Flame-retardant sheet and formed article therefrom

A fiber sheet, flame retardant technology, applied in the field of flame retardant fiber sheet and its molded products, can solve the problems of flame retardant toxicity, insufficient flame retardancy of fiber sheet, etc., and achieve high flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

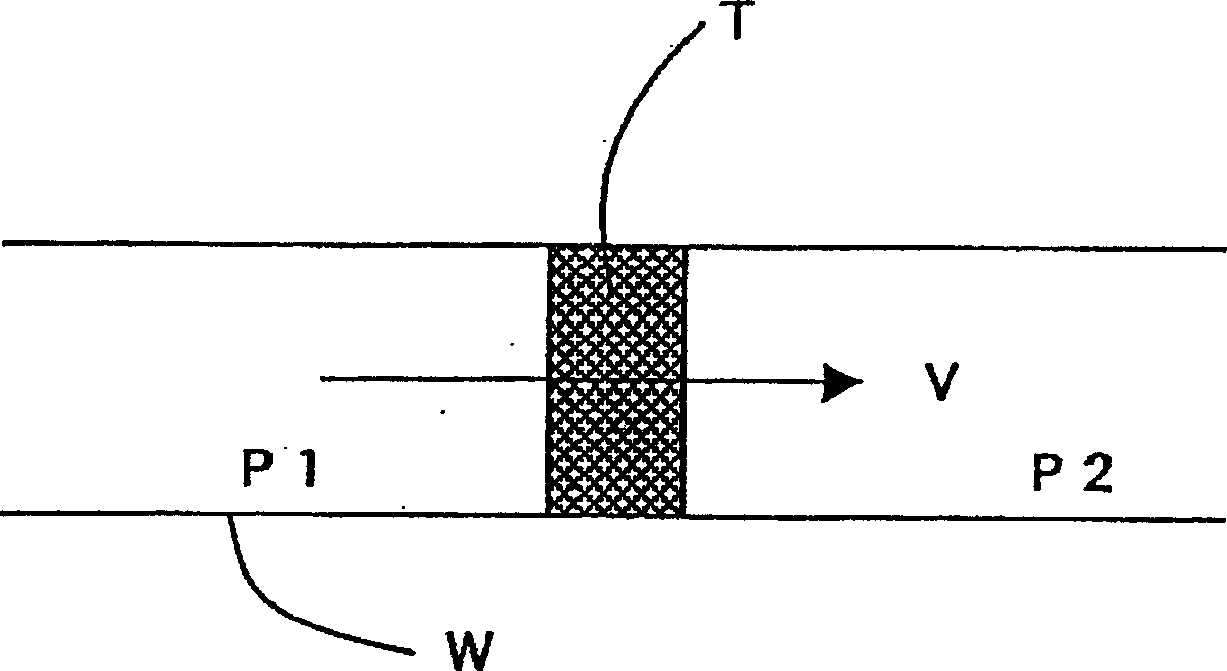

Image

Examples

Embodiment 1

[0096] A fiber web composed of 80 mass% polyester fibers (denier: 12dtex, fiber length: 52mm) and 20 mass% low-melting polyester fibers (softening point: 110°C, denier: 8dtex, fiber length: 54mm) , and made into a sheet of fiber by needle punching (weight per unit area: 500g / m 2 , thickness: 15mm). 20 parts by mass of expanded graphite (expansion start temperature: 300° C. to 320° C., expansion ratio: 100 times) was added and mixed to 80 parts by mass of phenol-formaldehyde initial condensate (50% by mass solid content) to prepare an impregnating solution. The viscosity of this immersion liquid is 100 mPa·s. Using this impregnating liquid, impregnate it into the above-mentioned sheet-like fibers so that the solid content becomes 50% by mass, and then dry the sheet at a temperature of 100 to 120°C for 3 minutes while pumping air in a drying chamber to precure the sheet. Fiber sheet is made by materializing fiber. The precured fiber sheet was thermocompressed at a temperature...

Embodiment 2

[0098] Add and mix 60 mass parts of phenol-formaldehyde initial condensation products (50% mass solid content), 20 mass parts of polyvinyl alcohol (10 mass parts solid content, degree of saponification: 98.5mol%) and 20 mass parts of expanded graphite (expanded Start temperature: 300°C to 320°C, expansion rate: 100 times) to prepare the impregnation solution. The viscosity of this dipping solution is 250 mPa·s. Except using this impregnating liquid instead of the impregnating liquid in Example 1, the compression molding was carried out in the same manner as in Example 1 to obtain a 10 mm thick molded article, and the ventilation resistance of this molded article was 4.1 kPa·s / m.

Embodiment 3

[0100] Add and mix 60 mass parts of phenol-formaldehyde initial condensate (50% mass solid content), 15 mass parts polyvinyl alcohol (10 mass mass solid content, degree of saponification: 98.5mol%), 4 mass parts of polyvinyl alcohol as an alkali-soluble The post-crosslinked copolymer latex of ethyl acrylate and methacrylic acid of the adhesive is PRIMAL, ASE-60 (manufactured by Rohm and Haas Company, trade name), 20 parts by mass of expanded graphite (expansion start temperature: 300° C. to 320° C. , Expansion rate: 130 times) and 1 mass part of 27% by mass ammonia water to prepare an immersion solution. The viscosity of this immersion liquid is 950 mPa·s. Except using this impregnating liquid instead of the impregnating liquid in Example 1, press molding was carried out in the same manner as in Example 1 to obtain a 10 mm thick molded article, and the air resistance of this molded article was 4.6 kPa·s / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Ventilation resistance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com