Modified unsaturated polyester resin composition and preparation method thereof

A technology of polyester resin and composition, applied in the field of modified unsaturated polyester resin composition and its preparation, can solve the problems of poor weather resistance of benzene ring structure, high brittleness of resin protective layer, poor mechanical strength, etc., and achieve mechanical strength Good, saving dehydration equipment and time, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

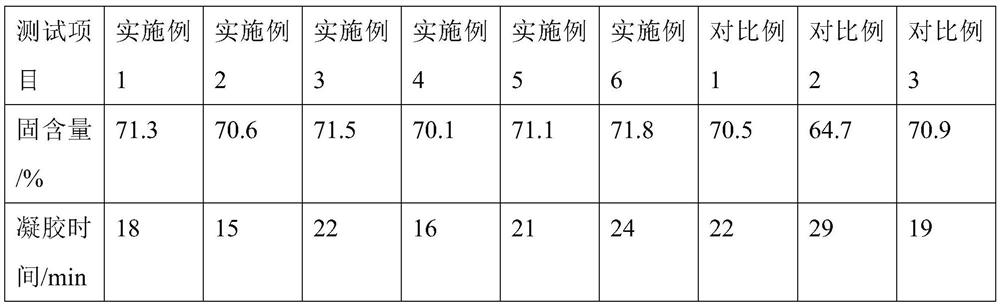

Examples

Embodiment 1

[0038] Prepare the following raw materials, 270 parts of epoxy resin, 125 parts of acrylic acid, 5 parts of triethylbenzyl ammonium chloride, 0.6 part of hydroquinone and 200 parts of hydroxyethyl acrylate,

[0039] Mix epoxy resin, hydroquinone, and triethylbenzylammonium chloride, raise the temperature to 81°C, add acrylic acid dropwise within 2 hours under stirring; Below 10mgKOH / g, lower the temperature to 78°C, add hydroxyethyl acrylate, stir for 1 hour, and obtain modified unsaturated polyester resin composition 1.

Embodiment 2

[0041] Prepare the following raw materials, 314 parts of epoxy resin, 115 parts of acrylic acid, 6 parts of triethylbenzyl ammonium chloride, 0.5 part of hydroquinone and 223 parts of hydroxyethyl acrylate,

[0042] Mix epoxy resin, hydroquinone and triethylbenzylammonium chloride, heat up to 78°C, add acrylic acid dropwise within 2 hours under stirring; Below 10mgKOH / g, lower the temperature to 80°C, add hydroxyethyl acrylate, and stir for 50min to obtain modified unsaturated polyester resin composition 2.

Embodiment 3

[0044] Prepare the following raw materials, 330 parts of epoxy resin, 127 parts of acrylic acid, 5.5 parts of triethylbenzyl ammonium chloride, 0.5 part of hydroquinone and 222 parts of hydroxyethyl acrylate,

[0045] Mix epoxy resin, hydroquinone, and triethylbenzylammonium chloride, raise the temperature to 81°C, add acrylic acid dropwise within 2 hours under stirring; Below 10 mgKOH / g, lower the temperature to 82°C, add hydroxyethyl acrylate, and stir for 1.5 hours to obtain modified unsaturated polyester resin composition 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com