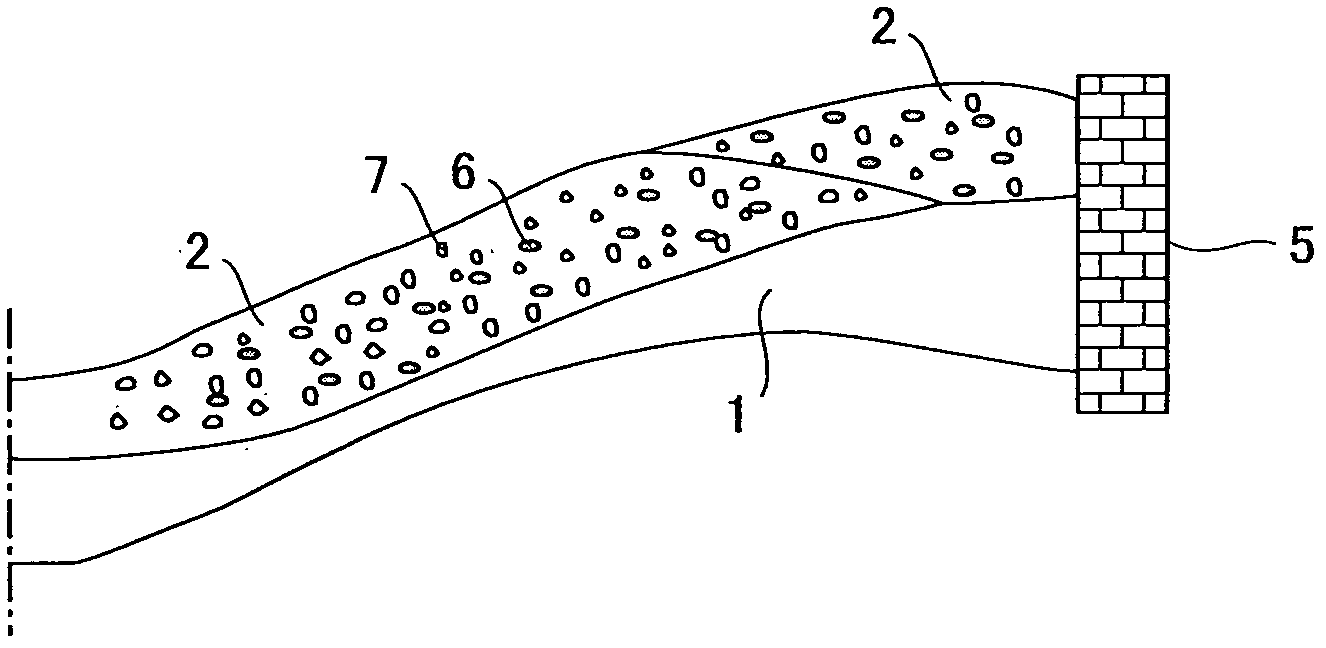

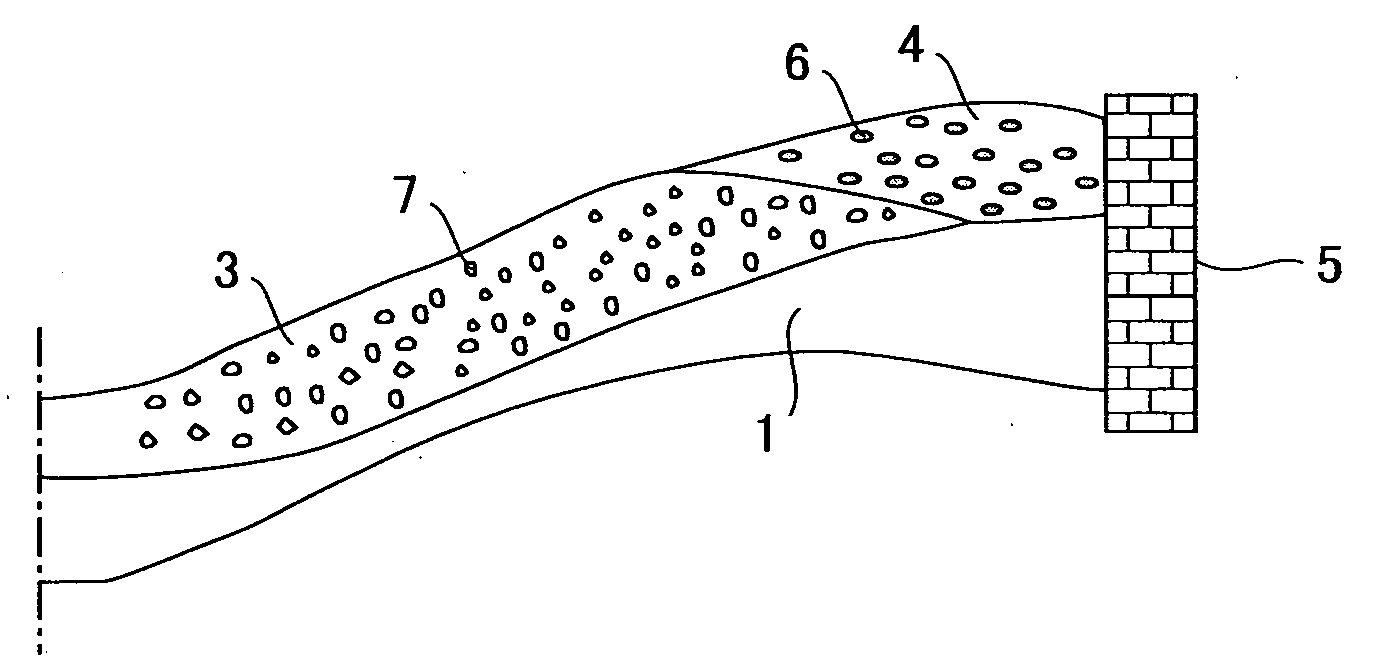

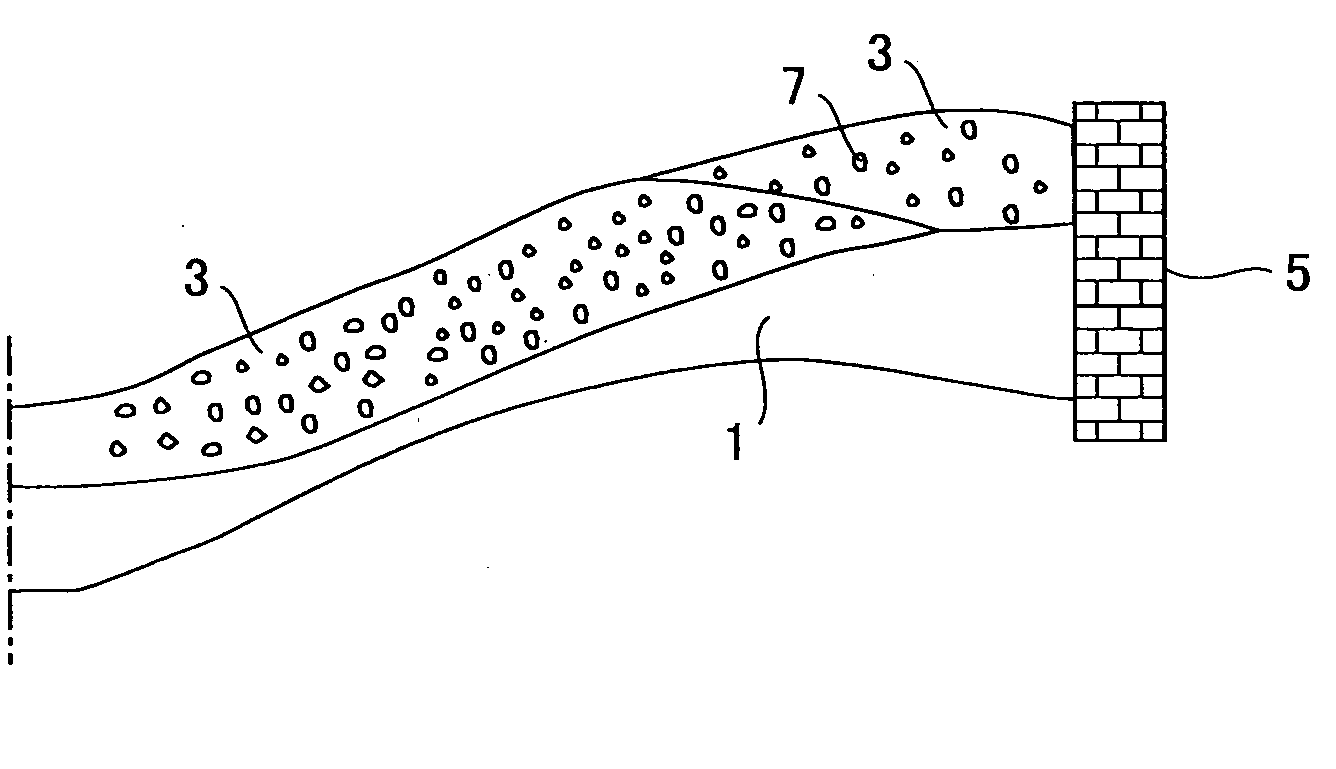

[0062] A blast furnace operation test to which the method of the present invention was applied was carried out. The iron coke used is produced by molding a mixture of coal and ore with a molding machine, putting it into a vertical combustion furnace, and performing dry distillation. The size of the above-mentioned iron coke is a printed box type of 30×25×18mm. In addition, the iron content in iron coke was set to 30% by mass.

[0063] Raw material charging to the blast furnace first forms a coke layer consisting of only coke oven coke, and an ore layer mixed with coke (iron coke and / or coke oven coke) is charged in two batches. As the ore layer, three kinds of charging were performed (test No. 1-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com