Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and diaphragm technology, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problems of poor adhesion of battery pole pieces, poor flame retardancy, and poor heat resistance of diaphragms, etc. Achieve good adhesion, improve flame retardant function, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

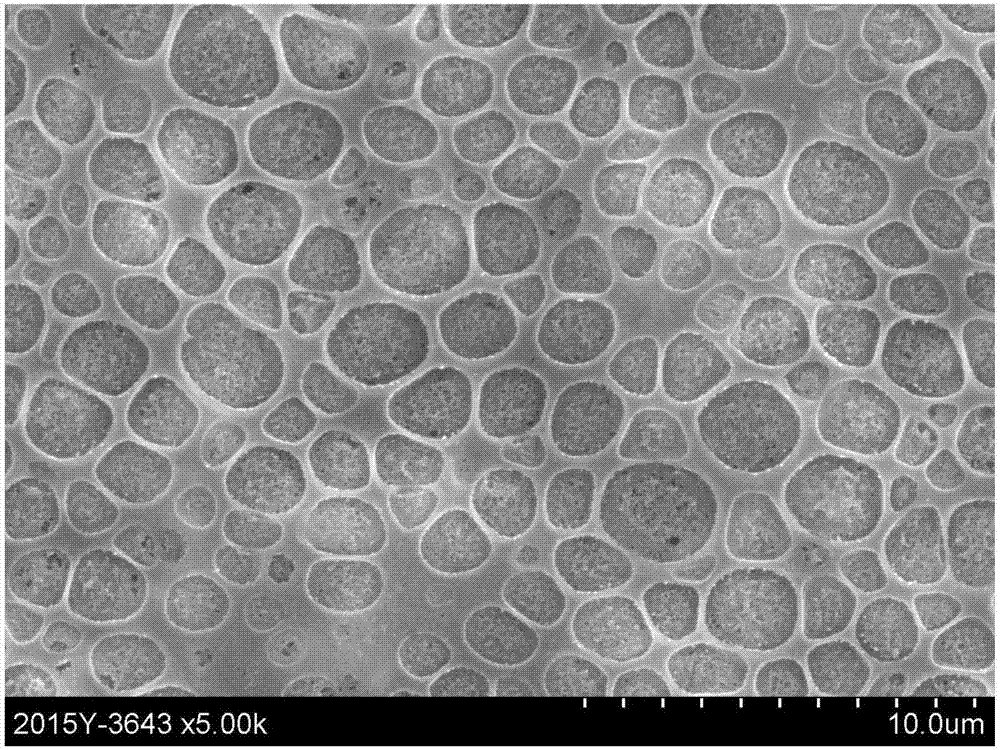

Image

Examples

preparation example Construction

[0035] 3. Preparation method of functional coating modified lithium-ion battery separator

[0036] The invention adopts a wet coating method to prepare a functional coating modified lithium ion battery diaphragm, and the wet coating method is a well-known method for preparing a microporous membrane or a microporous coating.

[0037] (1) Dissolving aromatic polyamide and gel polymer in a certain mass ratio in a solvent respectively, then mixing the two, adding metal hydroxide after mixing evenly, and obtaining a coating liquid after high-speed shearing and stirring. Wherein, the solid content of the coating liquid is 10%-25%.

[0038] (2) Using the polyolefin microporous membrane as the coating substrate, coating the coating solution prepared in step 1 on the surface of the polyolefin microporous membrane to obtain a film A containing a multifunctional coating.

[0039]The method of coating the coating liquid on the surface of the polyolefin microporous membrane is not particu...

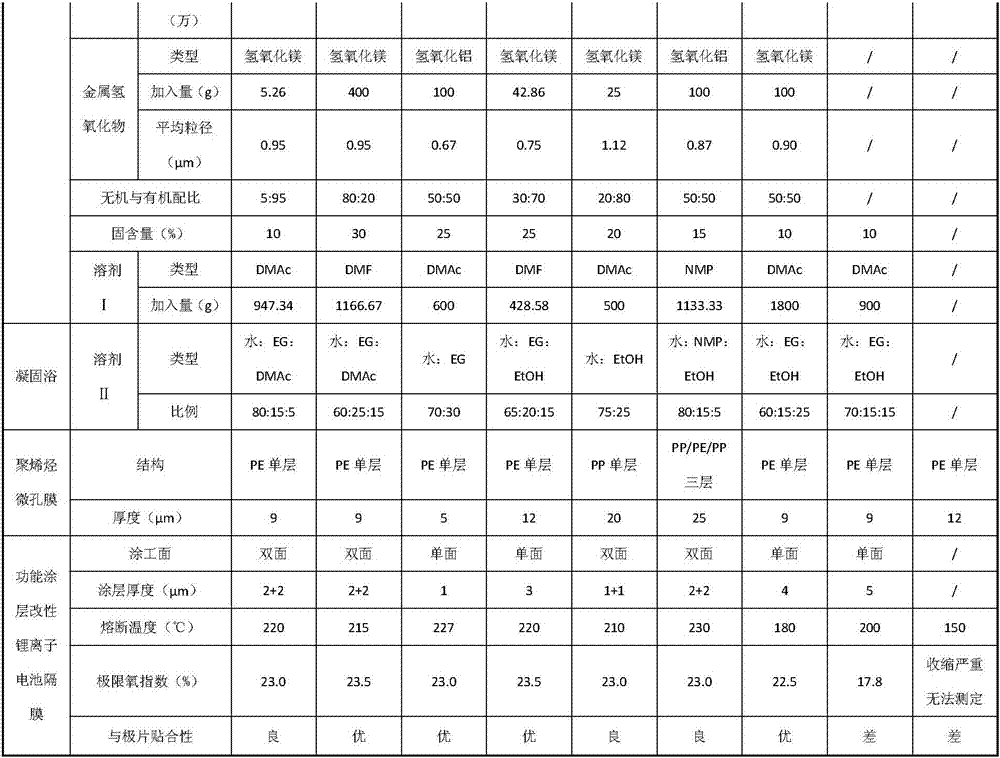

Embodiment 1

[0050] (1) Dissolve 90 grams of meta-aramid fibers with a molecular weight of 200,000 and 10 grams of PVDF with a molecular weight of 150,000 in 473.67 grams of DMAc, then mix the two, add 5.26 grams of magnesium hydroxide after mixing, and use high-speed After shearing and stirring, a coating liquid was obtained. At this time, the solid content of the coating solution was 10%, and the mass ratio of inorganic particles to organic substances was 5:95.

[0051] (2) The coating solution was coated on the surface of the PE base film with a thickness of 9 μm by a micro-gravure coating method to obtain a double-sided coated film A.

[0052] (3) The film A was immersed in a coagulation bath with water:EG:DMAc ratio of 80:15:5 for 10 seconds to obtain a film B containing a microporous structure coating.

[0053] (4) Dip the film B into water, stay for 15 seconds, remove the organic solvent on the surface of the film, and dry at 70° C. to obtain the lithium-ion battery separator conta...

Embodiment 2

[0056] (1) 40 grams of meta-aramid fibers with a molecular weight of 300,000 and 60 grams of PVDF with a molecular weight of 150,000 are dissolved in 583.33 grams of DMF respectively, then the two are mixed, and 400 grams of magnesium hydroxide are added after mixing. After shearing and stirring, a coating liquid was obtained. At this time, the solid content of the coating solution was 30%, and the mass ratio of inorganic particles to organic substances was 80:20.

[0057] (2) The coating solution was coated on the surface of the PE base film with a thickness of 9 μm by a micro-gravure coating method to obtain a double-sided coated film A.

[0058] (3) The film A was immersed in a coagulation bath of water: EG: DMAc ratio of 60:25:15 for 10 seconds to obtain a film B containing a microporous structure coating.

[0059] (4) Dip the film B into water, stay for 15 seconds, remove the organic solvent on the surface of the film, and dry at 70° C. to obtain the lithium-ion battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com