Patents

Literature

66results about How to "Fast curing reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Furanic resin aggregate binders and method

InactiveUS20080207796A1Improve acid cured binder performanceBoost metal casting form strengthFoundry mouldsFoundry coresProduction ratePhenol

Broadly, the invention provides for newly available bio-derived formaldehyde free furanic materials for aggregate binding. The specific example case is aggregate binding for forms used in the metal casting process. The new materials make possible higher productivity and lower phenol, formaldehyde, urea, and / or furfuryl alcohol content in the metal casting form-making process. It is expected that the formulations will work well in other aggregate binding situations as well.

Owner:BATTELLE MEMORIAL INST

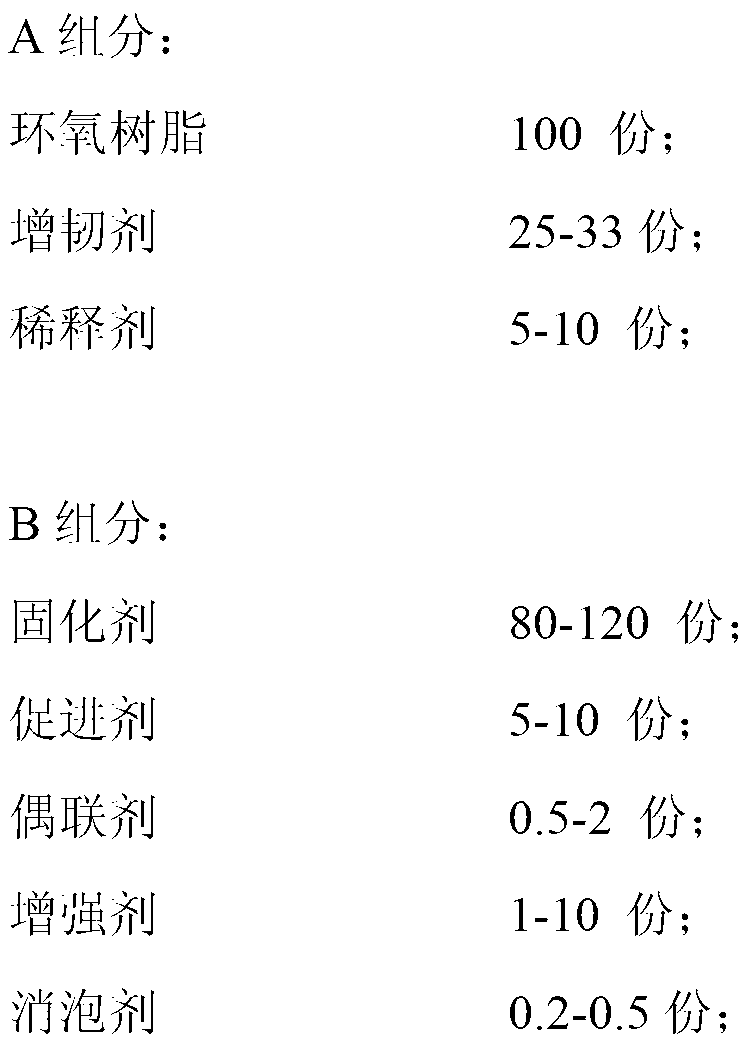

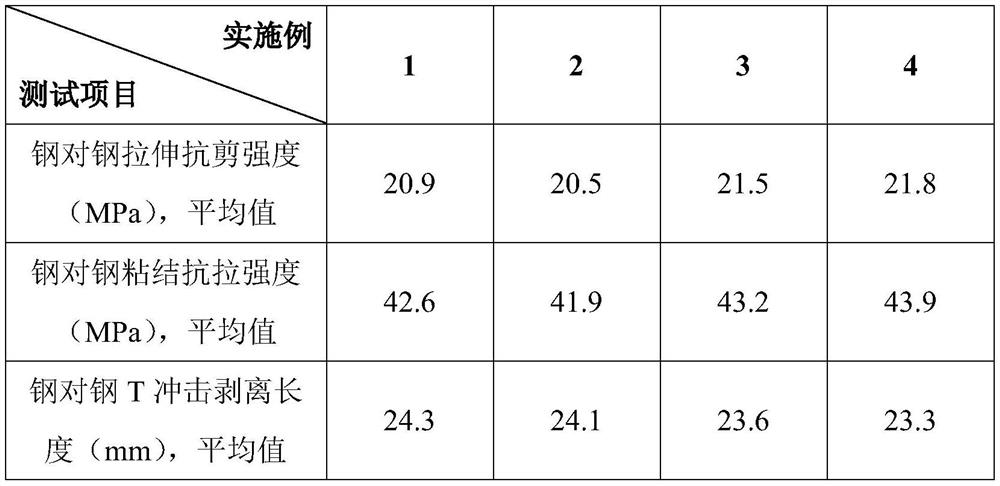

High-performance thermosetting epoxy resin adhesive for roads and bridges and preparation method thereof

InactiveCN103160234AIncreased durabilityFast curing reactionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyBridge deck

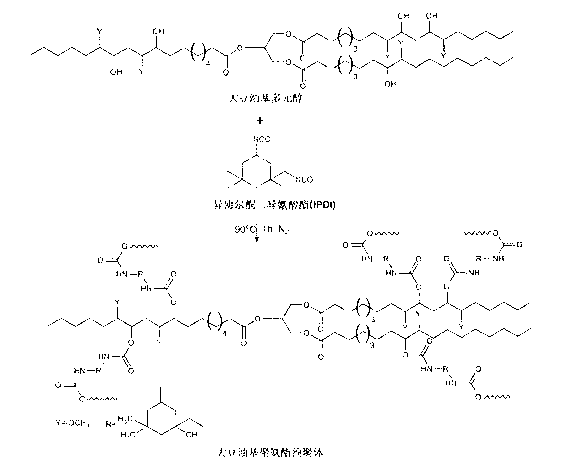

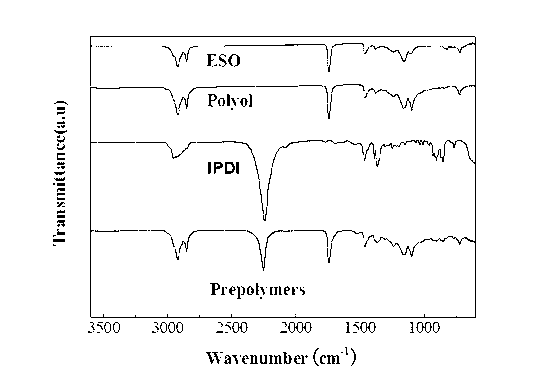

The invention provides a high-performance thermosetting epoxy resin adhesive for roads and bridges. The adhesive comprises a component A and a component B, wherein, the component A comprises the following components in parts by mass: 100 parts of epoxy resin, 25 to 33 parts of flexibilizer, and 5 to 10 parts of diluent; the component B comprises the following components in parts by mass: 80 to 120 parts of curing agent, 5 to 10 parts of accelerant, 0.5 to 2 parts of coupling agent, 1 to 10 parts of reinforcing agent, and 0.2 to 0.5 part of antifoaming agent; and the ratio of the component A to the component B is 100:100-100:120. According to the adhesive, a flexible long-chain aliphatic amine serving as the curing agent has a curing reaction with the epoxy resin to form a solid crosslinking structure, so that the epoxy resin adhesive is high in adhesion capability and water resistance; The toughness of the epoxy asphalt adhesive is improved by adopting the soybean oil-based polyurethane to be adapted to the flexibility of a steel plate, and the soybean oil-based polyurethane containing massive hydroxyl has good compatibility with the epoxy resin. The adhesive is applicable to adhesion and waterproofing of steel bridge decks, viaducts, cement concrete bridge decks, tunnels, expressways and other decks. The invention discloses a preparation method of the high-performance thermosetting epoxy resin adhesive.

Owner:NANJING UNIV

Modified benzoxazine resin capable of using for RTM and process for preparing same

A modified benzoxazine resin able to be used for RTM is prepared through feeding low-voscosity benzoxazine intermediate and epoxy resin (or arylacetylene resin) proportionally into a reactor, mixing,reaction at 50-100 deg.C for 5-10 min, adding catalyst, and reaction for 5-10 min. It can also be prepared from low-viscosity benzoxazine intermediate and bimaleimide resin.

Owner:SICHUAN UNIV

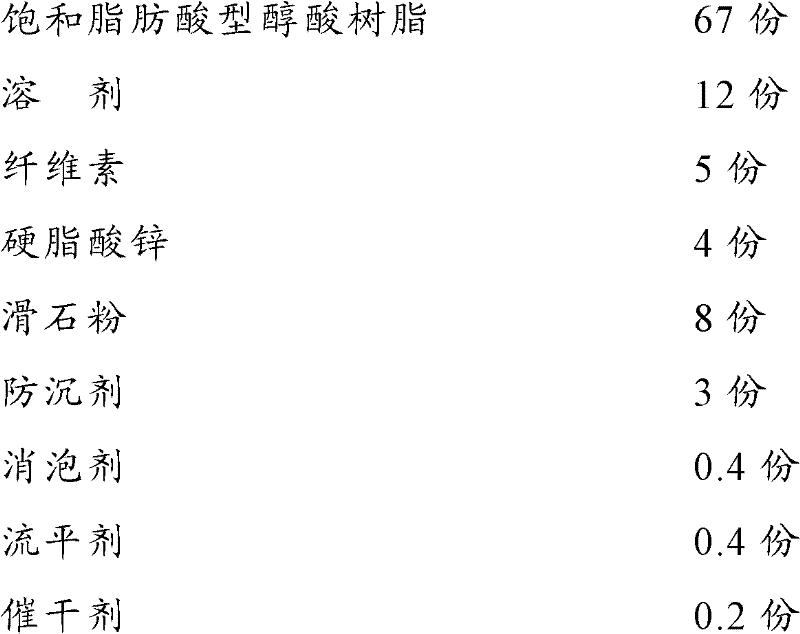

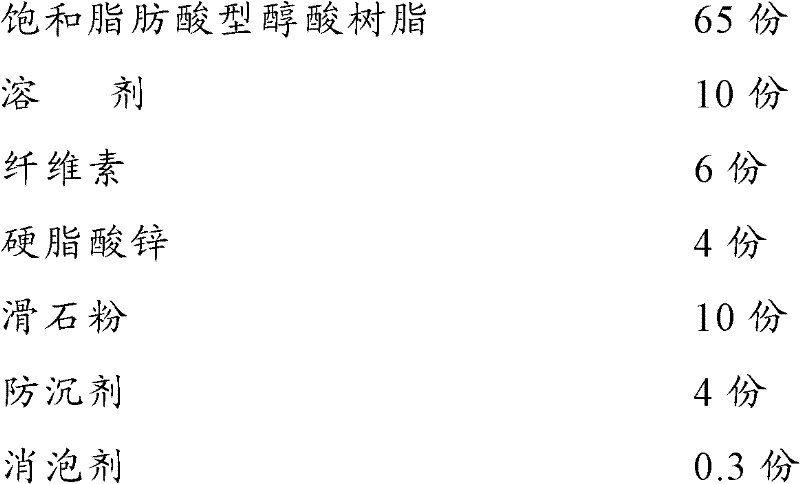

Two-component polyurethane coating and preparation method thereof

The invention provides a two-component polyurethane coating, comprising an A component and a B component, wherein the A component comprises fatty acid-type alkyd resin, cellulose, zinc stearate, talcum powder, anti-settling agent, anti-foaming agent, flatting agent, drier and solvent; the B component comprises toluene diisocyanate (TDI) trimer, toluene diisocynate additive product and solvent. The invention also provides a preparation method of the two-component polyurethane coating. The two-component polyurethane coating takes saturated fatty acid-type alkyd resin as main film-forming substance, adds the cellulose and mixes with TDI trimer and TDI additive product as curing agent, so as to be helpful for accelerating the drying of the coating and ensure the mechanical properties of the film. The two-component polyurethane coating provided by the invention has short polishing time which is not more than 1.5 h, excellent film mechanical property, and achieves H-level hardness and 1-level adhesive force.

Owner:珠海展辰新材料股份有限公司

Method for activating waste concrete micro powder

InactiveCN102992669AFast curing reactionFull curing reactionSolid waste managementRoom temperatureSodium silicate

The invention relates to a method for activating waste concrete micro powder, comprising the following steps of: (1) mixing waste concrete micro powder and powdered sodium silicate, heating to 250-350 DEG C, preserving heat for 1-2 hours, and decreasing the temperature to room temperature, wherein the weight of the added powdered sodium silicate is 1-3% of that of the added waste concrete micro powder; and (2) mixing the mixture of the waste concrete micro powder and the powdered sodium silicate with desulfurization gypsum and an admixture, grinding for 15-60 minutes to obtain the powder with the fineness and the specific surface area of more than 450m<2> / kg, wherein the weight of the desulfurization gypsum is 1-5% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate, and the weight of the admixture is 1-3% of that of the mixture of the waste concrete micro powder and the powdered sodium silicate. The method can improve the activity of the waste concrete micro powder so that the waste concrete micro powder is fully utilized.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

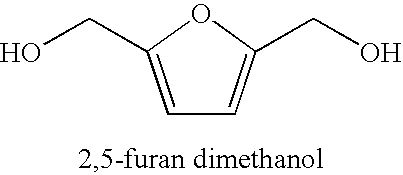

Accelerated furanic aggregate binders from bio-derived components

InactiveUS20080125517A1Reduce environmental impactImprove performanceFoundry mouldsFoundry coresProduction rateFuran

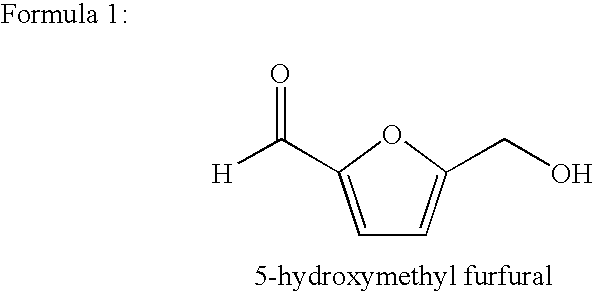

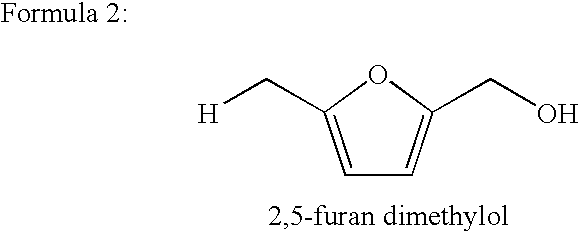

Broadly, the invention provides for newly available bio-derived formaldehyde-free furanic materials for aggregate binding. A specific example is aggregate binding for forms used in the metal casting process. The inventive binder formulations involve the use of 2,5-furan dimethanol and other “filler” components for high productivity and fast tensile development without formaldehyde, urea, urea-formaldehyde or formaldehyde containing compositions.

Owner:BATTELLE MEMORIAL INST

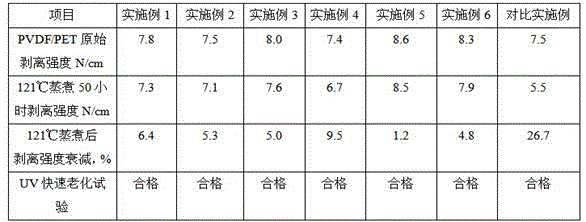

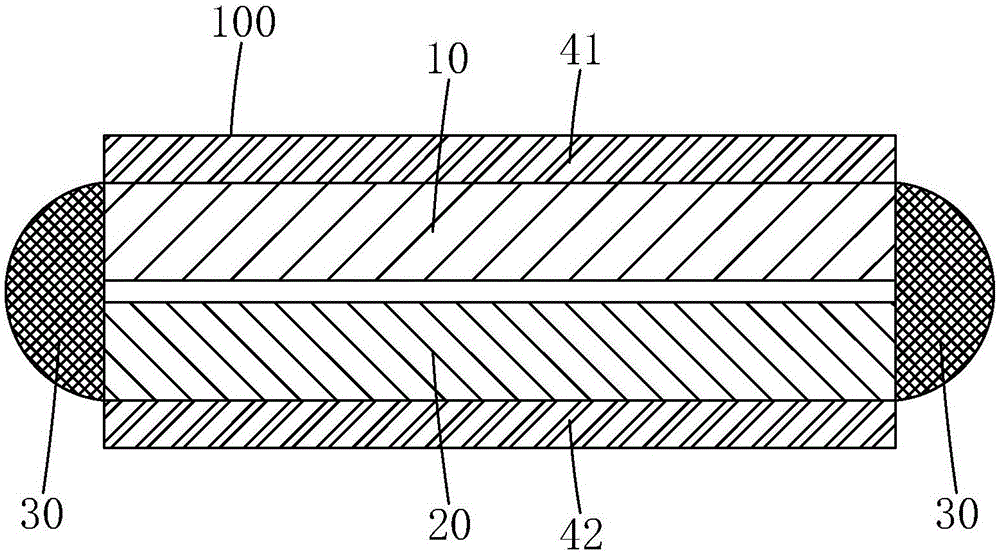

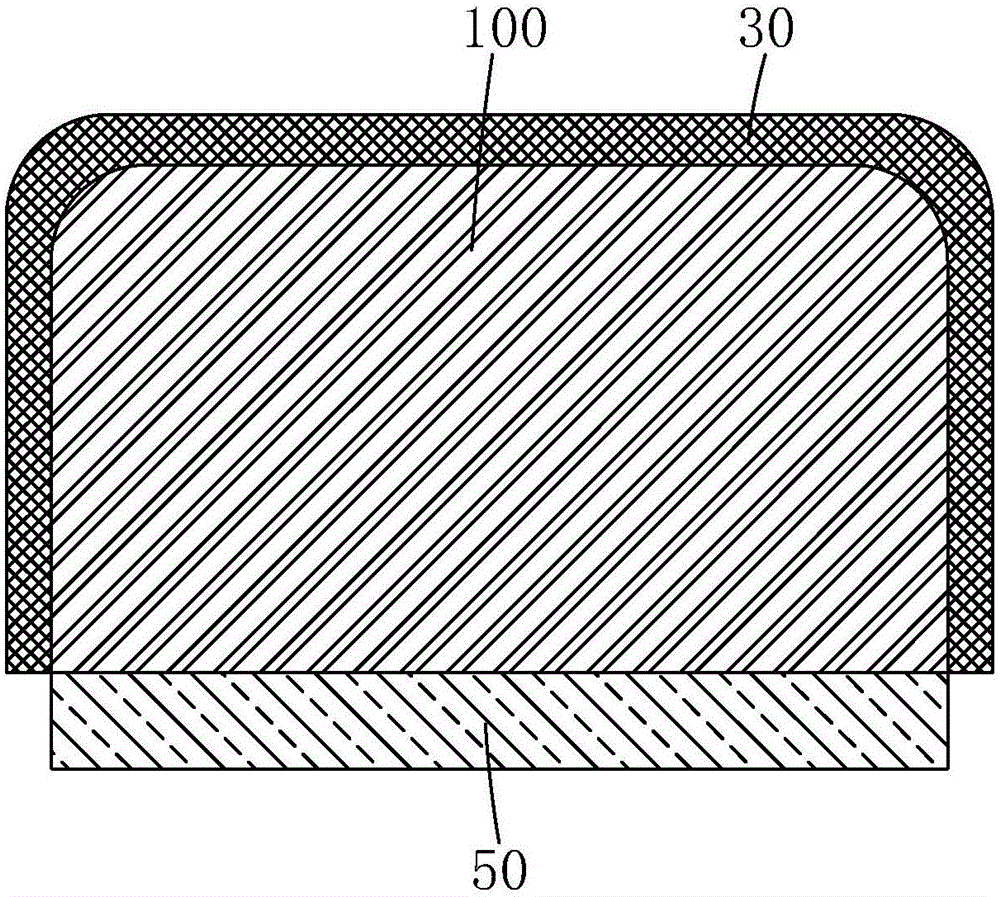

Bi-component composite adhesive for solar power back panel, and preparation method thereof

InactiveCN104804698AImprove temperature resistanceImprove hydrolysis resistancePolyureas/polyurethane adhesivesMacromolecular adhesive additivesAdhesiveCarbon chain

The invention relates to a bi-component composite adhesive for a solar power back panel, and a preparation method thereof. The adhesive consists of a component A and a component B, wherein the component A mainly comprises dipropylene glycol, hydroxypivalyl hydroxypivalate, 2,4-diethyl-1,5-pentanediol, terephthalic acid, phthalic anhydride, 1,12-dodecanoic acid, a hydrolysis-resistant stabilizing agent, ethyl acetate and a small amount of organotin catalyst, and the component B is an aliphatic polyisocyanate curing agent; the weight ratio of the component A to the component B is (10-16): 1. According to the bi-component composite adhesive, through a simple esterification synthesis reaction, high-hydrophobicity dibasic alcohol and long-carbon-chain dibasic acid are introduced to prepare polyester polyol which is good in temperature resistance and hydrolysis resistance; through the addition of the catalyst and the hydrolysis-resistant stabilizing agent, the curing reaction speed of the adhesive is further accelerated, and the hydrolysis resistance of the cured adhesive is further improved. The composite adhesive prepared by the invention is applied to the solar power assembly back panel to endow the solar power assembly back panel with better UV resistance, hydrolysis resistance and aging resistance.

Owner:WUHAN DIAPH TECH CO LTD

Photocurable adhesive, preparation method and application thereof

ActiveCN112126402AHigh functionalityMany branch pointsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

The invention provides a photocurable adhesive, a preparation method and application thereof. The photocurable adhesive is prepared from acrylate-terminated hyperbranched polyester, polyurethane acrylate, epoxy resin, a reactive diluent, a silane coupling agent, a photoinitiator and a photosensitizer, wherein the reactive diluent comprises an acrylate reactive diluent and an epoxy compound reactive diluent, and the photoinitiator comprises a free radical photoinitiator and a cationic photoinitiator. Acrylate-terminated hyperbranched polyester, polyurethane acrylate and epoxy resin are taken asreaction monomers, the acrylate reactive diluent and the epoxy compound reactive diluent are compounded to form a mixed diluent, and under the action of a free radical photoinitiator and a cationic photoinitiator, a cationic and free radical dual-curing system can be carried out, and moreover, the compatibility of the components in the system is good, and the prepared adhesive is relatively goodin overall performance.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Side edge shading glue and no-border display device

ActiveCN106554650AHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

The invention provides side edge shading glue and a no-border display device. The side edge shading glue comprises oligomer containing polymerizable groups, reactive monomers, photoinitiator, black dye, carbon black, graphene and additives. An adopted resin system composed of the oligomer containing the polymerizable groups, the reactive monomers and the photoinitiator has a high curing reaction speed under UV irradiation; by adding the carbon block for increasing black, the side edge shading glue has a high OD value, the color of the carbon black is fixed, and the situation that color fading is caused because of long time, and consequently insufficient shading is caused is avoided; a method that a dispersion agent is adopted for dispersing the carbon black and a polymer cross-linked network to fix the carbon black makes the side edge shading glue free of the conditions of precipitation and uneven dispersion of the carbon black; and in addition, by adding the graphene, the flexibility and the heat conduction performance of the side edge shading glue can be improved, and further, static electricity on the surface of a display panel can also be removed by means of the heat conduction performance of the graphene.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

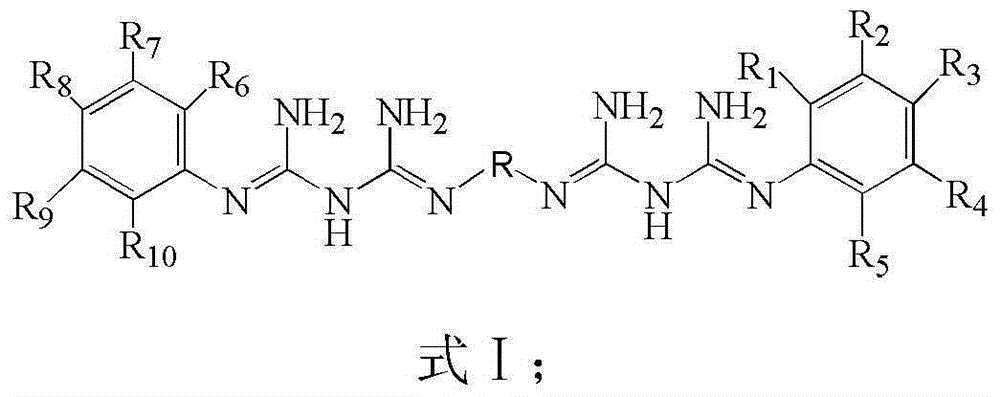

Dicyandiamide type epoxy resin curing agent and preparation method and application thereof

ActiveCN105237737AFast curing reactionLow curing temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyChemical synthesis

The invention belongs to the technical field of chemical synthesis and particularly provides a dicyandiamide type epoxy resin curing agent and a preparation method and application thereof. The dicyandiamide type epoxy resin curing agent comprises a compound of the structure shown in formula I. The curing agent is structurally a dicyandiamide derivative type, can be dissolved in multiple types of organic solvent and mixed solvent, contains various curing groups, can conduct a curing reaction with epoxy resin rapidly and lowers the curing temperature. The compound serves as a latent curing agent for obtaining a one-component adhesive, a cure product after curing is good in heat resistance, and the mechanical property is remarkably improved as well compared with dicyandiamide.

Owner:国科广化(南雄)新材料研究院有限公司

Halogen-free thermosetting resin composition and prepreg and printed circuit laminate employing halogen-free thermosetting resin composition

InactiveCN107177030AHigh TgHigh phosphorus contentSynthetic resin layered productsElectrical equipmentHalogenCyanate compound

The invention relates to a halogen-free thermosetting resin composition and a prepreg and a printed circuit laminate employing the halogen-free thermosetting resin composition. An organic condensate of the halogen-free thermosetting resin composition comprises the ingredients in parts by weight (based on 100 parts): (A) 5-50 parts of cyanate resin; (B) 5-40 parts of polyphenylether resin; (C) 5-30 parts of phosphoric bisphenol polymer; (D) 30-60 parts of halogen-free epoxy resin. The prepreg and the printed circuit laminate made from the halogen-free thermosetting resin composition, provided by the invention, have high glass transition temperature, excellent dielectric properties, low water absorption rate, high heat resistance, high peel strength, excellent humidity resistance and good process processability, can achieve no halogen and flame retardance and reaches UL94 V-0.

Owner:GUANGDONG SHENGYI SCI TECH

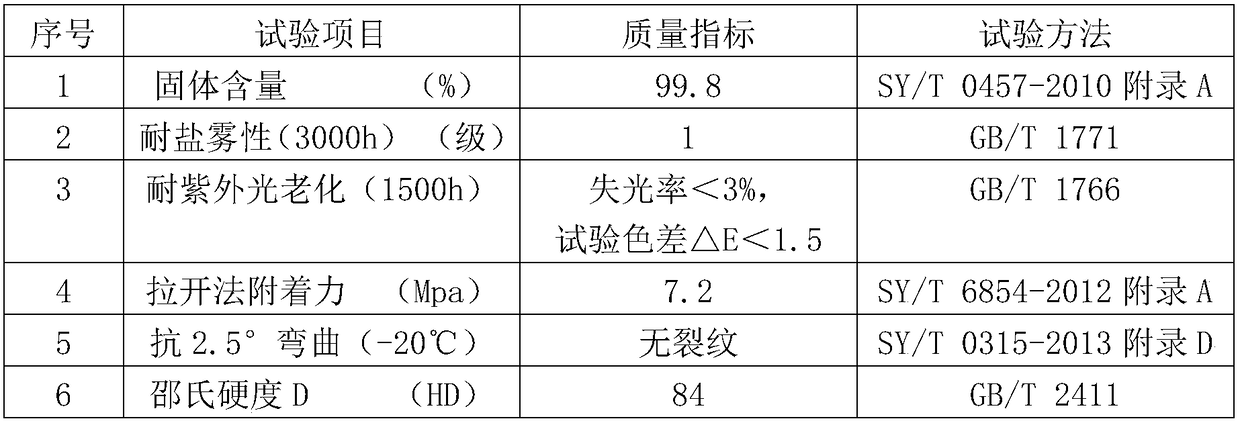

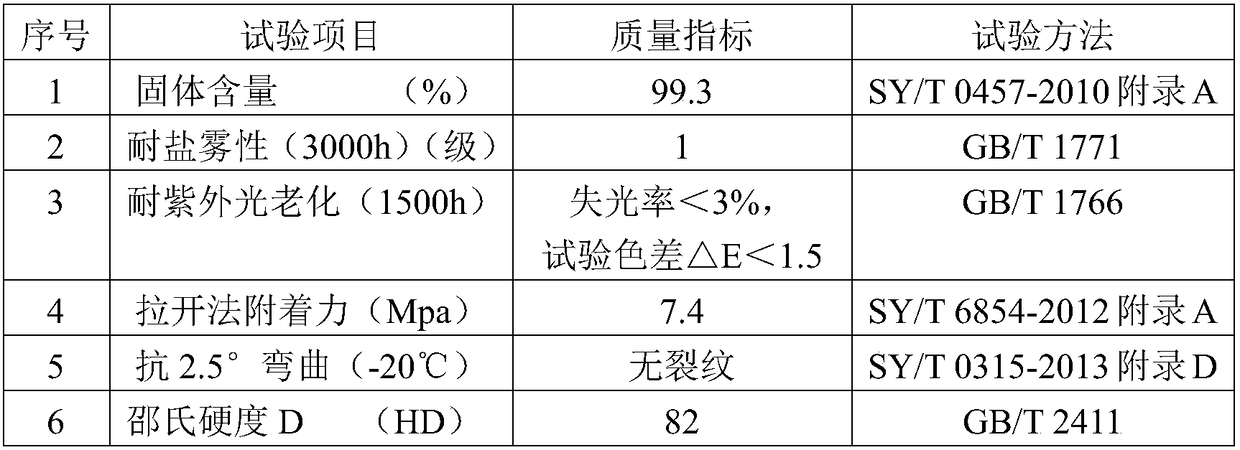

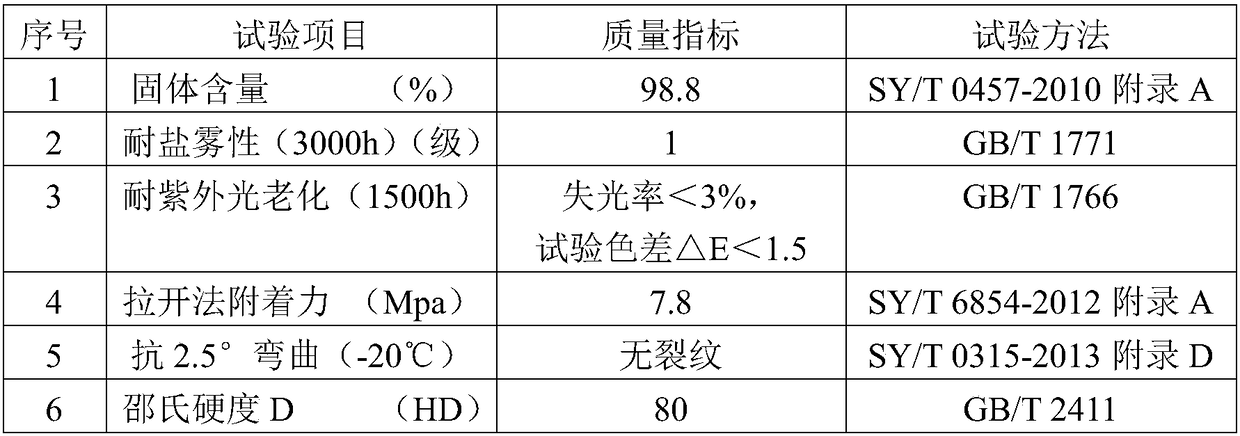

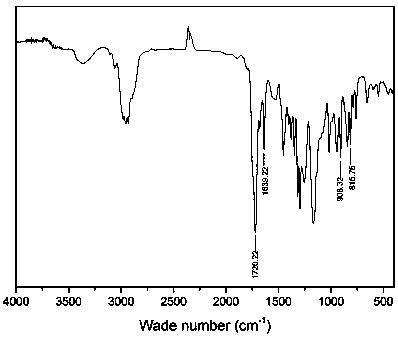

Solvent-free polyurea weather-resistant anticorrosion coating and method for preparing same

InactiveCN109439158AGood flexibility at low temperatureImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsAbove groundSolvent free

The invention discloses solvent-free polyurea weather-resistant anticorrosion coating. The solvent-free polyurea weather-resistant anticorrosion coating comprises components A and component B. The components A are hexamethylene diisocyanate curing agents with the solid contents of 100% by weight; the components B comprise, by weight, 40-50 parts of parahelium polymers, 0.3-0.5 part of dispersing agents, 0.3-0.5 part of defoaming agents, 0.8-1 part of thixotropic agents, 3-5 parts of coupling agents, 7-10 parts of titanium dioxide, 7-10 parts of sericite and 23-42 parts of glass powder; a weight ratio of the components A to the components B is 27:100-34:100. The solvent-free polyurea weather-resistant anticorrosion coating has the advantages that the solvent-free polyurea weather-resistantanticorrosion coating can be used for the outer walls of above-ground steel storage tanks and the outer surfaces of non-heat-insulation steel overhead pipelines; the solvent-free polyurea weather-resistant anticorrosion coating is good in low-temperature flexibility and is ultrahigh in bond force with the surfaces of coated objects; the solvent-free polyurea weather-resistant anticorrosion coatingis sufficient in abrasion-resistant hardness and ultrahigh in ultraviolet aging resistance and salt spray resistance; the solid content of the solvent-free polyurea weather-resistant anticorrosion coating can reach 98% at least, and the solvent-free polyurea weather-resistant anticorrosion coating is wide in curing reactive environmental temperature interval; curing reaction can be quickly carried out without curing agents or accelerators; the solvent-free polyurea weather-resistant anticorrosion coating is free of sagging when thickly coated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Silk-screen UV glaze printing ink and preparation method thereof

The invention discloses silk-screen UV glaze printing ink and a preparation method thereof, and belongs to the technical field of printing ink and preparation thereof. The printing ink is prepared from 28-32% of epoxy modified acrylate, 18-22% of urethane acrylate, 8-12% of tri(propylene glycol)diacrylate, 18-22% of 1,6-hexamethylene diacrylate, 6-10% of a 184 macroinitiator, 3-7% of an active-amine auxiliary photoinitiator, 0.8-3% of an organosilicone flatting agent, 0.8-3% of an organosilicone antifoaming agent and 3-7% of fumed silica, and is prepared by processes of mixing, stirring at a high speed, grinding, and the like. The preparation method is simple. The printing ink prepared by the method has a transparency effect and a matte effect, thus satisfying a conceive of applying the technical quality of blue and white porcelain and other famous porcelain in history to packaging and printing, and simulating the glaze quality, of the porcelain, that is mild and humid like jade. The printing ink provided by the invention has high environmental protection property. The VOCs smell residue totally reaches requirements of the national standards.

Owner:ZHEJIANG MINONG CENTURY GRP +1

Dual-curing unsaturated polyester white primer and preparation method thereof

ActiveCN105623493AIncrease curing cross-linking pointQuick responsePolyurea/polyurethane coatingsToluene diisocyanateOxygen

Owner:CHENGDU YOUPIN CHEM CO LTD

Silk-screening printing ink with high flexibility and high brightness

The invention relates to printing ink, in particular to silk-screening printing ink with high flexibility and high brightness. The silk-screening printing ink with high flexibility and high brightness is characterized by comprising the following components in percentage by weight: 44 to 48 percent of bifunctional polyurethane resin, 16 to 20 percent of tetra-functional polyester resin, 9 to 13 percent of amine modified acrylic resin, 11 to 15 percent of acrylic ester monomer, 1 to 4 percent of fluorocarbon surface modifier, 1 to 5 percent of macroinitiator BP, 1 to 3 percent of organic silicon defoaming agent, 1 to 4 percent of organic silicon polyether modified flatting agent and 1 to 4 percent of bentonite. The printing ink has extremely high flexibility; and a product is difficult to crack after the printing ink is printed on the product. The printing ink has excellent weather resistance, is difficult to yellow and has high brightness after the printing ink is dried to form a film.The printing ink - does not produce byproducts after curing reaction and has low mobility and volatility, so that the printing ink has high environment friendliness, and the odor residue of volatile organic compounds (Vocs) completely meets the national standard requirement.

Owner:ZHEJIANG MINONG CENTURY GRP +1

Ultraviolet light hybrid light curing waterborne polyurethane acrylate and preparation method and application thereof

InactiveCN108948321AImprove conversion rateFast curing reactionPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateEnd-group

The present invention provides an ultraviolet light hybrid light curing waterborne polyurethane acrylate comprising the following components by weight: 100 parts of polypropylene carbonate diol, 30-75parts of isocyanate, 3-10 parts of a hydrophilic chain extender, 5 to 20 parts of hydroxyethyl methacrylate, 5 to 20 parts of glycidol, 2 to 10 parts of a salt forming agent, 1 to 10 parts of a chainextender, and 0.01 to 2 parts of a catalyst. The invention also provides a preparation method of the ultraviolet light hybrid light curing waterborne polyurethane acrylate. The end group of the ultraviolet light hybrid light curing waterborne polyurethane acrylate prepared by the method contains unsaturated double bonds and epoxy groups, the ultraviolet light hybrid light curing waterborne polyurethane acrylate can be crosslinked according to the mechanism of free radicals and cations by adding of an initiator and irradiating with ultraviolet light. The curing reaction speed is faster, and prepolymer conversion rate is higher compared with a single curing method.

Owner:GUANGDONG UNIV OF TECH

Corrosion-resistant and wear-resistant coating for mortar pump

InactiveCN106675322AUniform structureCompact structureFireproof paintsNatural resin coatingsChemical industryEpoxy

The invention discloses a corrosion-resistant and wear-resistant coating for a mortar pump, and belongs to the field of chemical industry. Specifically, the corrosion-resistant and wear-resistant coating is prepared from the following substances: modified epoxy resin, a modified filler, a modified curing agent, polyoxyethylene polyoxypropylene ether, polyoxypropylene glycerol ether, triethyl-hexyl phosphoric acid, fatty acid polyethylene glycol ester, N-acetylimidazole, tri-(dimethylaminomethyl)phenol, ethylenediamine tetraacetic acid disodium, isopentyldiol, and propylene glycol monomethyl ether. The prepared coating has a high adhesive force to a metal pump body, is uniform in film forming, compact in structure, small in structure pore, and good in corrosion resistance, has good hardness, impact resistance and comprehensive performance, and can effectively improve service quality and prolong the service life of the mortar pump.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

Vacuum electroplating UV photo-curing primer and preparation method thereof

InactiveCN111793409AIncrease cross-linking pointImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterPolymer science

The invention relates to the technical field of vacuum electroplating, in particular to a vacuum electroplating UV photocuring prime coat and a preparation method thereof. The vacuum electroplating UVphoto-curing prime coat is prepared from the following components by weight percentage: 10-20 parts of epoxy acrylic resin, 10-15 parts of polyester acrylate and 10-15 parts of polyurethane acrylic resin; 0.3 to 0.5 part of an adhesion promoter; 15 to 25 parts of an active monomer diluent; 3-5 parts of a photoinitiator; and 30 to 40 parts of a cosolvent; and the adhesion promoter is vinyl trimethoxy silane. In the present application, an adhesion promoter is added into the vacuum electroplating UV photocuring prime coat; vinyl trimethoxy silane is subjected to a double bond addition reactionin the presence of a photoinitiator, and is copolymerized or grafted into a prepolymer, alkoxy and silica bonds are introduced, and the alkoxy increases the crosslinking point of the prepolymer duringcrosslinking and curing, so that the crosslinking density is improved, and the effect of improving the adhesive force of a cured coating is achieved.

Owner:上海蓝宝涂料有限公司

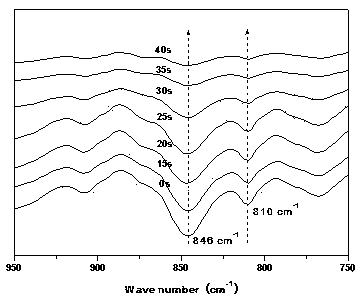

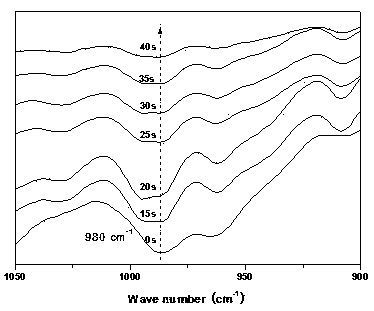

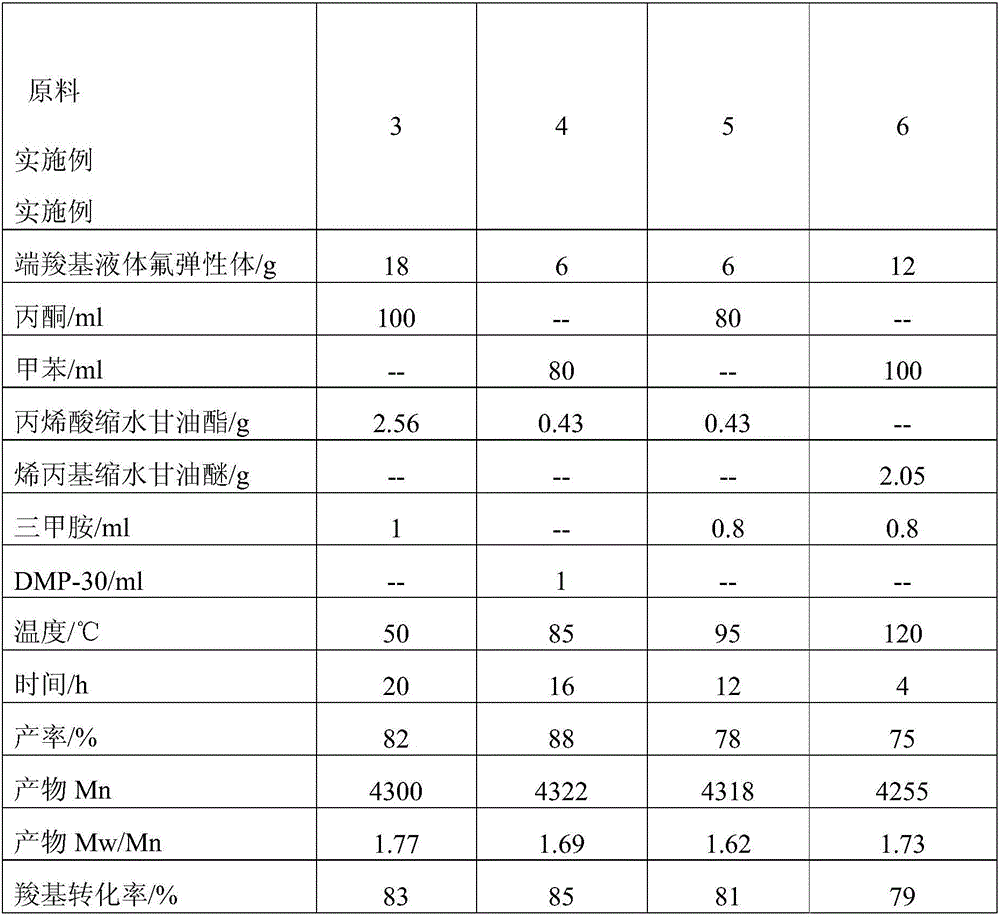

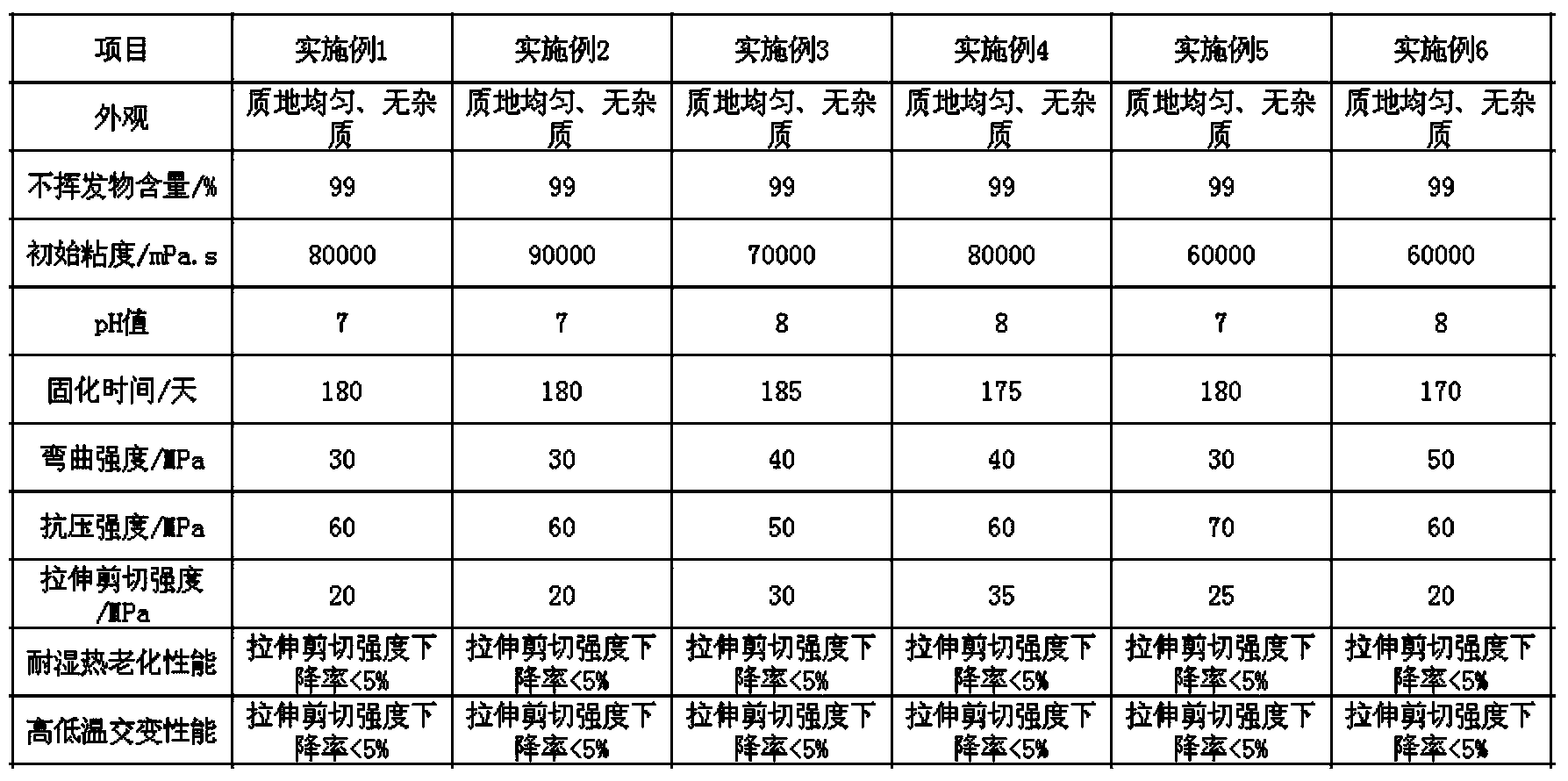

Preparation method of vinyl-terminated liquid fluoroelastomer supportive of room-temperature quick curing

The invention discloses a preparation method of vinyl-terminated liquid fluoroelastomer supportive of room-temperature quick curing. The preparation method includes: dissolving carboxyl-terminated liquid fluoroelastomer into an organic solvent; adding an epoxy group-vinyl compound into a system; in the presence of an alkaline catalyst, stirring for reaction for 4-20 h in nitrogen atmosphere, wherein reaction temperature is controlled to 50-120 DEG C, and reaction pressure is pressure generated by the system itself. Terminated vinyl of the vinyl-terminated liquid fluoroelastomer has quite high reaction activity, curing reaction speed is high, quick curing can be realized at room temperature, and curing agent options are diverse. Curing points are positioned at two ends of a liquid polymer, so that tensile strength and elongation rate of a curing product can realize optimal balance. The curing product has high resistance to chemical media and can be used in harsh environment. The preparation method is simple and easy to implement, free of danger, low in cost and high in yield.

Owner:BEIJING UNIV OF CHEM TECH

Prestressed steel strand slow-binding agent with good heat resistance and 6-month curing time

InactiveCN104388031AHigh activityHigh reactivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPhenol

The invention relates to a prestressed steel strand slow-binding agent with good heat resistance and 6-month curing time. The prestressed steel strand slow-binding agent is prepared from the following components in parts by weight: 100 of epoxy resin, 5-15 of a diluent, 20-25 of an amine curing agent and 50-80 of filler. According to the prestressed steel strand slow-binding agent disclosed by the invention, as modified aromatic amine with high curing temperature is used as one of the components of the curing agent, high heat resistance of the prestressed steel strand slow-binding agent is ensured; meanwhile, in order to overcome the disadvantages of low activity and toughness of the aromatic amine, phenol-aldehyde amine is added in the curing agent to improve the activity and the heat resistance, the polyether amine is added in the curing agent to improve the toughness, and the three types of the modified aromatic amine, the phenol-aldehyde amine and the polyether amine are uniformly mixed according to a certain ratio to prepare the curing agent with good heat resistance and high toughness.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

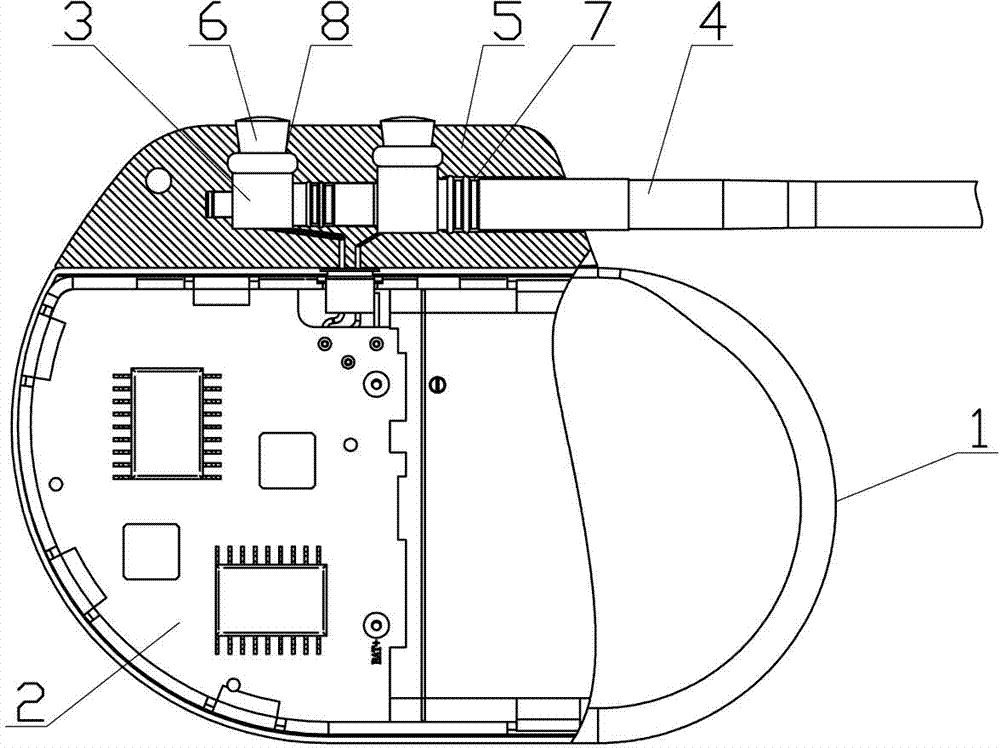

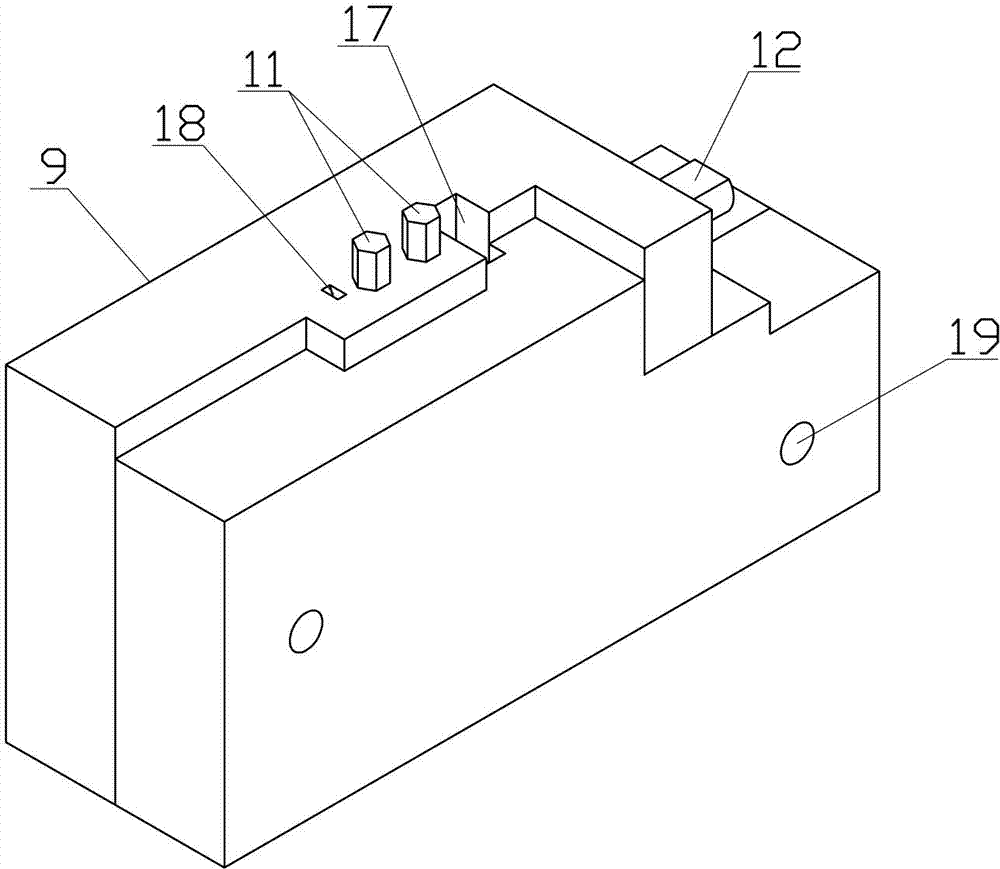

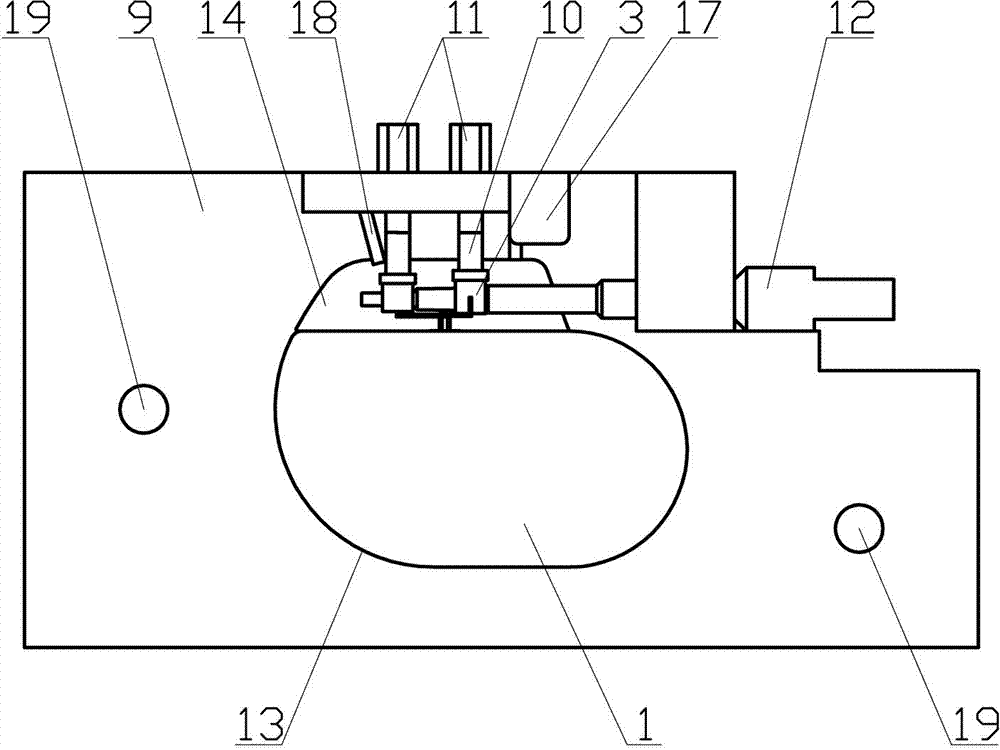

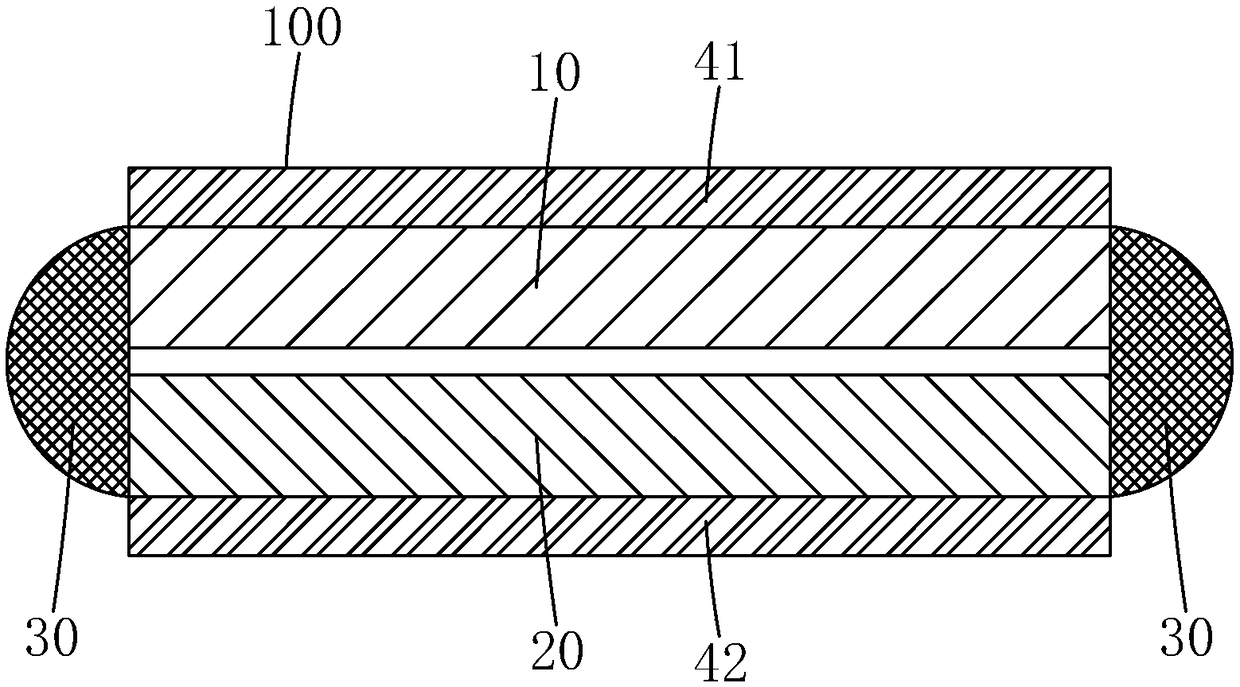

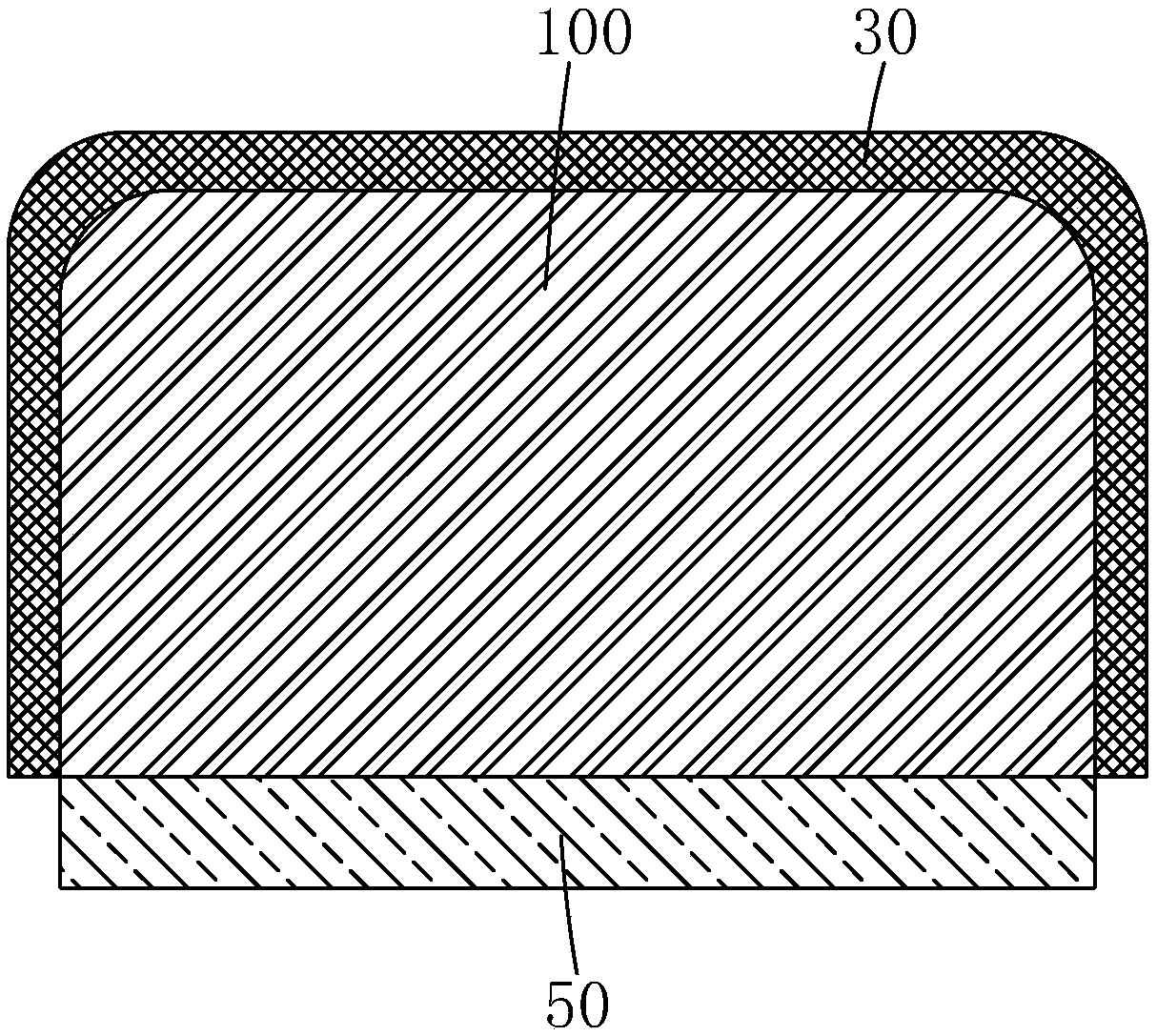

Implantable heart pacemaker packaging device and implantable heat pacemaker packaging method

InactiveCN102641555BQuality improvementEasy to demouldArtificial respirationVolume variationCardiac pacemaker electrode

The invention relates to an implantable heart pacemaker packaging device. The packaging device comprises a packaging mould, a sealing plug cavity forming mould, a positioning rod for fixing the sealing plug cavity forming mould and an electrode positioning mandrel for forming a pace-making electrode cavity and for controlling and determining a position of an electrode square block, wherein a titanium shell holding cavity, a top cover forming cavity, a positioning rod connection hole, an electrode positioning mandrel connection hole, a feeding port and a vent port are arranged inside the packaging mould. Since the packaging device is ingeniously adopted, the top cover forming an implantable heart pacemaker is packaged to the top part of a titanium shell through a filling and sealing way, not only easiness in filling and sealing is achieved, but also positions of all parts forming the packaging device are relatively stable and accurately positioned; and meanwhile, a reasonable packaging method is adopted, so that the material forming the top cover is free from having the problems such as volume variation, bubbles and the like during the entire solidification process, the stability of the shape and the size of the top cover and cavities on the top cover can be guaranteed, and the strength, transparency performance and completion of the top cover also can be guaranteed.

Owner:GUANGDONG PROV MEDICAL INSTR INST

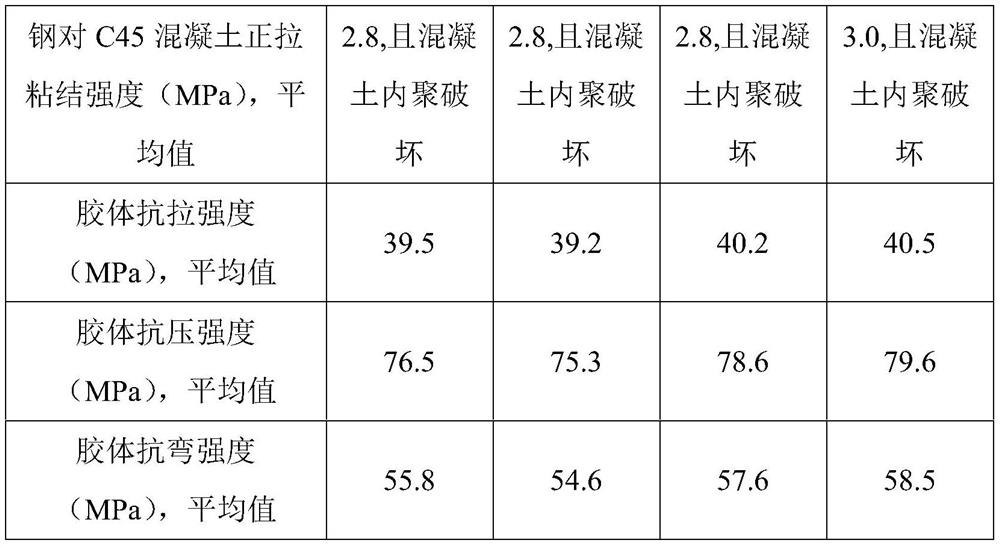

Carbon fiber cloth adhesive for underwater or humid environment reinforcement engineering and preparation method thereof

PendingCN113897160AImprove hydrophobicityImprove moisture resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementFiber

The invention discloses a carbon fiber cloth adhesive for underwater or humid environment reinforcement engineering and a preparation method thereof. The adhesive is obtained by well mixing a component A and a component B. The component A is prepared from fluorinated epoxy resin, hydroxymethyl bisphenol A type epoxy resin, bisphenol S type epoxy resin, diglycidyl aniline, trimethylolpropane triglycidyl ether, a toughening agent, water-absorbent resin, a defoaming agent, a dispersing agent, active silica powder, carbon nanotubes, cement and fumed silica. The component B is prepared from aliphatic amide polyamine, isophorone diamine, a curing agent, DMP-30, a coupling agent, a defoaming agent, a dispersing agent, active silica powder, carbon nanotubes, cement and fumed silica. The adhesive prepared by the invention has the advantages of high water interface bonding strength, high colloid mechanical strength, good toughness, strong impact resistance and fatigue resistance, good construction performance and the like, and the bonding effect and durability of the carbon fiber cloth adhesive in water environment reinforcement engineering can be remarkably improved.

Owner:山西省交通科技研发有限公司 +2

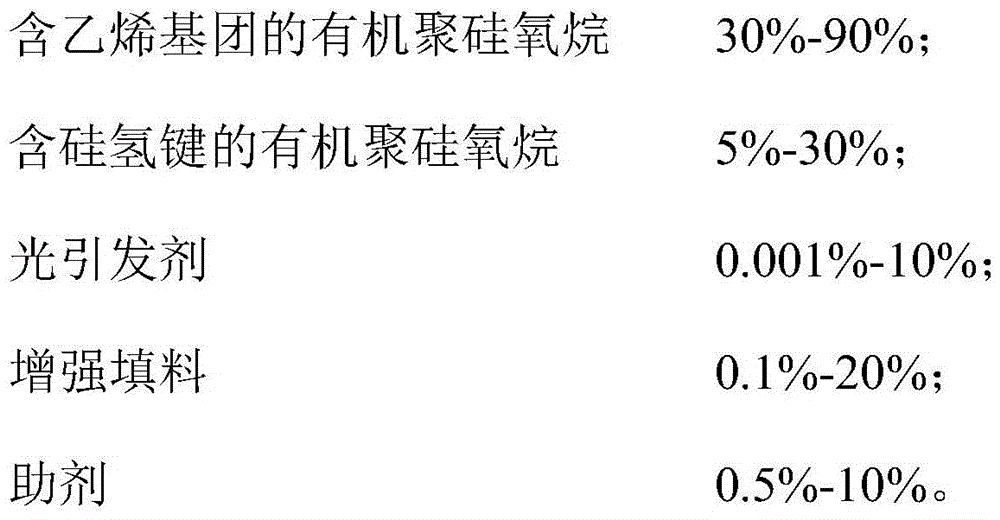

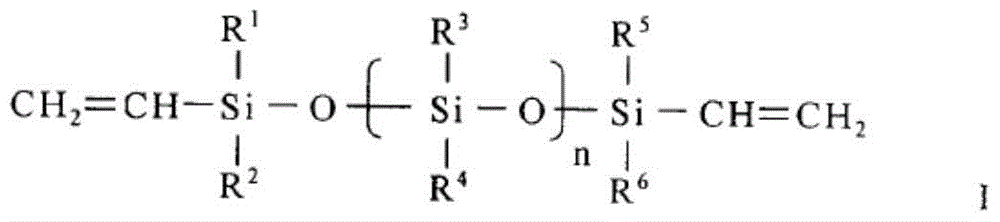

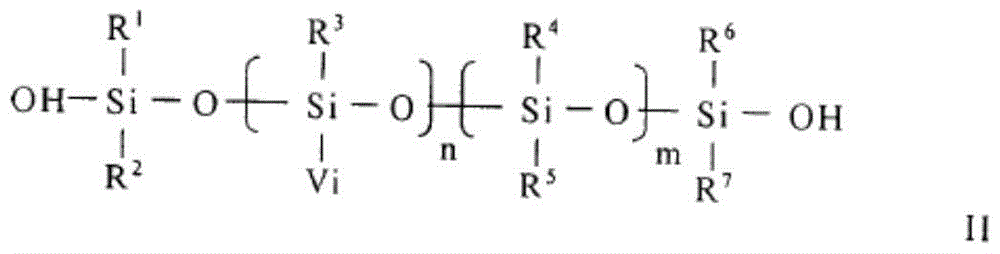

A colorless and transparent photocurable 3D printing material

The invention discloses a colorless and transparent light-cured 3D printing material and belongs to the technical field of cured materials. The printing material comprises organopolysiloxane containing a vinyl group, organopolysiloxane containing a silicon-hydrogen bond, a photoinitiator, reinforcing filler and an aid. A preparation method of the material comprises steps as follows: evenly mixing the organopolysiloxane containing the vinyl group, the organopolysiloxane containing the silicon-hydrogen bond, the reinforcing filler and the aid in percentage by mass; then adding the photoinitiator, and evenly mixing the mixture to obtain the colorless light-cured 3D printing material. The printing material has the benefits as follows: (1) the light-cured product is colorless, good in transparency and elastic; (2) the light-cured material is low in molding shrinkage, and the volume shrinkage is lower than 1.0%; (3) all components in a resin mixture participate in curing, no volatile solvent exists, and pollution is avoided; (4) the printing material is high in curing light source applicability, and the maximum curable light wavelength is 405 nm.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

Method for producing environment-friendly density boards, and special medium-low temperature solidifying agent

ActiveCN104610885APromote decompositionQuick breakdownNon-macromolecular adhesive additivesWood working apparatusFiberProduction line

The invention relates to a method for producing environment-friendly density boards, and a special medium-low temperature solidifying agent, and belongs to the technical field of the production of medium density fiberboards. The technical scheme of the method lies in that the method comprises the following steps: mixing ammonium bisulfate and ammonium polyphosphate, wherein the mass proportion of the ammonium bisulfate to the ammonium polyphosphate is 0.6-1.5, a liquid water solution with different pH values is formed according to different proportions, the mass concentration of the ammonium bisulfate in the liquid water solution is 5-20%, and the mass concentration of the ammonium polyphosphate in the liquid water solution is 3-25%; determining the pH value of the liquid water solution according to the pH value of wood fibers of fiberboards of density boards in production, wherein the pH value of the wood fibers is 7.5-8, and the pH value of the corresponding liquid water solution is 5.2-6.0. According to the method disclosed by the invention, the production capacity is not lowered under the condition of lower than 30 DEG C by the same proportion, and besides, the application effects of physical and mechanical properties and using properties of products can be guaranteed; under the production condition of medium-low temperature and in the use of the special medium-low temperature solidifying agent, the degree of acidity cannot cause larger influence on devices, the low-temperature high-speed operation of the production line can be realized, and the service lives of the devices are prolonged.

Owner:WENAN COUNTY TIANHUA DENSITY BOARD

Side shading glue and borderless display device

ActiveCN106554650BHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

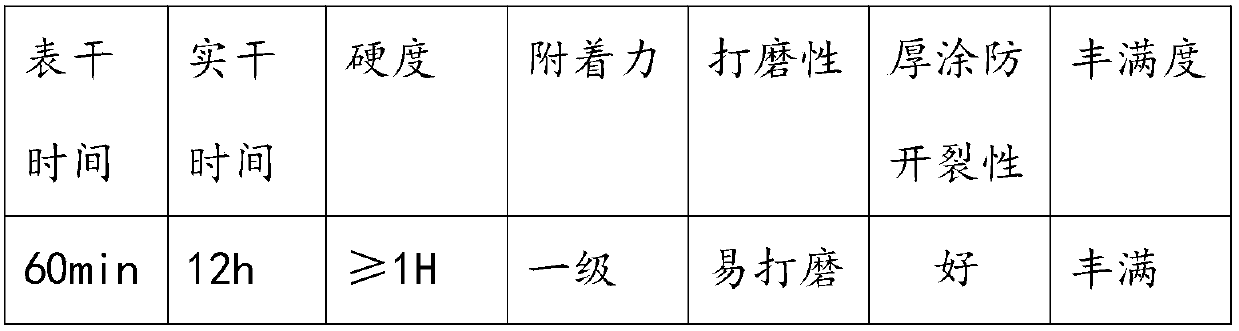

A dual cure unsaturated polyester white primer

ActiveCN105623493BIncrease curing cross-linking pointQuick responsePolyurea/polyurethane coatingsDual curePolymer science

The invention provides a dual-curing unsaturated polyester white primer and a preparation method thereof. The dual-curing unsaturated polyester white primer is composed of a main paint, a diluter, an initiator, an accelerator and a curing agent. The main paint is composed of an unsaturated polyester resin, a defoaming agent, a dispersing agent, an anti-settling agent, a leveling agent, a polymerization inhibitor, a sanding agent, titanium white, a filler and an active solvent. The curing agent is composed of a TDI (toluene diisocyanate) addition product and polyurethane-grade butyl acetate. The diluter is composed of butyl acetate, styrene and toluene. The unsaturated polyester resin is an air-drying unsaturated polyester resin, thereby avoiding the phenomenon of undried and sticking paint film surface since oxygen can easily have the polymerization inhibition effect in the construction process. The polyurethane contained in the raw materials can increase the curing crosslinking points of the unsaturated polyester, enhance the crosslinking reaction density, increase the curing reaction speed, enhance the sanding property and shorten the application production cycle, has the advantages of excellent adhesive force and favorable anti-cracking effect in case of thick coating, and completely satisfies the furniture application requirements.

Owner:CHENGDU YOUPIN CHEM CO LTD

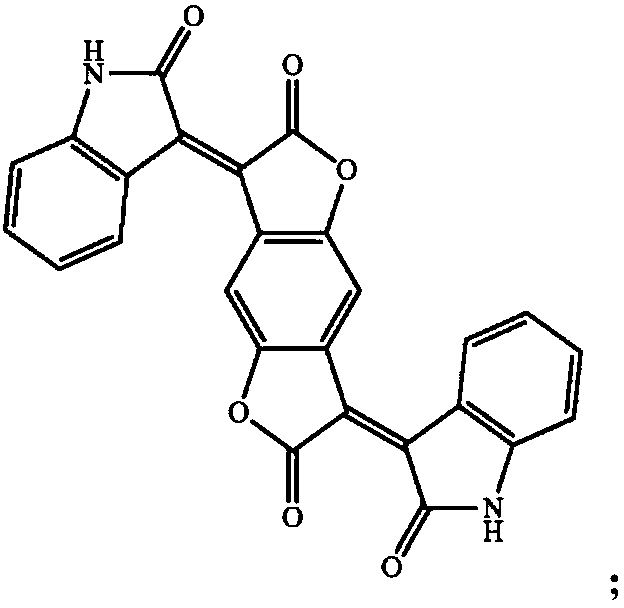

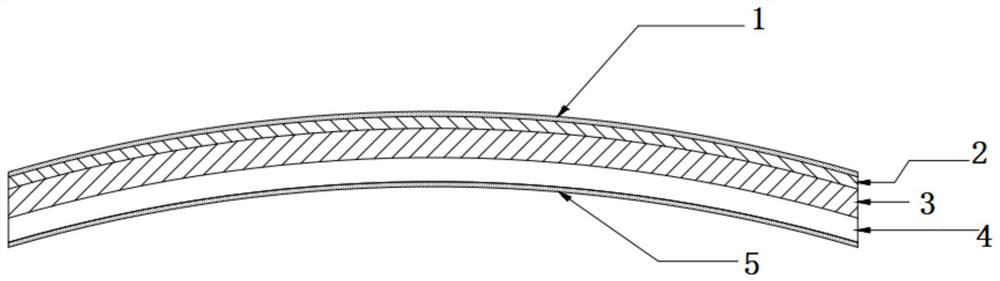

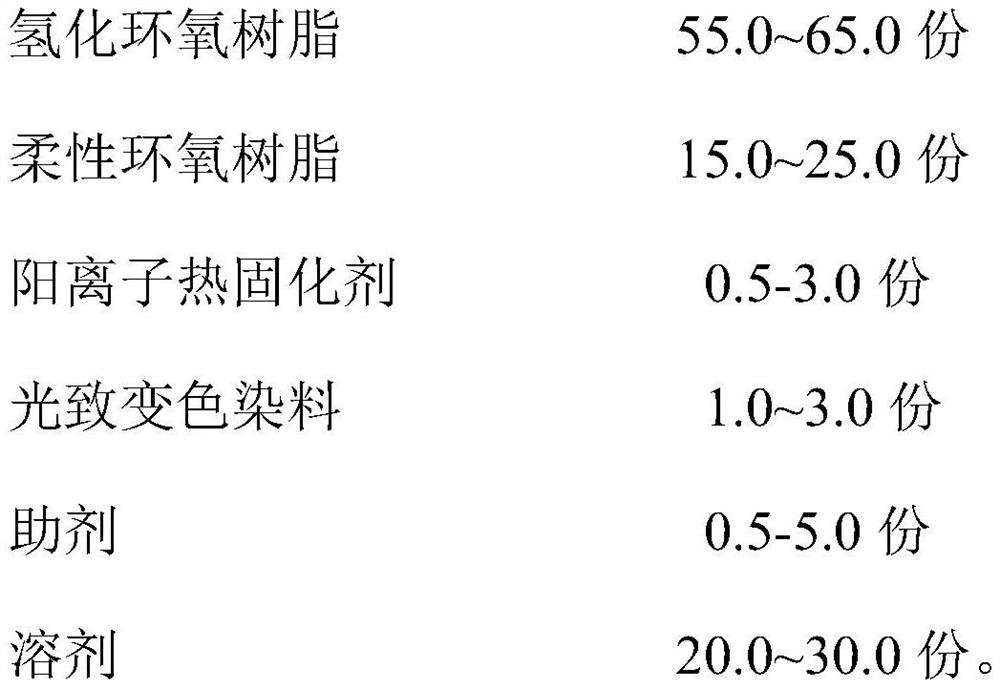

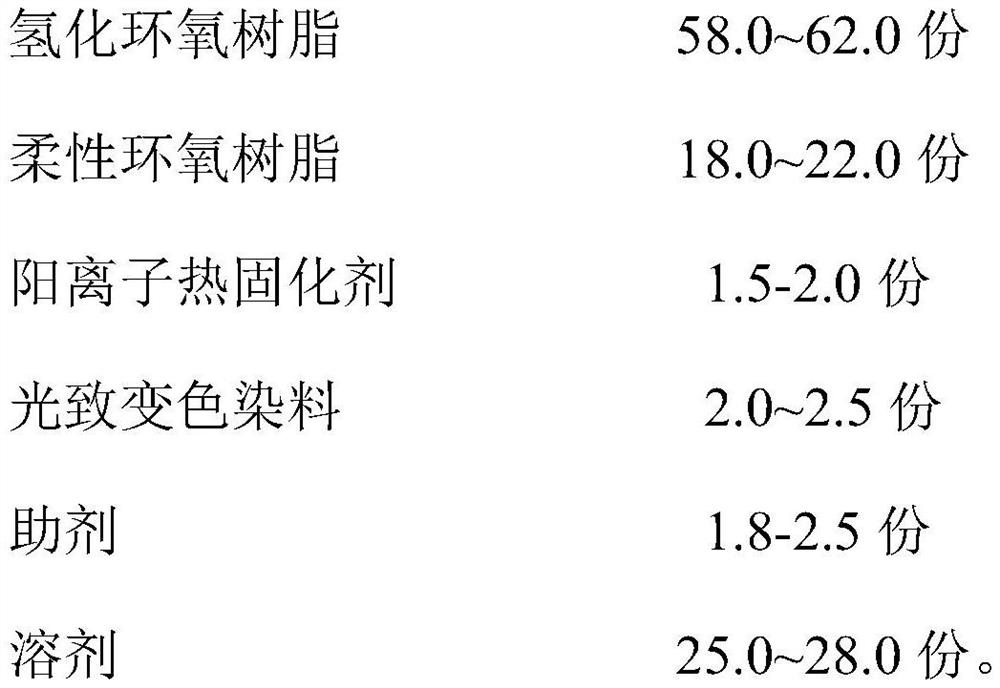

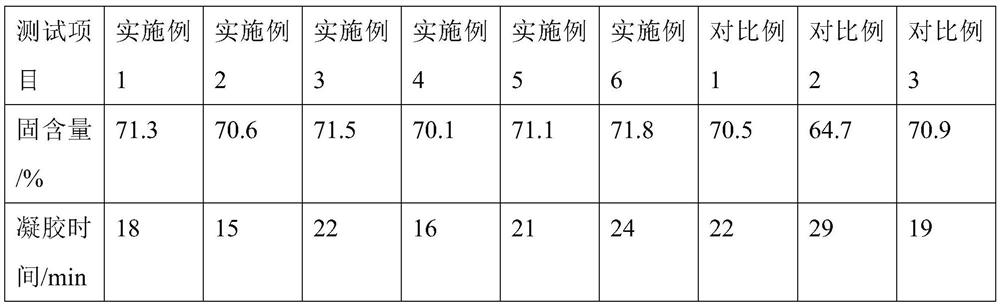

Photochromic spectacle lens with coating prepared from epoxy resin

ActiveCN111830733ALow curing temperatureFast curing reactionEpoxy resin coatingsOptical partsWeather resistanceDouble bond

The invention relates to a photochromic spectacle lens with a coating prepared from epoxy resin. The photochromic coating is formed by curing a composition consisting of hydrogenated epoxy resin, flexible epoxy resin, a cationic thermal curing agent, photochromic dye, an auxiliary agent and a solvent. The cationic thermal curing agent is applied, so that the coating curing temperature is reduced,the reaction temperature can be reduced to 80 DEG C or below, and the lens is not yellowed; the curing time of the coating is shortened, the reaction is rapid, and the epoxy resin can be completely cured within 0.5 hour; the curing agent does not react with the photochromic dye, so that abnormal color of the spectacle lens is avoided. The coating liquid prepared from the epoxy resin has good storage stability. The molecular structure of the hydrogenated epoxy resin adopted by the invention does not contain benzene rings, so that the fracture defect of double bonds is overcome, the outdoor weather resistance is greatly improved, and the yellowing resistance is very good; and the flexible epoxy resin is added to adjust the hardness of the coating, thereby adapting to the flexibility and hardness requirements of the spectacle lens coating and ensuring the high color change speed of the spectacle lens.

Owner:浙江伟星光学股份有限公司

Plaster for acid-resistant anti-corrosion carbon brick and preparation method of plaster

The invention provides plaster for an acid-resistant anti-corrosion carbon brick. The plaster comprises the following raw materials in percentage by mass: 10%-25% of furfuryl alcohol resin, 5%-15% of phenolic resin, 0.5%-3% of hexamethylenetetramine, the balance of one of calcined petroleum coke, electro-forged clean coal or asphalt calcined coke, and 3%-15% of external curing agent phosphoric acid. The plaster for the acid-resistant anti-corrosion carbon brick disclosed by the invention is rapid in solidifying reaction, low in heat release, stable in chemical performance in an acid environment, and not easy to permeate.

Owner:WUGANG REFRACTORY CO LTD

Modified unsaturated polyester resin composition and preparation method thereof

The invention belongs to the technical field of unsaturated polyester resin, and particularly relates to a modified unsaturated polyester composition and a preparation method thereof. The modified unsaturated polyester composition is prepared from, by weight, 250-400 parts of epoxy resin, 100-150 parts of acrylic acid, 3-9 parts of triethyl benzyl ammonium chloride, 0.2-0.9 part of hydroquinone and 190-250 parts of hydroxyethyl acrylate, wherein the epoxy resin is prepared from pentaerythritol, glycerol, triethylene glycol and epoxy chloropropane through ring opening and ring closing. The unsaturated polyester resin disclosed by the invention does not contain styrene, and is low in odor, good in environmental protection property, high in curing speed and high in mechanical strength after being cured.

Owner:厦门纬达树脂有限公司

Epoxy resin curing agent

The invention discloses an epoxy resin curing agent which consists of the following components in parts by weight: 20-30 parts of an acid anhydride mixture, 15-18 parts of aluminum oxide, 12-14 parts of isoprene, 6-9 parts of n-butyl alcohol phenyl glycidyl ether, 5-7 parts of an asbestos fiber, 8-9 parts of polypropylene glycol diglycidyl ether and 1 part of phenyl glycidyl ether. The epoxy resin curing agent disclosed by the invention is rapid in curing reaction velocity, and the complete curing time of an epoxy resin can be shortened to 6 hours.

Owner:吴丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com