PC/PBT alloy and method for producing the same

A technology of alloy and polycarbonate, which is applied in the field of PC/PBT alloy and its preparation, can solve the problem of less research on alloy halogen-free flame retardancy, achieve good optical performance, improve flame retardancy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

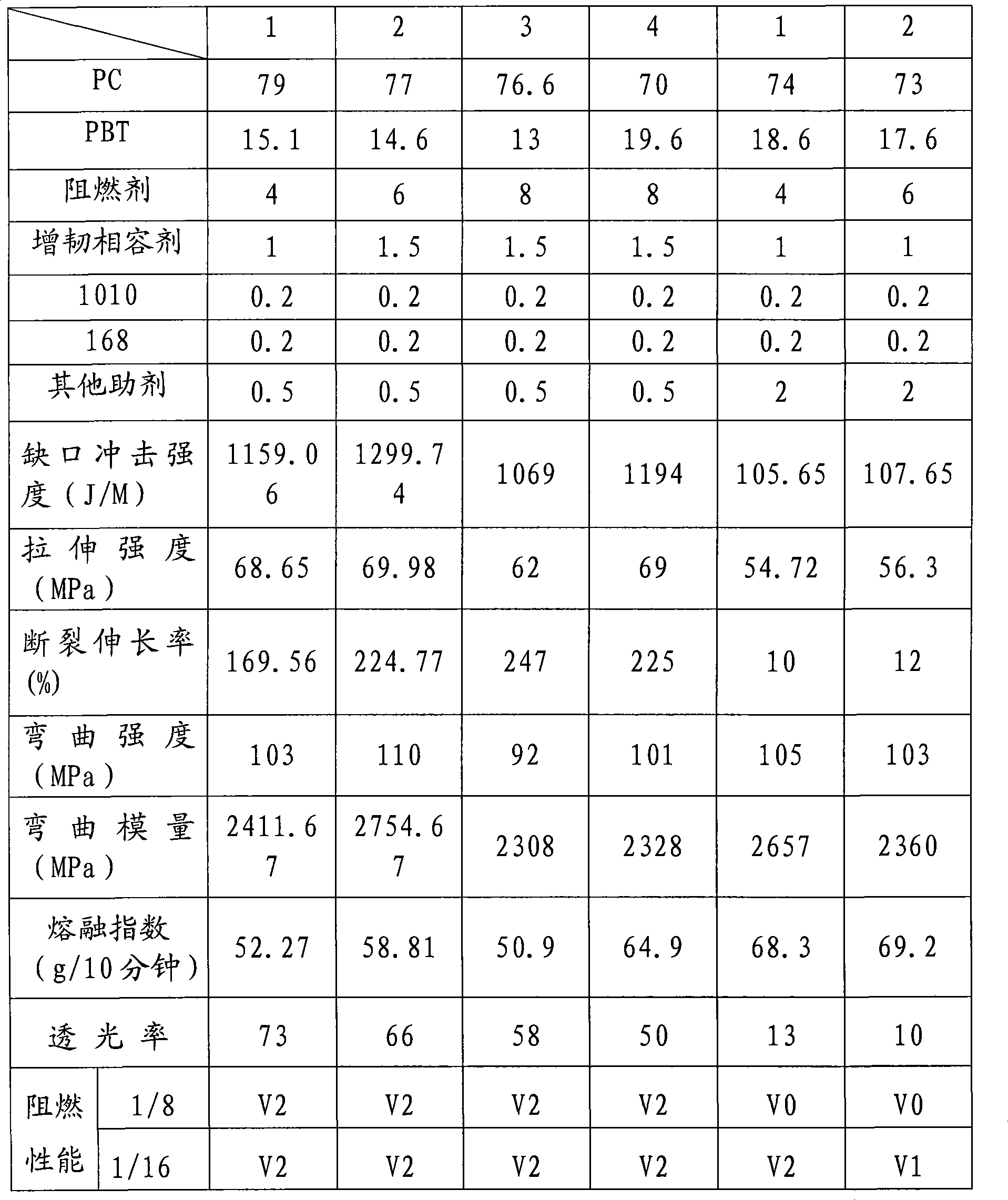

Embodiment 1

[0032] The weight ratio of PC is 79% (the following are weight ratios), PBT 15.1%, 1010 / 1680.2 / 0.2%, flame retardant PX-2204%, compatibilizer 1%, other 0.5%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 250°C; zone 2: 255°C; zone 3: 255°C; zone 4: 250°C; head: 245°C; residence time 2 to 3 minutes. The pressure is 15MPa.

Embodiment 2

[0034] The weight ratio of PC is 77% (the following are weight ratios), PBT 14.6%, 1010 / 1680.2 / 0.2%, flame retardant PX-2206%, compatibilizer 1.5%, and other 0.5%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 250°C; zone 2: 255°C; zone 3: 255°C; zone 4: 250°C; head: 245°C; residence time 2 to 3 minutes. The pressure is 15MPa.

Embodiment 3

[0036] The weight ratio of PC is 76.6% (the following are weight ratios), PBT 13%, 1010 / 1680.2 / 0.2%, flame retardant PX-2208%, compatibilizer 1.5%, and other 0.5%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 250°C; zone 2: 255°C; zone 3: 255°C; zone 4: 250°C; head: 245°C; residence time 2 to 3 minutes. The pressure is 15MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com