Insulating material for cable sealing and preparation method thereof

A sealing material, insulation and sealing technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesive additives, etc., can solve the corrosion damage of switchgear electrical components, line segment joint transmission mechanism, can not meet the safety of power system The need for prevention, the limited ability of rodent protection, etc., can improve the insulation performance and mechanical properties, improve the curing rate, and improve the thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

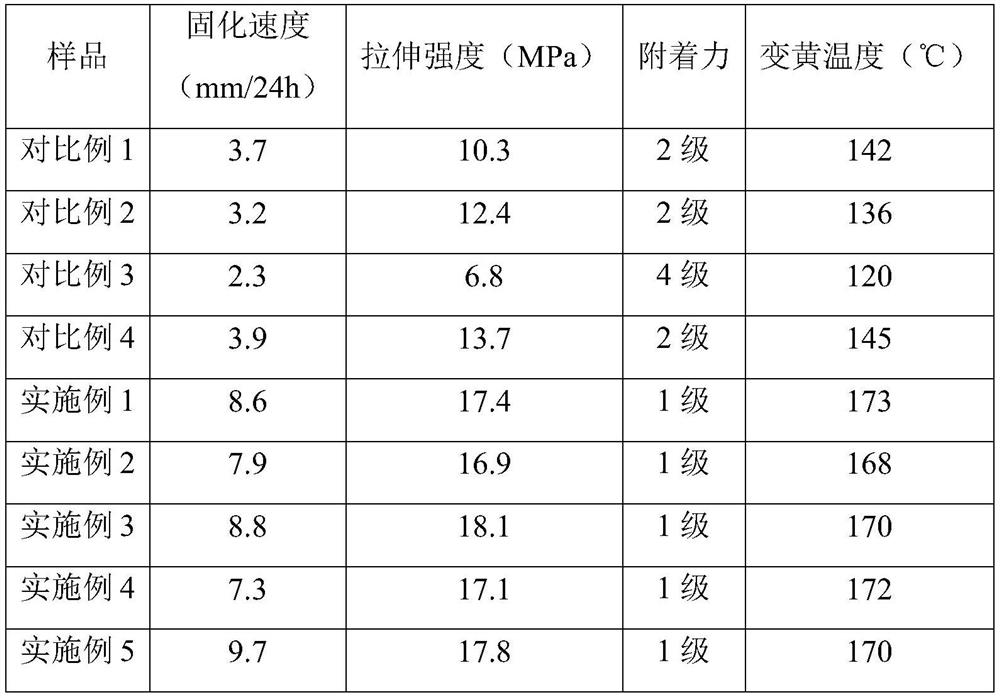

Embodiment 1

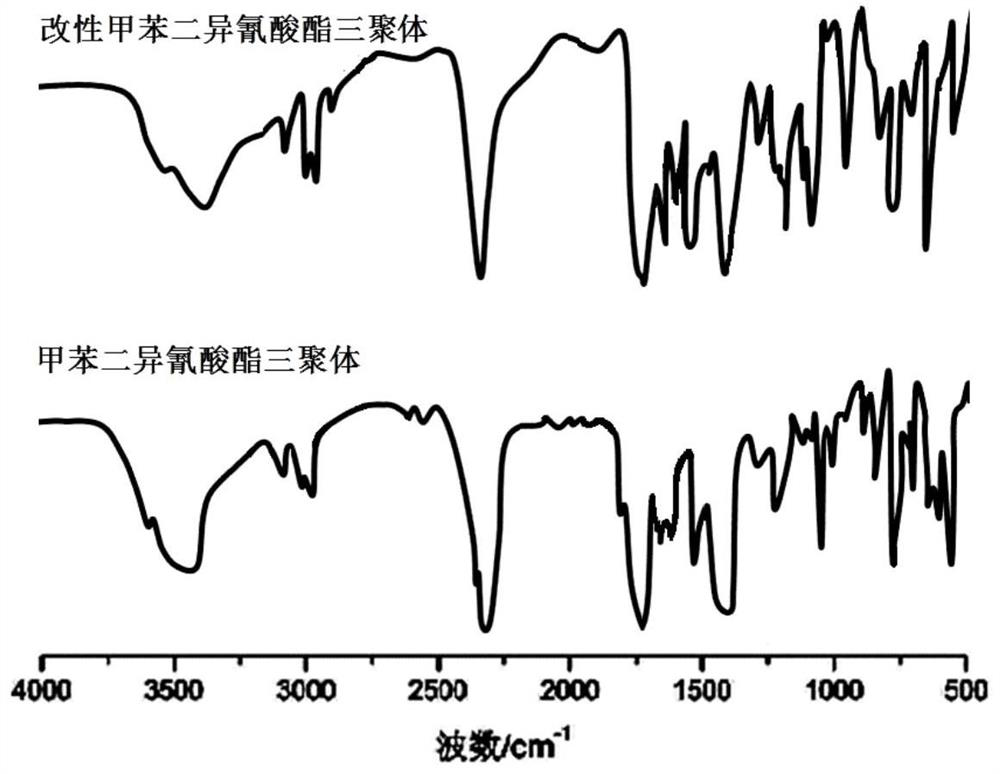

[0030] Preparation of 4-hydroxy-6-(trifluoromethyl)pyrimidine-2-thiol modified toluene diisocyanate trimer:

[0031] In a 100mL three-necked flask equipped with a stirrer and a thermometer, add toluene diisocyanate and butyl acetate at a ratio of 1:1, and then add 4-hydroxy-6-(trifluoromethyl)pyrimidine-2-thiol (with The mass ratio of toluene diisocyanate monomer is 1:0.9), then add dibutyltin dilaurate (the addition amount is 0.2% of the mass of toluene diisocyanate monomer), pass through nitrogen protection, stir and heat up to 70°C, and react for 1.5h Then add potassium acetate (add-on is 0.1% of toluene diisocyanate monomer quality), continue to react, every 1h detects the percentage content of free NCO group, when the weight percentage content of NCO reaches requirement, add immediately Benzoyl chloride, keep warm for 1h, cool down and discharge. The solid content was adjusted to 50%.

[0032] An insulating sealing material, comprising, A component, B component and C co...

Embodiment 2

[0042] The difference between the preparation of modified toluene diisocyanate trimer and Example 1 is that the mass ratio of 4-hydroxy-6-(trifluoromethyl)pyrimidine-2-thiol to toluene diisocyanate monomer is 1:1 .

[0043] An insulating sealing material, comprising, A component, B component and C component; Wherein, by weight:

[0044] Component A: 95 parts of modified toluene diisocyanate trimer, 12 parts of castor oil polyoxyethylene ether, 11 parts of polyoxypropylene glycol;

[0045] Component B: 5 parts of polyoxypropylene glycol, 3 parts of polyester polyol, 7 parts of propylene butane, 3 parts of dimethyl ether, 0.8 part of dodecyl sulfuric acid, 4 parts of nano-montmorillonite;

[0046] Component C: 1.1 parts of oleylamine polyoxyethylene ether, 4 parts of nano-sized silicon dioxide, 3 parts of fibrous nano-sized calcium carbonate whiskers, 0.2 parts of cuminyl phenyl phosphate, 0.4 parts of antimony trioxide, 0.3 parts of triaryl phosphate, 0.9 parts of silane coup...

Embodiment 3

[0049] The difference between the preparation of modified toluene diisocyanate trimer and Example 1 is that the mass ratio of 4-hydroxy-6-(trifluoromethyl)pyrimidine-2-thiol to toluene diisocyanate monomer is 1:1.1 .

[0050] An insulating sealing material, comprising, A component, B component and C component; Wherein, by weight:

[0051] Component A: 100 parts of modified toluene diisocyanate trimer, 14 parts of castor oil polyoxyethylene ether, 12 parts of polyoxypropylene glycol;

[0052] Component B: 7 parts of polyoxypropylene glycol, 5 parts of polyester polyol, 6 parts of propylene butane, 3 parts of dimethyl ether, 0.8 part of dodecyl sulfuric acid, 6 parts of nano-montmorillonite;

[0053] Component C: 0.9 parts of oleylamine polyoxyethylene ether, 6 parts of nano-sized silicon dioxide, 4 parts of fibrous nano-sized calcium carbonate whiskers, 0.1 part of cuminyl phenyl phosphate, 0.2 parts of antimony trioxide, 0.6 parts of triaryl phosphate, 0.7 parts of silane co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com