Flame retardant solid buoyancy material and preparation method thereof

A solid buoyancy and flame retardant technology, which is applied in the field of solid buoyancy materials for marine environments, can solve problems such as lack of flame retardant properties and fail to meet flame retardant safety, and achieve the effect of overcoming flame retardant requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

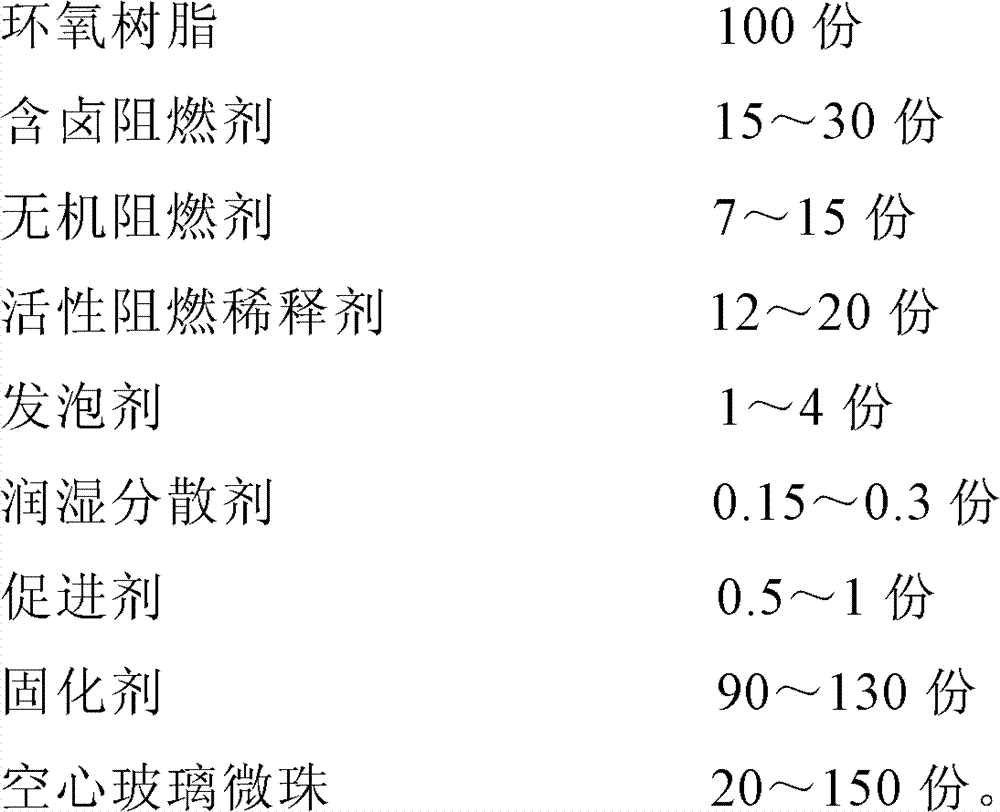

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described through several groups of typical embodiments below, but the present invention is not limited to these embodiments.

[0036] The oxygen index refers to the minimum oxygen concentration required for a material to burn flamingly in an oxygen-nitrogen mixed flow under specified conditions. It is expressed as the numerical value of the volume percentage of oxygen. A high oxygen index indicates that the material is not easy to burn, and a low oxygen index indicates that the material is easy to burn. It is generally believed that the oxygen index 27 belongs to flammable materials. The test standard adopted by the oxygen index test method of the present invention is the national standard GB2406 combustion test-oxygen index test method.

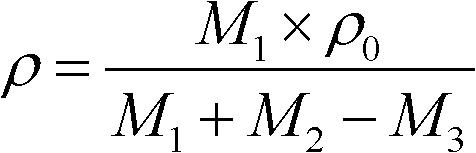

[0037] The density test of the present invention refers to method 5.1A of GB / T1033.1-2008 "Determination of Density of Plastics and Non-foamed Plastics": dipping method. The specific method is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com