Patents

Literature

32 results about "Diluent 12" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-hydrophilicity high-wear-resistance organic/inorganic hybrid photocuring paint composition

InactiveCN105153924AEmission reductionGood component compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsReactive diluentHigh wear resistance

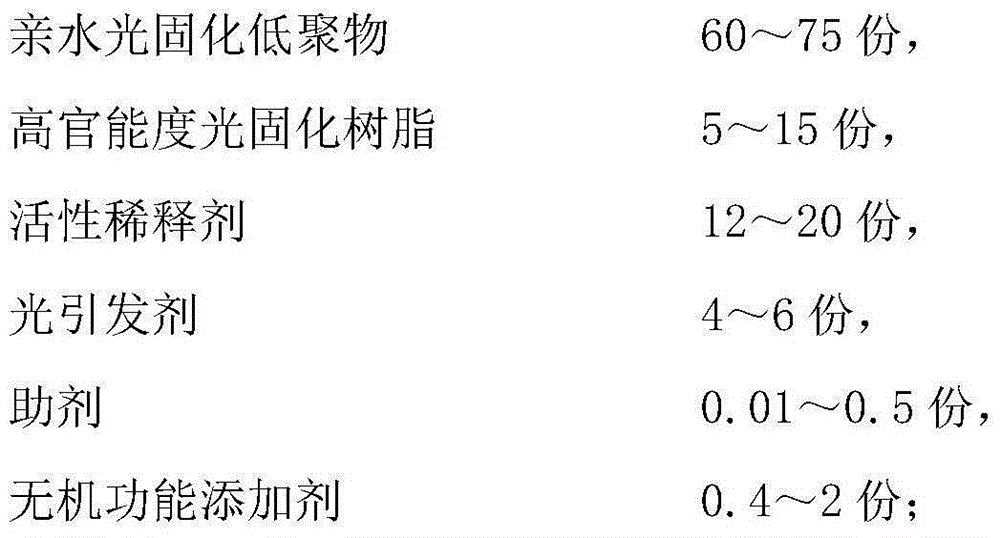

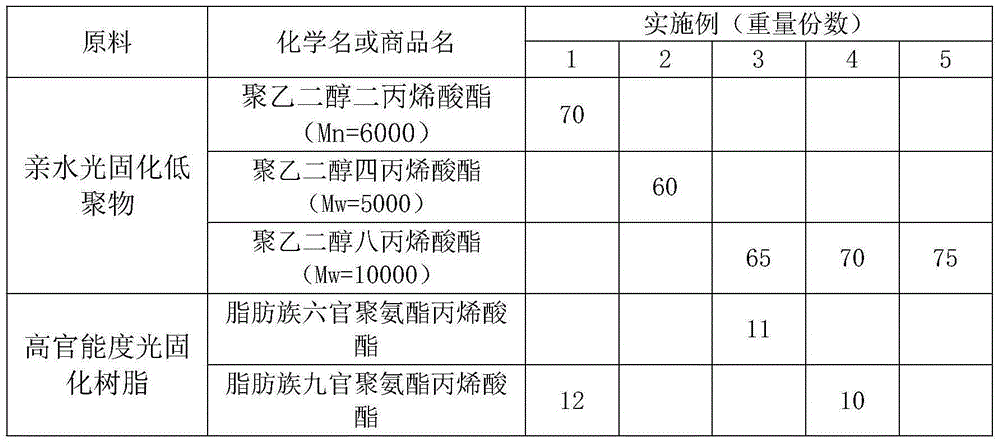

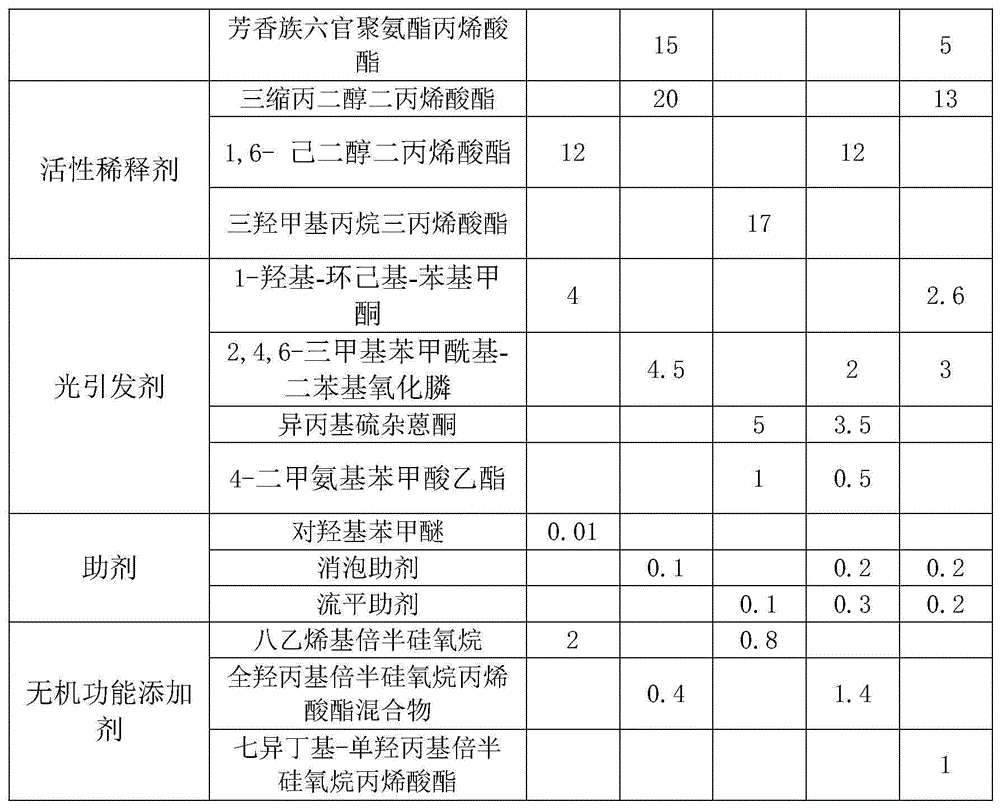

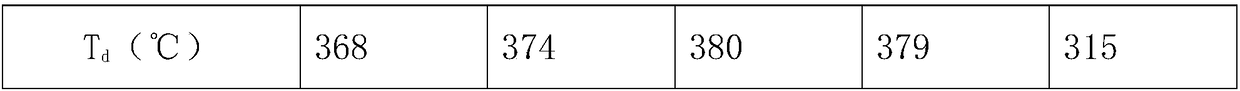

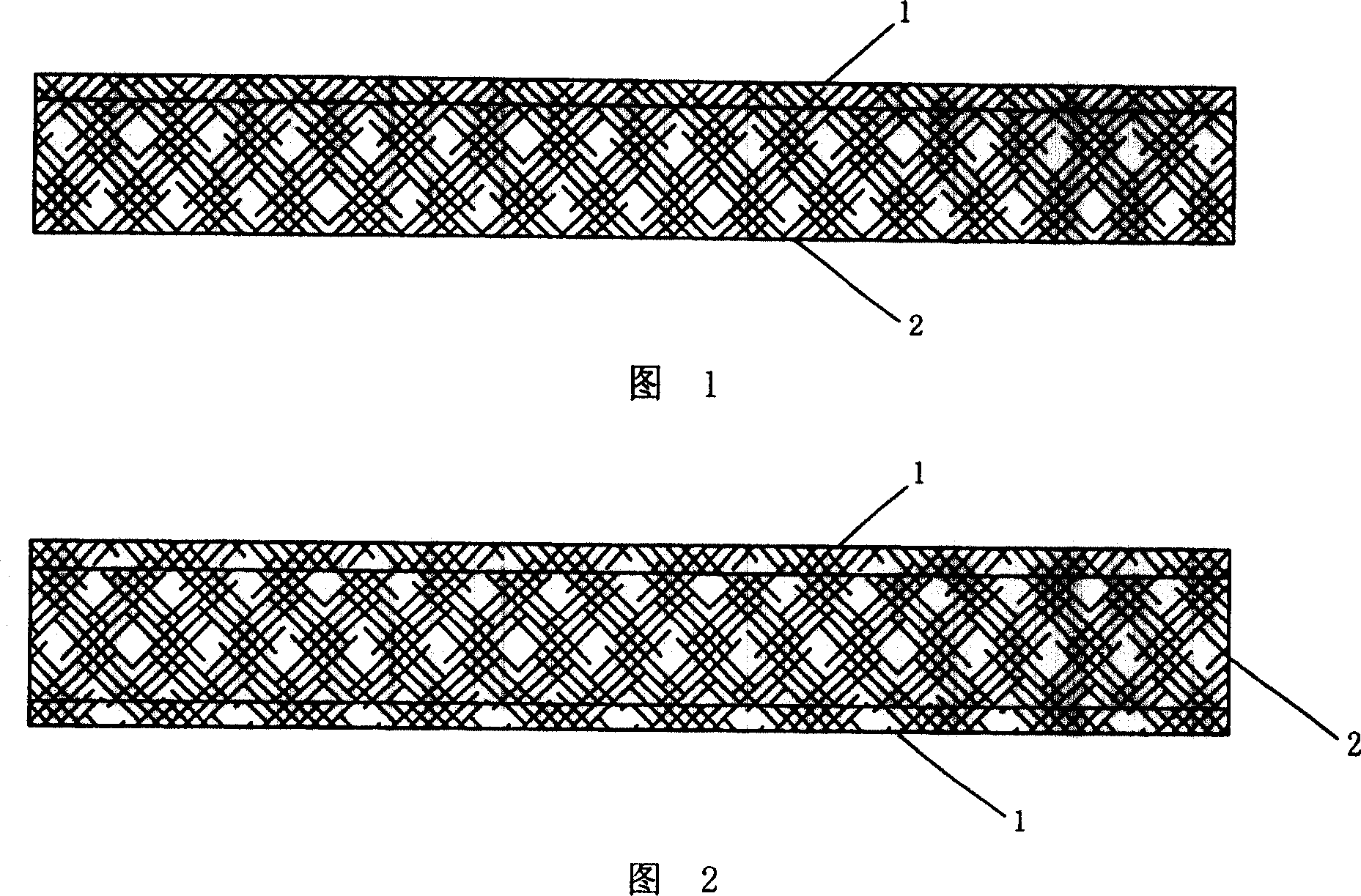

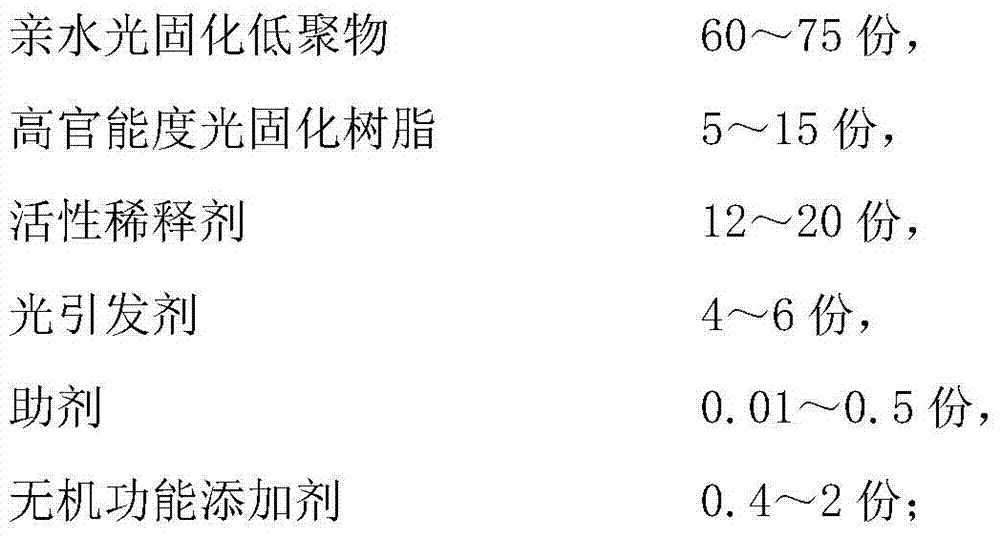

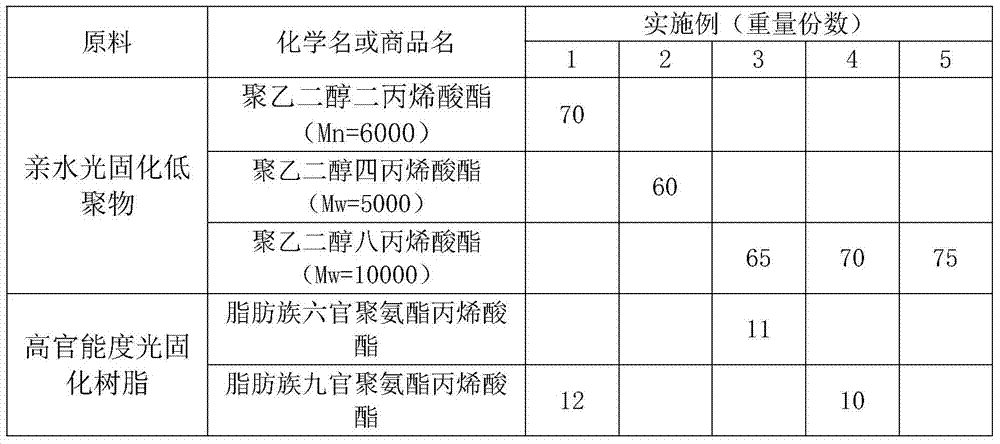

The invention discloses a high-hydrophilicity high-wear-resistance organic / inorganic hybrid photocuring paint composition. The composition comprises 60-75 parts of hydrophilic photocuring low polymer, 5-15 parts of high-functionality photocuring resin, 12-20 parts of reactive diluent, 4-6 parts of photoinitiator, 0.01-0.5 part of assistant and 0.4-2 parts of inorganic functional additive. The inorganic functional additive is selected from polyvinyl silsesquioxane, methylacryloyloxy silsesquioxane and acryloyloxy silsesquioxane. The ultraviolet-curing hydrophilic paint disclosed by the invention can be applied to a glass surface; and the cured paint has the advantages of excellent hydrophilicity, excellent physical properties, favorable adhesive force, favorable water resistance, favorable acid resistance and favorable wear resistance.

Owner:SHANGHAI WEIKAI CHEM +2

UV (Ultraviolet) curable coating

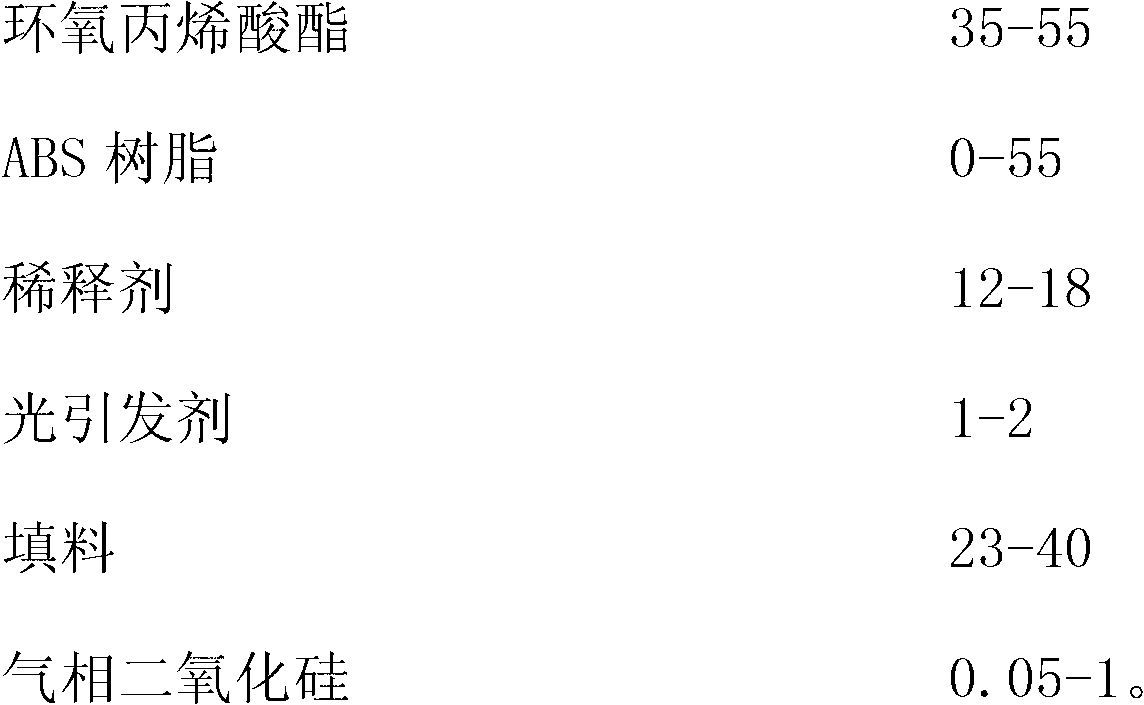

InactiveCN102702935AExcellent heat and chemical resistanceHigh hardnessEpoxy resin coatingsGas phaseAging resistance

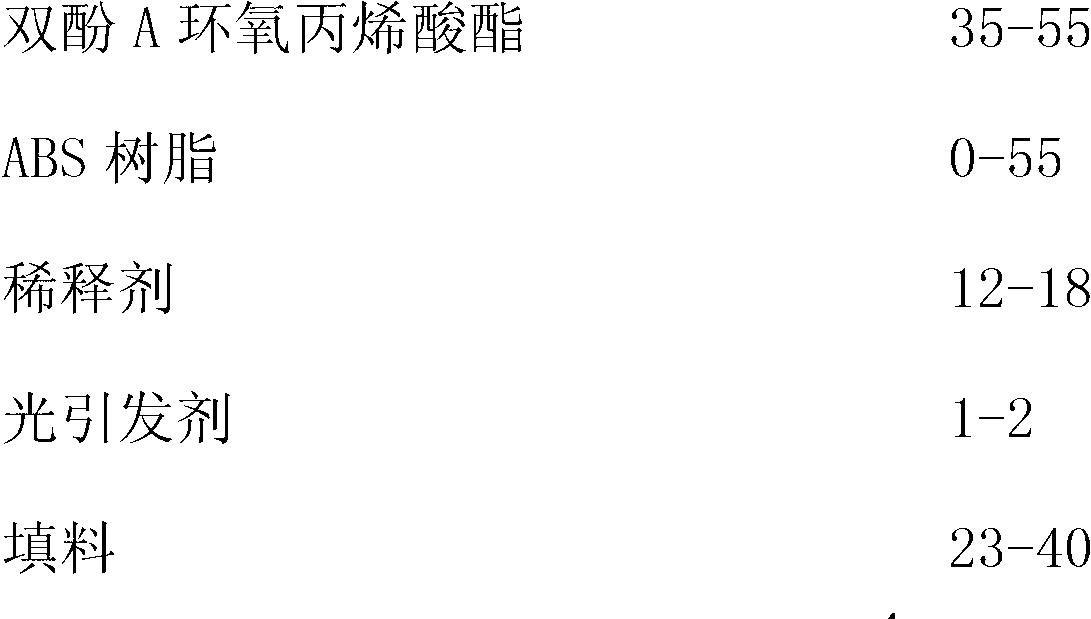

The invention discloses a UV (Ultraviolet) curable coating, which is characterized in that the coating comprises the following components in parts by weight: 35-55 parts of epoxy acrylate, 0-55 parts of ABS (Acrylonitrile Butadiene Styrene) resin, 12-18 parts of diluting agent, 1-2 parts of photo-initiator, 23-40 parts of filler and 0.05-1 part of gas-phase silicon dioxide. The UV curable coating is obtained by matching the epoxy acrylate and the ABS resin; and a cured film of the obtained coating has high hardness and superior heat resistance and chemical resistance performance, and also has good flexibility and superior aging resistance and yellowing resistance performance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Antistatic packaging material

InactiveCN1807541AEasy to getLow priceLiquid surface applicatorsOther chemical processesPolymer scienceConductive polymer

Disclosed is an antistatic packing material, characterized in that the surface of the package base material is coated or fused by a layer of conductive polymer comprising the following materials (by weight percent): carbon powder 0.5-10%, polyamine ester 40-60%, addition agent 15-50%, solvent 15-40%, the addition agent comprises dispersing agent 2-15%, coupling agent 0.5-10%, thinning agent 12.5-35%.

Owner:黄晖

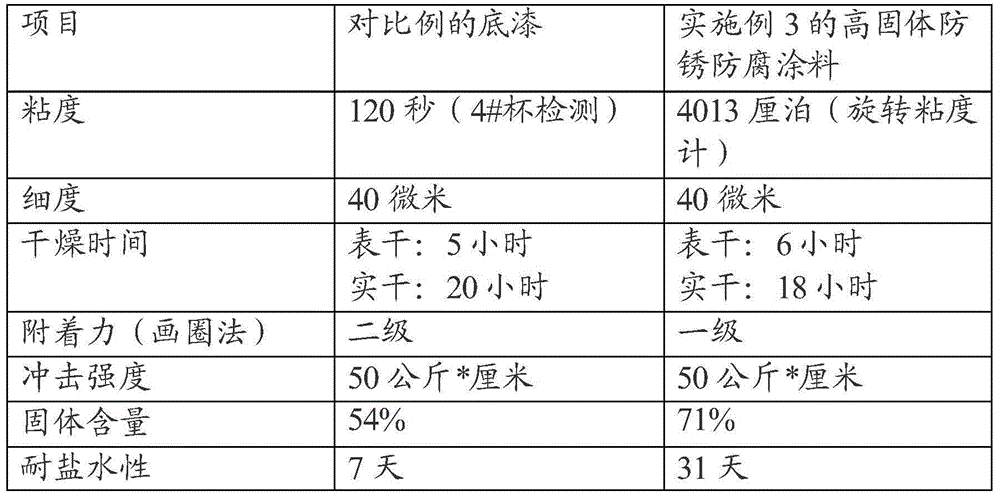

High-solid anti-rust and anti-corrosion coating

InactiveCN104449248AImprove thixotropyImprove salt water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilicon dioxide

The invention discloses a high-solid anti-rust and anti-corrosion coating. The coating comprises a component A and a component B in the weight ratio of 5: 1, wherein the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 3-6 parts of zinc phosphate, 1-6 parts of zinc powder, 0.1-0.2 part of a dispersant, 0.5-0.7 part of modified bentonite, 0.2-0.4 part of nano-silicon dioxide, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The high-solid anti-rust and anti-corrosion coating adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

Novel epoxy resin waterproof coating

InactiveCN105199546AAvoid defectsImprove waterproof performancePolyurea/polyurethane coatingsEpoxy resin coatingsCross-linkBasement

The invention discloses a novel epoxy resin waterproof coating. The waterproof coating comprises a component A and a component B, wherein the component A comprises raw materials in parts by weight as follows: 90-100 parts of epoxy modified polymers, 12-18 parts of a reactive diluent, 3-5 parts of sodium silicate, 1-3 parts of methyl sodium silicate, 2-4 parts of a surfactant, 1-4 parts of a defoaming agent and 300-400 parts of functional filler; the component B comprises raw materials in parts by weight as follows: 22-28 parts of a modified curing agent, 1-4 parts of a cross-linking agent and 2-3 parts of an accelerant. The waterproof coating has a reasonable formula and is simple to construct, high in ageing resistance, good in comprehensive performance, long in service life and capable of being applied to waterproof treatment of roofs, basements, toilets and the like.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

High-temperature-resistant hot melt adhesive based on application of air filter

InactiveCN106047240ASatisfy the requirement of 110℃ high temperature resistanceTo meet the high temperature requirementsMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesElastomerPolymer science

The invention discloses a high-temperature-resistant hot melt adhesive based on an application of an air filter. The high-temperature-resistant hot melt adhesive is prepared from components in percentage by mass as follows: 25%-36% of polyolefin elastomers, 32%-55% of tackifying resin, 12%-25% of a diluent and 0.2%-0.5% of an additive. The high-performance polymer is taken as a main raw material, and the hot melt adhesive meets the 110 DEG C high-temperature resistance demands, has stable performance, effectively meets the high-temperature resistance demands and is convenient to popularize and use on a large scale.

Owner:东莞市成铭胶粘剂有限公司

Insulating heat-dissipating coating and preparation method of same

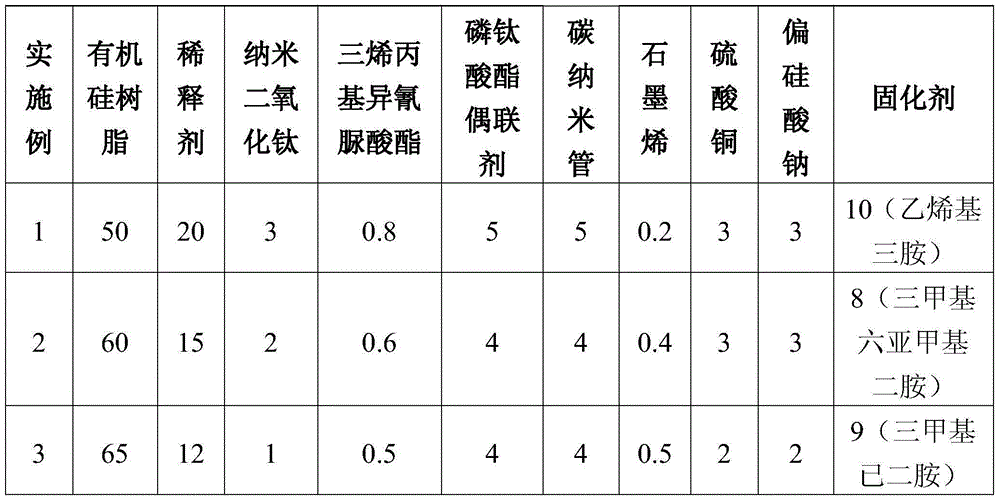

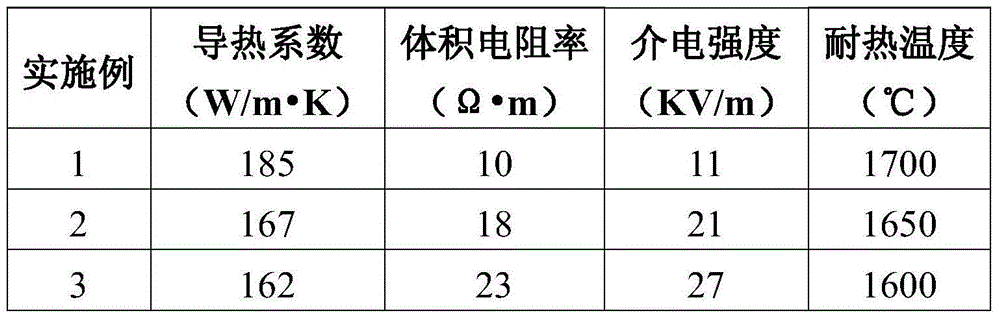

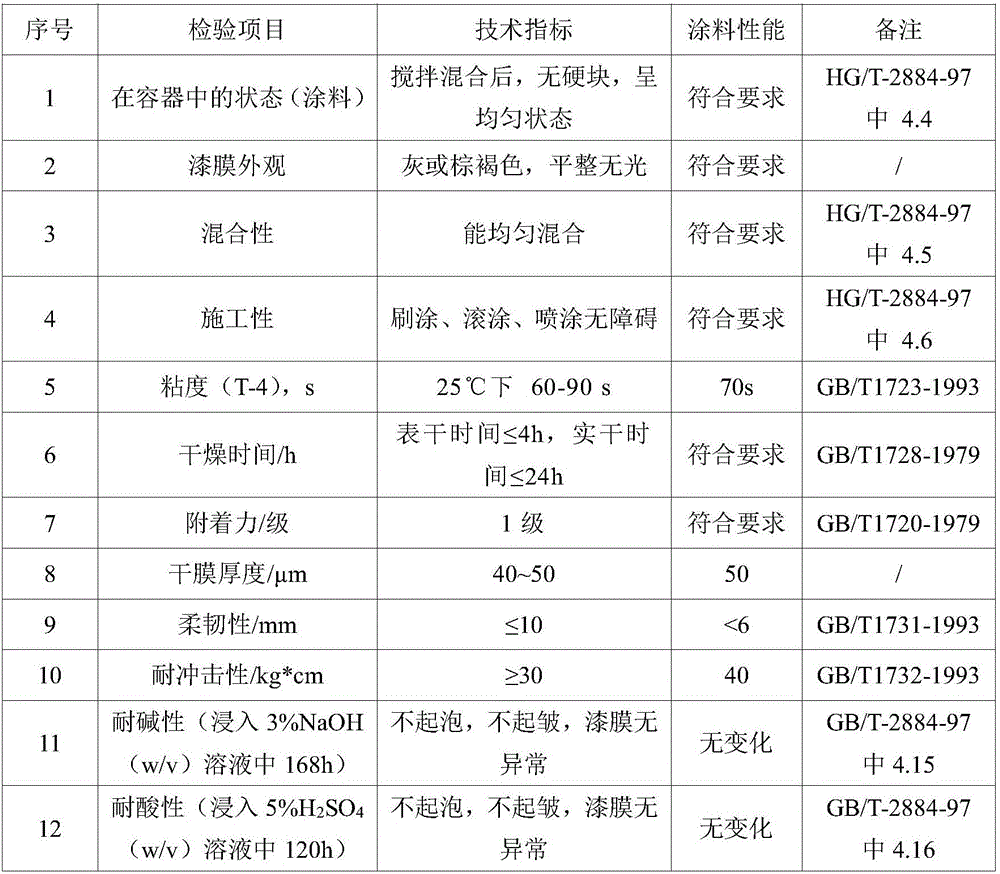

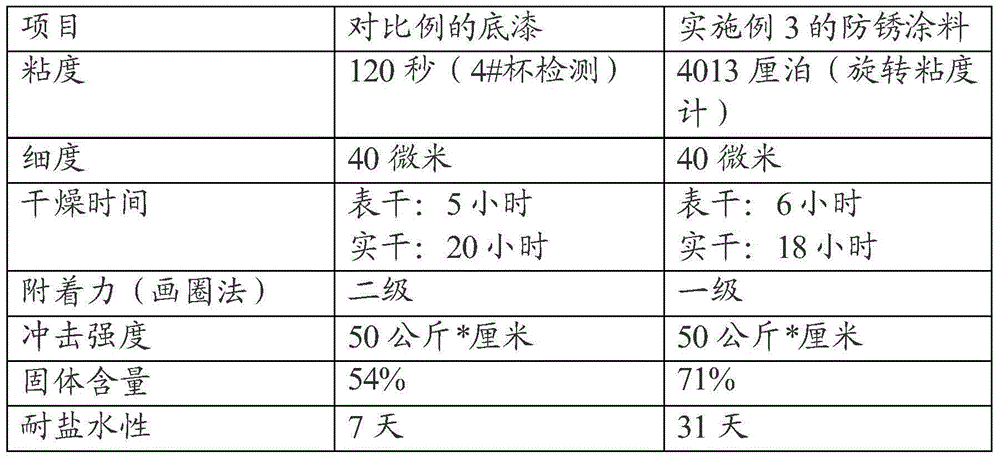

An insulating heat-dissipating coating and a preparation method of the same, wherein the insulating heat-dissipating coating includes following components: 50-65 parts of an organic silicone resin, 12-20 parts of a diluent, 1-3 parts of nano titanium dioxide, 0.5-0.8 parts of triallyl isocyanurate, 4-5 parts of a phosphrous titanate coupling agent, 4-5 parts of carbon nano tube, 0.2-0.5 parts of graphene, 2-3 parts of copper sulfate, 2-3 parts of sodium metasilicate and 8-10 parts of a curing agent. The preparation method includes following steps: 1) preparing the raw materials according to the mass ratio and mixing the organic silicone resin with the diluent to form a resin mixture; 2) mixing the resin mixture with the carbon nano tube and stirring the resin mixture with the carbon nano tube uniformly at normal temperature to form a coating (I); 3) mixing the coating (I) with the graphene with uniform stirring at normal temperature to form a coating (II); 4) mixing the coating (II) with the nano titanium dioxide, the triallyl isocyanurate, the phosphrous titanate coupling agent, the copper sulfate and the sodium metasilicate with uniform stirring at normal temperature to form a coating (III); and 5) mixing the coating (III) with the curing agent with uniform stirring to obtain the insulating heat-dissipating coating and allowing the insulating heat-dissipating coating to stand for 20 min for later use.

Owner:FOSHAN HECAI TECH SERVICE

Anticorrosion paint and preparation method thereof

InactiveCN106280905AEasy to makeImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFumed silica

The invention provides anticorrosion paint which comprises, by weight, 33-35 parts of epoxy resin, 12-15 parts of diluting agents, 0.5-1 part of dispersing agents, 10-12 parts of toughening agents, 35-38 parts of mica iron oxide, 1-2 parts of talcum powder, 4-5 parts of titanium dioxide, 2.5-3 parts of fumed silica and 12-13.2 parts of curing agents. According to the anticorrosion paint, proportion of various components is adjusted, so that compatibility of various raw materials is good, performances are synergistically facilitated, the paint is good in corrosion resistance and stability and long in service life.

Owner:安徽纽亚达科技有限责任公司

Rust-proof coating

InactiveCN104449201AImprove adsorption capacityAdjust colorAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a rust-proof coating. The coating comprises a component A and a component B in the weight ratio of 5: 1, wherein the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 3-6 parts of zinc phosphate, 1-6 parts of zinc powder, 0.1-0.2 part of a dispersant, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The rust-proof coating adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

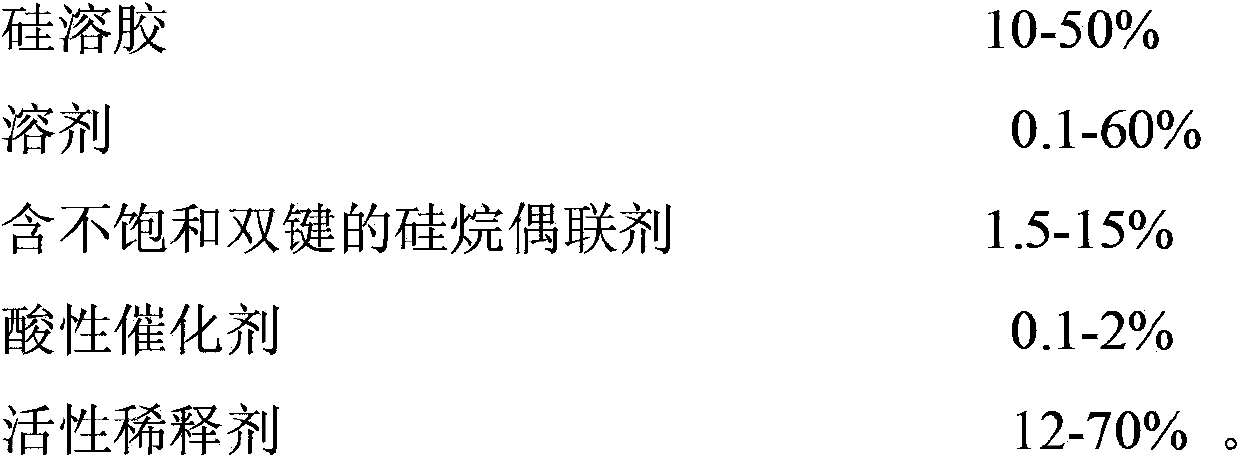

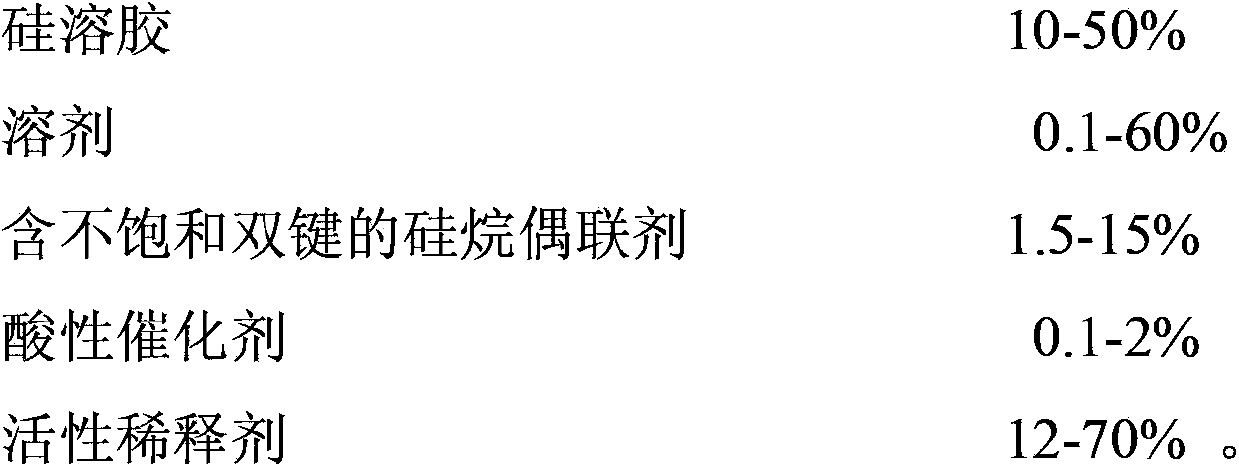

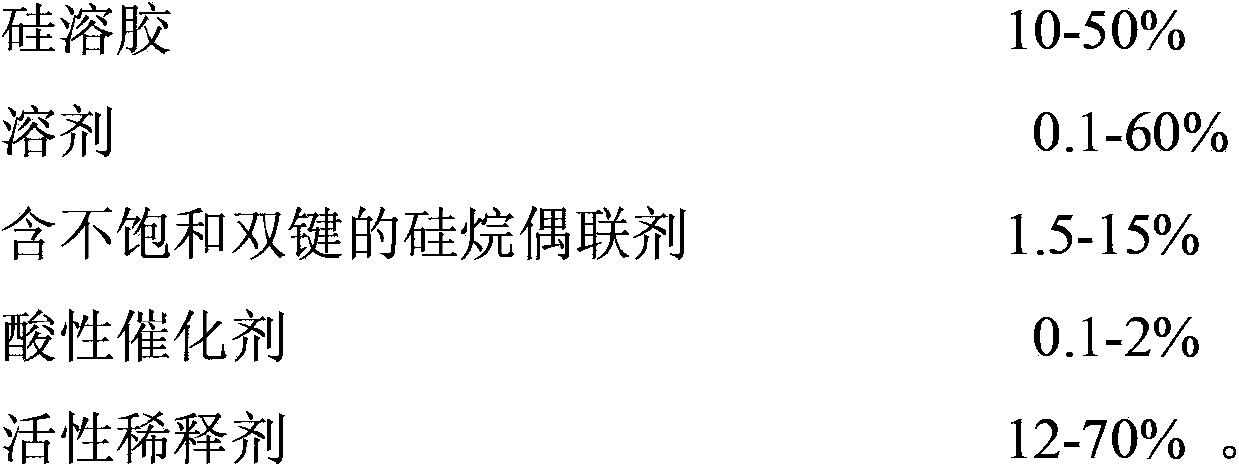

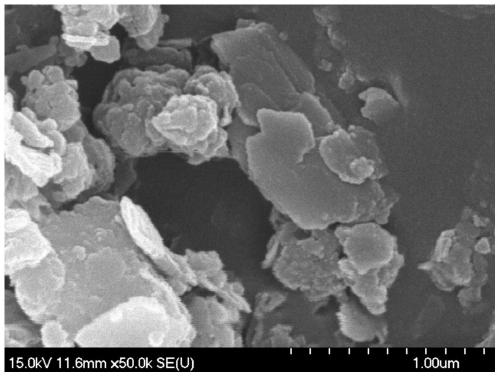

Organic/inorganic hybrid hardening agent, and preparation method and application thereof

InactiveCN103387759ASolve the problem of limited usageOvercome time-consuming difficultiesCoatingsWear resistantEvaporation

The invention discloses an organic / inorganic hybrid hardening agent. The hardening agent is characterized by being prepared from the following raw materials by weight: 10 to 50% of a silica sol, 0.1 to 60% of a solvent, 1.5 to 15% of a silane coupling agent containing an unsaturated double bond, 0.1 to 2% of an acidic catalyst and 12 to 70% of an active diluent. The invention further provides a preparation method for the hybrid hardening agent. The preparation method comprises the following steps: after preparation of the raw materials, adding the silica sol and the solvent, then adding the silane coupling agent drop by drop, adjusting a pH value by using the acidic catalyst, carrying out stirring, then adding the active diluent, carrying out rotary evaporation and cooling, continuing evaporation until no fraction is evaporated and then carrying out bottling and aging. The invention also discloses application of the hardening agent in a coating. The hardening agent is used as a film forming substance for a UV-cured nanometer composite coating and for preparation of wear-resistant and scrape-resistant coatings on the surfaces of resin eyeglass and optical discs. According to the invention, the silica sol is modified by using the silane coupling agent containing the unsaturated double bond through a sol-gel process, and a prepared coating has the advantages of environment friendliness, high transparency, high hardness, good wear resistance, etc.

Owner:东莞上海大学纳米技术研究院 +1

Epoxy resin/montmorillonite nanometer composite paint used on metal surface and application of epoxy resin/montmorillonite nanometer composite coating

ActiveCN109796845AEvenly dispersedReduce volatilityAnti-corrosive paintsEpoxy resin coatingsEpoxySalt resistance

The invention relates to the technical field of anti-corrosion paint, in particular to epoxy resin / montmorillonite nanometer composite paint used on a metal surface. The epoxy resin / montmorillonite nanometer composite paint is prepared from, by weight, 80-120 parts of epoxy resin, 12-18 parts of a diluent agent, 40-60 parts of a curing agent, 0.1-3 parts of an accelerator and 1-5 parts of organicmodified montmorillonite. By means of the paint, the interface bonding strength between coating and metal is enhanced, and the coating is not prone to falling off from the metal surface, the problem that the contact interface of a film and air is adhesive is relieved, and the contact interface between the paint and the air is smooth and stable. Therefore, the probability that the film layer adsorbs and adheres to impurities in the air to cause a self-corrosion phenomenon is reduced, the film layer curing and drying speed is increased, the flexibility, the salt resistance and the acid resistance of the film layer are remarkably improved, and development of the aluminum alloy anti-corrosion industrial will be certainly promoted.

Owner:ZHEJIANG UNIV OF TECH

Anticorrosion sealant and preparation method thereof

InactiveCN105602502AAvoid crackingImprove sealingNon-macromolecular adhesive additivesOther chemical processesScavengerWear resistant

The invention discloses an anticorrosion sealant. The anticorrosion sealant is prepared from, by weight, 52-72 parts of bisphenol epoxy resin, 20-32 parts of flexible epoxy resin, 12-18 parts of composite thinner, 5-10 parts of epoxy hardener, 1.5-3.5 parts of light calcium carbonate, 1.5-5.5 parts of synthetic resin tackifier, 1.2-2.5 parts of flexibilizer, 0.8-3.2 parts of antioxidant, 0.2-1.8 parts of corrosion inhibitor, 0.5-3.5 parts of wear-resistant agent, 0.6-2.2 parts of heat-resisting stabilizer and 1.2-4.5 parts of moisture scavenger. A preparation method includes the steps of firstly, evenly mixing and heating two types of resin; secondly, grinding, mixing and heating epoxy hardener, light calcium carbonate and synthetic resin tackifier; thirdly, mixing, heating and cooling the rest of additives and the mixtures of the first step and the second step. The prepared sealant has high corrosion resistance, heat resistance and adaptability, and the corrosion resistance of the prepared sealant is three to five times of corrosion resistance of sealant for a storage battery shell in the prior art.

Owner:SUZHOU RUINAIJIE ELECTRONICS SCI & TECH NEW MATERIAL

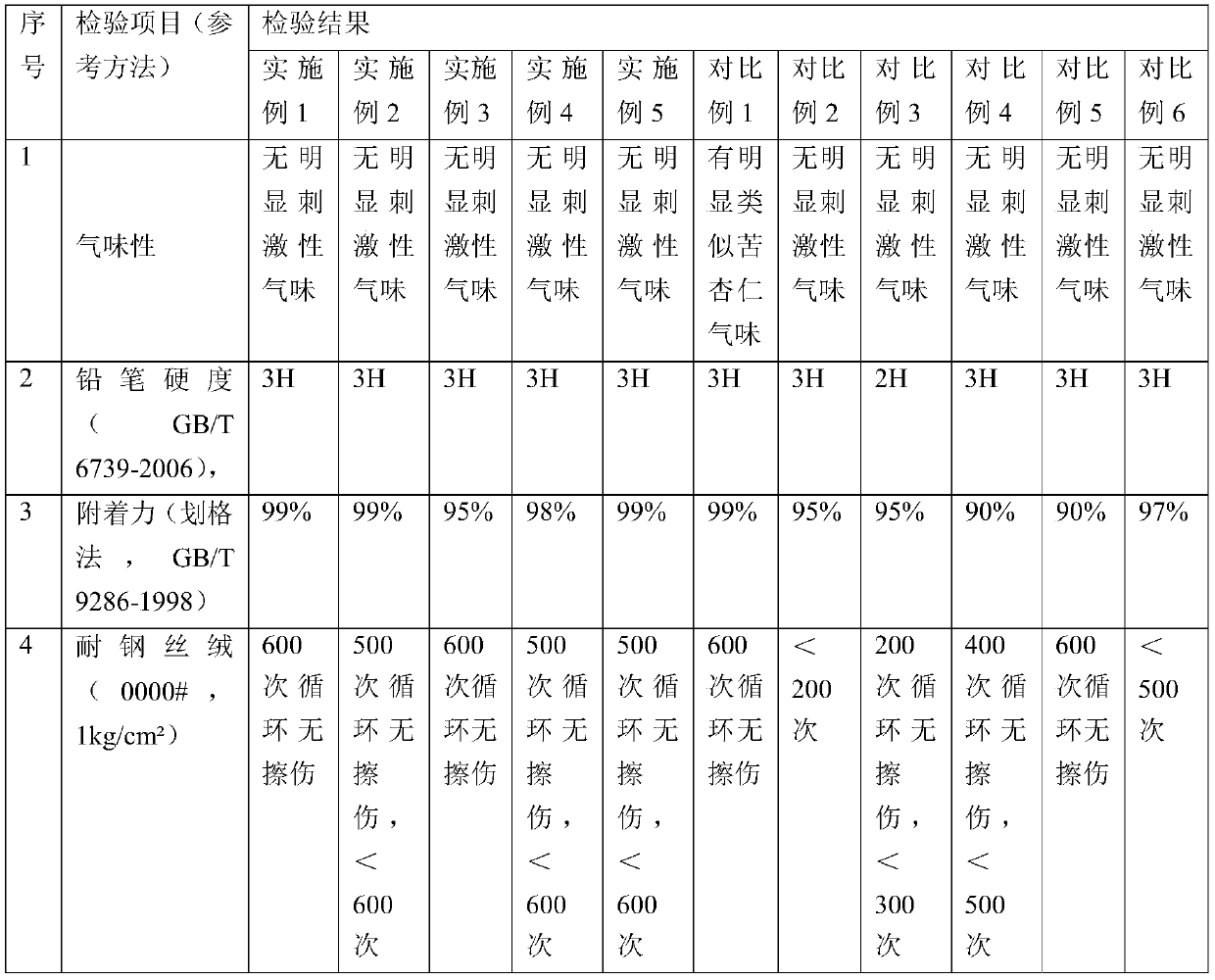

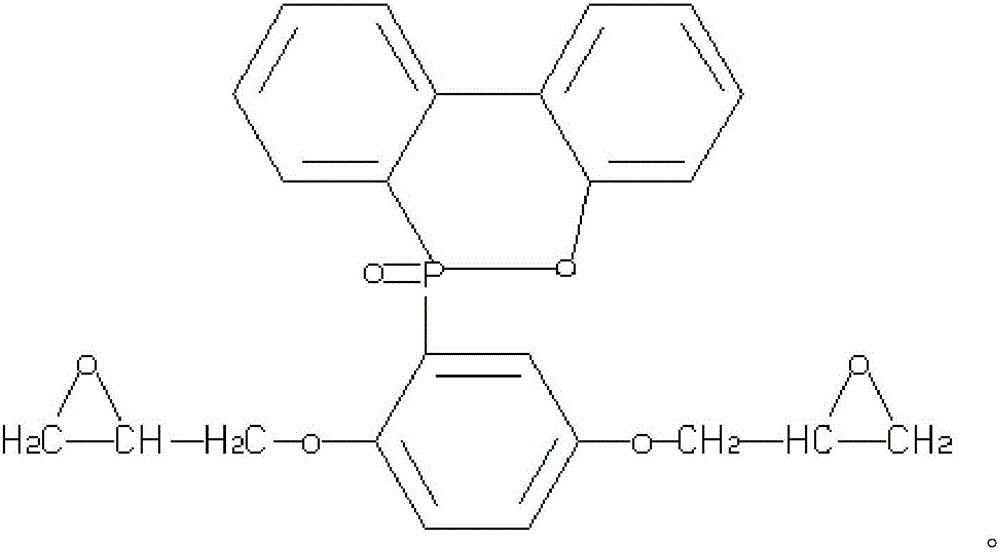

UV scratch-resistant agent of organic-inorganic composite system and preparation method and application of UV scratch-resistant agent

InactiveCN110577796ASmall smellImprove adhesionPolyurea/polyurethane coatingsPhosphateInorganic compound

The invention discloses a UV scratch-resistant agent of an organic-inorganic composite system and a preparation method and an application of the UV scratch-resistant agent. The UV scratch-resistant agent comprises the following raw materials by the weight percentage: 26-34% of a urethane acrylate oligomer, 2.4-6.4% of a nano silicon dioxide dispersion liquid, 0.3% of an adhesion promoter, 44-52% of a solvent, 0.3% of a reactive leveling agent, 3% of a macromolecular photoinitiator and 12% of an acrylate reactive diluent, wherein the sum of the weight percentages of the raw materials is 100%. The urethane acrylate oligomer comprises a urethane acrylate oligomer with six functional groups; the adhesion promoter comprises a phosphate modified acrylate oligomer; the leveling agent comprises acrylic acid modified polysiloxane; the macromolecular photoinitiator comprises 2-hydroxy-4-(2-hydroxyethyl)-2-methyl propiophenone. After coating the surface of a window film and being cured into a film, the scratch-resistant agent has the characteristics of low odor, high hardness, good adhesive force, excellent wear resistance and the like, and meets the index requirements of the window film market on film hardening treatment.

Owner:西安航天三沃化学有限公司

Seawater-corrosion-preventing paint

InactiveCN103555089ASuitable for constructionImprove seawater corrosion resistanceAnti-corrosive paintsWater basedFiber

The invention relates to a seawater-corrosion-preventing paint comprising the components of: 65 parts of diatomaceous earth, 24 parts of hemihydrate gypsum, 12 parts of a diluent, 23 parts of talc powder, 2 parts of superfine glass powder, 22 parts of titanium dioxide, 5 parts of carbon fiber, and 23 parts of acetic tert-carbonate emulsion. The paint also comprises 7 parts of nano-grade titanium dioxide and 4 parts of water-based inorganic aluminum sol. With the seawater-corrosion-resistant road pavement material, paint water-corrosion-preventing performance is improved. Less organic chemical agent is adopted, seawater corrosion resistance is high, and the components are easy to obtain. The paint is suitable for construction of coastal roads.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Method for preparing halogen-free flame-retardant high-Tg copper-clad plate

InactiveCN106240132AImprove heat resistanceImprove flame retardant performanceLaminationLamination apparatusEpoxyPoly ether ether ketone

The invention discloses a method for preparing a halogen-free flame-retardant high-Tg copper-clad plate, and the method comprises the following steps: preparing a glue solution, to be more specific, preparing the glue solution comprising the components of 50-80 parts by weight of bismaleimide resin, 40-70 parts by weight of phosphorus-containing epoxy resin, 10-18 parts by weight of Polyetheretherketone resin, 10-16 parts by weight of low molecular weight polyimide, 12-14 parts by weight of an active diluent, 10-30 parts by weight of a DICY curing agent, 5-10 parts by weight of a curing agent promoter, 50-72 parts by weight of an inorganic filler and 60-80 parts by weight of a solvent, and evenly mixing; applying the glue solution; overlapping and pressing. The pressed formed copper-clad plate has conventional copper-clad plate basic properties such as electrical performance, insulation performance and the like, the flame retardant performance can achieve V-0 level (UL94 standard), the Tg > 250 DEG C, at the same time the halogen-free flame-retardant high-Tg copper-clad plate also has special performance such as low dielectric constant and dielectric loss, and can meet the market demand.

Owner:重庆德凯实业股份有限公司

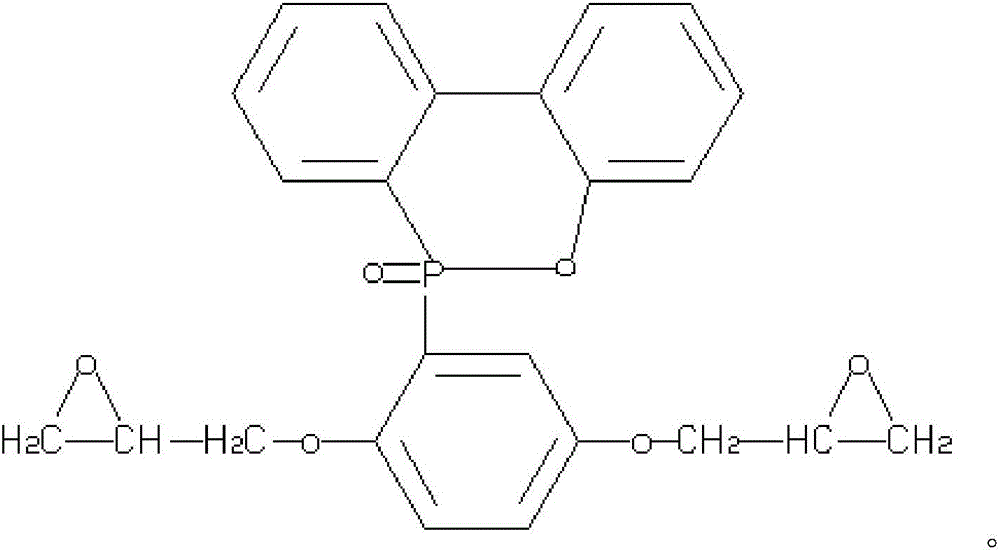

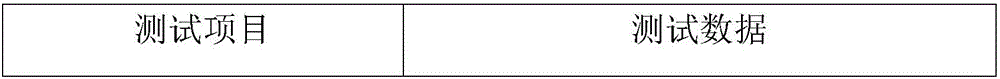

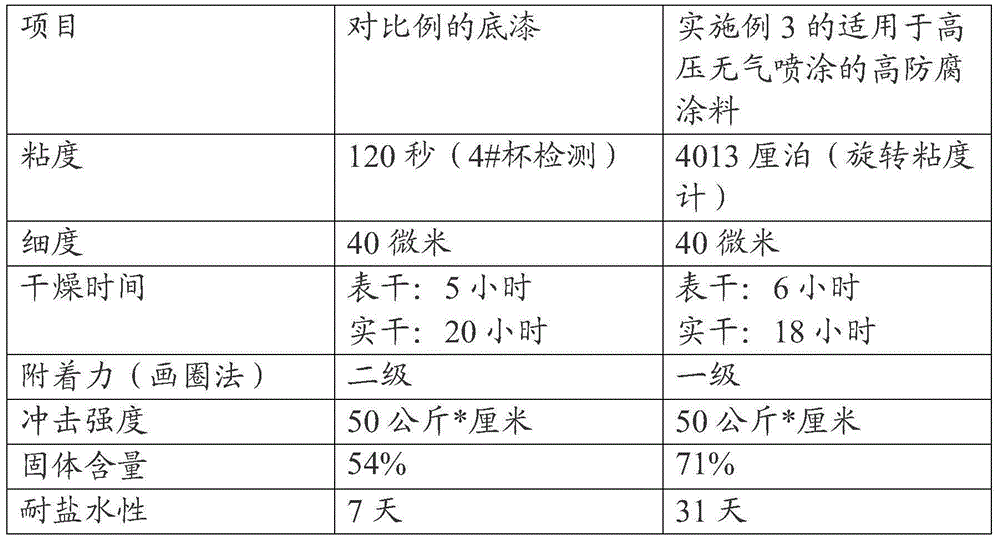

High anti-corrosion coating suitable for high-pressure airless spraying

InactiveCN104449202AImprove thixotropyHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyHigh pressure

The invention discloses a high anti-corrosion coating suitable for high-pressure airless spraying. The coating comprises a component A and a component B in the weight ratio of 5: 1, and the component A comprises the following components in parts by weight: 18-22 parts of first epoxy resin, 18-24 parts of second epoxy resin, 10-15 parts of magnet powder, 2-10 parts of iron oxide red, 0.2-0.5 part of polyvinyl butyral resin, 0.1-0.2 part of a dispersant, 0.5-0.7 part of modified bentonite, 0.2-0.4 part of nano-silicon dioxide, 0.2-0.3 part of an assistant and 12-15 parts of a diluent; and the component B comprises the following components in parts by weight: 56-62 parts of a first amine curing agent, 12-18 parts of a second amine curing agent and 20-30 parts of ethanol. The high anti-corrosion coating suitable for high-pressure airless spraying adopts two different types of epoxy resin and curing agents to form a film by crosslinking and curing. The film-forming mechanism is that active H<+> is contained in the amine curing agents and can react with epoxy groups in epoxy resin at normal temperature and form a reticular structure by crosslinking; and the reticular structure is dense and hard, good in anti-corrosion performance, strong in adhesion and outstanding in chemical resistance.

Owner:湖南中汉高分子材料科技有限公司

Easy-to-clean coating for metal surface and preparation method of easy-to-clean coating

InactiveCN110343440AImprove adaptabilityStrong adhesionAntifouling/underwater paintsPaints with biocidesEpoxyDefoaming Agents

The invention discloses an easy-to-clean coating for the metal surface and a preparation method of the easy-to-clean coating, and belongs to the technical field of coatings. The easy-to-clean coatingfor the metal surface with the good material surface adaptability, the high coating adhesion, the high hardness and good wear resistance is provided. According to the technical scheme, the easy-to-clean coating is prepared from the following components in parts by weight: 100-120 parts of a modified epoxy resin emulsion, 10-13 parts of lithium silicate, 0.9-1.2 parts of a KH-560 silane coupling agent, 12-15 parts of a diluent, 1-2 parts of a coalescing agent, 1-2 parts of modified nanometer CaCO3, 1-3 parts of a leveling agent, 1.2-2.5 parts of a defoaming agent, 0.2-0.5 part of a wetting agent and 1-2 parts of a wax emulsion.

Owner:东莞市罗孚化工有限公司

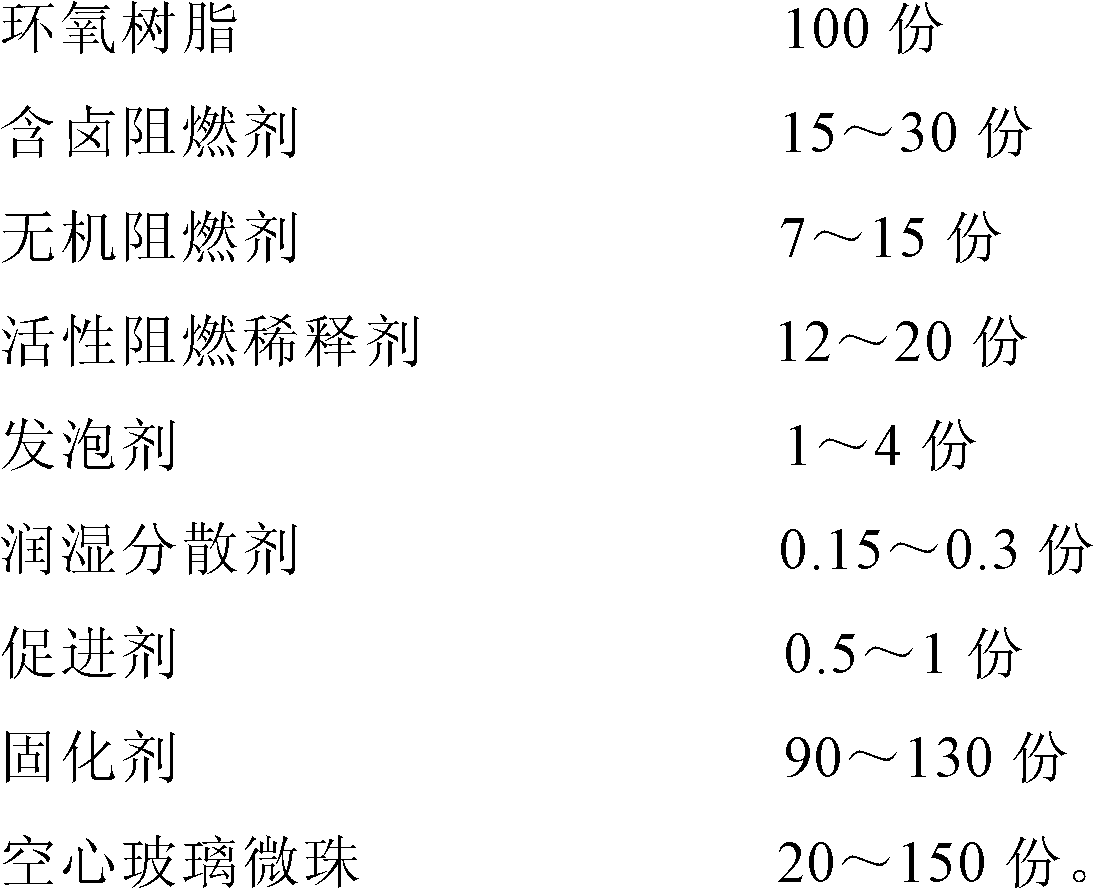

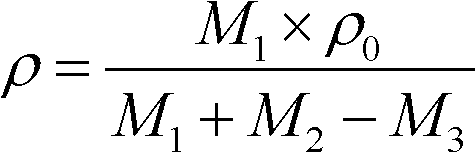

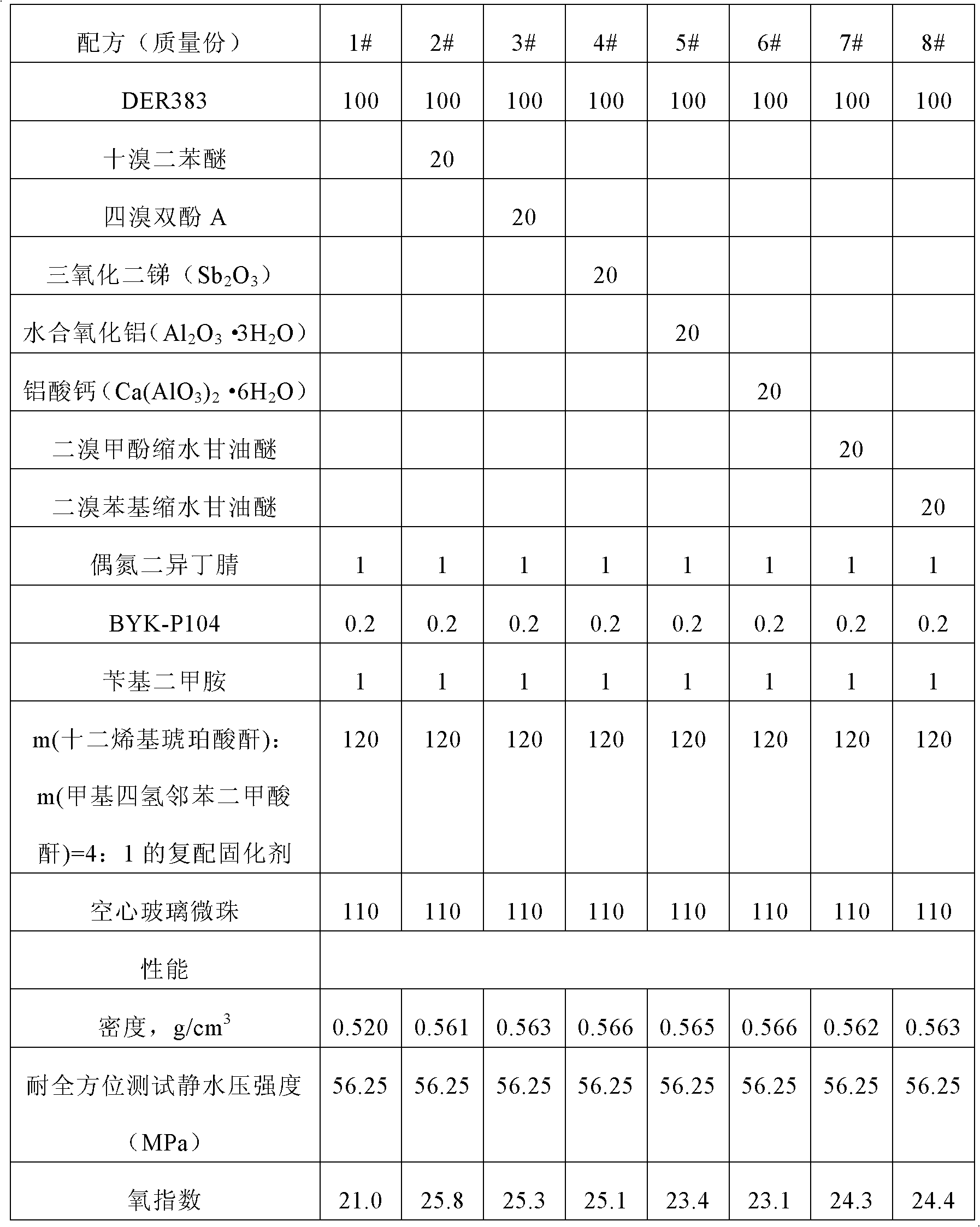

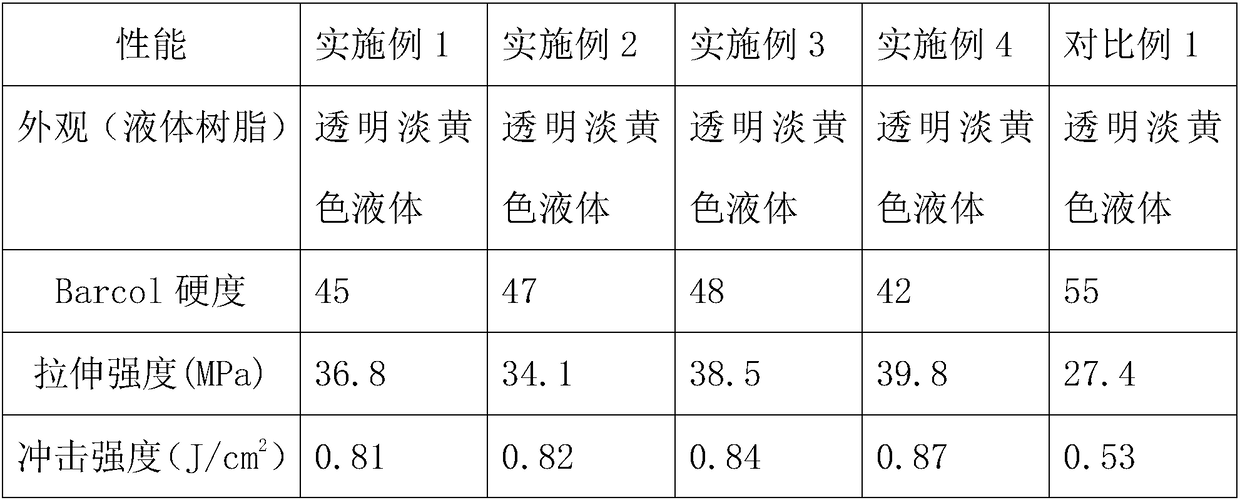

Flame retardant solid buoyancy material and preparation method thereof

The invention relates to the technical field of a solid buoyancy material used in a marine environment and specifically to a flame retardant solid buoyancy material and a preparation method thereof. The flame retardant solid buoyancy material comprises, by mass, 100 parts of an epoxy resin, 15 to 30 parts of a halogen-containing fire retardant, 7 to 15 parts of an inorganic fire retardant, 12 to 20 parts of an active flame retardant diluent, 1 to 4 parts of a foaming agent, 0.15 to 0.3 part of a wetting dispersant, 0.5 to 1 part of an accelerator, 90 to 130 parts of a curing agent and 20 to 150 parts of hollow glass beads. The flame retardant solid buoyancy material provided in the invention has the characteristic of flame retardation, can be used in deep sea, is free of loss of net buoyancy and is processable.

Owner:MARINE CHEM RES INST CO LTD

Cured epoxy resin and epoxy resin composition

The invention provides cured epoxy resin and an epoxy resin composition. The cured epoxy resin is prepared from 45 to 55 parts of high-temperature mixture, 21 to 23 parts of aluminum oxide, 17 to 20 parts of isoprene, 15 to 20 parts of N-butanol glycidyl ether, 10 to 13 parts of carbon fibers, and 12 to 13 parts of diluting agent. The curing reaction rate of the cured epoxy resin is high, and thecuring effect can be improved. Moreover, the epoxy resin composition utilizing the cured epoxy resin has the advantages of good curing effect, high stability, excellent viscosity and the like.

Owner:SHANGHAI HUAYI RESINS CO LTD

High-temperature-resistant unsaturated polyester resin for fiber reinforced plastic septic tanks, and preparation method thereof

The invention discloses a high-temperature-resistant unsaturated polyester resin for fiber reinforced plastic septic tanks, wherein the unsaturated polyester resin is an organosilicon modified unsaturated polyester resin, and comprises the following raw materials by weight: 17-28 parts of maleic anhydride, 12-28 parts of tetrahydrophthalic anhydride, 4-12 parts of adipic acid, 23-38 parts of propylene glycol, 3-9 parts of ethylene glycol, 4-8 parts of diethylene glycol, 5-12 parts of N-(polydimethylsiloxane)maleimide, 0.01-0.1 part of an initiator, 0.01-0.1 part of a polymerization inhibitor,and 12-24 parts of a diluent. The unsaturated polyester resin of the present invention can effectively improve the high temperature resistance while the excellent processability and the excellent mechanical property are maintained.

Owner:安徽汇创新材料有限公司

Discoloration coating of ceramic tiles and production process thereof

The invention relates to a ceramic tile allochromatic coating and the production technology thereof, the allochromatic coating comprises the following components by weight ratios: fluorocarbon resin 65 to 75, polarizing pigments 1 to 2, curing agents 12 to 16, diluents 12 to 16, antifoaming agents 0 to 1, levelling agents 0 to 1 and wetting and dispersing agents 0 to 1; wherein, the polarizing pigments are put in a small container and stirred after adding a few diluents; the fluorocarbon resin, the antifoaming agents, the levelling agents and the wetting and dispersing agents are put in a big container and stirred for 5 to 15 minutes; the polarizing pigments, the curing agents and the residual diluents are added into the big container and mixed and stirred to form homogenous solution; the adjusting viscosity is 20 to 30 seconds, the specific gravity is 0.5 to 1.5g / ml, and then the homogenous solution is filtered by a 75 to 85 mesh screen; the mixed solution is uniformly sprayed on glazed tiles by a spray gun, the quantity for spray is 130 to 170g per square meter, and then the sprayed glazed tiles are baked at the temperature of 70 to 90 DEG C for 50 to 70 minutes. The coating has the advantages of not affecting the strength of tiles, simple structure and production technology, low production cost, being easy to realize and uniform discoloration.

Owner:厦门三荣陶瓷开发有限公司

Carbon nanotube modified conductive anticorrosive coating for grounding grid

InactiveCN106675317ASave raw materialsCompatibility is reasonableAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyvinyl alcohol

The invention discloses a carbon nanotube modified conductive anticorrosive coating for a grounding grid, and belongs to the technical field of conductive coatings. The carbon nanotube modified conductive anticorrosive coating for the grounding grid mainly comprises the following raw materials calculated in parts by mass: 25 to 27 parts of nano-carbon powder fillers, 30 to 32 parts of epoxy resin matrixes, 22 to 25 parts of nano-magnetic iron oxide, 12 to 14 parts of inert diluents, 6 to 8 parts of polyurethane resin, 15 to 17 parts of alkyd resin, 6 to 7 parts of polyvinyl alcohol, 10 to 11 parts of ethyl acetate, 2 parts of dispersants, 11 to 13 parts of acetone, 12 to 13 parts of methyl isobutyl ketone, and 2 to 2.5 parts of tributyl phosphate. The carbon nanotube modified conductive anticorrosive coating for the grounding grid disclosed by the invention is cheap in price of the raw materials and reasonable in compatibility, has high corrosion resistance and conductivity, and is mainly used for a carbon nanotube of the grounding grid.

Owner:STATE GRID SHANDONG TANCHENG POWER SUPPLY +1

Antistatic packaging material

InactiveCN100372906CEasy to getLow priceLiquid surface applicatorsOther chemical processesPolymer scienceConductive polymer

Disclosed is an antistatic packing material, characterized in that the surface of the package base material is coated or fused by a layer of conductive polymer comprising the following materials (by weight percent): carbon powder 0.5-10%, polyamine ester 40-60%, addition agent 15-50%, solvent 15-40%, the addition agent comprises dispersing agent 2-15%, coupling agent 0.5-10%, thinning agent 12.5-35%.

Owner:黄晖

Highly hydrophilic and highly wear-resistant organic/inorganic hybrid photocurable coating composition

InactiveCN105153924BEmission reductionGood component compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsHydrophilic coatingOligomer

The invention discloses a highly hydrophilic and highly wear-resistant organic / inorganic hybrid photocurable coating composition; the composition comprises 60-75 parts of a hydrophilic photocurable oligomer and 5-15 parts of a high-functionality photocurable resin , 12-20 parts of reactive diluent, 4-6 parts of photoinitiator, 0.01-0.5 part of auxiliary agent, 0.4-2 parts of inorganic functional additive; the inorganic functional additive is selected from polyvinyl silsesquioxane, methyl Acryloxysilsesquioxane, Acryloxysilsesquioxane. The UV-curable hydrophilic coating provided by the invention can be applied to the surface of glass, and has excellent hydrophilicity and physical properties after curing, as well as good adhesion, water resistance, acid resistance and abrasion resistance.

Owner:SHANGHAI WEIKAI CHEM +2

Welding agent for weld holder welding

InactiveCN108406168AAvoid disadvantagesImprove performanceWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention relates to a welding agent for weld holder welding. The welding agent for weld holder welding is prepared from the following components in parts by weight: 11 to 23 parts of sulfate, 3 to 7 parts of ferrosilicon powder, 12 to 24 parts of metallic oxide, 8 to 13 parts of wetting agent, 34 to 54 parts of manganese powder, 2 to 13 parts of silicon dioxide, 11 to 31 parts of calcium fluoride, 5 to 7 parts of graphite, 17 to 23 parts of water glass, 6 to 15 parts of slag former, and 12 to 22 parts of diluent. The welding agent for weld holder welding provided by the invention has theadvantages that the invention aims at applying a chemical welding principle to solve the technical problem of direct welding of aluminum and steel so as to design a steel claw, so that the full-area welding between the aluminum and the steel can be realized, the electrical resistivity is reduced, the mechanical strength of the welding surface is improved, the welding agent is convenient to use, high in welding efficiency and good in quality, the automation in welding can be realized, the labor intensity of workers is low, and the efficiency is high.

Owner:NANTONG HUINING MECHANICAL & ELECTRICAL TECH CO LTD

Method for spray coloring rubber surface

ActiveCN100408203CImprove adhesionNo crackRubber derivative coatingsPretreated surfacesPolymer scienceLacquer

The process of spraying and colorizing rubber surface includes the following steps: 1. compounding paint with rubber paint 40-55 weight portions, color paste 5.0-9.5 weight portions, curing agent 15-20 weight portions and diluent 12-16 weight portions and through stirring at normal temperature; 2. spraying the paint with paint gun in the pressure of 2.5-4.0 kg / sq cm to the surface of rubber product; and 3. roasting the sprayed product in oven at 75-95 deg.C for 40-50 min and taking out to cool naturally. The process has high production speed, and the paint has bright color, high adhesion, high impact strength and other advantages.

Owner:BEIJING KINGCO TECH DEV

Method for preparing solar cell back film

InactiveCN109585605AWeather resistantHas acid and alkali resistancePhotovoltaic energy generationSemiconductor devicesEpoxyWeather resistance

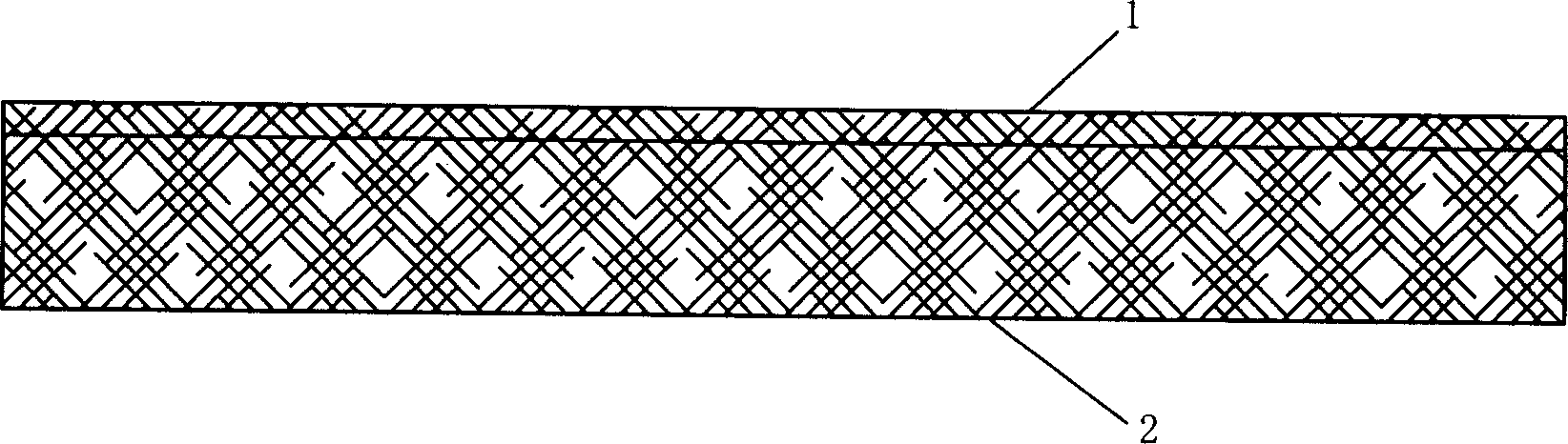

The invention discloses a method for preparing a solar cell back film. A weather resistant layer, a PET layer and a bonding layer are arranged in order from inside to outside. The thickness of the weather resistant layer is 30-60 [Mu]m, and the weather resistant layer is composed by the following compositions in parts by mass: 50-70 parts of epoxy resin, 4-10 parts of first curing agent, 10-18 parts of inorganic filler and 12-20 parts of first diluent; and the thickness of the bonding layer is 20 to 50 [Mu]m, and the bonding layer is composed by the following compositions in parts by mass: 40-50 parts of epoxy resin, 8-20 parts of silicone resin, 8-12 parts of second curing agent, 6-10 parts of silane coupling agent and 16-26 of second diluent. The inorganic filler is a mixture of magnesium fluoride and talc, the component ratio of the magnesium fluoride and the talc is 4:3, the inorganic filler is ground to 200 mesh, the first curing agent is polyisocyanates curing agent, the second curing agent is a polyamide curing agent. The method for preparing a solar cell back film has weather resistance and acid and alkali resistance, and is suitable for popularization and popularization ina wide range.

Owner:江苏中宇光伏科技有限公司

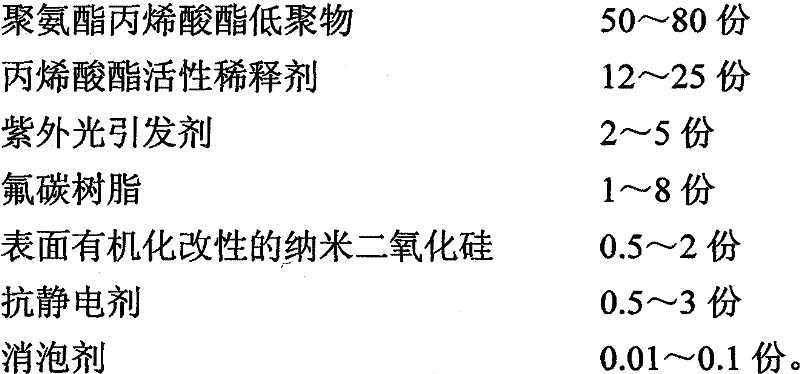

Noctilucent organic composite coating and preparation method thereof

InactiveCN105670409AImprove stabilityImprove adsorption capacityLuminescent paintsSodium BentoniteAcrylic resin

The invention provides noctilucent organic composite coating. The noctilucent organic composite coating comprises, by weight, 35-42 parts of fluororesin, 7-14 parts of acrylic resin, 5-10 parts of polyurethane resin, 0.1-0.2 part of levelling agent, 12-16 parts of diluent, 0.6-1.2 parts of dispersing agent, 8-10 parts of pigment, 10-14 parts of filler, 11-16 parts of modified noctilucent powder, 0.3-0.8 part of organic bentonite and 5-7 parts of hollow glass microspheres. The invention further provides a preparation method of the noctilucent organic composite coating. The noctilucent organic composite coating is good in noctilucent performance and mechanical performance.

Owner:HUZHOU GUOXIN MATERIALS

Inner rubber material used for water delivery hose

InactiveCN106519491AGood flexibilityImproved resistance to twistingPolytetramethylene terephthalateRubber material

The invention discloses an inner rubber material used for a water delivery hose. The inner rubber material is prepared from raw materials including, by weight, 140-150 parts of PVC, 80-85 parts of fluorinated silicone rubber, 20-30 parts of poly (butylenes terephthalate), 5-14 parts of an antioxidant, 4-8 parts of aluminum oxide, 3-5 parts of triphenyl phosphate, 13-15 parts of acrylic resin, 8-12 parts of thiocarbanilide, 12-17 parts of a reactive diluent, 30-40 parts of glass fiber, 5-9 parts of phthalic anhydride, 3-8 parts of a benzenesulfonic acid type catalyst, 1-5 parts of methyltin mercaptide and 1-4 parts of an aluminate coupling agent. The inner rubber material used for the water delivery hose is good in flexibility, resistant to distortion, good in bending performance, capable of bearing heavy loads and resistant to flex cracking.

Owner:WUXI YONGXING METAL HOSE

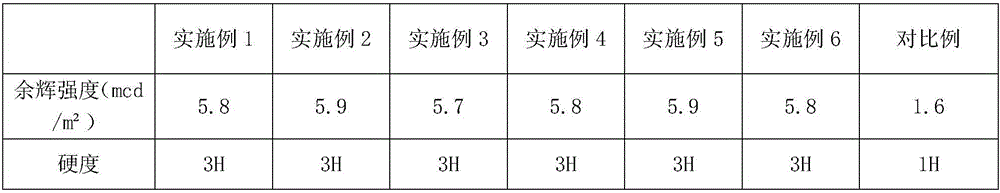

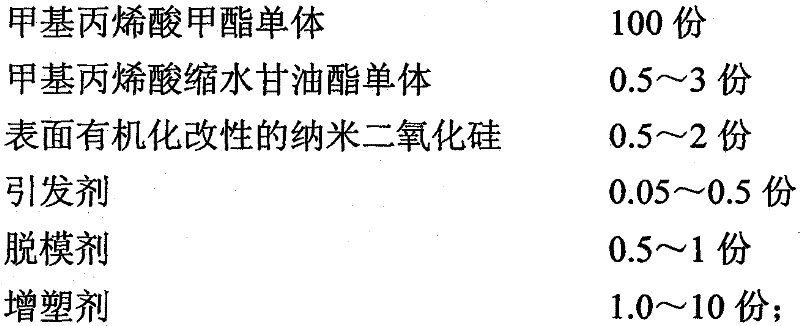

Transparent PMMA composite sound barrier board and preparation method thereof

ActiveCN101818483BEliminate pollutionImprove performanceNoise reduction constructionCoatingsGlycidyl methacrylateSilicon dioxide

The invention discloses a transparent PMMA composite sound barrier board, comprising a PMMA sound barrier substrate and an ultraviolet curable coating coated on the surface of the substrate, wherein the PMMA sound barrier substrate comprises the following raw materials in parts by weight: 100 parts of methyl methacrylate, 0.5-3 parts of glycidyl methacrylate, 0.5-2 parts of modified silica, 0.05-0.5 part of initiator, 0.5-1 part of release agent and 1-10 parts of plasticizers; and the ultraviolet curable coating comprises the following raw materials in parts by weight: 50-80 parts of polyurethane acrylate oligomers, 12-25 parts of acrylate reactive diluents, 1-8 parts of fluorocarbon resins, 2-5 parts of ultraviolet initiators, 0.5-2 parts of modified silica, 0.5-3 parts of antistatic agents and 0.10-0.1 part of antifoaming agent. The invention also discloses a preparation method of the transparent PMMA composite sound barrier board. The PMMA sound barrier board has the characteristics of excellent wear resistance, impact resistance, corrosion resistance and the like and has good transparency and long service life.

Owner:HAIYAN HUASHUAITE PLASTIC ELECTRICAL APPLIANCES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com