Solvent-free polyurea weather-resistant anticorrosion coating and method for preparing same

An anti-corrosion coating, solvent-free technology, applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of affecting the mechanical properties and anti-corrosion properties of the coating, cannot completely prevent the reaction of polyisocyanates, and has not been popularized and applied And other problems, to achieve super anti-ultraviolet aging performance, super salt spray resistance performance, good low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Described in the embodiment of the present invention is a method for preparing a solvent-free polyurea weather-resistant anti-corrosion coating, the method comprising:

[0034] Step 1. Add secondary amino polymer, dispersant, defoamer and thixotropic agent in sequence in proportion to the batching tank, and stir at a stirring speed of 1000 rpm for 15-20 minutes. After stirring evenly, reduce the stirring speed to 200 rev / min;

[0035] Step 2. Add coupling agent, titanium dioxide, sericite and glass powder to the batching tank in turn, and stir for 35 to 50 minutes at a stirring speed of 400 to 500 rpm;

[0036] Step 3, use a sand mill to grind the prepared mixture, and test the fineness of the mixture during the grinding process, stop grinding until the fineness reaches below 100 μm, and obtain component B;

[0037] Step 4. Separately package the components A and B according to the ratio to obtain the solvent-free polyurea weather-resistant anticorrosion coating. The c...

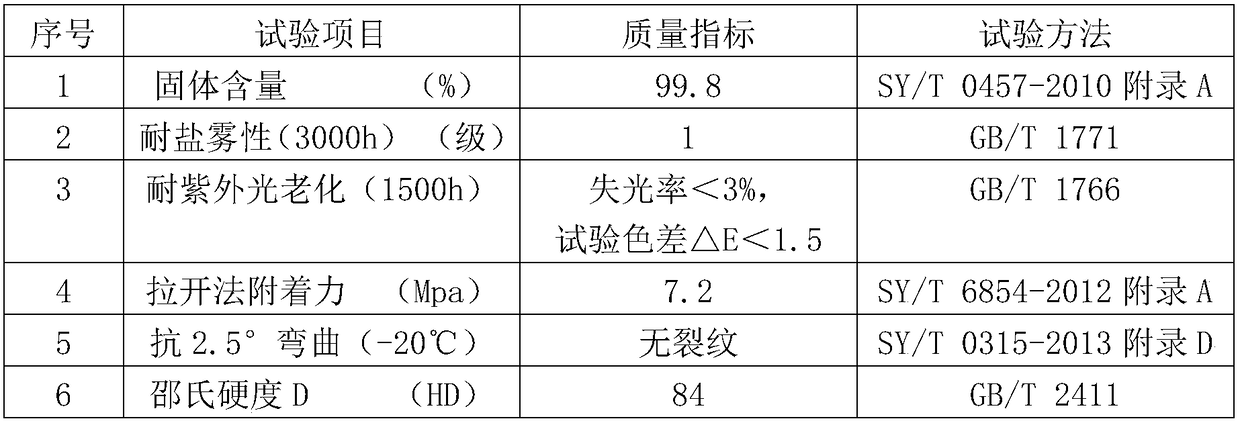

Embodiment 1

[0040] (1) Preparation of component A: Open the lid of the directly purchased HDI trimer (imported) in 200L packaging, visually observe whether it is clear, whether there are flocculation products, stir, and check whether there are hard sediments at the bottom, such as If the above phenomenon occurs, mark it and place it uniformly for return or exchange. If there is no above phenomenon, subcontract according to the proportion. Get A component;

[0041] (2) Preparation of component B: Add 42 parts of secondary amino polymer, 0.3 part of dispersant, 0.3 part of defoamer, and 0.8 part of thixotropic agent in the batching tank according to the formula, and stir for 15 to 20 minutes. 1000 rpm, after stirring evenly, slow down the stirring speed, the stirring speed is 200 rpm, add 3 parts of coupling agent, 7 parts of titanium dioxide, 7 parts of mica powder, and 39.6 parts of glass powder in sequence, increase the stirring speed, and the rotation speed is 400~ Stir at 500 rpm for ...

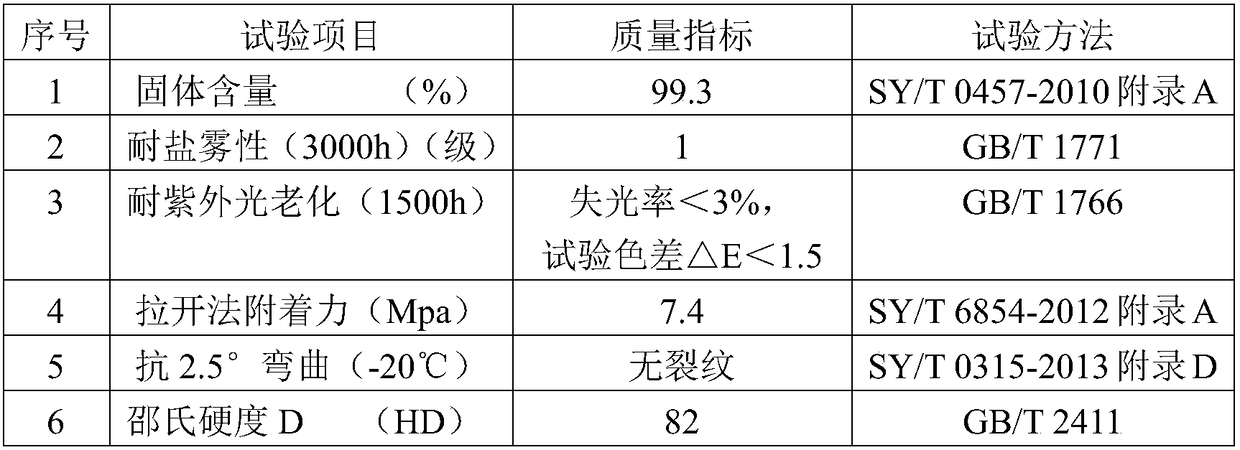

Embodiment 2

[0046] (1) Preparation of component A: Open the lid of the directly purchased HDI trimer (imported) in 200L packaging, visually observe whether it is clear, whether there are flocculation products, stir, and check whether there are hard sediments at the bottom, such as If the above phenomenon occurs, mark it and place it uniformly for return or exchange. If there is no above phenomenon, subcontract according to the proportion. Get A component;

[0047] (2) Preparation of component B: Add 46 parts of secondary amino polymer, 0.4 part of dispersant, 0.4 part of defoamer, and 0.9 part of thixotropic agent in the batching tank according to the formula, and stir for 15 to 20 minutes. 1000 rpm, after stirring evenly, slow down the stirring speed, the stirring speed is 200 rpm, add 5 parts of coupling agent, 9 parts of titanium dioxide, 9.8 parts of mica powder, 28.5 parts of glass powder in turn, increase the stirring speed, and the speed is 400~ Stir at 500 rpm for 35-40 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com