Method for preparing halogen-free flame-retardant high-Tg copper-clad plate

A manufacturing method and technology of copper clad laminates, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of low heat resistance, unfavorable alignment, resin greasy, etc. The effect of market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Preparation of halogen-free flame-retardant high Tg copper clad laminate

[0047] 1) Preparation of insulating layer glue formula (parts by weight):

[0048] Bismaleimide resin 50;

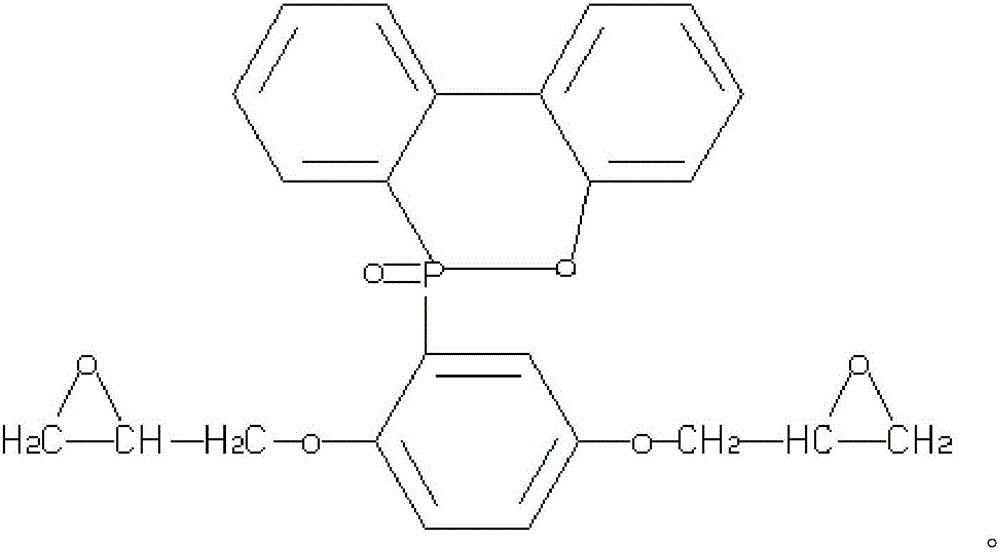

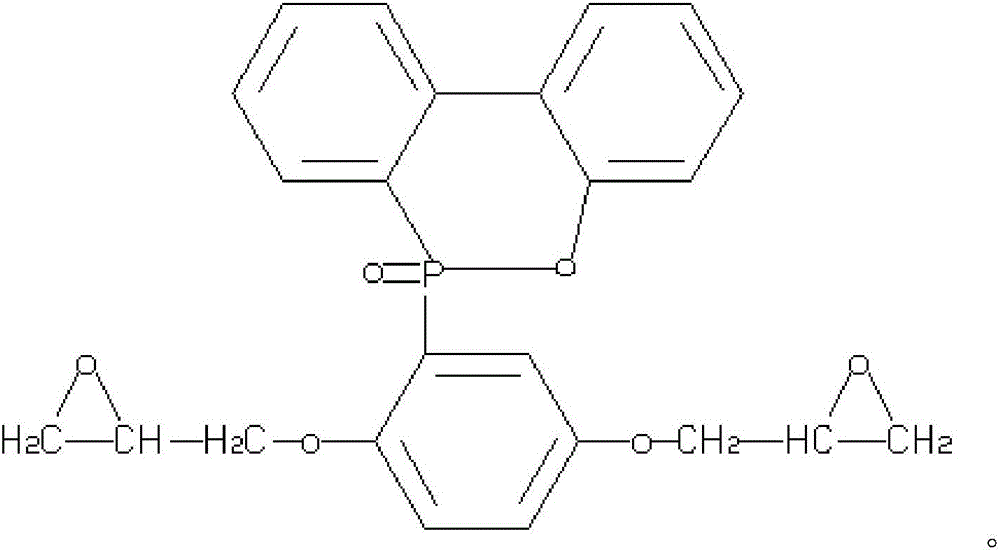

[0049] Phosphorus epoxy resin 40;

[0050] Polyetheretherketone resin 10;

[0051] Low molecular weight polyimide 10;

[0052] Active diluent 12;

[0053] DICY curing agent 10;

[0054] Curing agent accelerator 0.5;

[0055] Inorganic filler 50;

[0056] Solvent 160;

[0057] The components are mixed thoroughly for 8 hours, and the gel time is 255S.

[0058] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to prepare a prepreg. The gluing speed is 20m / min. Control parameters: gelation time is 100S, resin content is 40%, fluidity 28%;

[0059] 3) Laminating and pressing: Control the pressing parameters according to product thickness requirements:

[0060] Vacuum degree: 0.05Mpa;

[0061] Pressure: 500PSI;

[0062] Heating rate: 2℃ / min;

[0063] Hot plate temperature: 120~23...

Embodiment 2

[0067] Example 2 Preparation of halogen-free flame-retardant high Tg copper clad laminate

[0068] 1) Preparation of insulating layer glue formula (parts by weight):

[0069] Bismaleimide resin 65;

[0070] Phosphorus epoxy resin 55;

[0071] Polyetheretherketone resin 15;

[0072] Low molecular weight polyimide 14;

[0073] Active diluent 13;

[0074] DICY curing agent 20;

[0075] Curing agent accelerator 0.8;

[0076] Inorganic filler 60;

[0077] Solvent 180;

[0078] The components are mixed thoroughly for 8 hours, and the gel time is 255S.

[0079] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to prepare a prepreg. The gluing speed is 22m / min. Control parameters: gelation time is 120S, resin content is 43%, fluidity 25%;

[0080] 3) Laminating and pressing: Control the pressing parameters according to product thickness requirements:

[0081] Vacuum degree: 0.05Mpa;

[0082] Pressure: 550PSI;

[0083] Heating rate: 2℃ / min;

[0084] Hot plate temperature: 120~23...

Embodiment 3

[0088] Example 3 Preparation of halogen-free flame-retardant high Tg copper clad laminate

[0089] 1) Preparation of insulating layer glue formula (parts by weight):

[0090] Bismaleimide resin 80;

[0091] Phosphorus epoxy resin 70;

[0092] Polyetheretherketone resin 18;

[0093] Low molecular weight polyimide 16;

[0094] Active diluent 14;

[0095] DICY curing agent 30;

[0096] Curing agent accelerator 1;

[0097] Inorganic filler 72;

[0098] Solvent 80;

[0099] The components are mixed thoroughly for 8 hours, and the gel time is 255S.

[0100] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to prepare a prepreg. The gluing speed is 22m / min. Control parameters: gelation time is 120S, resin content is 43%, fluidity 25%;

[0101] 3) Laminating and pressing: Control the pressing parameters according to product thickness requirements:

[0102] Vacuum degree: 0.05Mpa;

[0103] Pressure: 550PSI;

[0104] Heating rate: 2℃ / min;

[0105] Hot plate temperature: 120~230℃;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com