Antibacterial rat-proof and termite-proof magnetic polyethylene material and preparation method thereof

A polyethylene and rodent-proof technology, applied in the field of cable materials, can solve the problems of difficult material sources and procurement, human hazards, high labor costs, etc., and achieve long-term release, safety, heat resistance, and stable processing performance , the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

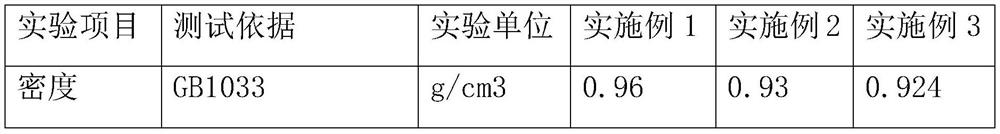

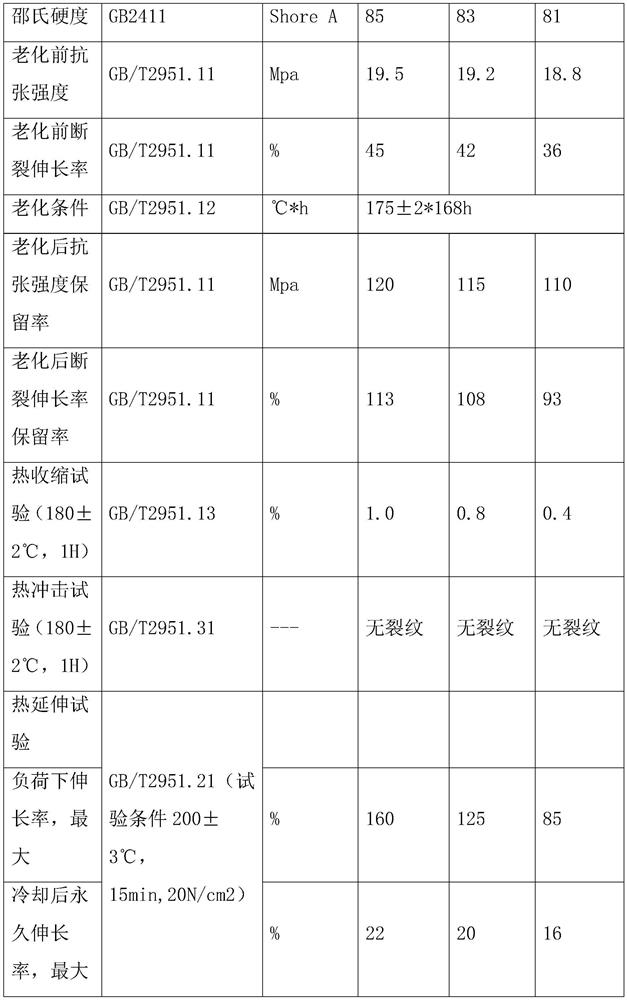

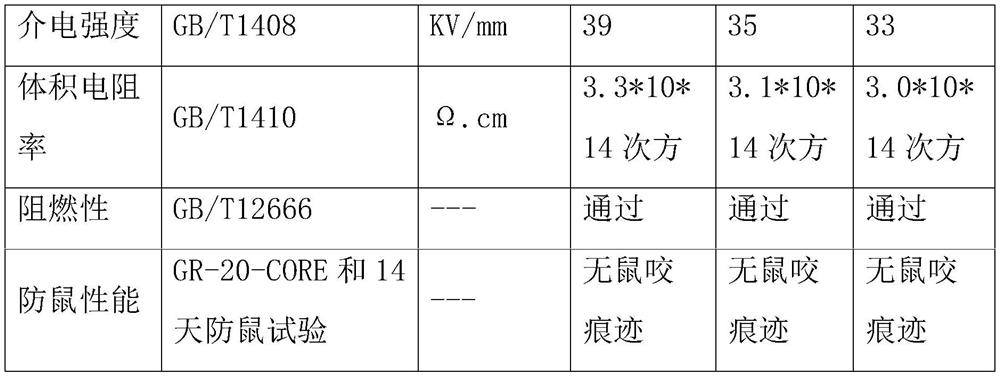

Embodiment 1

[0023] An antibacterial rodent and ant-proof magnetic polyethylene material, which is composed of the following raw materials in parts by weight: 100 parts of polyethylene resin, 2 parts of environmentally friendly plastic anti-rodent agent DH-600, 2 parts of environmentally friendly plastic anti-termite agent DH-203, 5 parts 1 part of environmentally friendly modified heat stabilizer DH-361, 2 parts of polymer permanent antistatic agent Pentax MH2030, 2 parts of conductive carbon black VULCAN XC-72, 10 parts of light shielding agent high wear-resistant carbon black JY-2, 1 part Antioxidant 1010, 1 part of antioxidant 168, 10 parts of polyol benzoate, 20 parts of brominated epoxy resin flame retardant F-2001, 10 parts of calcium carbonate 800 mesh, 1 part of bright lubricant GL-10 , 1 part of PE wax, 1 part of stearic acid 1801, 1 part of zinc stearate, 5 parts of polyethylene octene co-elastomer toughening modifier, 2 parts of new phenolic resin, 4 parts of zinc ion antibacter...

Embodiment 2

[0025] An antibacterial rodent and ant-proof magnetic polyethylene material, which is composed of the following raw materials in parts by weight: 100 parts of polyethylene resin, 2 parts of environmentally friendly plastic anti-rodent agent DH-600, 2 parts of environmentally friendly plastic anti-termite agent DH-203, 8 parts 1 part of environmentally friendly modified heat stabilizer DH-361, 4 parts of polymer permanent antistatic agent Pentax MH2030, 3 parts of conductive carbon black VULCAN XC-72, 10 parts of light shielding agent high wear-resistant carbon black JY-2, 2 parts Antioxidant 1010, 2 parts of antioxidant 168, 12 parts of polyol benzoate, 25 parts of brominated epoxy resin flame retardant F-2001, 12 parts of calcium carbonate 800 mesh, 2 parts of bright lubricant, 1 part PE wax, 2 parts of stearic acid 1801, 2 parts of zinc stearate, 8 parts of polyethylene octene co-elastomer toughening modifier, 2 parts of new phenolic resin, 5 parts of zinc ion antibacterial a...

Embodiment 3

[0027] An antibacterial rodent and ant-proof magnetic polyethylene material, which is composed of the following raw materials in parts by weight: 100 parts of polyethylene resin, 3 parts of environmentally friendly plastic anti-rodent agent DH-600, 3 parts of environmentally friendly plastic anti-termite agent DH-203, 10 parts 1 part of environmentally friendly modified heat stabilizer DH-361, 5 parts of polymer permanent antistatic agent Pentax MH2030, 5 parts of conductive carbon black VULCAN XC-72, 10 parts of light shielding agent high wear-resistant carbon black JY-2, 2 parts Antioxidant 1010, 2 parts of antioxidant 168, 15 parts of polyol benzoate, 30 parts of brominated epoxy resin flame retardant F-2001, 15 parts of calcium carbonate 800 mesh, 2 parts of bright lubricant GL-10 , 2 parts of PE wax, 2 parts of stearic acid 1801, 2 parts of zinc stearate, 10 parts of polyethylene octene co-elastomer toughening modifier, 3 parts of new phenolic resin, 6 parts of zinc ion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com