High-performance thermosetting epoxy resin adhesive for roads and bridges and preparation method thereof

An epoxy resin, high-performance technology, used in epoxy resin glue, polymer adhesive additives, non-polymer adhesive additives and other directions, can solve the problem of high price, expensive epoxy asphalt materials, epoxy asphalt Complex material construction process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

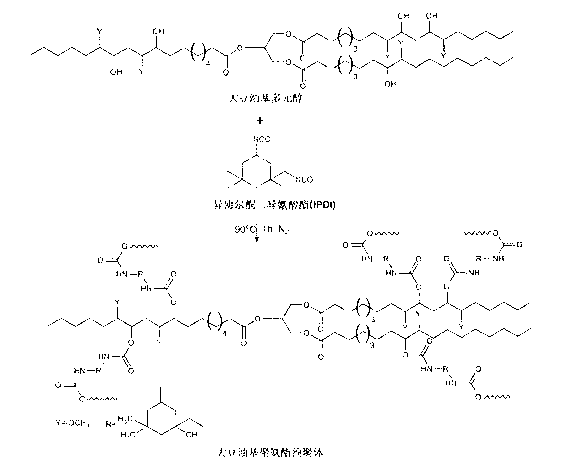

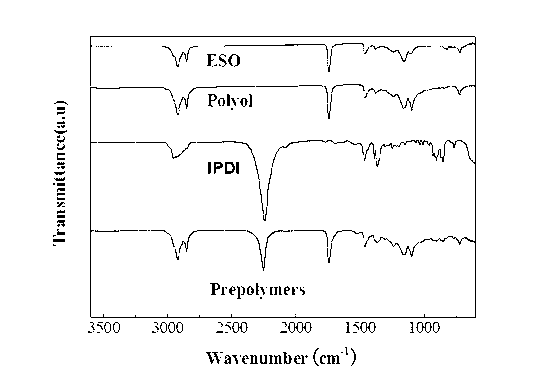

[0043] Example 1: Using tetrafluoroboric acid (provided by Nanjing Chemical Reagent Co., Ltd.) as a catalyst, epoxy soybean oil is added to the boiled methanol and tetrafluoroboric acid mixture, wherein the molar ratio of epoxy groups to methanol is 1: 11. Reflux reaction for 1 hour. After the reaction, stop heating, cool to room temperature, add concentrated ammonia water dropwise to neutralize. Methanol was distilled off under reduced pressure, and suction filtered to obtain a light yellow transparent liquid soybean oil polyol with a hydroxyl value of 115 mg KOH / g. Add 0.5 parts of butyl ditin laurate ( (provided by Shanghai Yutian Chemical Co., Ltd.) under nitrogen protection at 90°C for 1 h with mechanical stirring to obtain a soybean oil-based polyurethane prepolymer, in which epoxy soybean oil (ESO), soybean oil-based polyol (polyol), isophorone di The infrared spectra of isocyanate (IPDI) and soybean oil-based polyurethane prepolymer (prepolymer) are shown in figure...

Embodiment 2

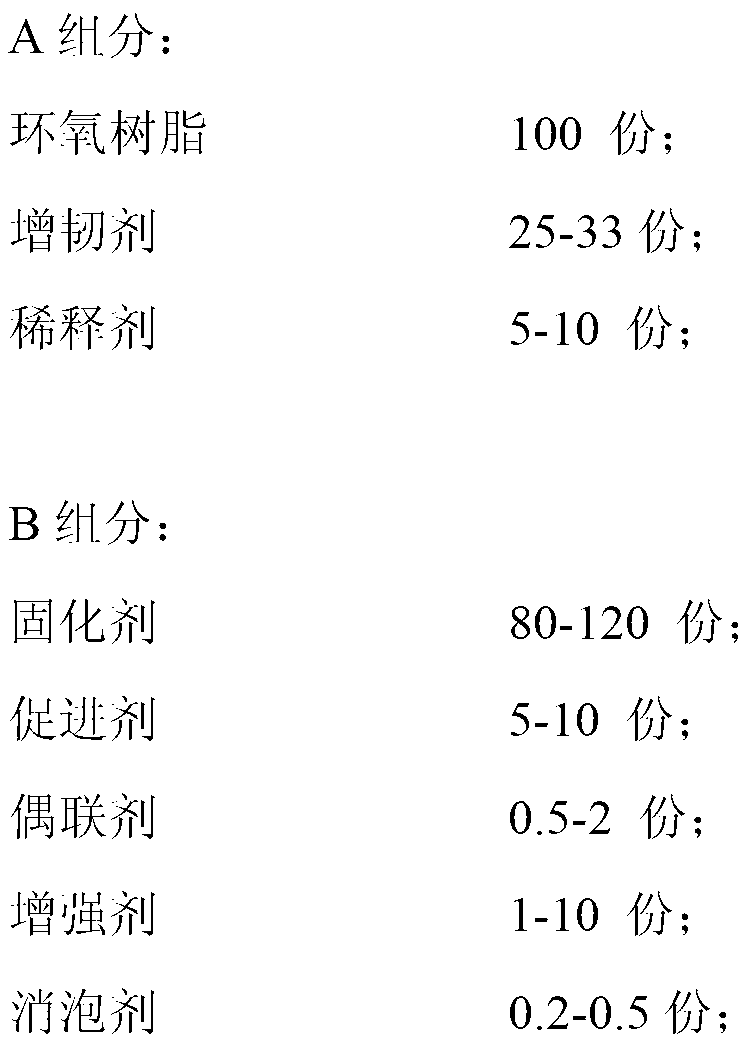

[0045]Embodiment 2: Weigh 100 parts of bisphenol A glycidyl ether epoxy resin (E51, provided by Wuxi Bluestar Petrochemical Co., Ltd.), add 25 parts of soybean oil-based polyurethane prepolymer obtained in Example 1, and start stirring. And raise the temperature to 60°C, cool to room temperature after reacting for 2 hours, add 10 parts of C12-C14 alkyl glycidyl ether (provided by Wuxi Pulitai Chemical Coating Co., Ltd.), to obtain high-performance thermosetting epoxy resin adhesive for road and bridge A component of the binder.

Embodiment 3

[0046] Example 3: Weigh 100 parts of bisphenol A glycidyl ether epoxy resin (E51), add 33 parts of the soybean oil-based polyurethane prepolymer obtained in Example 1, start stirring, and raise the temperature to 60°C, After reacting for 2 hours, cool to room temperature, and add 8 parts of C12-C14 alkyl glycidyl ether to obtain component A of high-performance thermosetting epoxy resin adhesive for road and bridge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com