Antistatic packaging material

A packaging material and anti-static technology, applied in polyurea/polyurethane coatings, devices for coating liquid on the surface, and other chemical processes, can solve the problems of complicated production and high cost, and achieve simple preparation process, low cost, and easy The effect obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A conductive polymer packaging material, comprising a substrate and at least one conductive polymer layer coated on the substrate, characterized in that the conductive polymer layer is composed of the following materials in weight percentage:

[0026] Carbon powder 5%, polyurethane 40%, dispersant 5%, coupling agent 4%, thinner 20%, thickener 1%, solvent 25%;

[0027]The base material of the present invention selects PS polystyrene, the dispersant selects PVP polyvinyl pyrrolidone, the described coupling agent selects heptyl trimethoxysilane, and the described diluent selects epoxy resin diluent , The thickener is an associative polyurethane thickener, and the solvent is deionized water.

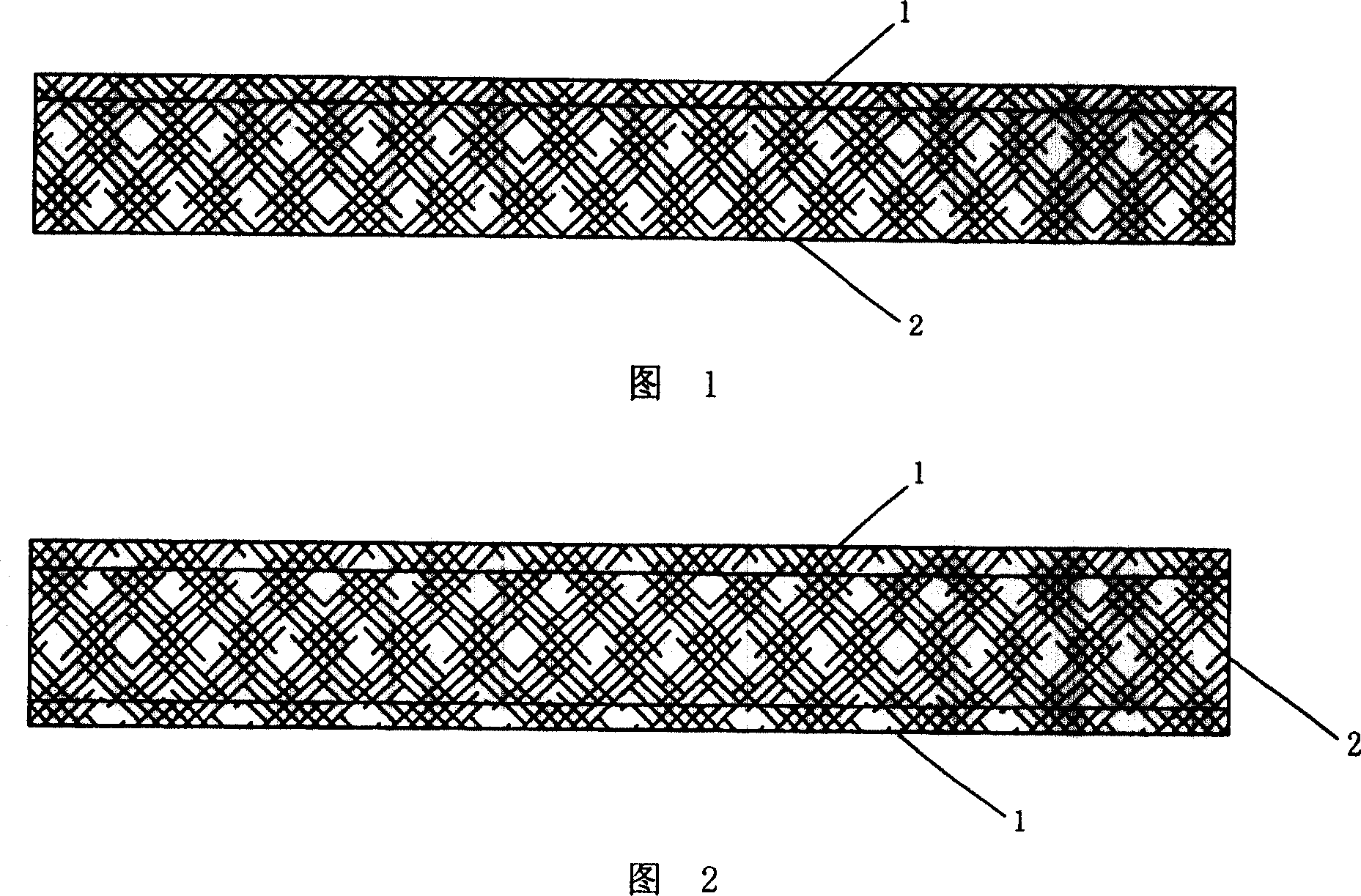

[0028] First, after debugging the conductive polymer formula, heat the substrate to the required temperature below the melting point, and then apply the mixed conductive polymer on the surface of the substrate through the coating equipment, as shown in Figure 1, on the substrate 2 On...

Embodiment 2

[0030] A conductive polymer packaging material, comprising a substrate and at least one conductive polymer layer coated on the substrate, characterized in that the conductive polymer layer is composed of the following materials in weight percentage:

[0031] Carbon powder 0.5%, polyurethane 60%, dispersant 2%, coupling agent 0.5%, thinner 18%, thickener 2.5%, solvent 16.5%.

[0032] Wherein the substrate is selected from PE polyethylene, the dispersant is selected from RSH alkyl mercaptan, the coupling agent is selected from dodecyl trimethoxysilane, and the diluent is selected from epoxy resin diluent. The agent is polycarboxylic acid thickener, and the solvent is distilled water.

Embodiment 3

[0034] A conductive polymer packaging material, comprising a substrate and at least one conductive polymer layer coated on the substrate, characterized in that the formula of the conductive polymer layer is as follows:

[0035] Carbon powder 2%, polyurethane 55%, dispersant 3%, coupling agent 2%, thinner 18%, thickener 0.6%, solvent 17.4%, anti-blocking agent 2%.

[0036] Wherein the base material is selected PET polyethylene terephthalate, the dispersant is selected PVP polyvinylpyrrolidone, the described coupling agent is selected long-chain alkyl trimethoxysilane, and the described diluent is selected epoxy resin to dilute The thickener is a cross-linked polymer emulsion formed by copolymerization of ethyl acrylate and methacrylic acid, the anti-blocking agent is talc, and the solvent is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com