Photochromic spectacle lens with coating prepared from epoxy resin

A technology for preparing and hydrogenating epoxy resin, which is applied in the field of photochromic eyeglass lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

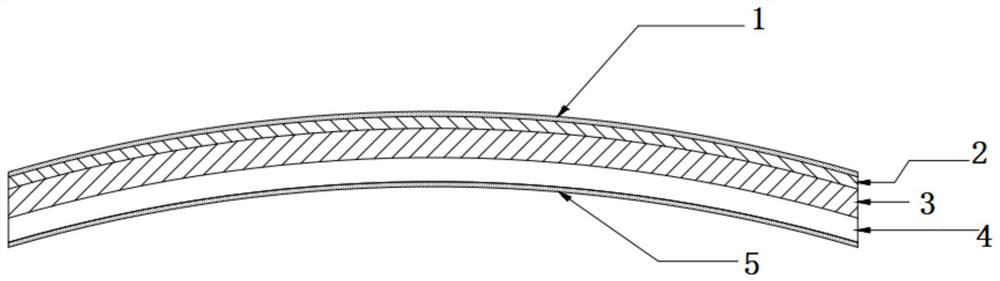

[0033] See attached figure 1 , A color-changing spectacle lens coated with epoxy resin, comprising a color-changing coating, characterized in that the lower surface of the color-changing coating 3 is attached to the upper surface of the substrate 4, and the upper surface of the color-changing coating is provided with a protective layer 2 and an upper surface Hard layer 1 is provided, and a lower hard layer 5 is provided on the lower surface of the substrate.

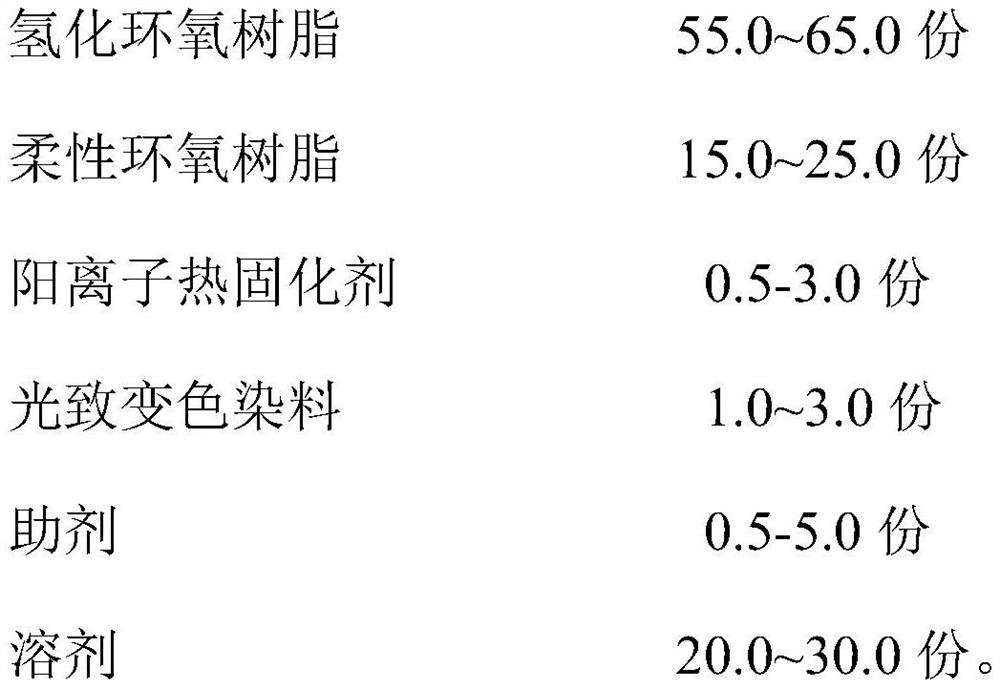

[0034] The material and formula of the color changing coating are as follows:

[0035]

[0036]

[0037] Accurately weigh EP-4080E, polypropylene glycol diglycidyl ether, n-butanol and 50% of the formula xylene, add them to the batching tank at room temperature, slowly add BYK-333 under stirring, and stir until all materials are completely dissolved, continue Stir for 1 hour. Take another small pot, add the weighed photochromic dye, cationic thermal curing agent, and then add the remaining 50% formula amount of xylene, stir...

Embodiment 2

[0043] See attached figure 1 , A color-changing spectacle lens coated with epoxy resin, comprising a color-changing coating, characterized in that the lower surface of the color-changing coating 3 is attached to the upper surface of the substrate 4, and the upper surface of the color-changing coating is provided with a protective layer 2 and an upper surface Hard layer 1 is provided, and a lower hard layer 5 is provided on the lower surface of the substrate.

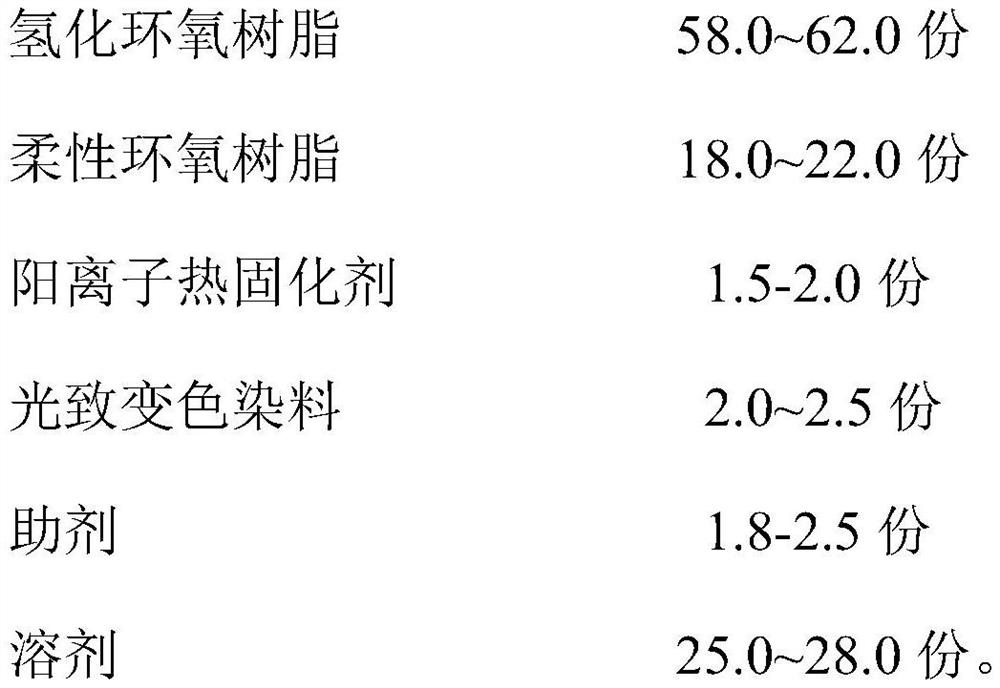

[0044] The material and formula of the color changing coating are as follows:

[0045]

[0046] The mixed liquid was prepared by a similar process in Example 1, and sampled and tested. The viscosity of the mixed liquid was 32.5 cps@25°C.

[0047] The color-changing spectacle lens containing the epoxy resin preparation coating is prepared by a process similar to Example 1. Through Filmetrics' F10-AR optical thickness tester, the thickness of the photochromic coating is 20.2 microns, and the thickness of the hardened layer is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com