Furanic resin aggregate binders and method

a technology of furfuryl alcohol and aggregate, which is applied in the field of plant-based compositions, can solve the problems of petrochemically-derived materials that need to be replaced with bio-derived materials, the supply of furfuryl alcohol is likely to become more restricted, and the supply of furfuryl alcohol is likely to increase. , to achieve the effect of improving the performance of acid cured binder, and boosting the strength of metal casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

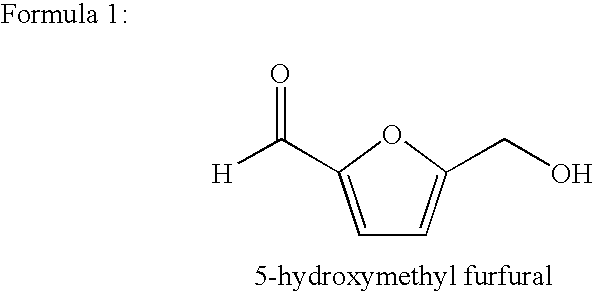

[0064]This example illustrates the use of 5-hydroxymethyl furfural in a furanic acid-cured binder formulation. Table 1 shows formulations with 5-hydroxymethyl furfural as a binder element.

TABLE 1Formulations with HMF binderTest NumberControl123Furfuryl Alcohol96.091.086.076.0(pph1)Resorcinol3.853.853.853.85(pph1)Silane20.150.150.150.15(pph1)5-hydroxymethyl05.010.020.0furfural (pph1)1pph = parts per hundred (weight)23-(diethoxymethylsilyl) propylamine

[0065]The ingredients in each of the Table 1 formulations were added to an 8 oz jar and shaken until dissolved to a clear amber solution.

[0066]The catalyst solution was comprised of 38% tap water, 2% methanol, and 60% para-toluene sulfonic acid (Aldrich).

[0067]To 4000 grams of Wedron 540™ sand, 20 grams of an aromatic sulfonic acid catalyst solution was added and mixed for one minute in a Hobart N50 mixer. This aggregate mixture then was manually flipped and mixed for another minute. Each formulation (50 grams) was added to the aggregate...

example 2

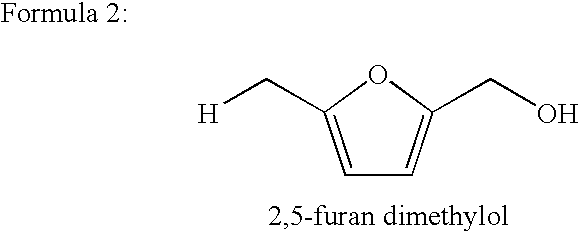

[0072]This example illustrates the use of 2,5-furan dimethylol as a filler and replacement for a portion of the furfuryl alcohol in furanic acid-cured binder formulations. Table 3 shows formulations utilizing 2,5-furan dimethylol in furanic acid-cured binder formulations. The acid in this case is the standard p-toluene sulfonic acid described in Example 1. The Example illustrates that the 2,5-furan dimethylol can be used as an accelerator / filler despite the absence of added free formaldehyde.

TABLE 3Test No.Control12345Furfuryl Alcohol96.091.086.076.066.056.0(pph1)Resorcinol23.853.853.853.853.853.85(pph1)Silane30.150.150.150.150.150.15(pph1)2,5-Furan Dimethylol05.010.020.030.040.0(pph1)1pph = parts per hundred (weight)2Resorcinol, 98% (Sigma-Aldrich)33-(diethoxymethylsilyl) propylamine (Aldrich)

[0073]Each Table 3 formula was compounded and tested as in Example 1, the test results are shown in Table 4.

TABLE 4TestControl12345Work time (minutes)292222191512Strip time (minutes)4538332519...

example 3

[0077]This example illustrates the use of 2,5-furan dimethylol as a component of a filler package and replacement for a portion of the furfuryl alcohol in furanic acid-cured binder formulations using weak acid catalyst. Table 5 shows formulations utilizing 2,5-furan dimethylol in furanic acid-cured binder formulations. The acid is 85% phosphoric at 50% based upon resin. The Example illustrates that the 2,5-furan dimethylol can be used as an accelerator / filler despite the absence of added free formaldehyde and even with a weak acid catalyst. Table 5 shows 2,5-furan dimethylol in various combinations of typical furanic additives at up to 30% replacement of furfuryl alcohol.

TABLE 5TestControl123Furfuryl Alcohol96.078.568.569.85(pph1)Resorcinol23.853.853.850.0(pph1)Silane30.150.150.150.15(pph1)Phenrez 17807.57.502,5-Furan Dimethylol010.020.030.0(pph1)1pph = parts per hundred (weight)2Resorcinol, 98% (Sigma-Aldrich)33-(diethoxymethylsilyl) propylamine (Aldrich)

[0078]Each Table 3 formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

| wt % ratios | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com