Wear-resistant and durable stone honeycomb aluminum plate

A honeycomb aluminum panel, honeycomb aluminum technology, applied in building elements, layered products, chemical instruments and methods, etc., can solve problems such as insufficient strength, peeling, easy deviation, etc., to improve hardness and withstand pressure, easy to paste and fix, Improve the effect of flame retardant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

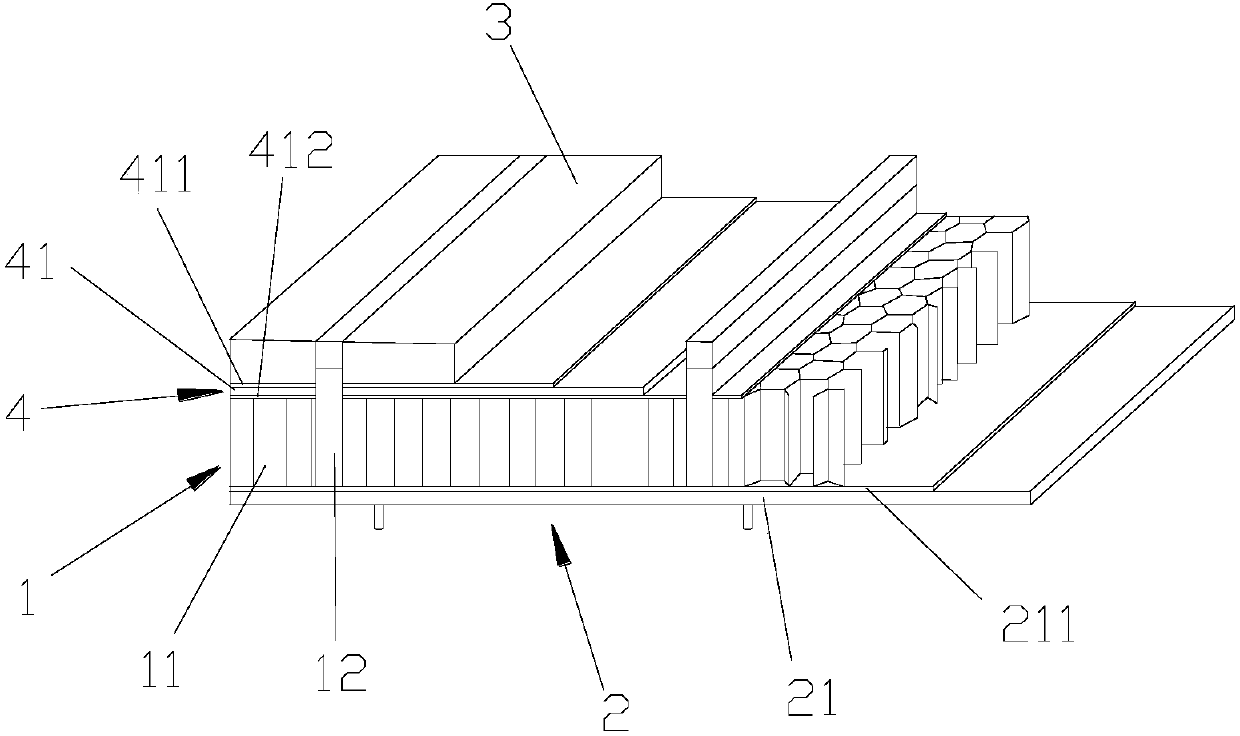

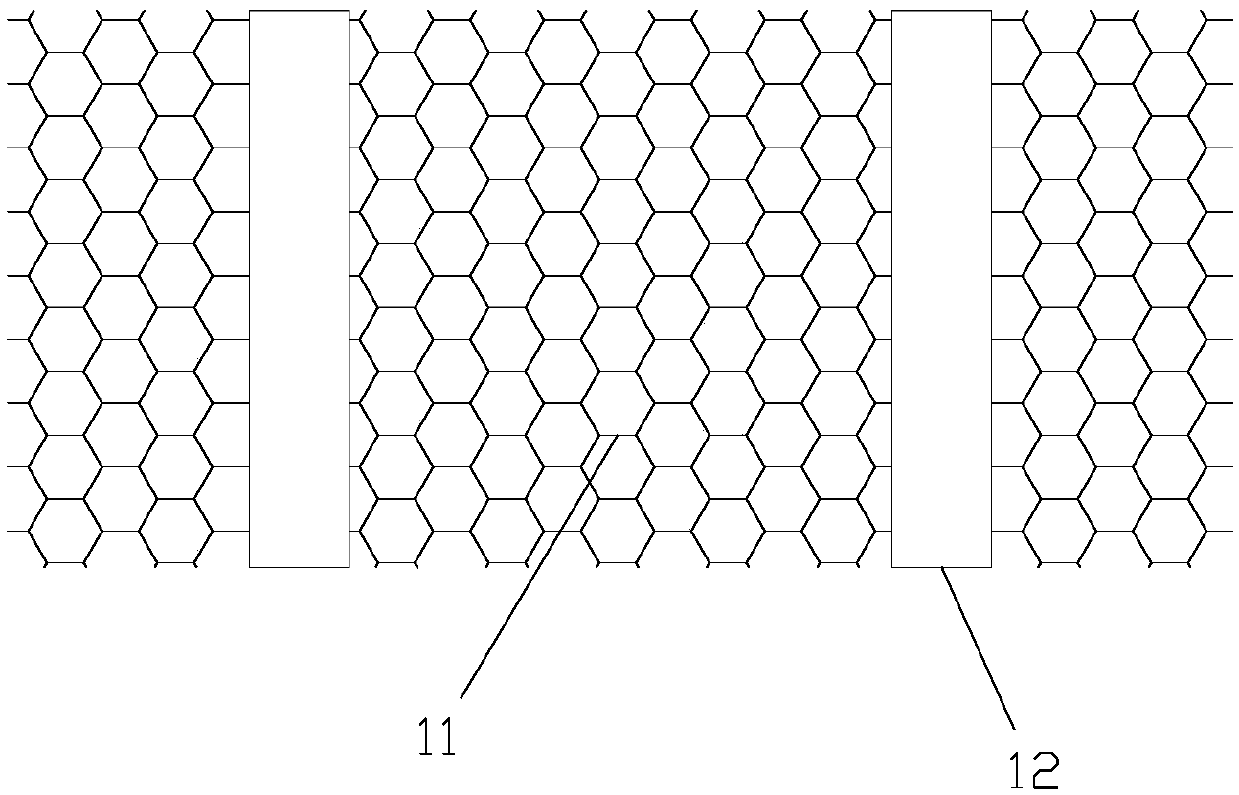

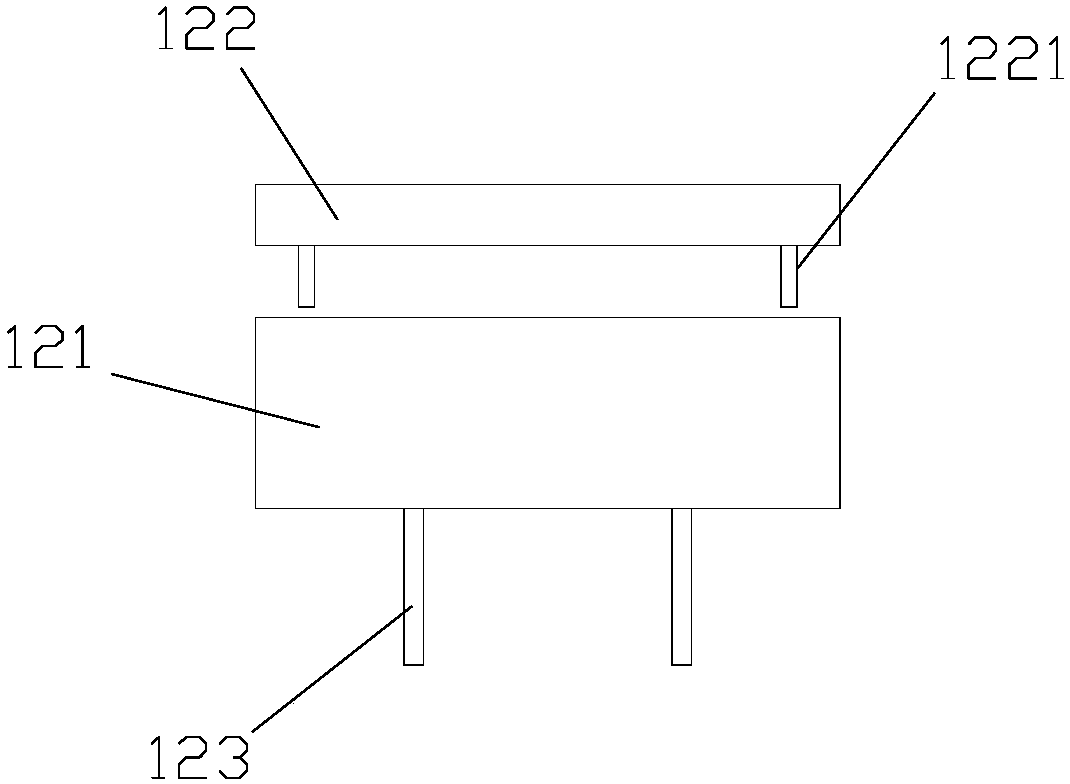

[0028] A wear-resistant and durable stone honeycomb aluminum plate, such as figure 1 As shown, it includes a honeycomb aluminum layer 1, a soft buffer layer 2 arranged at the bottom of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1, and a soft buffer layer 2 arranged on the upper surface of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1 The marble slab 3, and the interlayer 4 arranged between the honeycomb aluminum layer 1 and the marble slab 3; The first adhesive layer 211 to which the layer 1 is bonded. The interlayer 4 includes a galvanized sheet 41, and a second adhesive layer 411 and a third adhesive layer 412 arranged on both surfaces of the galvalume sheet 41 for bonding the honeycomb aluminum 11 and the marble slab 3 respectively . Such as figure 2 As shown, the honeycomb aluminum layer 1 includes honeycomb aluminum 11 , and a copper plate 12 arranged between the honeycomb aluminum 11 and fixed with the ho...

Embodiment 2

[0038] A wear-resistant and durable stone honeycomb aluminum plate, such as figure 1 As shown, it includes a honeycomb aluminum layer 1, a soft buffer layer 2 arranged at the bottom of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1, and a soft buffer layer 2 arranged on the upper surface of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1 The marble slab 3, and the interlayer 4 arranged between the honeycomb aluminum layer 1 and the marble slab 3; The first adhesive layer 211 to which the layer 1 is bonded. The interlayer 4 includes a galvanized sheet 41, and a second adhesive layer 411 and a third adhesive layer 412 arranged on both surfaces of the galvalume sheet 41 for bonding the honeycomb aluminum 11 and the marble slab 3 respectively . Such as figure 2 As shown, the honeycomb aluminum layer 1 includes honeycomb aluminum 11 , and a copper plate 12 arranged between the honeycomb aluminum 11 and fixed with the ho...

Embodiment 3

[0048] A wear-resistant and durable stone honeycomb aluminum plate, such as figure 1 As shown, it includes a honeycomb aluminum layer 1, a soft buffer layer 2 arranged at the bottom of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1, and a soft buffer layer 2 arranged on the upper surface of the honeycomb aluminum layer 1 and fixed with the honeycomb aluminum layer 1 The marble slab 3, and the interlayer 4 arranged between the honeycomb aluminum layer 1 and the marble slab 3; The first adhesive layer 211 to which the layer 1 is bonded. The interlayer 4 includes a galvanized sheet 41, and a second adhesive layer 411 and a third adhesive layer 412 arranged on both surfaces of the galvalume sheet 41 for bonding the honeycomb aluminum 11 and the marble slab 3 respectively . Such as figure 2 As shown, the honeycomb aluminum layer 1 includes honeycomb aluminum 11 , and a copper plate 12 arranged between the honeycomb aluminum 11 and fixed with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com