Accelerated furanic aggregate binders from bio-derived components

a technology of furanic aggregate and binders, which is applied in the field of bioderived binder materials, can solve the problems of corrosive action, waste removal, health, and each of these components can have negative effects on the environment, so as to reduce any environmental impact and improve the overall performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

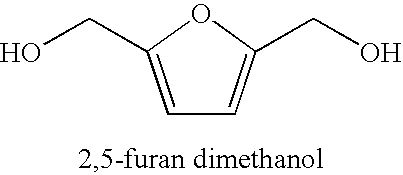

[0062]Example 1 illustrates the use of FDM in a furanic a cid-cured binder formulation.

[0063]Table 1 shows formulations with FDM as a binder element.

TABLE 1FDM as an Additive in a Furanic No Bake (FNB) BinderTest No.IngredientsControl123456Furfuryl Alcohol96.091.086.076.066.069.856.0(pph*)Resorcinol3.853.853.853.853.8503.85(pph*)Silane**0.150.150.150.150.150.150.15(pph*)FDM05.010.020.030.03040.0(pph*)*pph = parts per hundred (weight)

[0064]Table 1 lists six formulations and a control for FDM as an additive in an FNB binder. The ingredients in each of the formulations were added to an 8 oz jar and shaken until dissolved to a clear amber solution.

[0065]The catalyst solution was comprised of 38 (weight percent) wt % Columbus, Ohio tap water, 2 wt % methanol, and 60 wt % para-toluene sulfonic acid (Aldrich).

[0066]To 4000 grams of Wedron 540® sand (Fairmont Minerals), 20 grams (40% on binder weight) of this aromatic sulfonic acid catalyst solution was added and mixed for one minute in a H...

example 2

The Use of Phosphoric Acid

[0071]This example illustrates the use of phosphoric acid instead of para-toluene sulfonic acid. The use of phosphoric acid is advantageous for those alloys negatively impacted by sulfur contamination and by the elimination of benzene-like molecules into the work environment after pouring the metal. Typically, phosphoric acid is not acceptable for use with “cold-blended” furan binder systems due the slow reactivity and lack of tensile development, especially on colder aggregates. The Control was run at 50% of 85% phosphoric based on binder weight. The test formulations were tested at 50 and 40% of phosphoric acid as shown on Table 3. The Table 3 series also shows the tests for several typical polyester fillers in combination with the FDM.

[0072]The formulations on Table 3 were made in the laboratory as described and tested in example one, except for the use of two different levels of the catalyst.

TABLE 3FDM-containing FNB Binder FormulationsCured with 85% Ph...

example 3

[0075]This example illustrates FDM formulation performance on warm and cold aggregates.

[0076]The performance of furan no-bake binders can be severely affected by the temperature of the aggregates as well as ambient temperatures and humidity. A faster curing binder formulation should perform better on cold sands. Ideally, such a binder formulation should still perform acceptably on warm sand as well. A typical-means of achieving fast cure on cold sand is the use of reacted base formulations, the reacted base being, for example, a urea-formaldehyde resin. Such resins increase the reactivity, but also introduce free formaldehyde into the formulations. Another means of achieving faster cure on cold sands is to use either higher levels of an acid catalyst, use a higher reactivity sulfonic acid, or one containing an inorganic acid “kicker”, such as straight sulfuric acid or hydrochloric acid. Other means of increasing reactivity on cold sands include the addition of alcohols, such as meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com