Building reinforcing epoxy adhesive and preparation method thereof

An epoxy type, adhesive technology, used in adhesives, epoxy resin adhesives, adhesive additives, etc., can solve the problems of weak strength and toughness of adhesives, and the adhesive does not have flame retardant function, and achieves slow acid resistance, strength and stability. The effect of strong toughness and increased function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

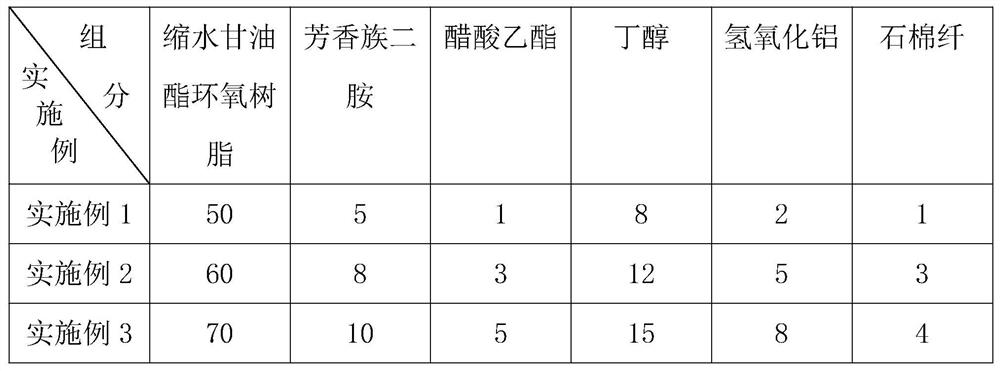

Embodiment 1

[0046] The invention provides a building reinforcement epoxy adhesive, comprising the following raw materials in parts by weight:

[0047] 50 parts of epoxy resin;

[0048] 5 parts curing agent;

[0049] Accelerator 1 part;

[0050] 8 parts of diluent;

[0051] 2 parts aluminum hydroxide;

[0052] 1 part filler;

[0053] As a preferred technical solution of this embodiment, the epoxy resin is glycidyl ester epoxy resin.

[0054] As a preferred technical solution of this embodiment, the curing agent is aromatic diamine, and the curing temperature is 150-170°C.

[0055] As a preferred technical solution of this embodiment, the filler is asbestos fiber.

[0056] As a preferred technical solution of this embodiment, the accelerator is ethyl acetate.

[0057] As a preferred technical solution of this embodiment, the diluent is butanol.

[0058] The preparation method of this building reinforcement epoxy type adhesive comprises the following steps:

[0059] S1. Weigh the co...

Embodiment 2

[0063] The invention provides a building reinforcement epoxy adhesive, comprising the following raw materials in parts by weight:

[0064] 60 parts of epoxy resin;

[0065] 8 parts of curing agent;

[0066] Accelerator 3 parts;

[0067] 12 parts of diluent;

[0068] 5 parts of aluminum hydroxide;

[0069] 3 parts of filler;

[0070] As a preferred technical solution of this embodiment, the epoxy resin is glycidyl ester epoxy resin.

[0071] As a preferred technical solution of this embodiment, the curing agent is aromatic diamine, and the curing temperature is 150-170°C.

[0072] As a preferred technical solution of this embodiment, the filler is asbestos fiber.

[0073] As a preferred technical solution of this embodiment, the accelerator is ethyl acetate.

[0074] As a preferred technical solution of this embodiment, the diluent is butanol.

[0075] The preparation method of this building reinforcement epoxy type adhesive comprises the following steps:

[0076] S1. ...

Embodiment 3

[0080] The invention provides a building reinforcement epoxy adhesive, comprising the following raw materials in parts by weight:

[0081] 70 parts of epoxy resin;

[0082] 10 parts of curing agent;

[0083] Accelerator 5 parts;

[0084] 15 parts of diluent;

[0085] 8 parts of aluminum hydroxide;

[0086] 4 parts of stuffing;

[0087] As a preferred technical solution of this embodiment, the epoxy resin is glycidyl ester epoxy resin.

[0088] As a preferred technical solution of this embodiment, the curing agent is aromatic diamine, and the curing temperature is 150-170°C.

[0089] As a preferred technical solution of this embodiment, the filler is asbestos fiber.

[0090] As a preferred technical solution of this embodiment, the accelerator is ethyl acetate.

[0091] As a preferred technical solution of this embodiment, the diluent is butanol.

[0092] The preparation method of this building reinforcement epoxy type adhesive comprises the following steps:

[0093] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com