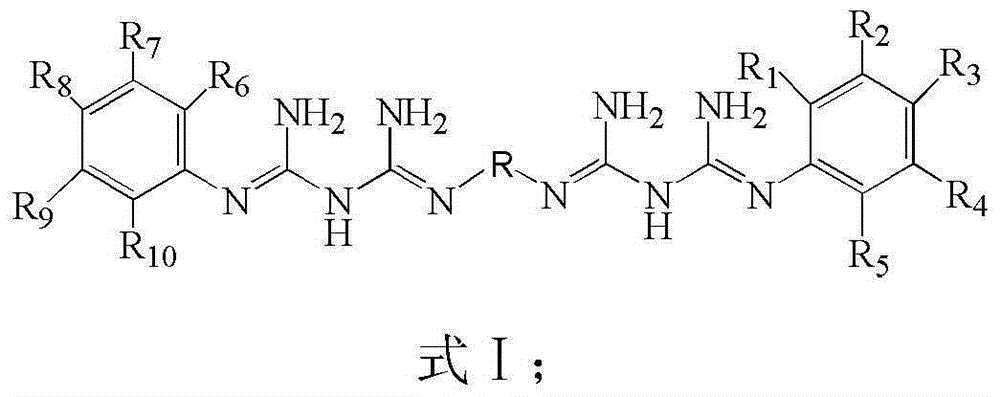

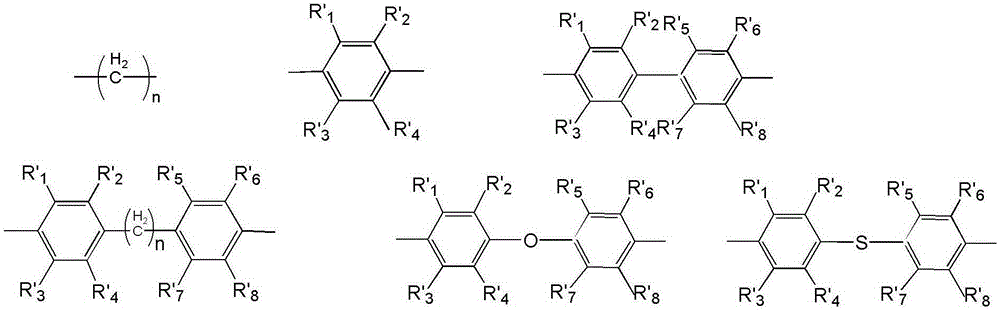

Dicyandiamide type epoxy resin curing agent and preparation method and application thereof

An epoxy resin curing and epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of complicated process and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The synthesis of embodiment 1 dicyandiamide epoxy resin curing agent

[0060] (1) Dissolve sodium dicyanamide and 4,4'-diaminodiphenylmethane in DMSO respectively to form a saturated DMSO solution; in an environment of inert gas, dissolve 4,4'-diaminodiphenylmethane The saturated DMSO solution of dicyanamide was slowly added dropwise to the saturated DMSO solution of sodium dicyanamide, reacted at 120°C for 6 hours, washed and dried to obtain a white solid;

[0061] (2) the white solid substance that step (1) is obtained is dissolved in DMSO, is made into saturated DMSO solution; Benzylamine is dissolved in DMSO, is made into saturated DMSO solution; The saturated DMSO solution of benzylamine is added dropwise to In the saturated DMSO solution of the white solid obtained in step (1), react at 90° C. for 10 h, then wash and dry to obtain a solid dicyandiamide epoxy resin curing agent, whose structural formula is shown in formula IV.

[0062]

Embodiment 2

[0063] The synthesis of embodiment 2 dicyandiamide epoxy resin curing agent

[0064] (1) Sodium dicyanamide and 4,4'-diaminodiphenylmethane were dissolved in DMSO respectively to form a saturated DMSO solution. In an inert gas atmosphere, 4,4'-diaminodiphenylmethane The saturated DMSO solution of dicyanamide was slowly added dropwise to the saturated DMSO solution of sodium dicyanamide, reacted at 80°C for 8 hours, washed and dried to obtain a white solid;

[0065] (2) the white solid substance that step (1) is obtained is dissolved in DMSO, is made into saturated DMSO solution, and benzylamine is dissolved in DMSO, is made into saturated DMSO solution; The saturated DMSO solution of benzylamine is added dropwise to In the saturated DMSO solution of the white solid obtained in step (1), react at 120° C. for 4 h, then wash and dry to obtain a solid dicyandiamide epoxy resin curing agent, whose structural formula is shown in formula IV.

Embodiment 3

[0066] The synthesis of embodiment 3 dicyandiamide epoxy resin curing agent

[0067] (1) Sodium dicyanamide and 4,4'-diaminodiphenylmethane were dissolved in DMSO respectively to form a saturated DMSO solution. In an inert gas atmosphere, 4,4'-diaminodiphenylmethane The saturated DMSO solution of dicyanamide was slowly added dropwise to the saturated DMSO solution of sodium dicyanamide, reacted at 100°C for 7 hours, washed and dried to obtain a white solid;

[0068] (2) the white solid substance that step (1) is obtained is dissolved in DMSO, is made into saturated DMSO solution; Benzylamine is dissolved in DMSO, is made into saturated DMSO solution; The saturated DMSO solution of benzylamine is added dropwise to In the saturated DMSO solution of the white solid obtained in step (1), react at 100° C. for 8 hours, then wash and dry to obtain a solid dicyandiamide epoxy resin curing agent, the structural formula of which is shown in formula IV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com