High-strength flame-retardant jean and production process and uses thereof

A production process and denim technology, applied in the textile field, can solve problems such as insufficient strength, narrow application range, and no flame-retardant function, and achieve the effects of improving strength and wear resistance, expanding application range, and increasing flame-retardant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

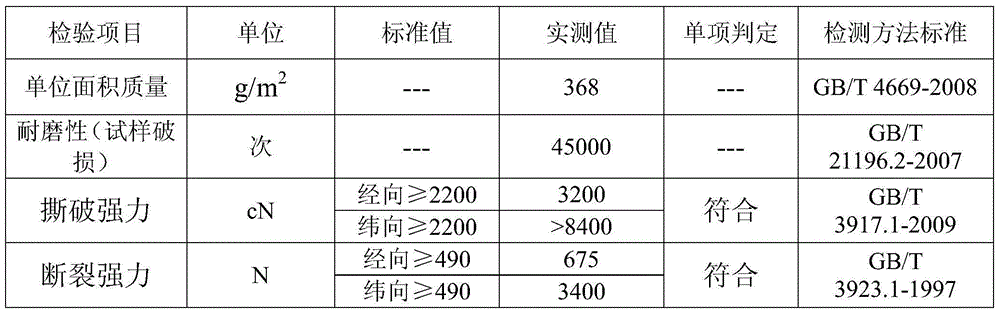

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0021] The invention is a high-strength flame-resistant denim fabric, the weft yarn of which is spun from aramid 1414. The fineness of aramid 1414 fiber is 1.5D-6D, and the length is 38-51mm. After spinning on the spinning machine, the aramid 1414 is spun into denim weft yarn with a fineness of 7 counts. Cotton warp yarns and aramid fiber weft yarns are machine-woven into denim gray fabrics; the denim gray fabrics are burnt off by a singeing machine to make the surface of the finished product smooth and smooth; the singeed gray fabrics are dried with grout to improve the texture of the fabric. Water repellency, stabilize the shrinkage of the fabric; eliminate the potential wef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com