Power cable for new energy vehicle

A new energy vehicle, power cable technology, applied in power cables, power cables with shielding/conductive layers, insulated cables, etc., can solve short-circuit fires, threaten personal and property safety, damage valuable electronic components of new energy vehicles, etc. problem, to achieve the effect of neat structure and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

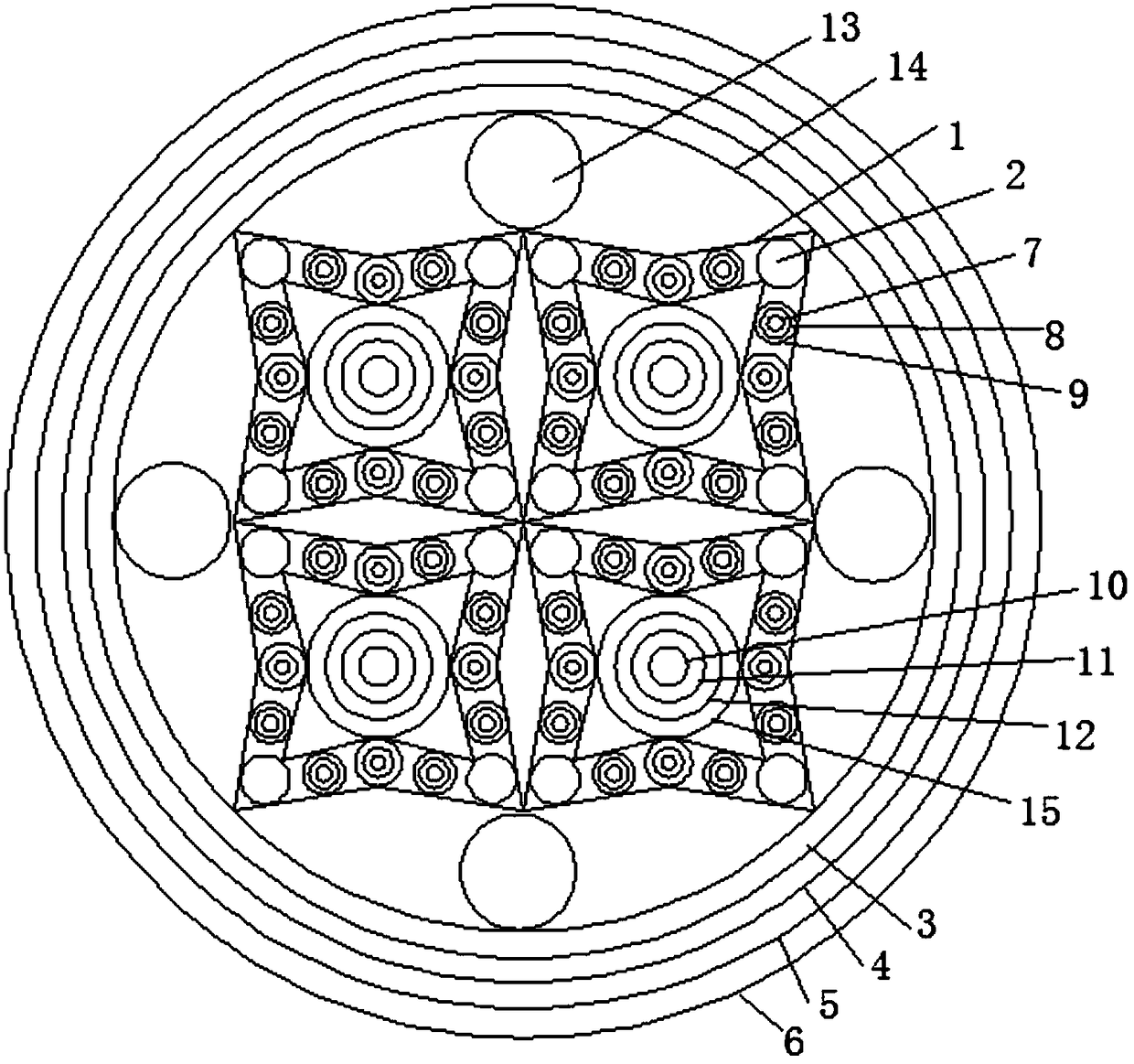

[0012] Such as figure 1 As shown, a power cable for new energy vehicles includes a cable core. The cable core includes four square rubber skeletons 1 with a square cross section. The square rubber skeleton 1 is double-layered, and the inner side Between the outer layer and the outer layer is a cavity, and the centers of the four faces of the square rubber skeleton 1 are all bent inwardly, and a plurality of wire cores are arranged in the cavity of the square rubber skeleton 1, and are located at each corner in the cavity. There are polyurethane elastic rods 2 at each place, and a wire core 2 is provided at the center of each square rubber skeleton 1. Four square rubber skeletons 1 are spliced into a square cable core, and the outside of the cable core is sequentially covered with three layers of galvanized steel. With armor layer 3, nano silicon waterproof glue filling layer 4, Kevlar fiber braiding layer 5 and halogen-free low-smoke flame-retardant polyolefin outer sheath 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com