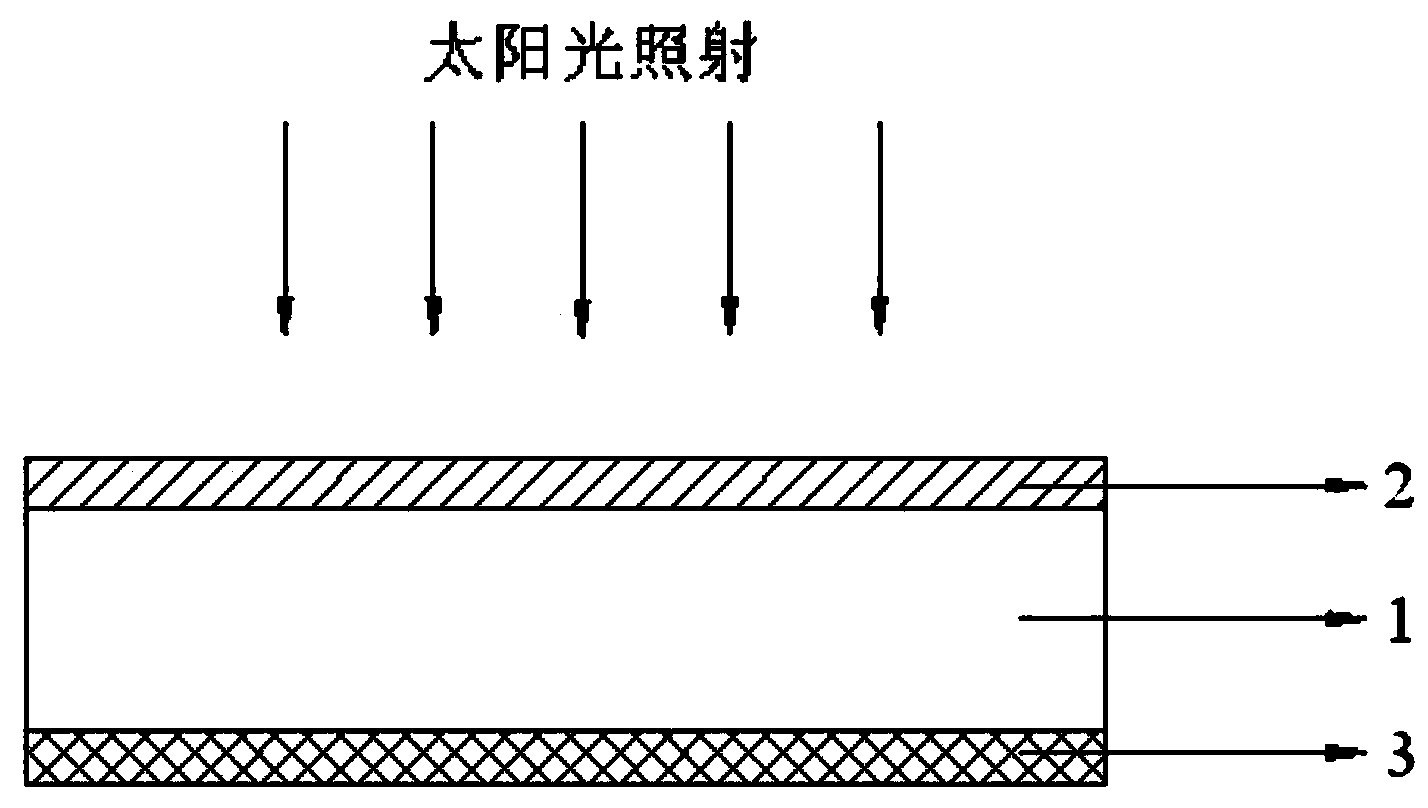

Preparation method of flame-retardant insulation board for building exterior wall

A flame retardant heat preservation and heat insulation board technology, applied in the field of building materials, can solve the problems of easy combustion, complex preparation process and required conditions, poor heat insulation performance, etc., achieve high flame retardancy, prevent heat transfer, The effect of stable temperature difference between the upper and lower enclosed spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The first step is to prepare an inorganic mineral nanofiber powder sheet matrix with an internal porous structure

[0044] (1.1) Take the required amount of palygorskite fiber powder, go through purification, high-speed stirring, coupling modification, drying and deep debundling of supersonic airflow to obtain palygorskite nanofiber powder, ready for use,

[0045] (1.2) Take the sodium silicate with a weight percentage of 2% of the palygorskite nanofiber powder obtained in step (1.1), dissolve it in water, adjust the pH value=5 with acetic acid, and make a weight percentage concentration of 2% Acidic sodium silicate aqueous solution,

[0046] (1.3) In the sodium silicate aqueous solution obtained in the step (1.2), add ammonium fluorosilicate that accounts for 5% by weight of the amount of the palygorskite nanofiber powder prepared, and then add the sodium silicate solution obtained in the step (1.1). The palygorskite nanofiber powder was stirred at 200r / min for 5min t...

Embodiment 2

[0057] The first step is to prepare an inorganic mineral nanofiber powder sheet matrix with an internal porous structure

[0058] (1.1) Take the required amount of sepiolite fiber powder, go through purification, high-speed stirring, coupling modification, drying and deep debundling of supersonic airflow to obtain sepiolite nanofiber powder, which is ready for use,

[0059] (1.2) Take aluminum silicate with an amount of 2% by weight of the sepiolite nanofiber powder prepared in step (1.1), dissolve it in water, adjust pH=5.5 with acetic acid, and make a weight percentage concentration of 2% Acidic aluminum silicate aqueous solution,

[0060] (1.3) In the aqueous solution of aluminum silicate prepared in step (1.2), add zinc fluorosilicate that accounts for 5% by weight of the amount of sepiolite nanofiber powder prepared, and then add the solution prepared in step (1.1). The sepiolite nanofiber powder was stirred at 200r / min for 5min to obtain a suspension.

[0061] (1.4) Ad...

Embodiment 3

[0071] The first step is to prepare an inorganic mineral nanofiber powder sheet matrix with an internal porous structure

[0072] (1.1) Take the required amount of palygorskite fiber powder, go through purification, high-speed stirring, coupling modification, drying and deep debundling of supersonic airflow to obtain palygorskite nanofiber powder, ready for use,

[0073] (1.2) Take the zinc silicate with a weight percentage of 2% of the palygorskite nanofiber powder obtained in step (1.1), dissolve it in water, adjust the pH value=6 with acetic acid, and make a weight percentage concentration of 2% Acidic zinc silicate aqueous solution,

[0074] (1.3) In the aqueous solution of zinc silicate prepared in step (1.2), add sodium fluorosilicate with a weight percentage of 5% by weight of the amount of palygorskite nanofiber powder prepared, and then add the solution prepared in step (1.1). The palygorskite nanofiber powder was stirred at 200r / min for 5min to obtain a suspension. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com