Two-component polyurethane coating and preparation method thereof

A two-component polyurethane, two-component polyurethane technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of long drying time, easy rash, long waiting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Correspondingly, the present invention also provides a kind of preparation method of above-mentioned two-component polyurethane coating, comprises the steps:

[0061] Take 50-70 parts by weight of saturated fatty acid alkyd resin and dissolve it in 10-15 parts by weight of solvent to obtain a solution of saturated fatty acid alkyd resin;

[0062] Under medium-speed dispersion conditions, 3 to 8 parts by weight of cellulose, 0.1 to 0.5 parts by weight of an antifoaming agent, 0.2 to 0.5 parts by weight of a leveling agent, 3 ~15 parts by weight of talcum powder, 3~5 parts by weight of zinc stearate and 0.1~0.3 parts by weight of drier until the fineness is less than 55 microns to obtain component A;

[0063] Under medium-speed dispersion conditions, mix 25-35 parts by weight of diphenylmethane diisocyanate trimer and 40-55 parts by weight of toluene diisocyanate adduct evenly, and then add 10-20 parts by weight of solvent to obtain group B point.

[0064] As a preferre...

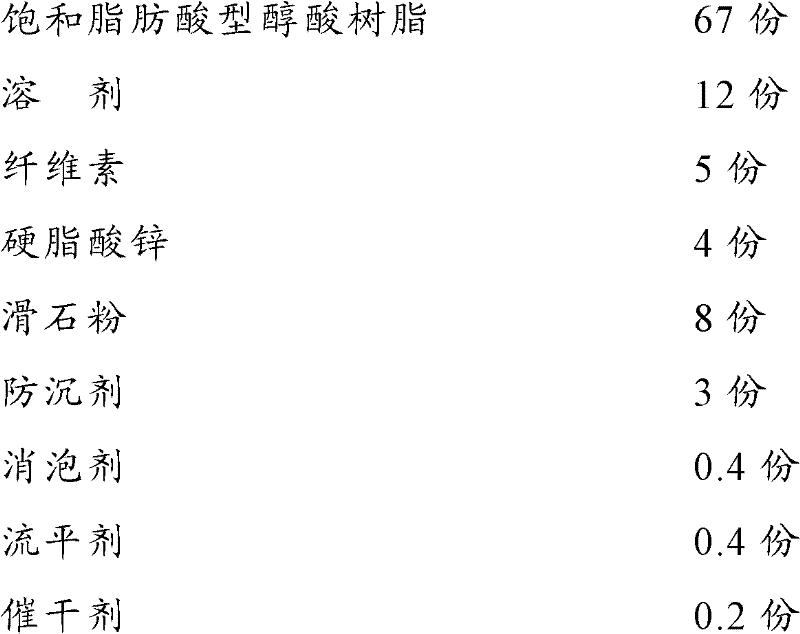

Embodiment 1

[0081] The formulation of this implementation two-component polyurethane coating is as follows:

[0082] Component A

[0083]

[0084] Component B

[0085] TDI trimer 35 parts

[0086] TDI adduct 47 parts

[0087] Polyurethane grade solvent 18 parts

[0088] The production process of two-component polyurethane coatings is as follows:

[0089] Deploying component A:

[0090] Put the saturated fatty acid type alkyd resin into the disperser, set the dispersion speed to 700-800 rpm, add solvent, disperse evenly, add cellulose until completely dissolved, set the dispersion speed to 1000 rpm, and then add defoaming Add agent and leveling agent to disperse for 10 minutes, then add talcum powder and zinc stearate to disperse for 20 minutes until the fineness is ≤55 microns.

[0091] Configure component B:

[0092] Put the TDI trimer and TDI adduct into the disperser, set the dispersion speed to 700-800 rpm, and add polyurethane grade solvent under stirring to disperse evenly...

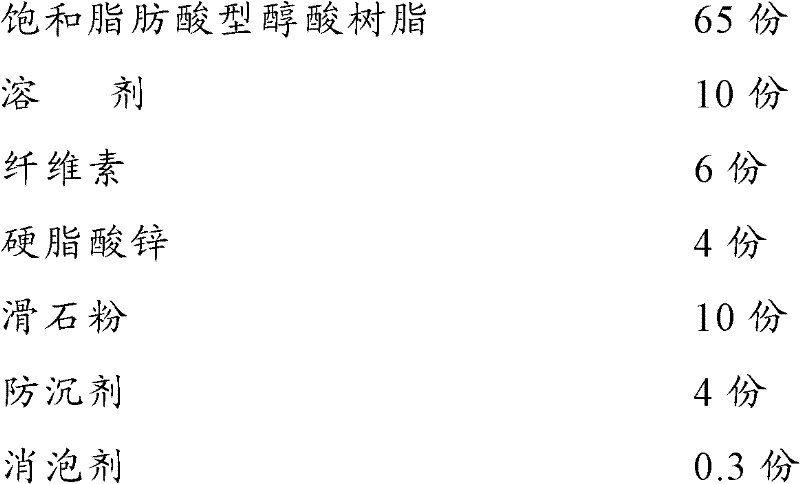

Embodiment 2

[0101] The formulation of this implementation two-component polyurethane coating is as follows:

[0102] Component A

[0103]

[0104]

[0105] Component B

[0106] TDI trimer 32 parts

[0107] TDI adduct 49 parts

[0108] Polyurethane grade solvent 19 parts

[0109] The making process of two-component polyurethane coating is identical with embodiment.

[0110] During construction, just mix component A: component B uniformly at a ratio of 2:1, and the properties of the obtained quick-drying modified polyurethane primer are as follows (test room temperature: 25°C):

[0111] Surface dry time: ≤15 minutes;

[0112] Drying time: ≤1h;

[0113] Grinding time: ≤1.5h;

[0114] Hardness: ≥H;

[0115] Adhesion: Grade 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com