Halogen-free red phosphorus flame retardant nylon with high toughness and preparation method of nylon

A technology of flame-retardant nylon and high toughness, which is applied in the field of halogen-free high-toughness red phosphorus flame-retardant nylon and its preparation, can solve the problems that nylon materials cannot meet high flame retardancy, high toughness and halogen-free green environmental protection at the same time, and achieve Improve oxidation resistance, good impact resistance, and reduce friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

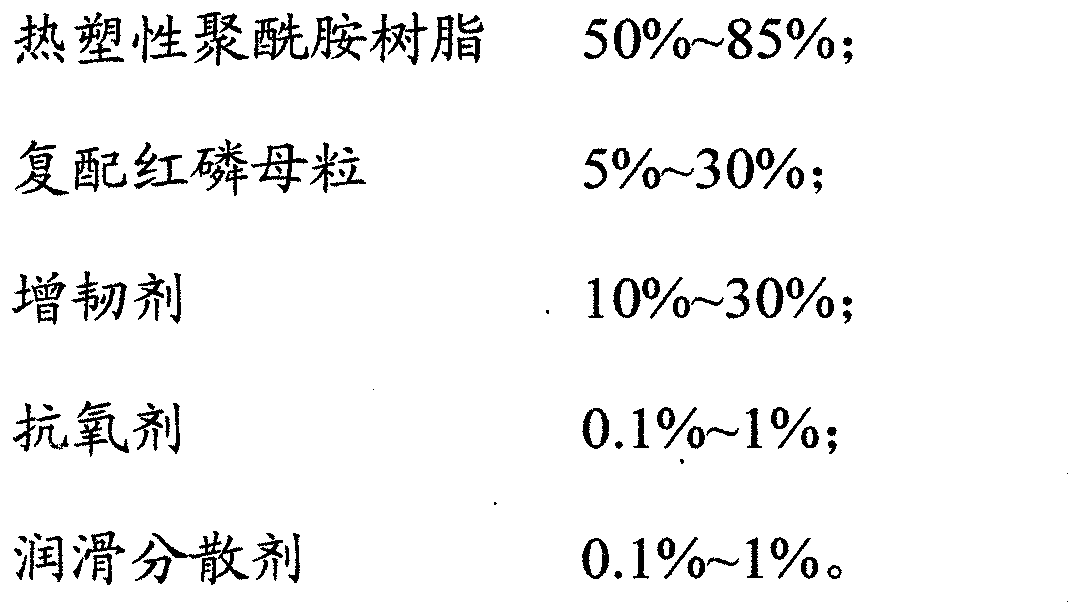

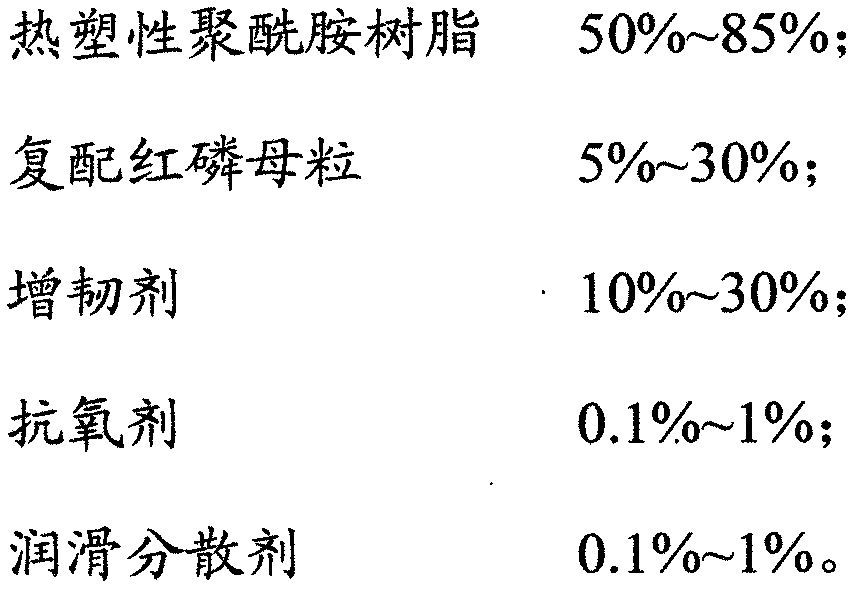

[0022] Use the following raw materials in weight ratio:

[0023] The ratio of polyamide 66 and polyamide 6 is 1:1 (relative viscosity is 2.7) 75.2%;

[0024] Ordinary red phosphorus masterbatch 8%;

[0025] Toughening agent (maleic anhydride grafted POE) 16%;

[0026] Antioxidant (hindered phenols) 0.3%;

[0027] Lubricating and dispersing agent (silicone powder) 0.5%;

[0028] Put the above-mentioned raw materials with good weight ratio into the high mixer and fully mix for 2-5 minutes, and then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and then melt and extrude, Water-cooled, air-dried, pelletized, and then prepared high-toughness red phosphorus flame-retardant nylon. The temperature of each zone of the twin-screw extruder is controlled at 220-280℃, and the screw speed is controlled at 300-400RPM.

Embodiment 2

[0030] Use the following raw materials in weight ratio:

[0031] The ratio of polyamide 66 and polyamide 6 is 1:1 (relative viscosity is 2.7) 72.2%;

[0032] Ordinary red phosphorus masterbatch 9%;

[0033] Toughening agent (maleic anhydride grafted POE) 18%;

[0034] Antioxidant (hindered phenols) 0.3%;

[0035] Lubricating and dispersing agent (silicone powder) 0.5%;

[0036] Put the above-mentioned raw materials with good weight ratio into the high mixer and fully mix for 2-5 minutes, and then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and then melt and extrude, Water-cooled, air-dried, pelletized, and then prepared high-toughness red phosphorus flame-retardant nylon. The temperature of each zone of the twin-screw extruder is controlled at 220-280℃, and the screw speed is controlled at 300-400RPM.

Embodiment 3

[0038] Use the following raw materials in weight ratio:

[0039] The ratio of polyamide 66 and polyamide 6 is 1:1 (relative viscosity is 2.7) 75.2%;

[0040] Compound red phosphorus masterbatch 8%;

[0041] Toughening agent (maleic anhydride grafted POE) 16%;

[0042] Antioxidant (hindered phenols) 0.3%;

[0043] Lubricating and dispersing agent (silicone powder) 0.5%;

[0044] Put the above-mentioned raw materials with good weight ratio into the high mixer and fully mix for 2-5 minutes, and then put the mixed materials into the extruder from the main feed port of the twin-screw extruder, and then melt and extrude, Water-cooled, air-dried, pelletized, and then prepared high-toughness red phosphorus flame-retardant nylon. The temperature of each zone of the twin-screw extruder is controlled at 220-280℃, and the screw speed is controlled at 300-400RPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com