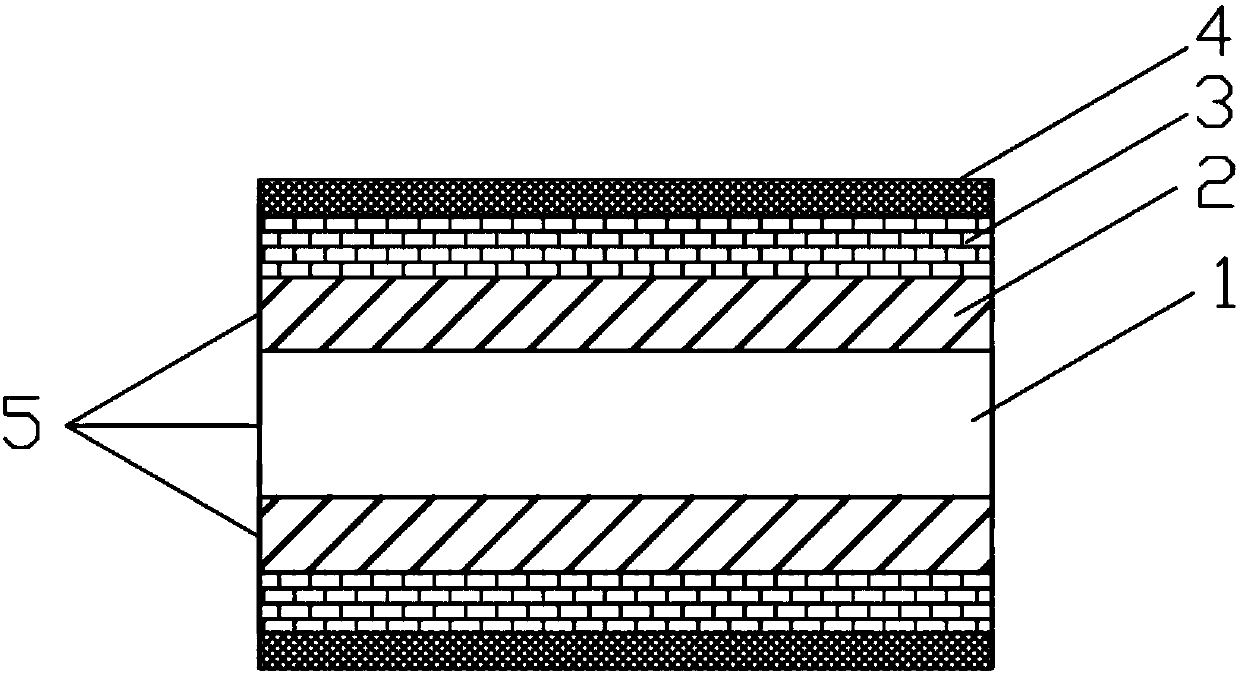

Flame-retardant ecological board and manufacturing method thereof

An ecological board and ecological technology, applied in the direction of manufacturing tools, chemical instruments and methods, wood-layered products, etc., can solve the problems of poor flame retardancy of ecological boards, and achieve the effect of improving the qualification rate, avoiding inconvenience and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 118

[0037] Example 1 Production of 18mm plywood core flame retardant ecological board

[0038] Step ① short core flame retardant impregnation treatment: put 3.6mm eucalyptus short core into a vacuum pressurized tank, and carry out vacuum pressure impregnation treatment with uniform nitrogen, phosphorus and boron series flame retardant aqueous solution with a concentration of 12.5%, and impregnate the impregnated Take out the short core of eucalyptus and dry it until the moisture content is less than 12%, and the oxygen index reaches more than 50%;

[0039] Step ② Coating the board core with melamine-modified urea-formaldehyde resin glue evenly on the 11mm plywood board core, the glue amount is 200g / m 2 ;

[0040]Step 3. Assembling the billet, compounding two 3.6mm impregnated eucalyptus short cores on the glued plywood core, and putting them into the cold press for cold pressing within 30 minutes after the billet assembly is completed;

[0041] Step ④ Cold pressing: put the plyw...

Embodiment 2

[0051] Example 2 Production of 18mm blockboard core flame retardant ecological board

[0052] Step ① short core flame retardant impregnation treatment: put 3.6mm poplar short core into a vacuum pressurized tank, and carry out vacuum pressure impregnation treatment with an aqueous solution with a concentration of 15% intumescent flame retardant and inorganic metal flame retardant mixed uniformly , take out the impregnated poplar short core and dry it until the moisture content is within 12%, and the oxygen index reaches more than 50%;

[0053] Step 2. Apply glue to the board core. Apply melamine-modified urea-formaldehyde resin glue evenly on the 11mm blockboard core. The amount of glue applied is 210g / m 2 ;

[0054] Step 3. Assembling the blanks, compounding two 3.6mm impregnated poplar short cores on the glued blockboard cores, and putting them into a cold press within 30 minutes after the completion of the assembly for cold pressing;

[0055] Step ④ Cold pressing: put the ...

Embodiment 318

[0065] Example 3 Production of 18mm plywood core flame-retardant ecological board

[0066] Example 3 of the present invention provides another technical solution for preparing a flame-retardant ecological board, the basic preparation method of which is the same as that of Example 1, except that the flame retardant is an inorganic metal flame retardant with a concentration of 11.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com