A kind of chitosan tetramethylene phosphine sulfate flame retardant and its preparation method and application

A technology of chitosan tetramethylene sulfuric acid and tetrahydroxymethyl phosphorus sulfate is applied in the field of halogen-free flame retardants, which can solve the problems of poor compatibility, small molecular weight of flame retardants, poor degradability, etc., and achieve antibacterial properties. performance, good water resistance persistence, good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

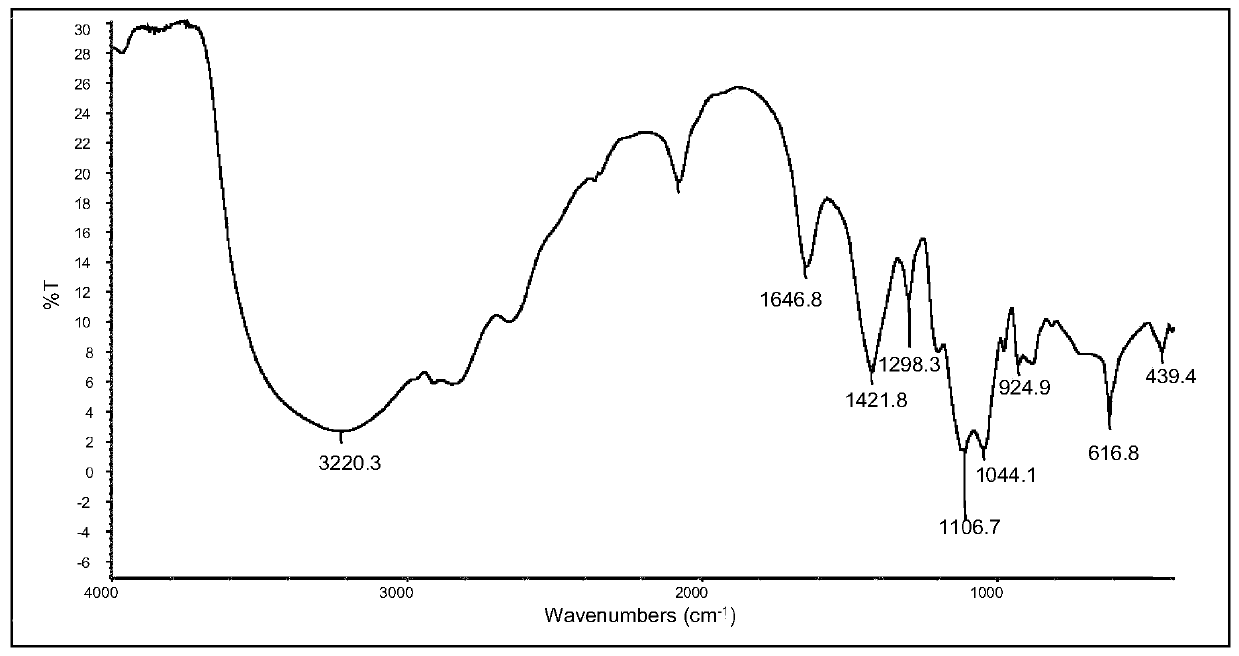

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of chitosan tetramethylene phosphine sulfate flame retardant, comprising following preparation steps:

[0025] Carry out electrostatic adsorption of tetrakis hydroxymethyl phosphorus sulfate and chitosan in water, obtain tetrakis hydroxymethyl phosphorus sulfate / chitosan complex;

[0026] Dehydrating and covalently grafting the tetrakis phosphine hydroxymethyl sulfate / chitosan complex to obtain the chitosan tetramethylene phosphine sulfate flame retardant.

[0027] In the invention, tetrakis hydroxymethyl phosphorus sulfate and chitosan are electrostatically adsorbed in water to obtain tetrakis hydroxymethyl phosphorus sulfate / chitosan complex. In the present invention, the mass ratio of tetrakis hydroxymethyl phosphorus sulfate to chitosan is preferably 1:1 to 5:1, more preferably 2:1 to 4:1; the mass ratio of chitosan to water is The ratio is preferably 1:0.5 to 1:1, more preferably 1:1. In the present invention, t...

Embodiment 1

[0039]At room temperature, weigh 10 g of chitosan, and weigh tetrakis hydroxymethyl sulfate according to the mass ratio of tetrakis hydroxymethyl phosphorus sulfate to chitosan is 5:1, and the mass ratio of water to chitosan is 1:1. Phosphorus, chitosan (viscosity-average molecular weight is 150,000) and water are added to the reaction kettle, stirred until the chitosan is completely dissolved, heated to 90°C, kept stirring for 2 hours, unloaded, and then left to react in an oven. Reaction conditions: 150°C, keep warm for 2h. After that, the temperature was lowered to 80° C., and dried for 12 hours to obtain 40.61 g of chitosan tetramethylene phosphine sulfate solid powder.

Embodiment 2

[0041] At room temperature, weigh 10 g of chitosan, and weigh tetrakis hydroxymethyl sulfate according to the ratio of tetrakis hydroxymethyl phosphorus sulfate to chitosan mass ratio of 4:1 and water to chitosan mass ratio of 1:1. Phosphorus, chitosan (viscosity-average molecular weight is 30,000) and water are added to the reaction kettle, stirred until the chitosan is completely dissolved, heated to 80°C, kept stirring for 3 hours, unloaded, and then left to react in an oven. 140°C, keep warm for 4h. Afterwards, the temperature was lowered to 60° C., and dried for 12 hours to obtain 34.31 g of chitosan tetramethylene phosphine sulfate solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com