Novel environment-friendly composite reinforced polypropylene building template

A composite reinforced, polypropylene technology, applied in the field of new environmentally friendly composite reinforced polypropylene building formwork, can solve the technical problems of waste tire recycling, treatment and reuse, fire hazards, black pollution and other problems, to broaden the use temperature range, improve Compatibility, the effect of improving melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

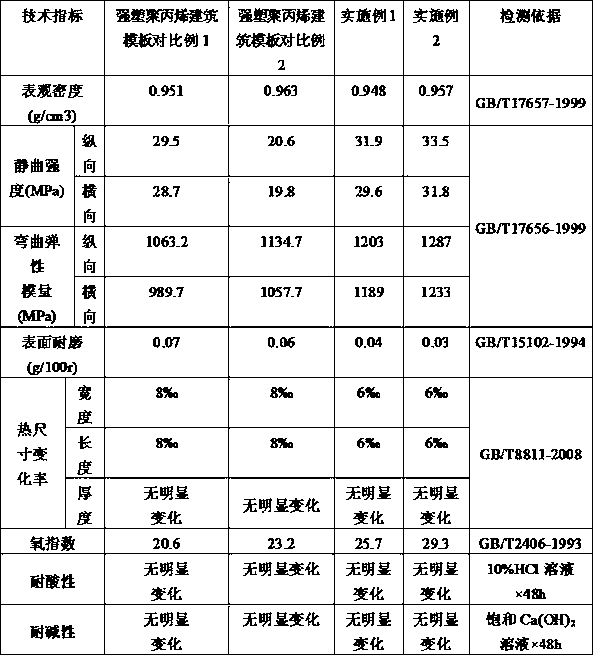

[0044] The present invention will be further described below in conjunction with specific embodiment:

[0045] Prepare raw materials according to the above-mentioned raw material weight percentages of the upper and lower surface layers (see Table 1):

[0046] raw material name Example 1 Example 2 Recycled polypropylene pellets 61 53 800 mesh aluminum hydroxide 26 31 Antioxidant 1010 0.3 0.3 Polypropylene-dibromostyrene graft copolymer 8 11 7# white oil 3 3 silicone 1 1 Auxiliary antioxidant DLTDP 0.2 0.2 UV-531 0.5 0.5

[0047] Prepare raw materials (see Table 2) by the raw material weight percent of above-mentioned microfoaming core layer:

[0048] raw material name Example 1 Example 2 Modification of recycled polypropylene masterbatch with waste tire fine rubber powder 89.4 89.4 800 mesh clay 5 5 Blowing agent AC 0.6 0.6 7# white oil 2 2 KZ-110 Foaming Stabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com