Preparation method of vinyl-terminated liquid fluoroelastomer supportive of room-temperature quick curing

A fast-curing, vinyl-terminated technology, applied in the field of preparation of vinyl-terminated liquid fluoroelastomers, can solve the problems of affecting service life, prone to degradation, long curing time, etc., and achieves good chemical resistance performance and simple preparation process. Easy to operate, fast curing reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 6g of carboxyl-terminated liquid fluoroelastomer (vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene copolymer, carboxyl mass percentage content is 2.2%, number average molecular weight is 4000, weight average molecular weight is 5286) is dissolved with 70ml of acetone, Put it into a reaction glass container, add 0.852g of glycidyl acrylate and 0.8ml of trimethylamine, and simultaneously add 0.03g of hydroquinone (to inhibit cross-linking reaction), and then react at 95°C for 12 hours. After the reaction was finished, 0.5 ml of hydrochloric acid was added to the reaction system to neutralize trimethylamine. Then directly dry under reduced pressure to obtain vinyl-terminated liquid fluoroelastomer. The yield of the obtained product is 85%, the number average molecular weight of the product is 4355g / mol, the molecular weight distribution is 1.88, and the carboxyl conversion rate is between 84% and 93%. The infrared spectrum shows that the product is at 1770cm -...

Embodiment 2

[0020] Dissolve 12g of carboxyl-terminated liquid fluoroelastomer (vinylidene fluoride-hexafluoropropylene copolymer, carboxyl mass percentage content is 1.8%, number-average molecular weight is 4800, weight-average molecular weight is 5900) with 100ml of toluene, add to the reaction glass In the container, add 2.05g allyl glycidyl ether and 0.8ml trimethylamine, and add 0.06g hydroquinone (to inhibit cross-linking reaction) at the same time, and then react at 80°C for 18 hours. After the reaction was finished, 0.5 ml of hydrochloric acid was added to the reaction system to neutralize trimethylamine. Then directly dry under reduced pressure to obtain vinyl-terminated liquid fluoroelastomer. The yield of the obtained product is 78%, the number average molecular weight of the product is 4210g / mol, the molecular weight distribution is 1.68, and the carboxyl conversion rate is between 75% and 86%. The infrared spectrum shows that the product is at 1770cm -1 The characteristic pe...

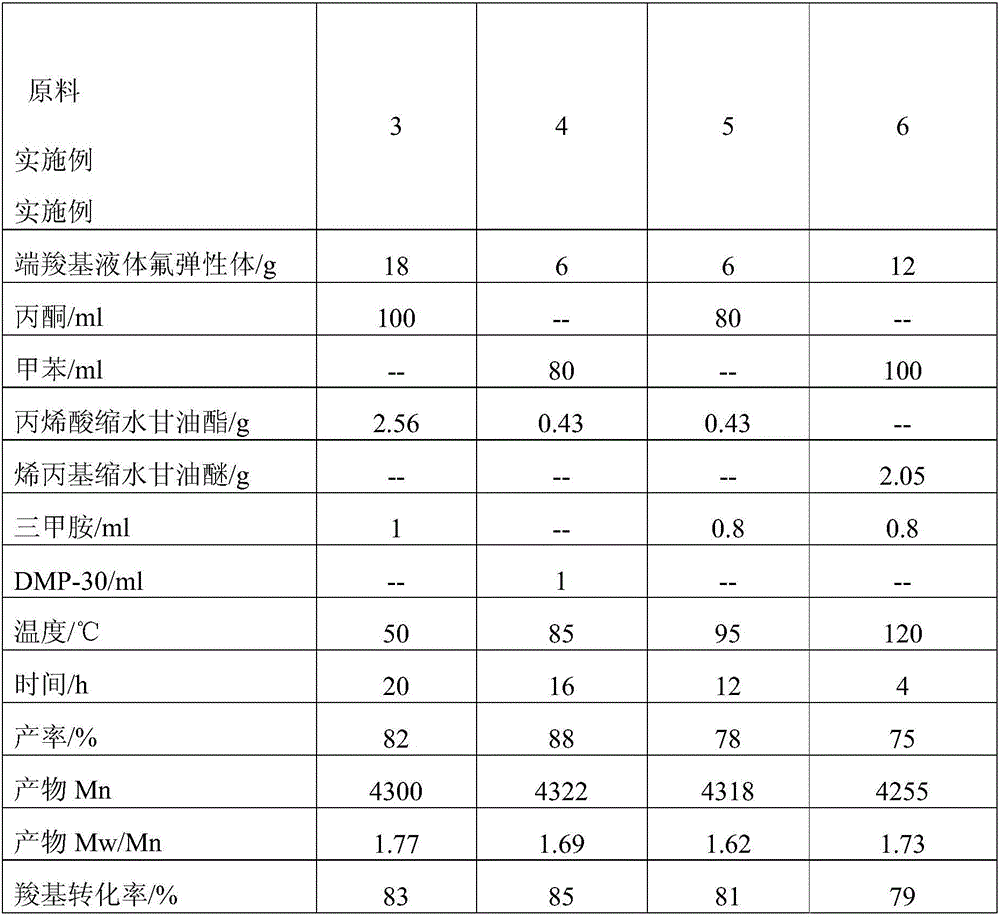

Embodiment 3-6

[0022] The specific implementation methods are listed in the table below:

[0023]

[0024] Note: The carboxyl-terminated liquid fluoroelastomer used in Example 3 is vinylidene fluoride-tetrafluoroethylene-hexafluoropropylene terpolymer; the carboxyl-terminated liquid fluoroelastomer used in Example 4 is vinylidene fluoride-trifluorochloro Ethylene copolymer; The carboxyl-terminated liquid fluoroelastomer used in Example 5 is vinylidene fluoride-perfluoroethyl vinyl ether copolymer; The carboxyl-terminated liquid fluoroelastomer used in Example 6 is vinylidene fluoride-hexafluoro Propylene copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com