UV scratch-resistant agent of organic-inorganic composite system and preparation method and application of UV scratch-resistant agent

An inorganic composite, scratch-resistant technology, applied in coatings, polyurea/polyurethane coatings, etc., to improve environmental protection, durability, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

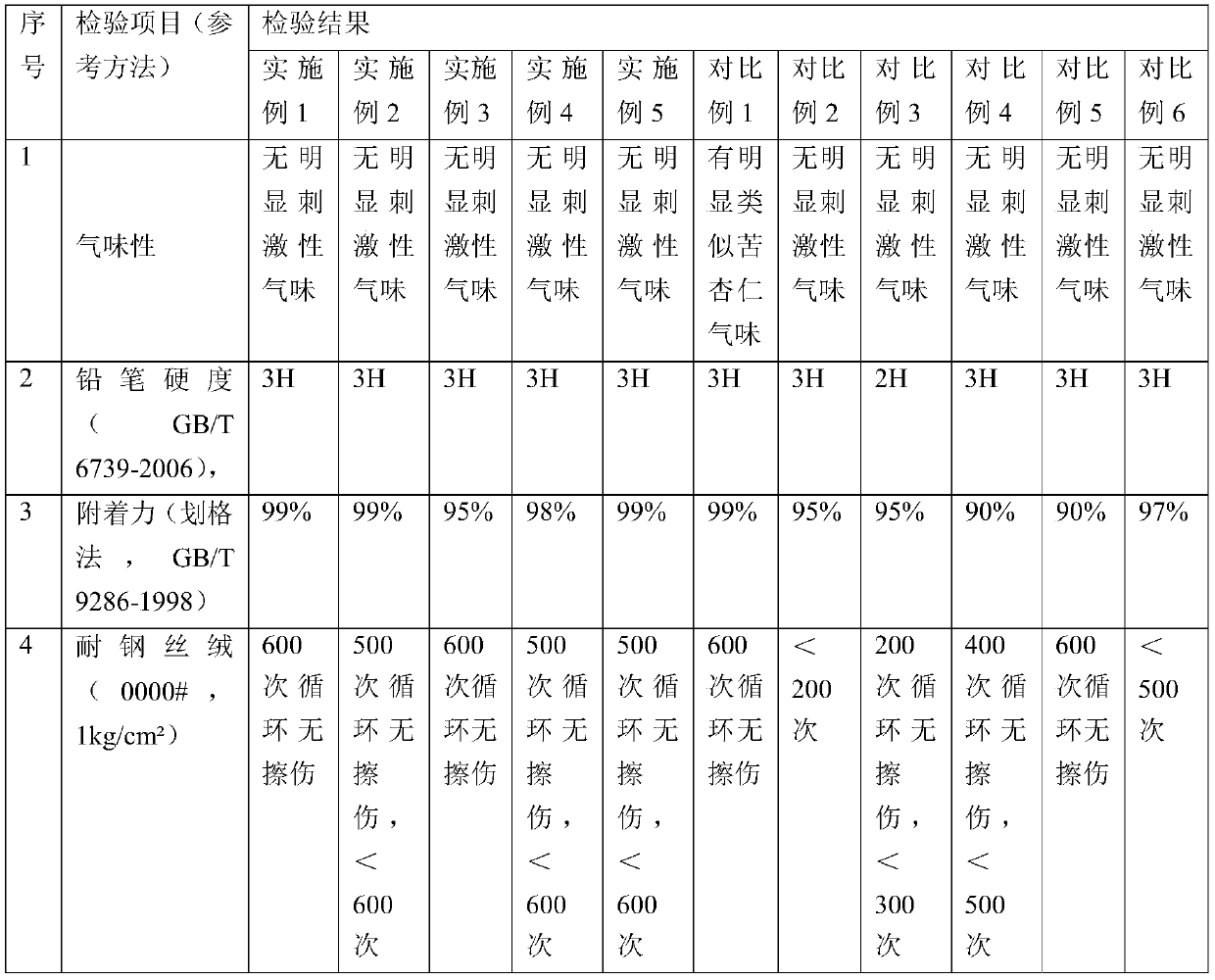

Examples

preparation example Construction

[0026] This embodiment also provides a method for preparing a UV scratch-resistant agent of an organic-inorganic composite system, which specifically includes the following steps:

[0027] Step 1: Weigh the polyurethane acrylate oligomer, nano-silica dispersion, adhesion promoter, reactive leveling agent, macromolecular photoinitiator and acrylate reactive diluent according to the formula and add them to the stirring tank. Weigh part of the solvent to rinse the weighing container and pour it into the stirring tank;

[0028] Step 2, add the remaining part of the solvent into the stirring tank, and stir until the urethane acrylate oligomer and the macromolecular photoinitiator are completely dissolved and uniform;

[0029] Step 3, 400-mesh eight-layer filter screen to filter and discharge.

[0030] An organic-inorganic composite system UV scratch-resistant agent is used for the application of automobile window film and architectural window film.

Embodiment 1

[0033] This embodiment provides a UV scratch-resistant agent of an organic-inorganic composite system, including the following raw materials in weight percentage: 30% of polyurethane acrylate oligomer, 6.4% of nano-silica dispersion, 0.3% of adhesion promoter, solvent 48%, reactive leveling agent 0.3%, macromolecular photoinitiator 3% and acrylate reactive diluent 12%.

[0034] In this example, the urethane acrylate oligomer is an aliphatic urethane acrylate oligomer with six functional groups; the nano-silica dispersion is Tego’s C150; the adhesion promoter is a phosphate-modified acrylate oligomer The solvent in the present embodiment is toluene and butanone, and the consumption of toluene is 24%, and the consumption of butanone is also 24%; Reactive type leveling agent is polysiloxane modified by acrylic acid; Macromolecular photoinitiated The agent is IRGACURE 2959 of IGM Company; the acrylate reactive diluent is a mixture of dipentaerythritol hexaacrylate and pentaerythri...

Embodiment 2

[0037] This example provides an organic-inorganic composite system UV scratch-resistant agent and its preparation method. The difference between this example and Example 1 is that this example includes the following raw materials in weight percentage: polyurethane acrylate oligomer 26% , 6.4% nano-silica dispersion, 0.3% adhesion promoter, 52% solvent, 0.3% reactive leveling agent, 3% macromolecular photoinitiator and 12% acrylate reactive diluent.

[0038] In this embodiment, in this embodiment, the urethane acrylate oligomer is an aliphatic urethane acrylate oligomer with six functional groups; the nano-silica dispersion is Tego's C150; the adhesion promoter is phosphate modified acrylate oligomer; the solvent in this embodiment is toluene and butanone, and the consumption of toluene is 26%, and the consumption of methyl ethyl ketone is also 26%; Reactive type leveling agent is polysiloxane modified by acrylic acid alkane; the macromolecular photoinitiator is the IRGACURE295...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com