Patents

Literature

45results about How to "High OD value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reagent casing for detecting blood-lacking modification albumin and method thereof

InactiveCN101013137AStrong specificityOD value is trueMaterial analysis by observing effect on chemical indicatorBiological material analysisUltrafiltrationFiltration

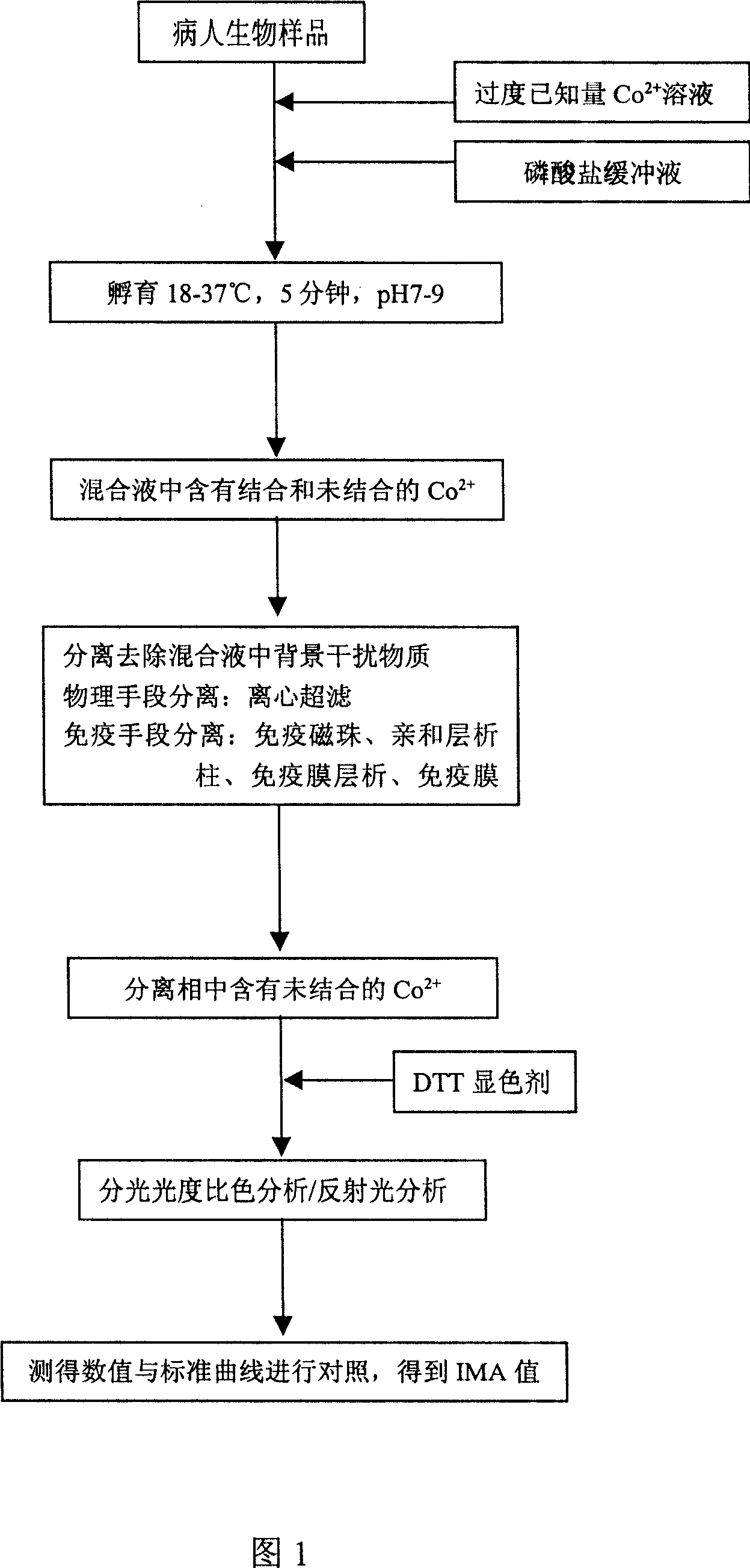

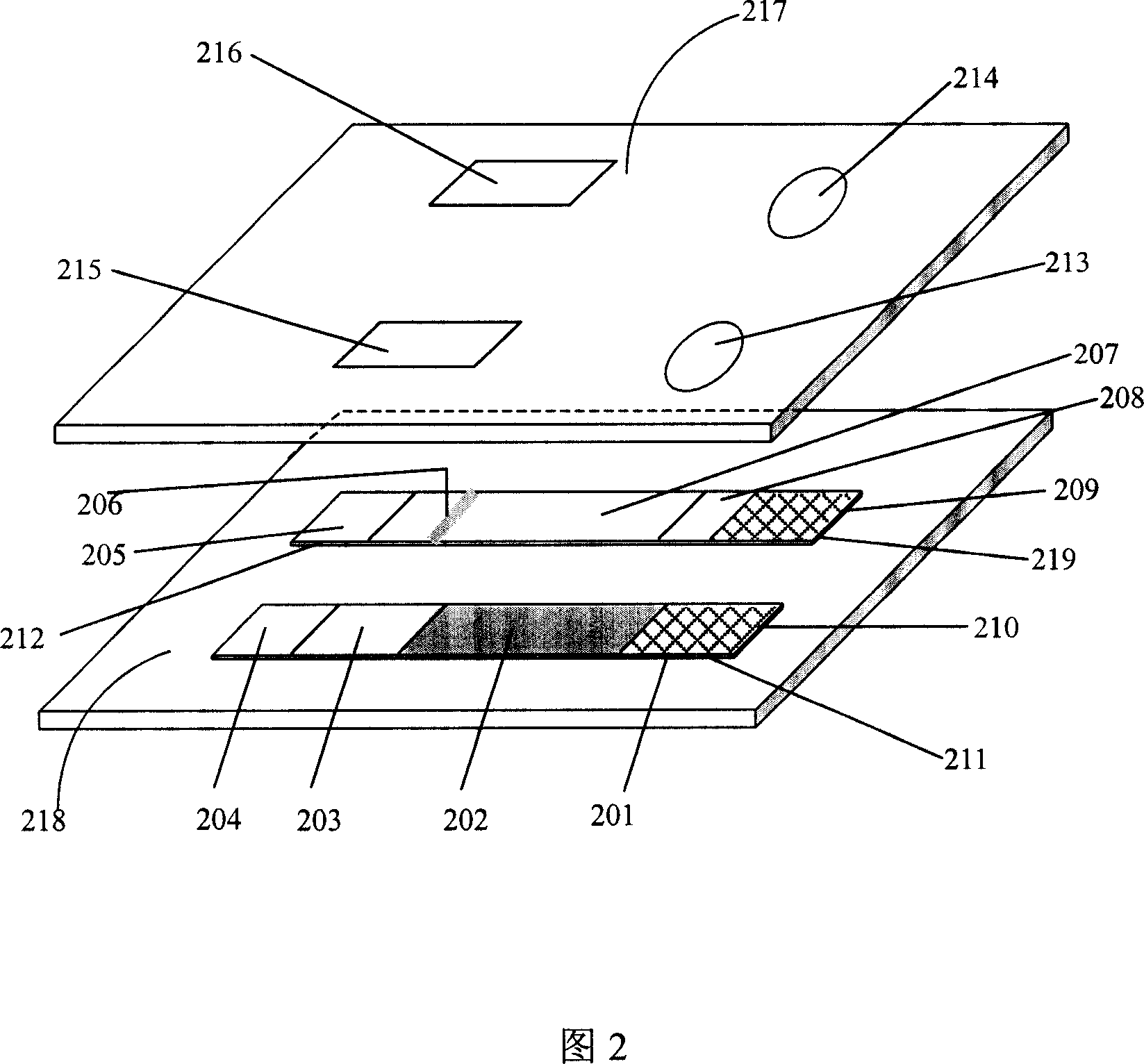

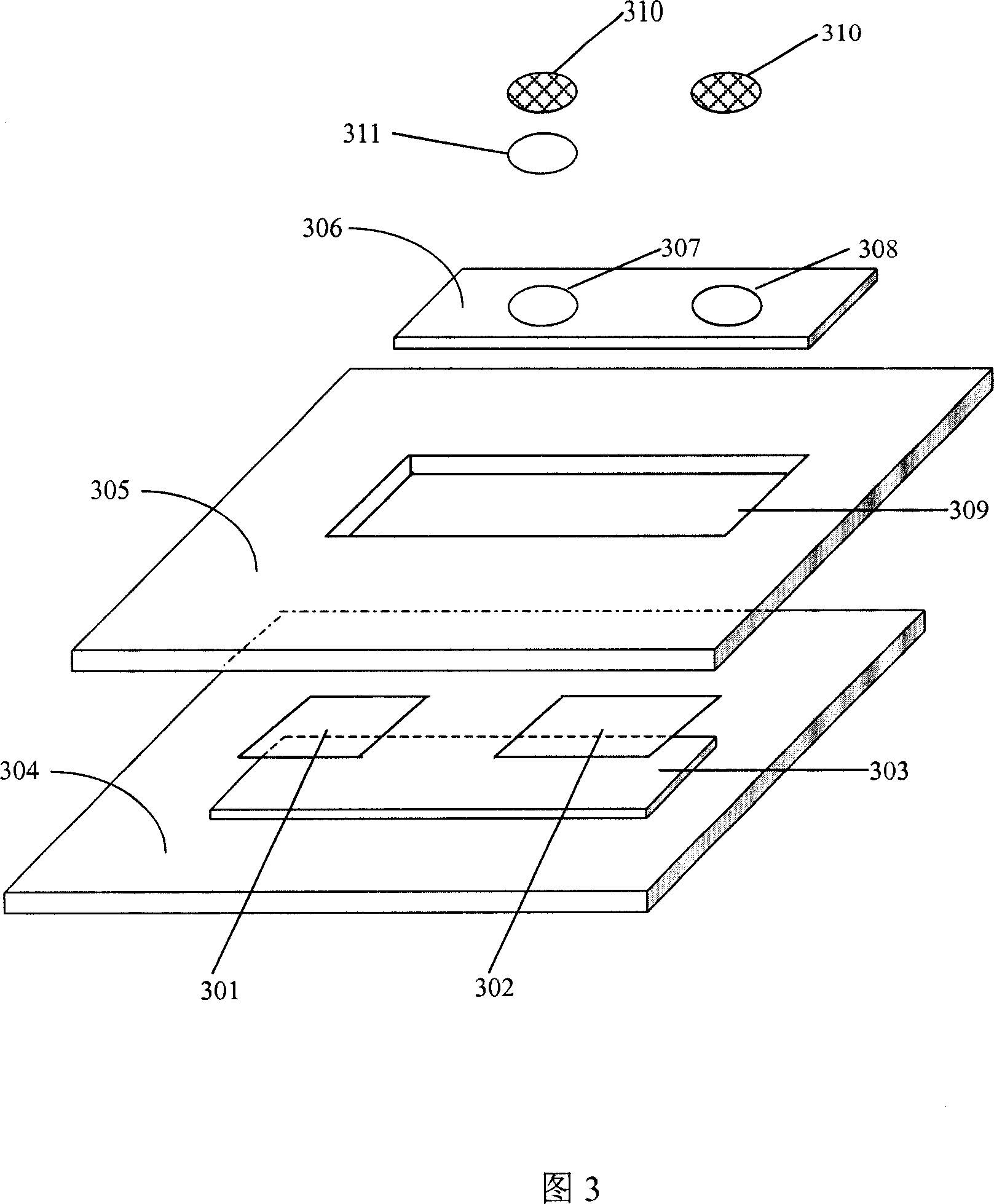

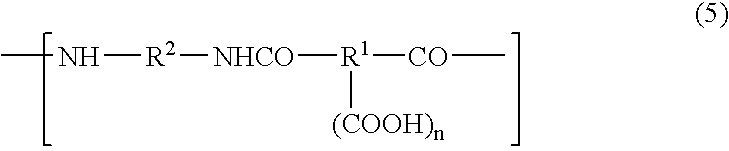

It is a detecting ischemia modified albumin (IMA) reagent kit and detection method, and the reagent kit contains different division to remove the background interference material device, which can be centrifugal ultrafiltration IMA detection reagent kit, immunomagnetic beads IMA detection reagent kit, immunochromatography IMA detection reagent kit, immune chromatography membrane IMA detection board reagent kit or immune membrane filtration plate IMA detection reagent kit. After division removal of the background interference material, it can enhance the specific of detection IMA reagent kit and detection method, and using this reagent kit and hospital existing equipments, in about half an hour, it can measure the IMA value to diagnosis myocardial ischemia symptoms. Particularly suitable for bedside rapid detection kit development, ease to use, low cost, it is a very development promising product.

Owner:贺坚慧

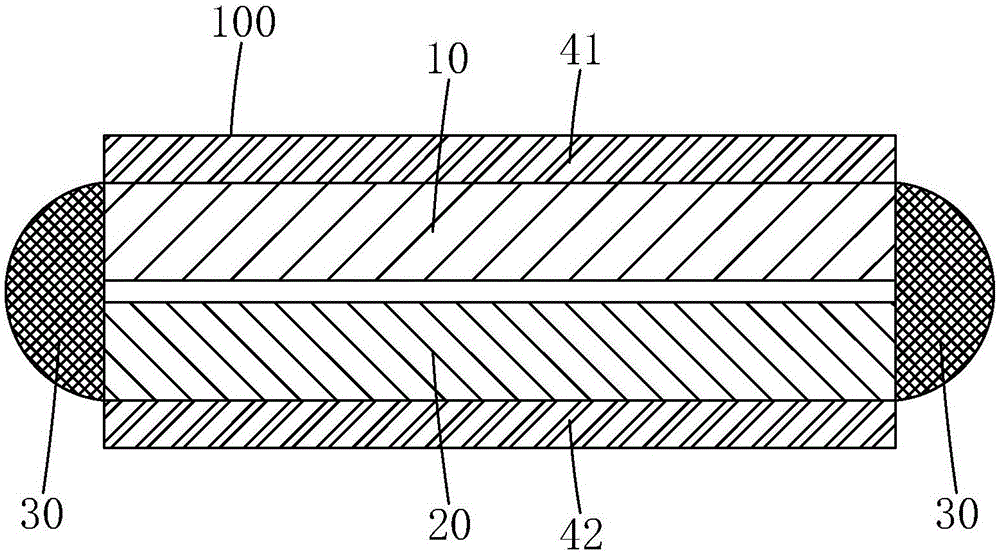

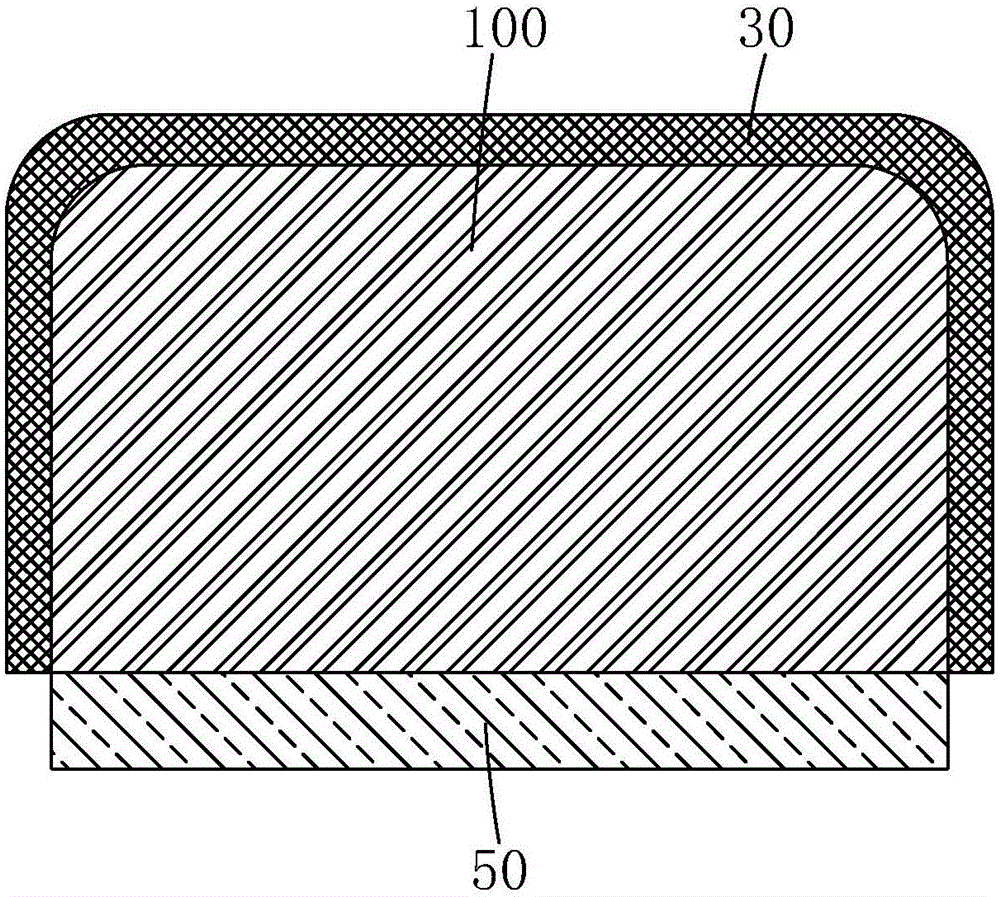

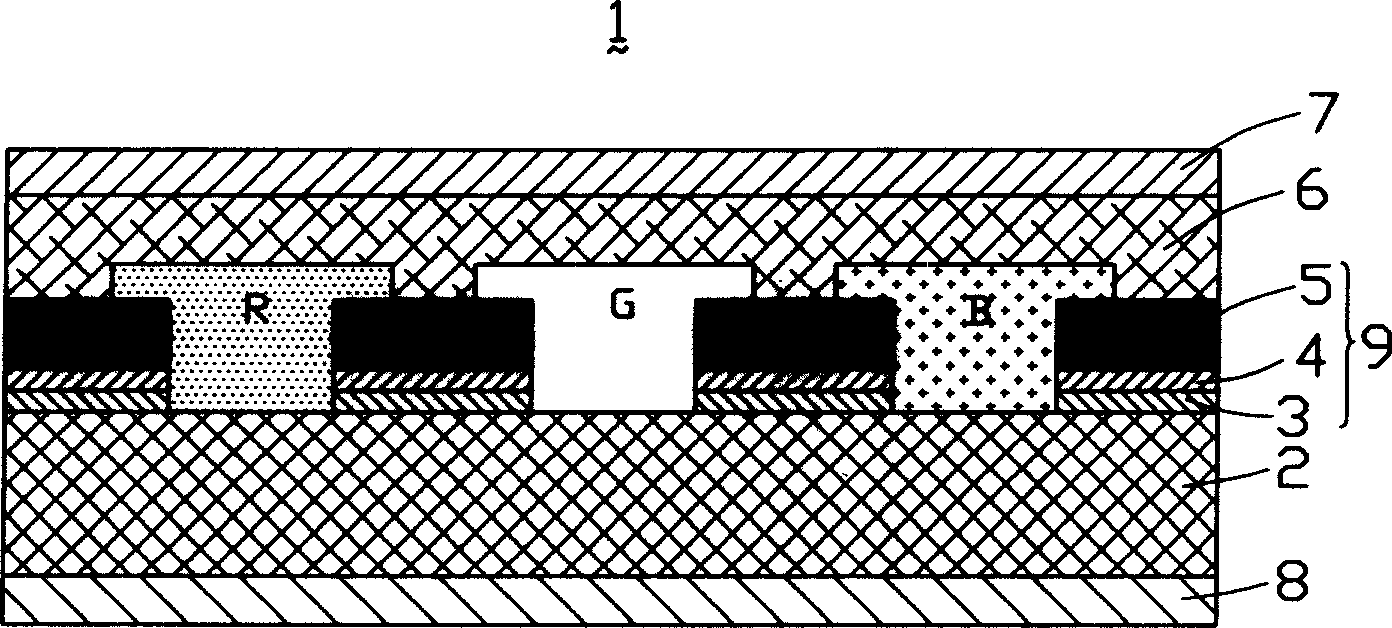

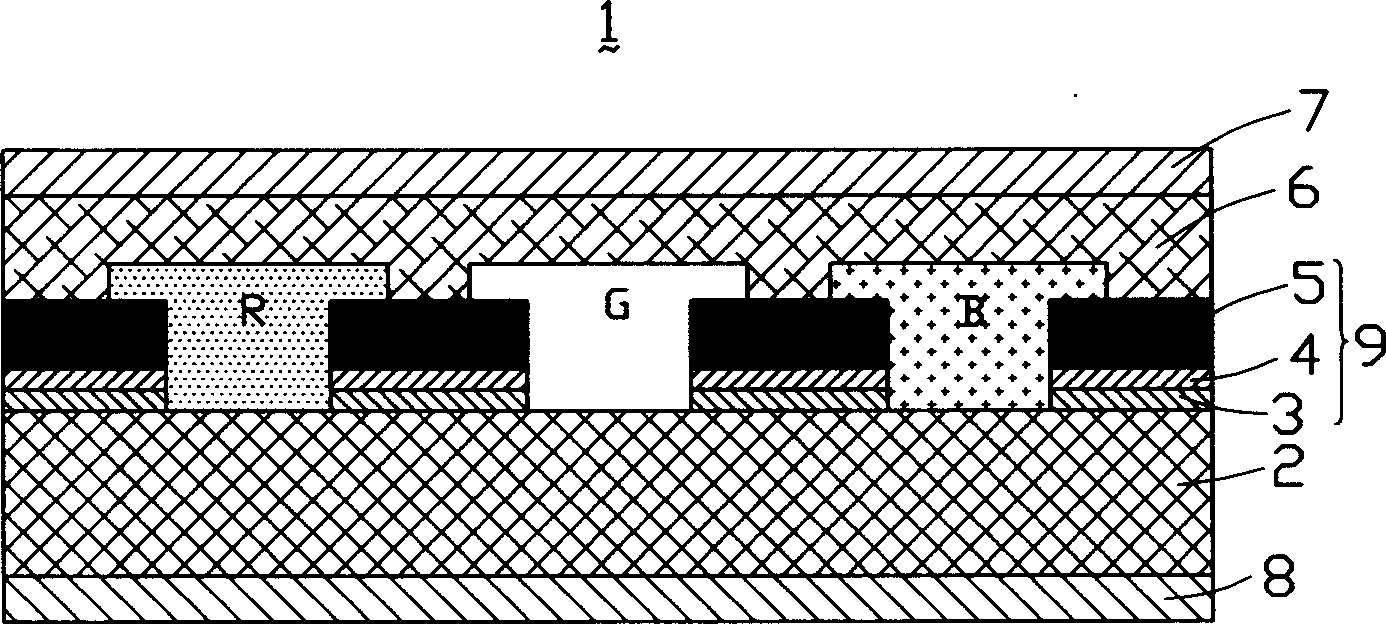

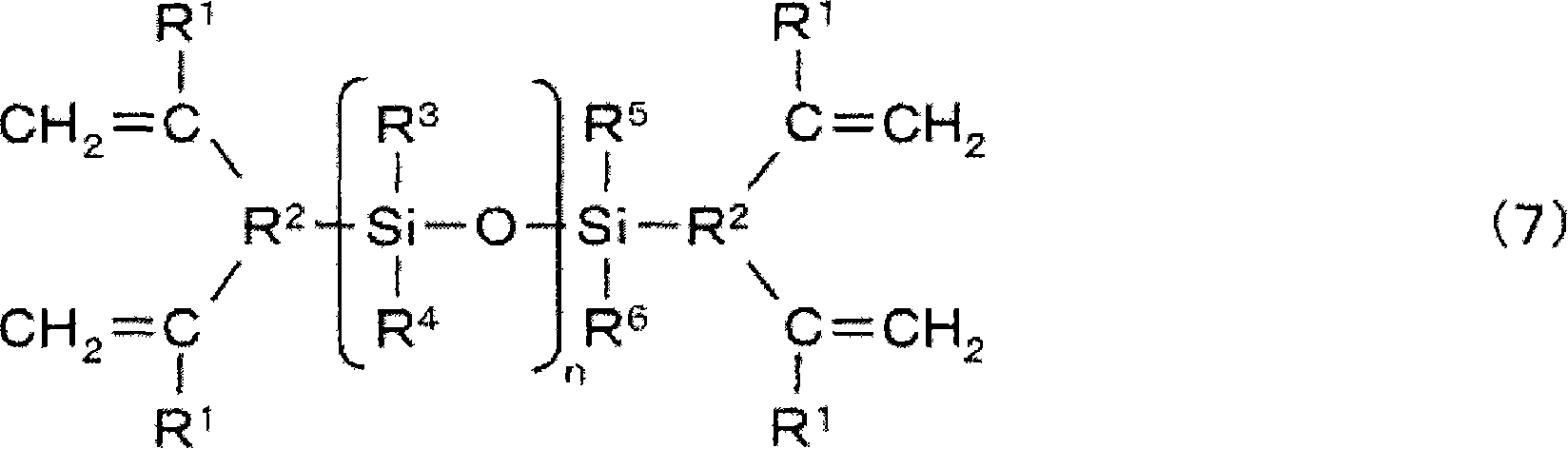

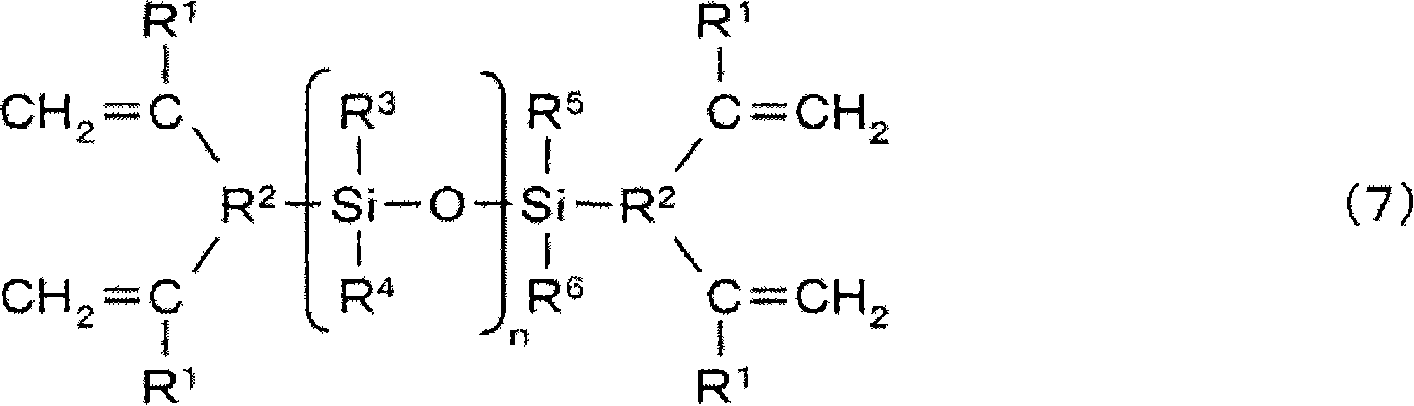

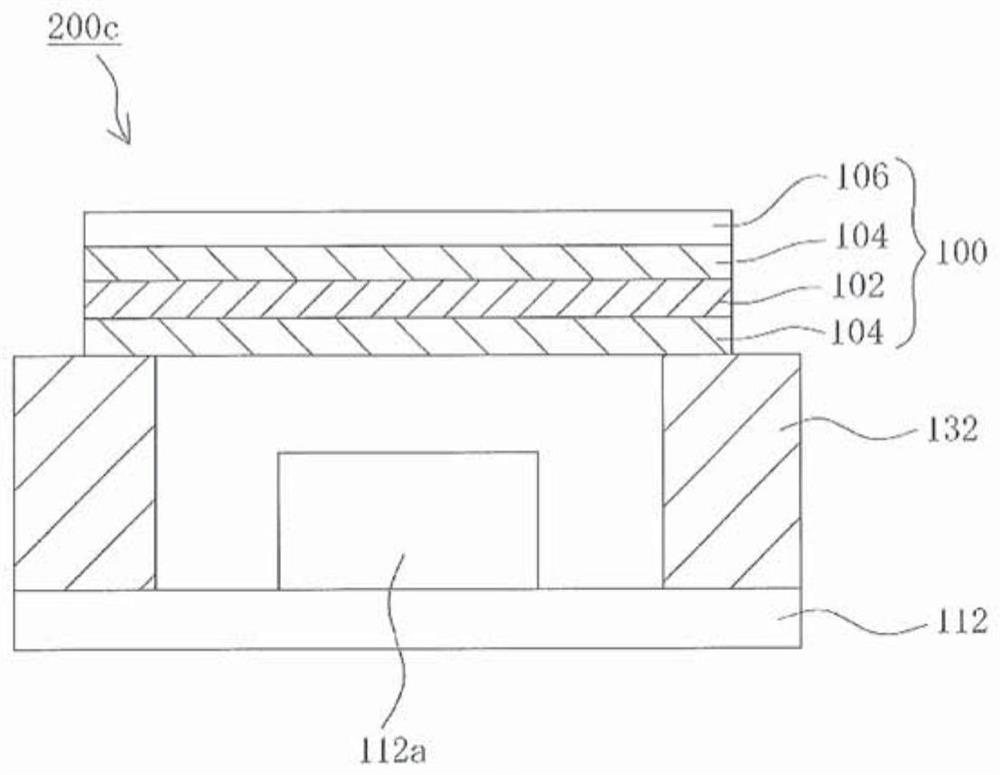

Black composition, black coating composition, resin black matrix, color filter for liquid crystal display and liquid crystal display

ActiveUS20070059612A1Prevention of decrease in yieldHigh valueLiquid crystal compositionsPhotosensitive materialsLiquid-crystal displayCrystallography

A black coating composition which gives a highly adhesive resin black matrix that exhibits a high OD value which was able to be attained only by metal thin film black matrices is disclosed. The black coating composition comprises as indispensable components a titanium nitride oxide and a resin. The X-ray intensity ratios R1 and R2 of the titanium nitride oxide represented by the Equations (1) and (2) below, respectively, satisfy the relationships represented by Formulae (3) and (4)below:R1=I3 / {I3+1.8(I1+1.8I2)} (1)R2=I2 / I1 (2)R1>0.70 (3)0.85<R2<1.80 (4)wherein I1 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ, determined by using CuKα line as the X-ray source, is 25° to 26°, I2 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ is 27° to 28°, and I3 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ is 36° to 38°.

Owner:TORAY IND INC

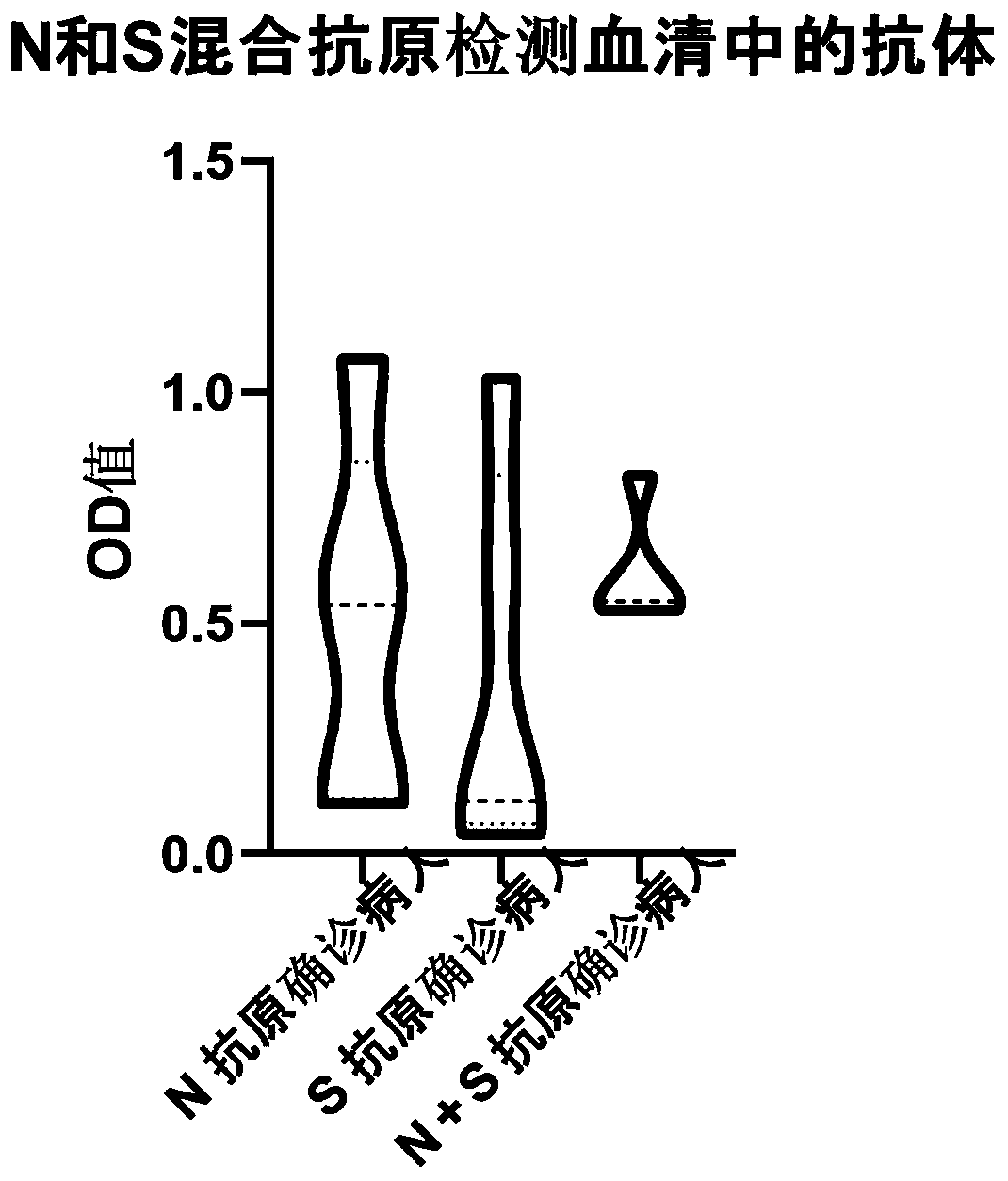

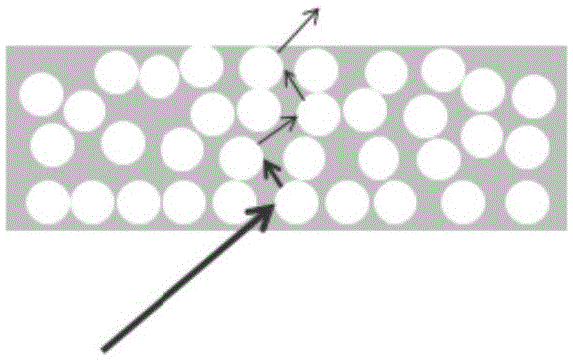

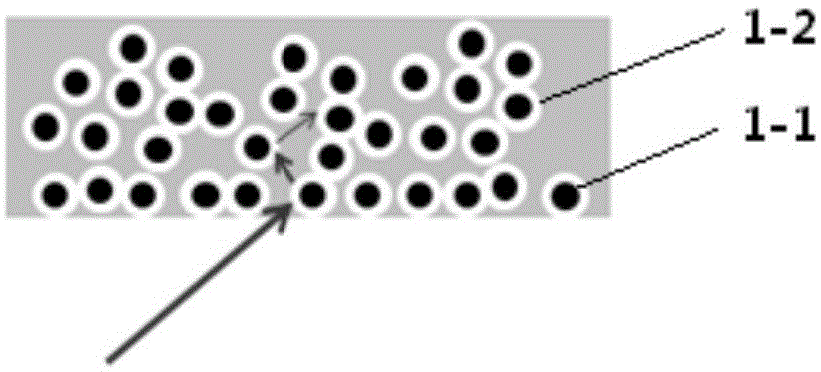

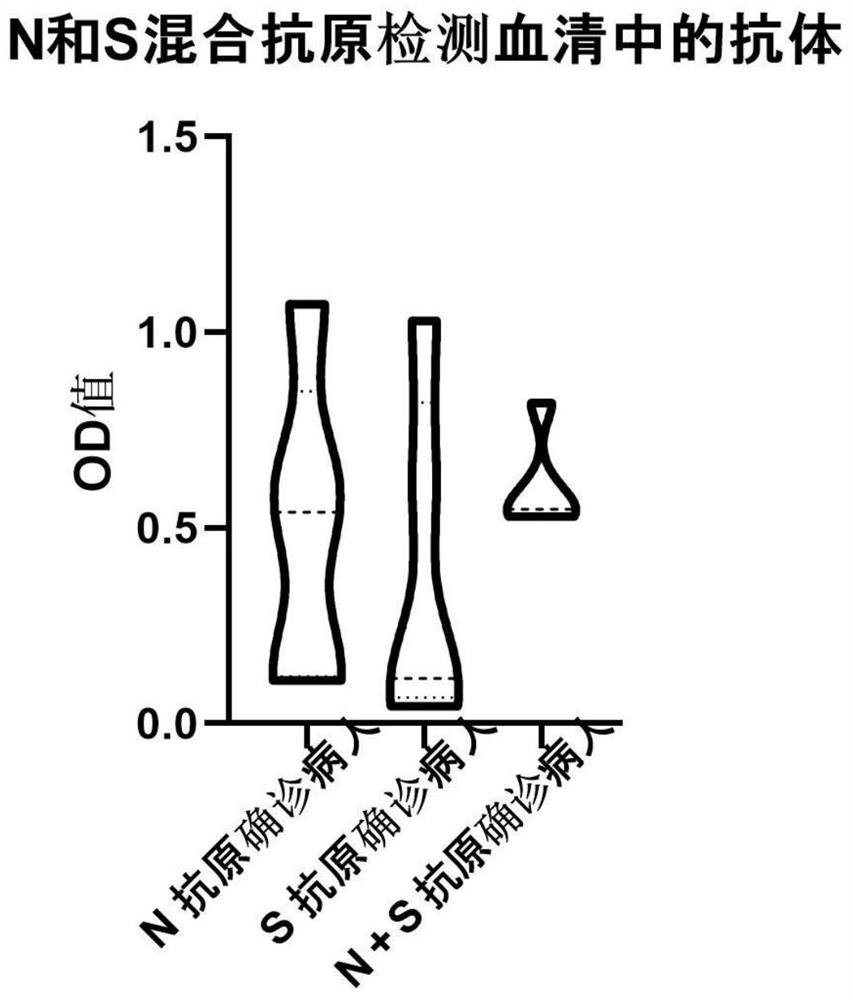

Kit for rapidly detecting novel coronavirus antibody based on mixed antigen

ActiveCN111239394AEasy to operateHigh detection sensitivitySsRNA viruses positive-senseAntibody mimetics/scaffoldsAntigenFibrin

The invention discloses a kit for rapidly detecting a novel coronavirus antibody based on a mixed antigen. The kit comprises COVID-19 nucleocapsid protein antigen colloidal gold and COVID-19 fibrin antigen colloidal gold. The kit is used for diagnosing the novel coronal pneumonia, is simple in operation, and the COVID-19 nucleocapsid protein antigen colloidal gold and the COVID-19 fibrin antigen colloidal gold can be directly mixed to be used as a whole for detection, or during detection, the COVID-19 nucleocapsid protein antigen colloidal gold and the COVID-19 fibrin antigen colloidal gold are directly mixed for detection, so that the detection sensitivity is high, and effective control of epidemic situations is facilitated.

Owner:SICHUAN MACCURA BIOTECH CO LTD

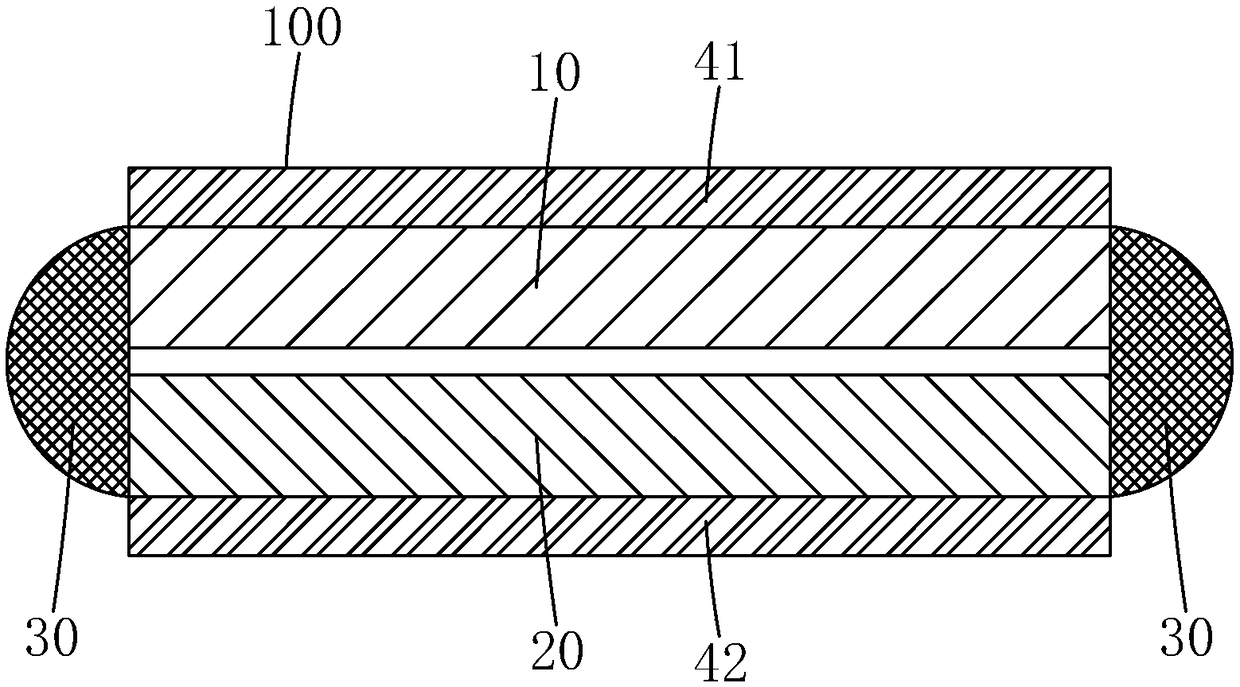

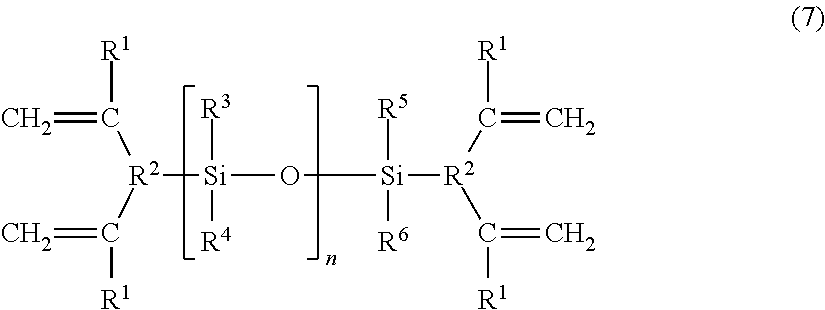

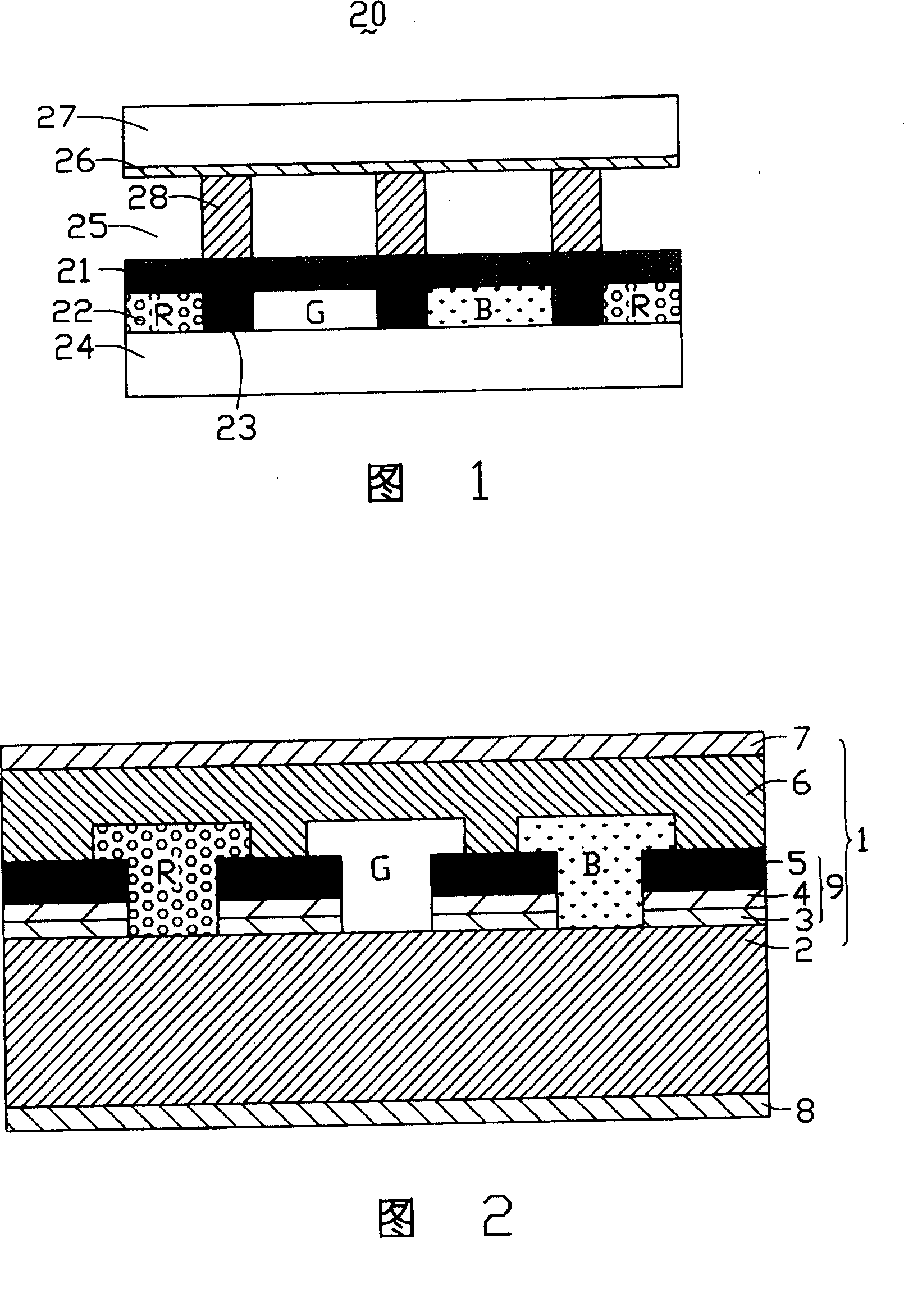

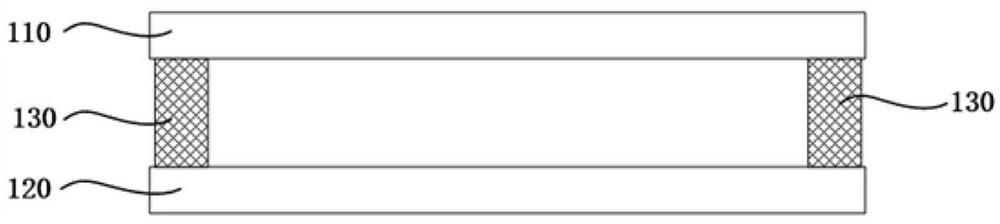

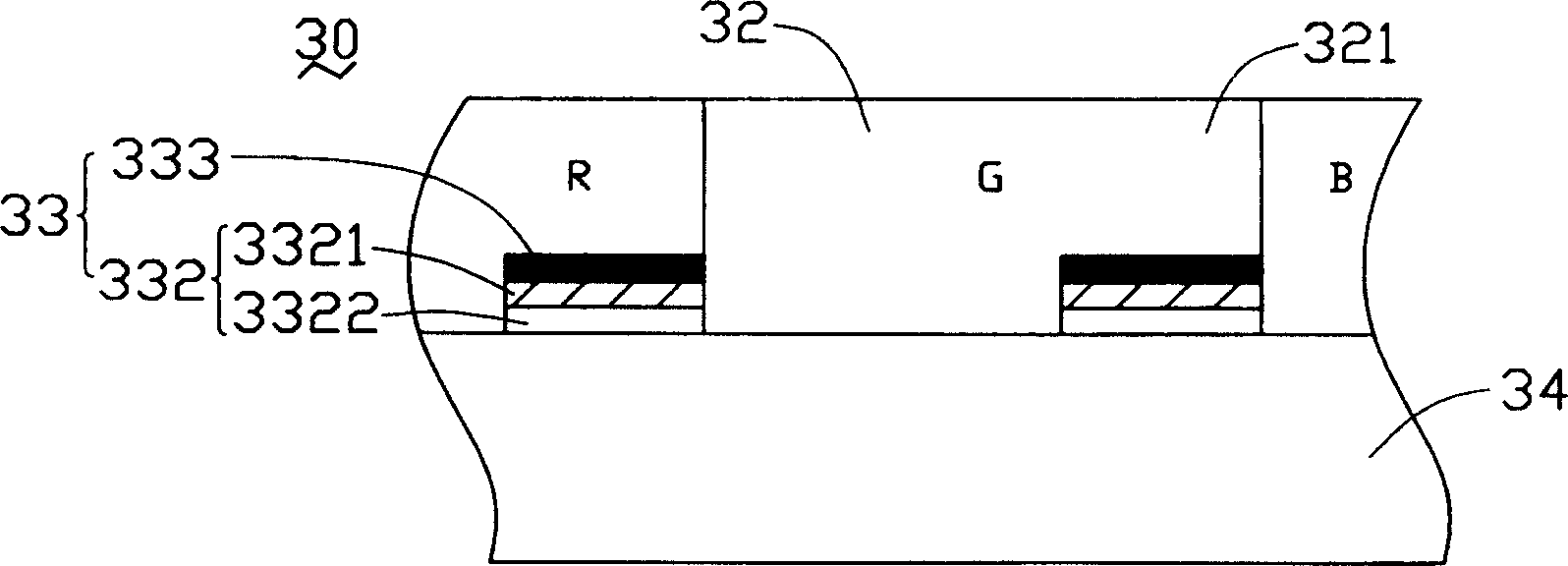

Side edge shading glue and no-border display device

ActiveCN106554650AHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

The invention provides side edge shading glue and a no-border display device. The side edge shading glue comprises oligomer containing polymerizable groups, reactive monomers, photoinitiator, black dye, carbon black, graphene and additives. An adopted resin system composed of the oligomer containing the polymerizable groups, the reactive monomers and the photoinitiator has a high curing reaction speed under UV irradiation; by adding the carbon block for increasing black, the side edge shading glue has a high OD value, the color of the carbon black is fixed, and the situation that color fading is caused because of long time, and consequently insufficient shading is caused is avoided; a method that a dispersion agent is adopted for dispersing the carbon black and a polymer cross-linked network to fix the carbon black makes the side edge shading glue free of the conditions of precipitation and uneven dispersion of the carbon black; and in addition, by adding the graphene, the flexibility and the heat conduction performance of the side edge shading glue can be improved, and further, static electricity on the surface of a display panel can also be removed by means of the heat conduction performance of the graphene.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

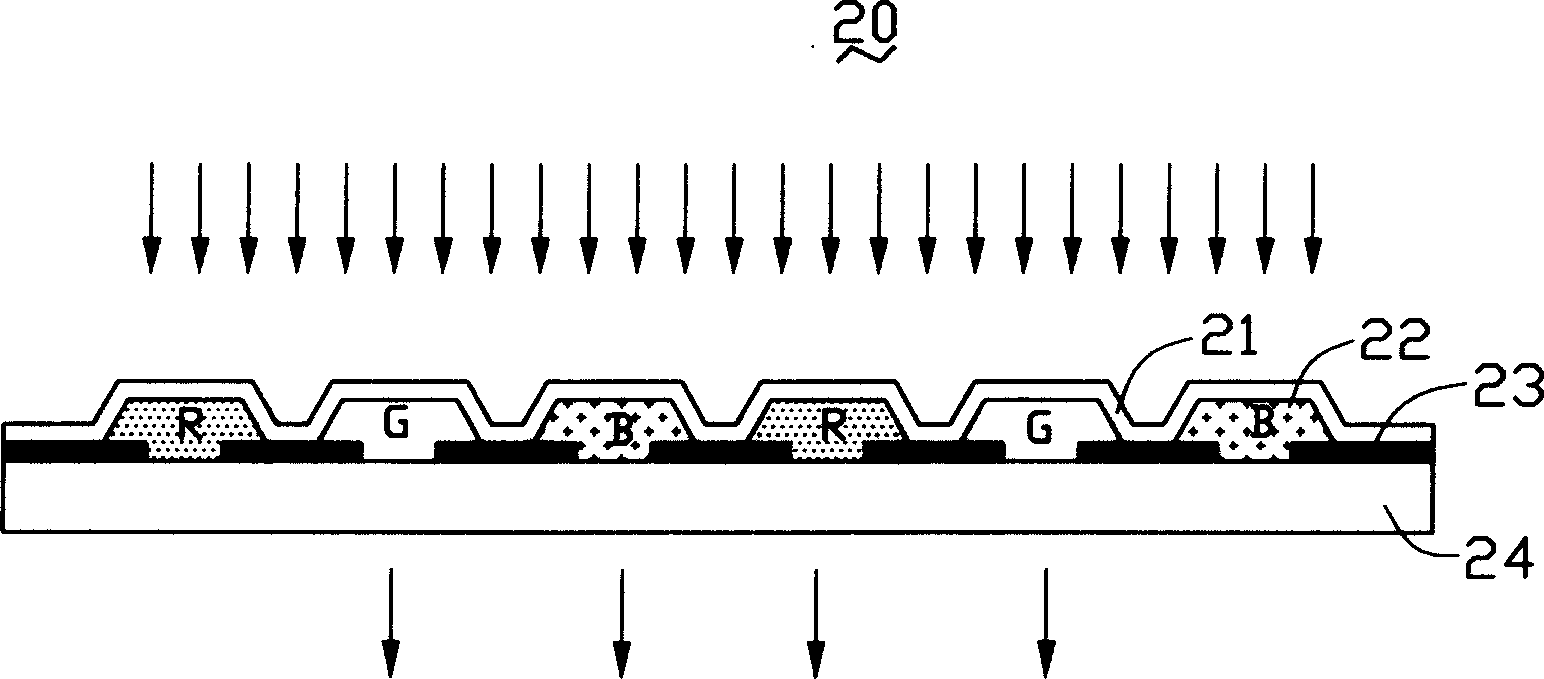

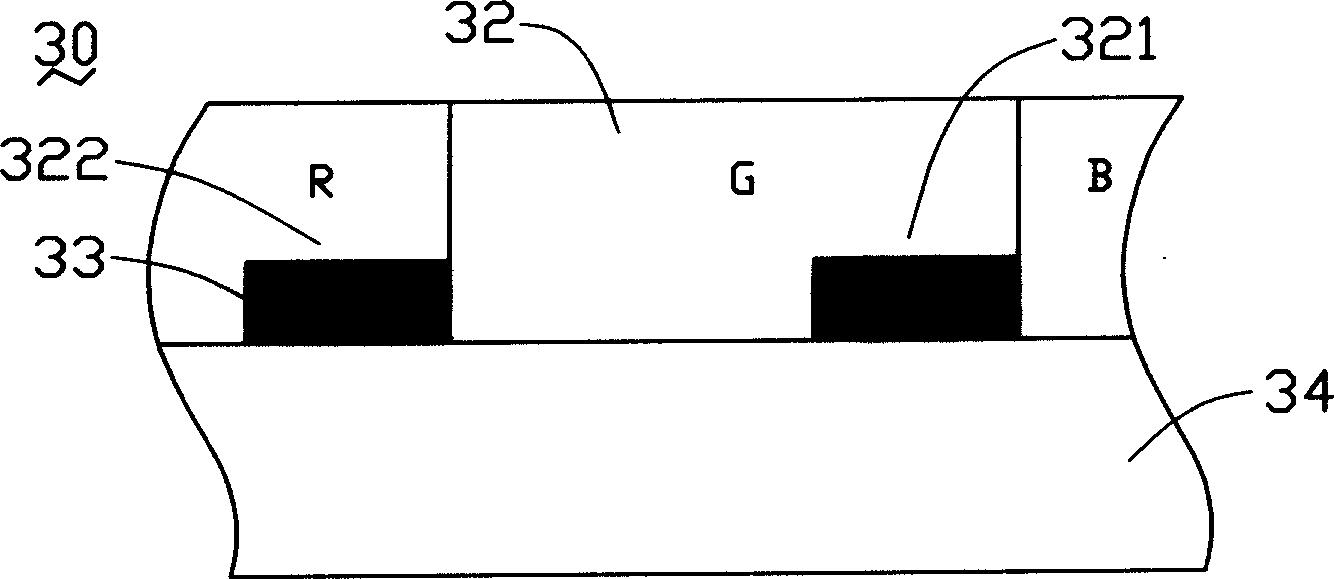

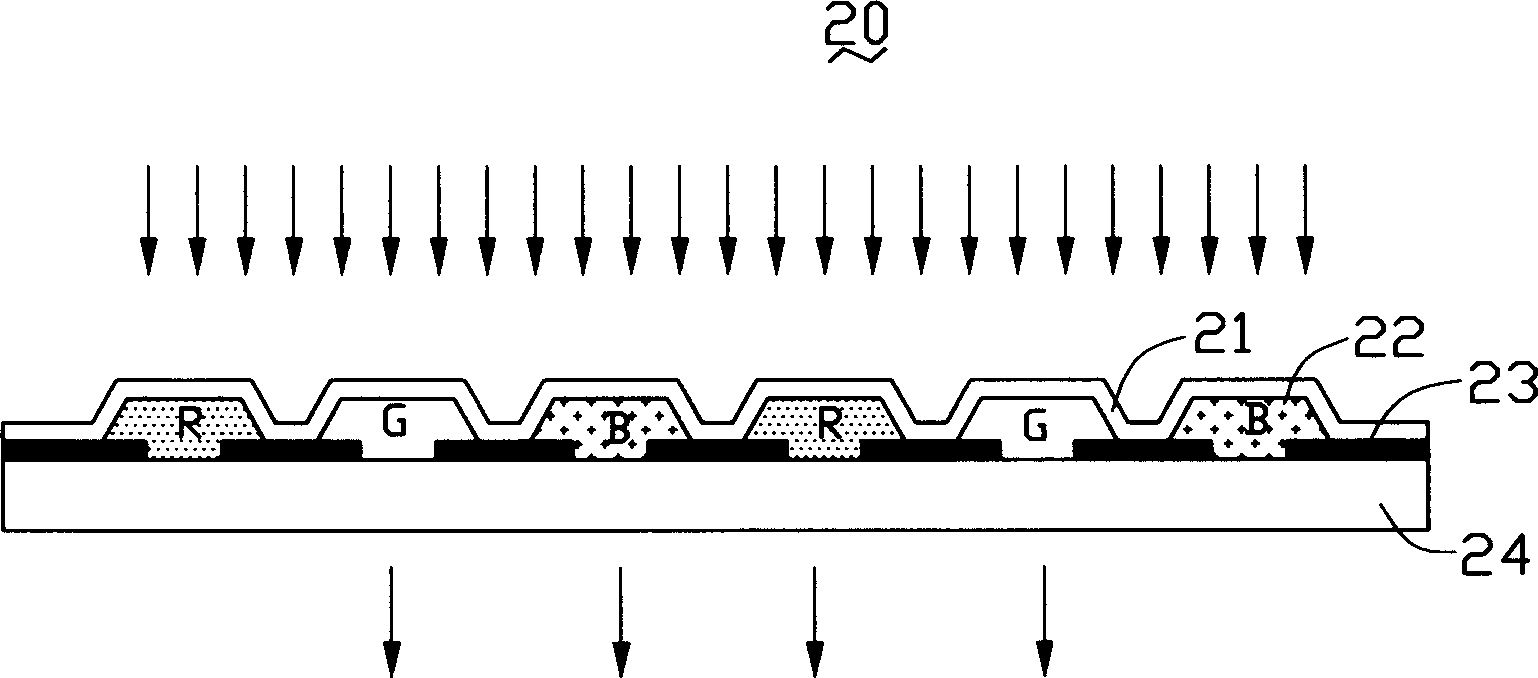

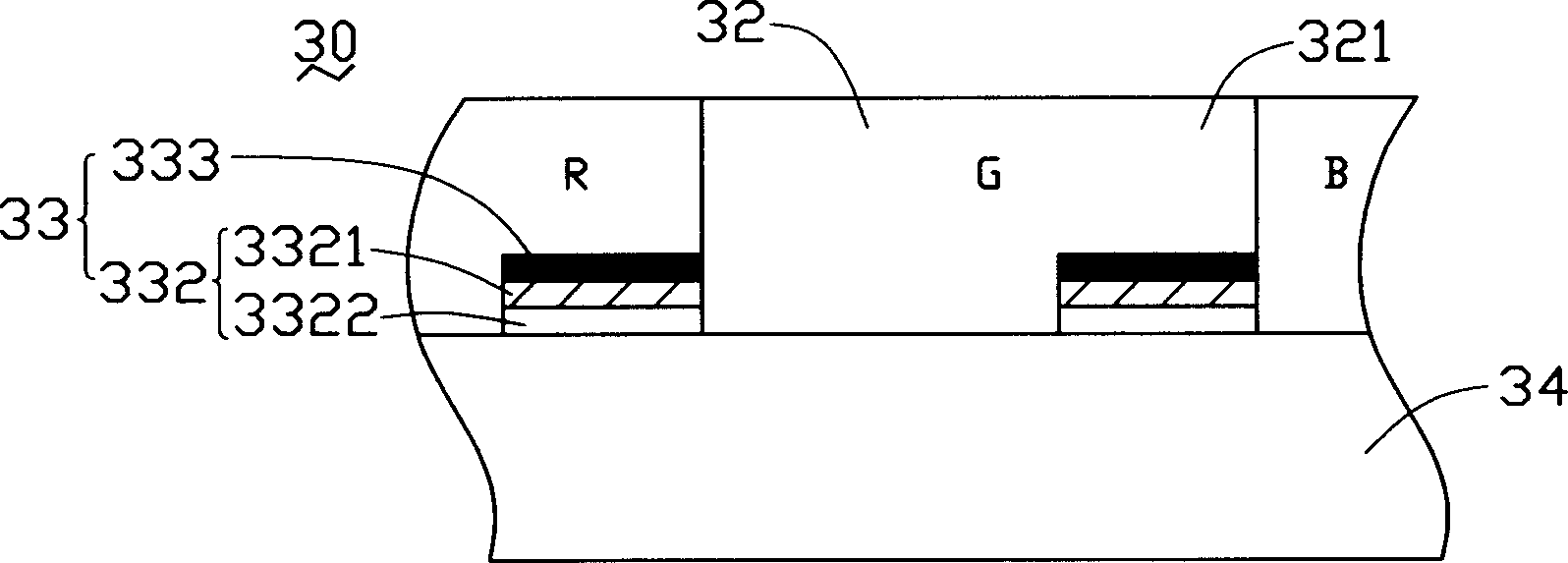

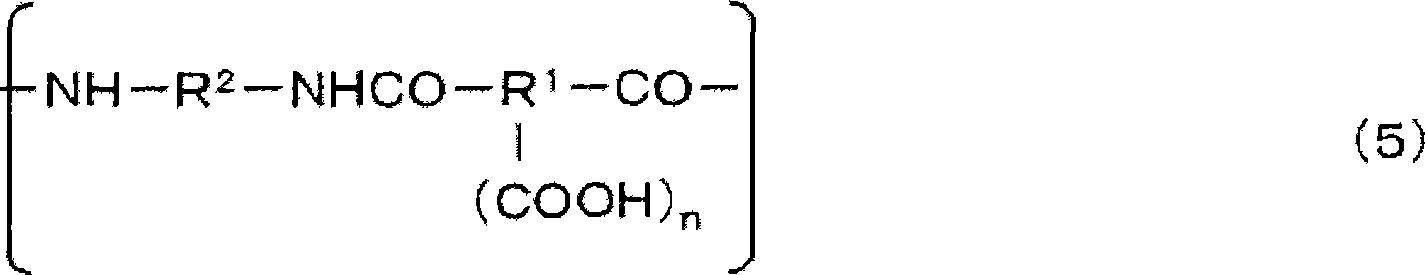

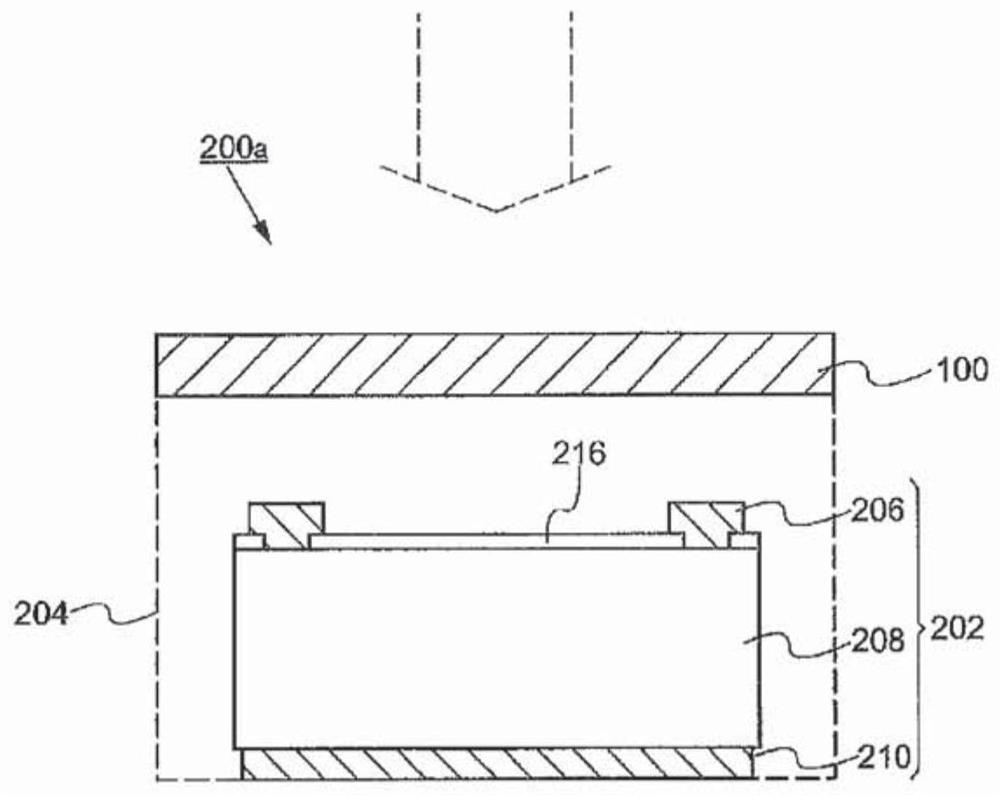

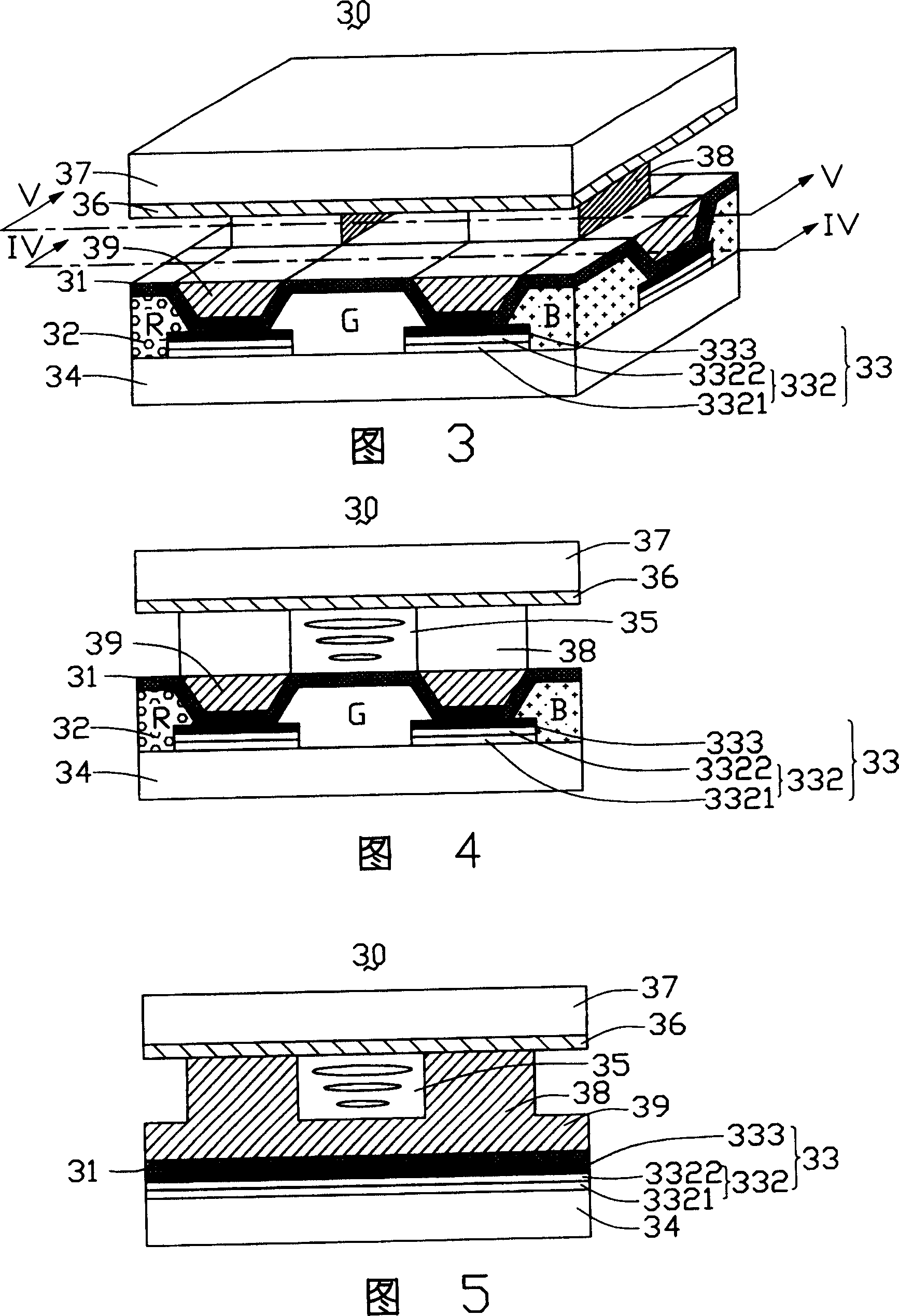

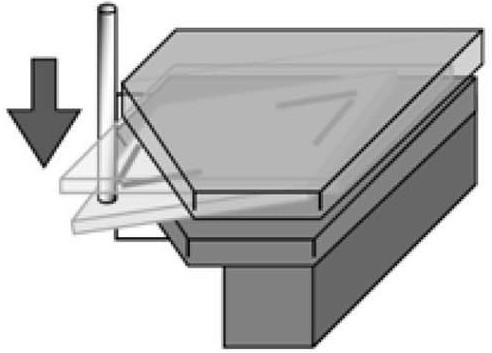

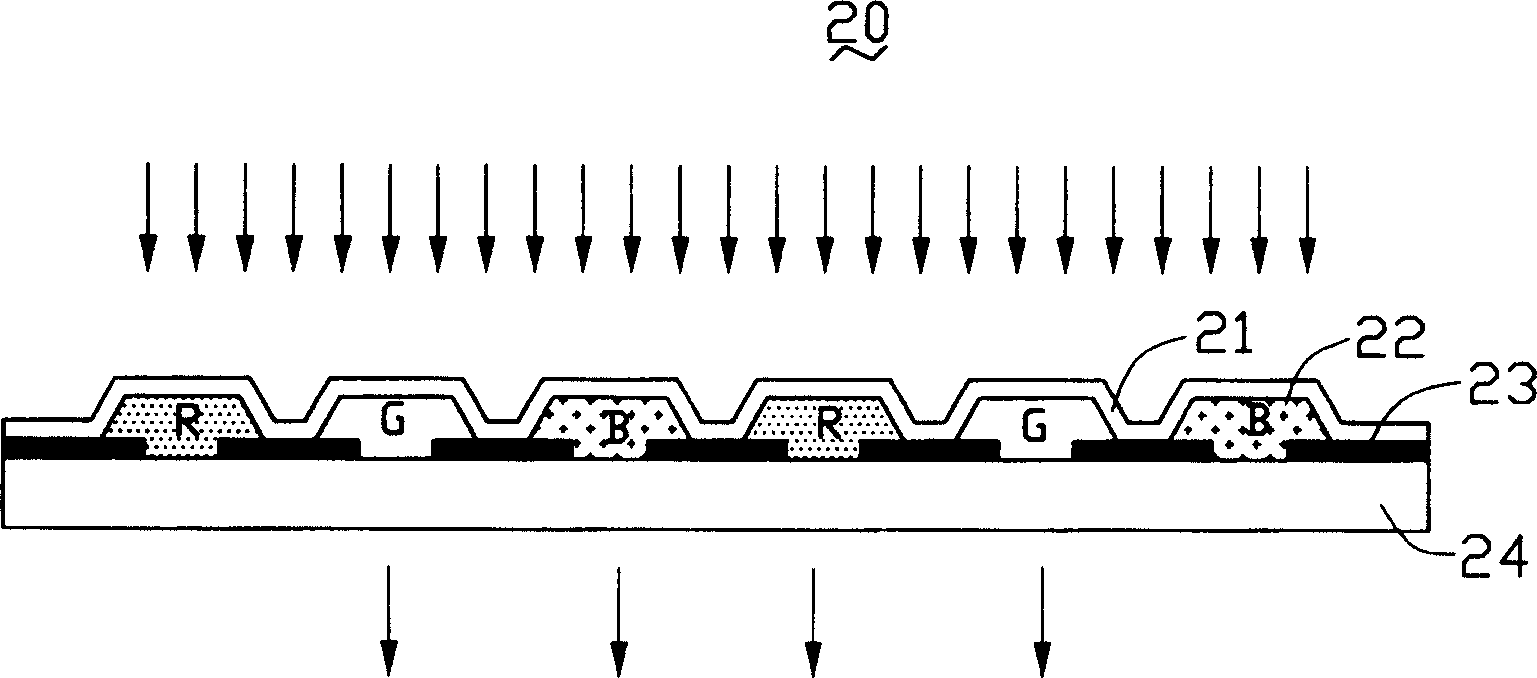

Method for preparing color filter and method for manufactring liquid crystal display

InactiveCN1540371AImprove shading effectHigh OD valueNon-linear opticsOptical elementsChemistryColor gel

Method for fabricating color filter includes following steps: preparing first base layer; preparing a black resin matrix layer on surface of the first base layer; forming a chromatic layer on surface of the first base layer, the chromatic layer and the black resin matrix layer are distributed on the first base layer alternately, and part of the chromatic layer is extended to whole surface of the black resin matrix layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

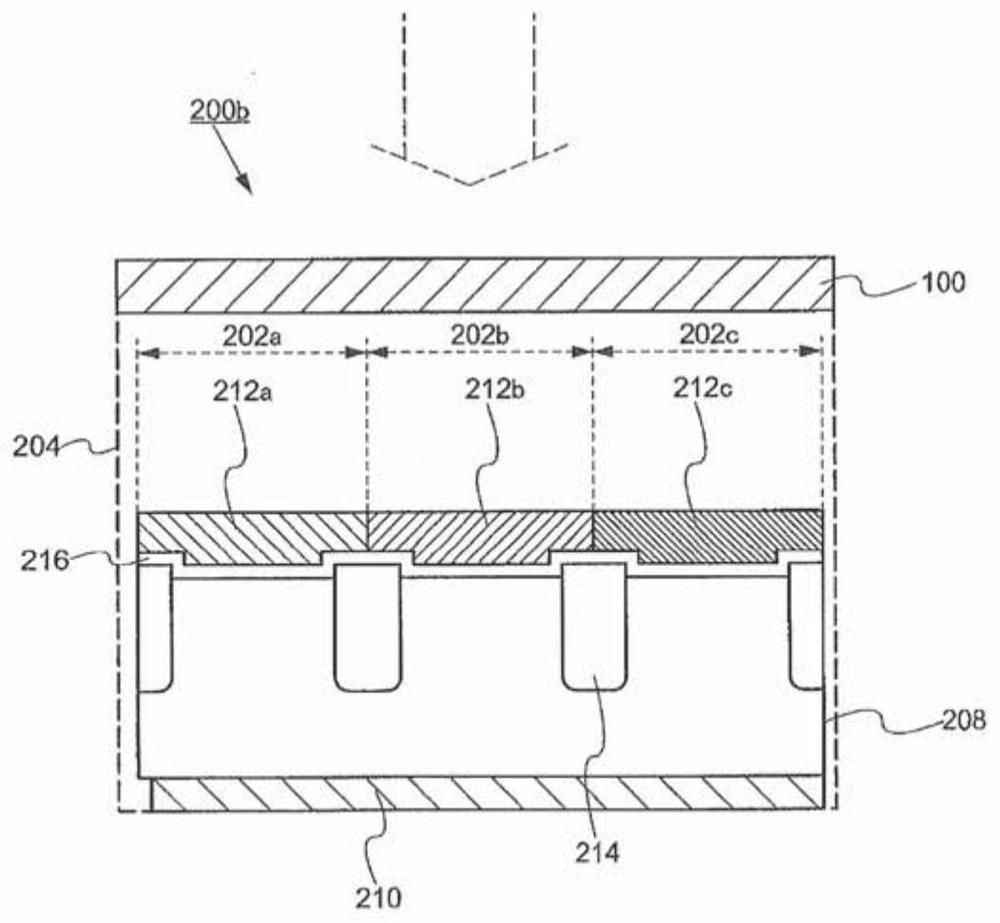

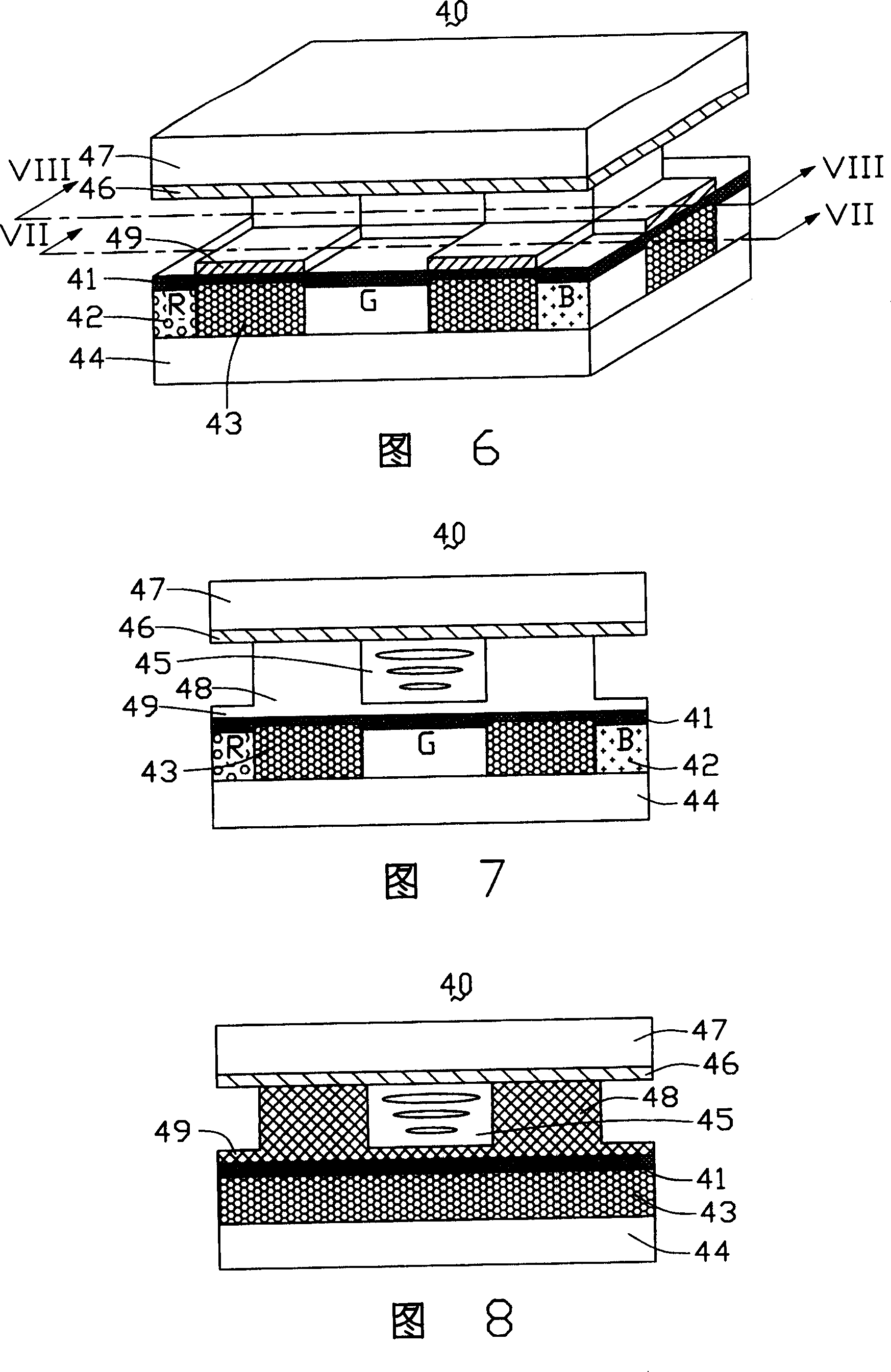

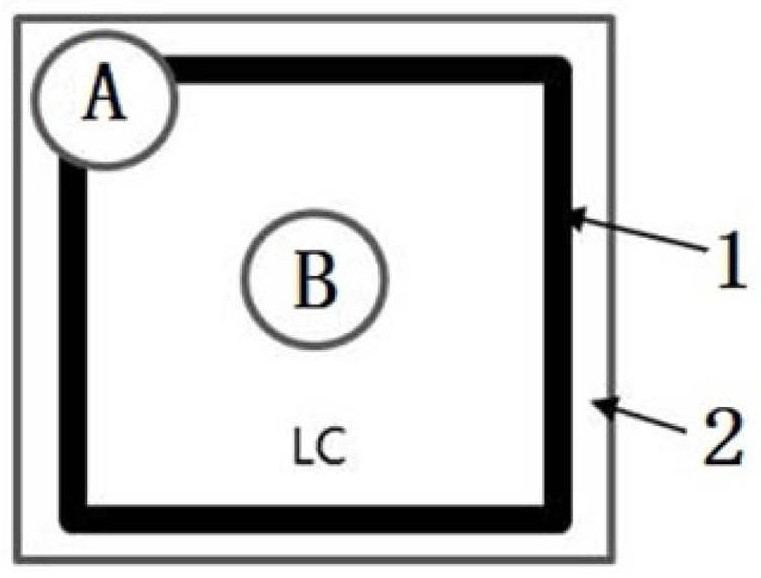

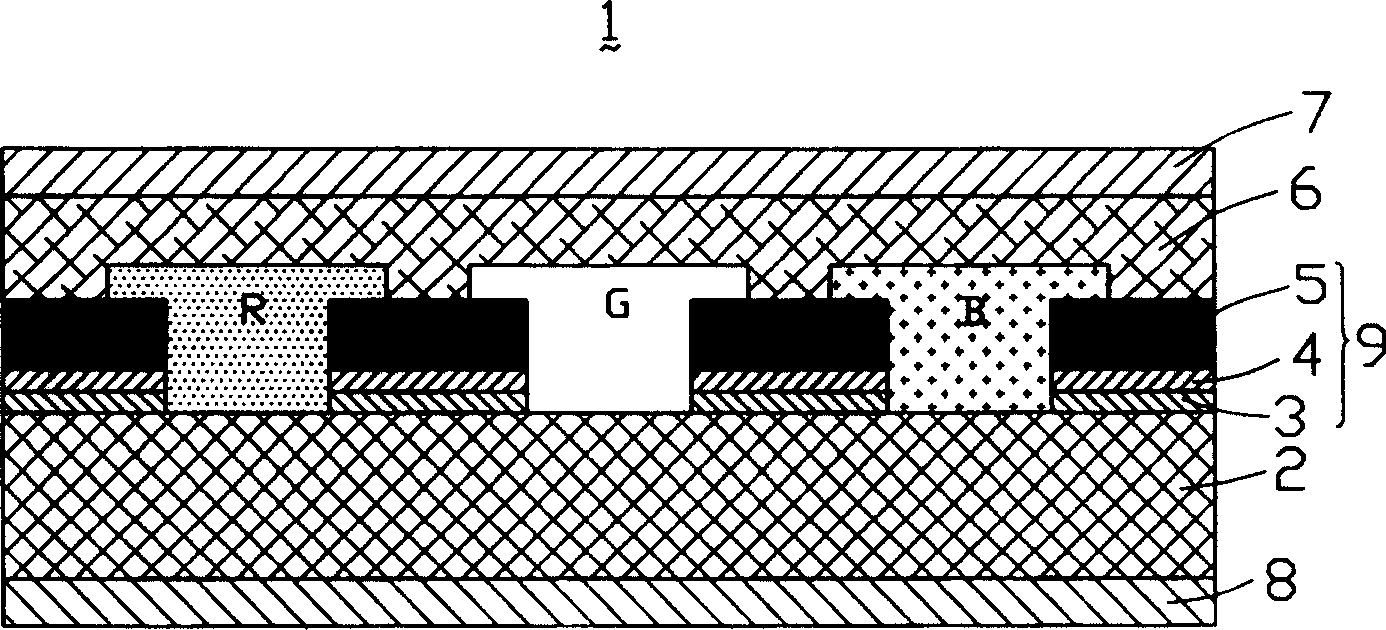

Color optical filter and liquid crystal display device

InactiveCN1532567AGood optical performanceReduce reflectionNon-linear opticsOptical elementsLight filterComputer science

The present invention relates to color optical filter and LCD device therewith. The color optical filter includes one first substrate, and one black matrix and coloring layer. The black matrix layer includes one anti-reflecting layer and one mask layer set on the first substrate layer successively; the coloring layer and the black matrix layer are set on the first substrate alternately; and the coloring layer covers the surface of the mask layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Black composition, black coating composition, resin black matrix, color filter for liquid crystal display and liquid crystal display

A black coating composition which gives a highly adhesive resin black matrix that exhibits a high OD value which was able to be attained only by metal thin film black matrices is disclosed. The black coating composition comprises as indispensable components a titanium nitride oxide and a resin. The X-ray intensity ratios R 1 and R 2 of the titanium nitride oxide represented by the Equations (1) and (2) below, respectively, satisfy the relationships represented by Formulae (3) and (4) below: R 1 = I 3 / { I 3 + 1.8 ( I 1 + 1.8 I 2 ) } R 2 = I 2 / I 1 R 1 > 0.70 0.85 < R 2 < 1.80 wherein I 1 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2 , determined by using CuK+- line as the X-ray source, is 25 DEG to 26 DEG , I 2 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2 is 27 DEG to 28 DEG , and I 3 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2 is 36 DEG to 38 DEG .

Owner:TORAY IND INC

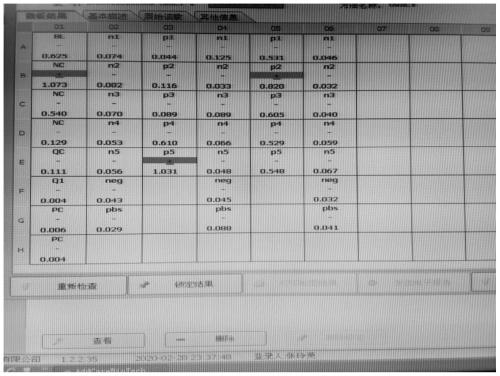

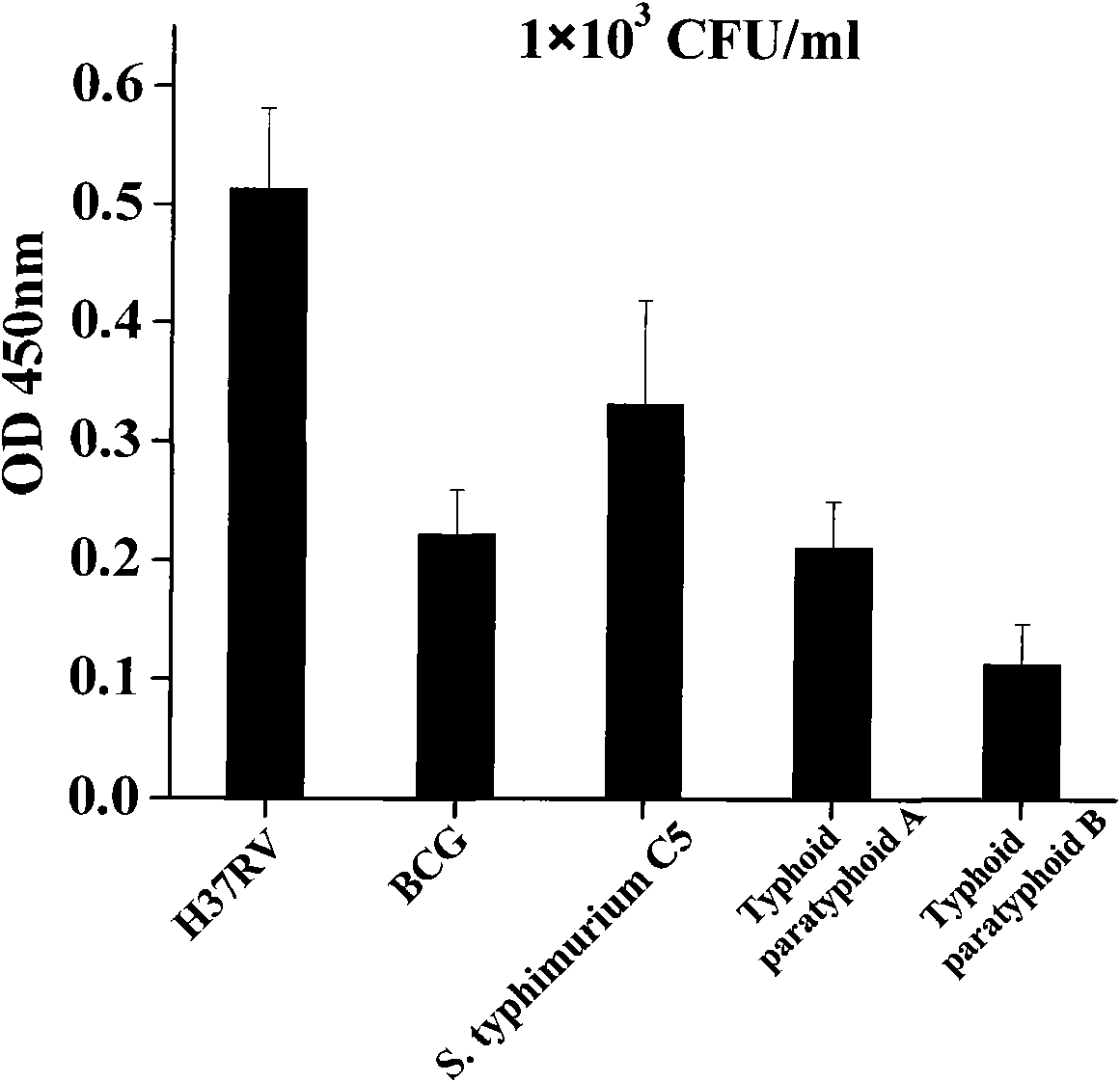

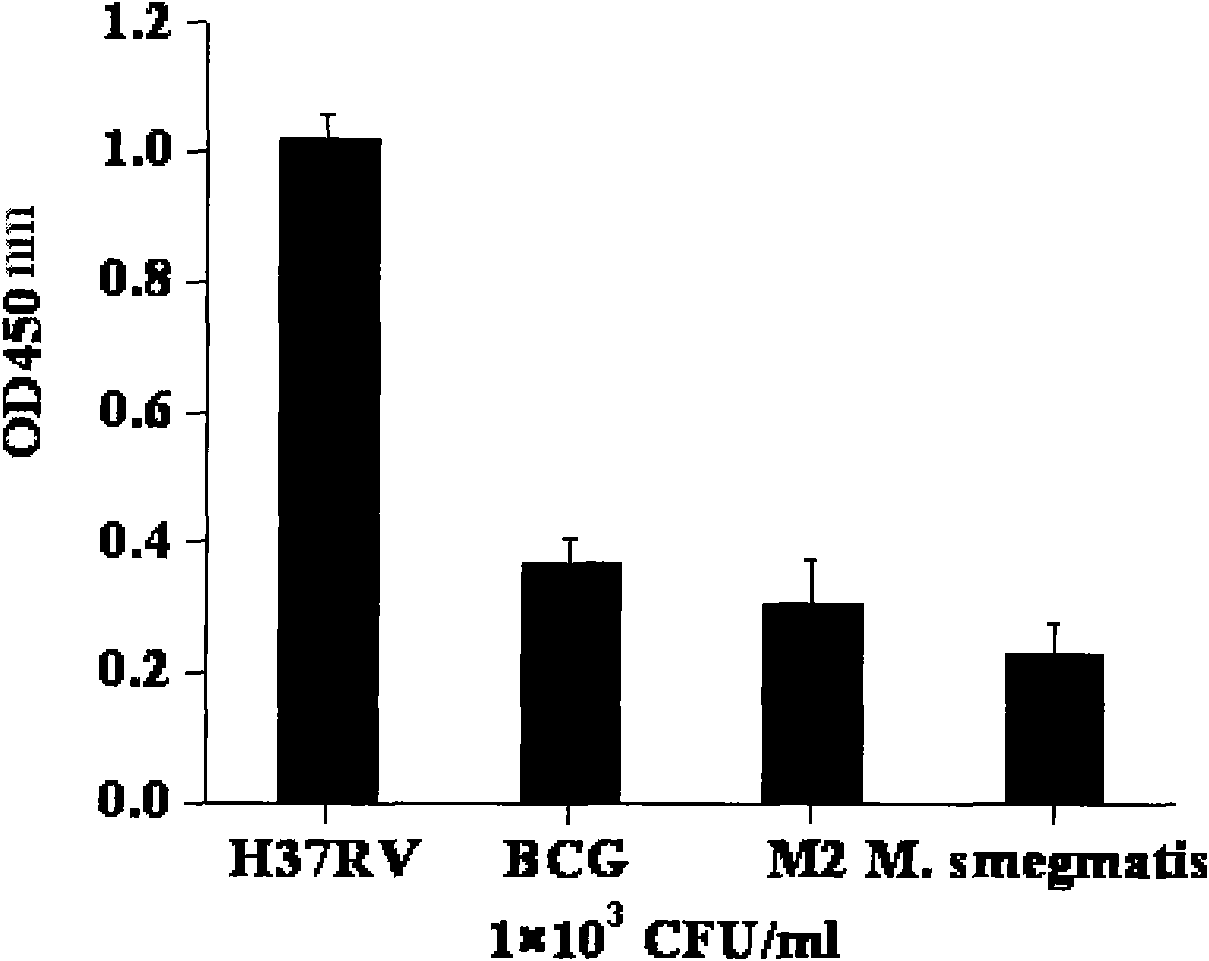

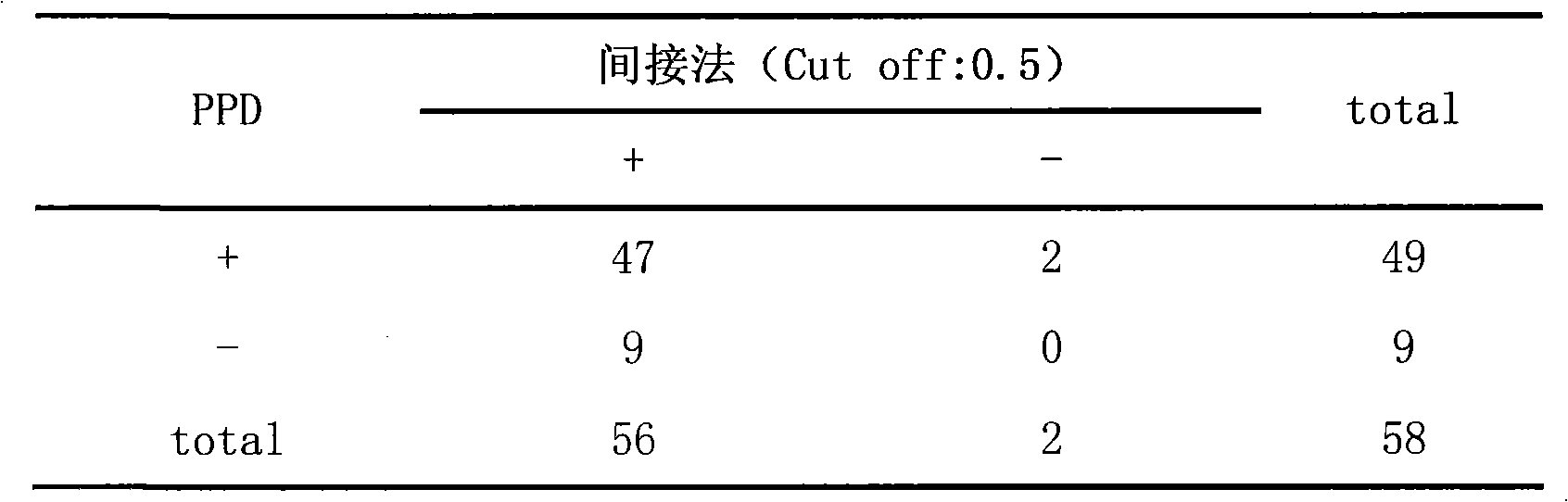

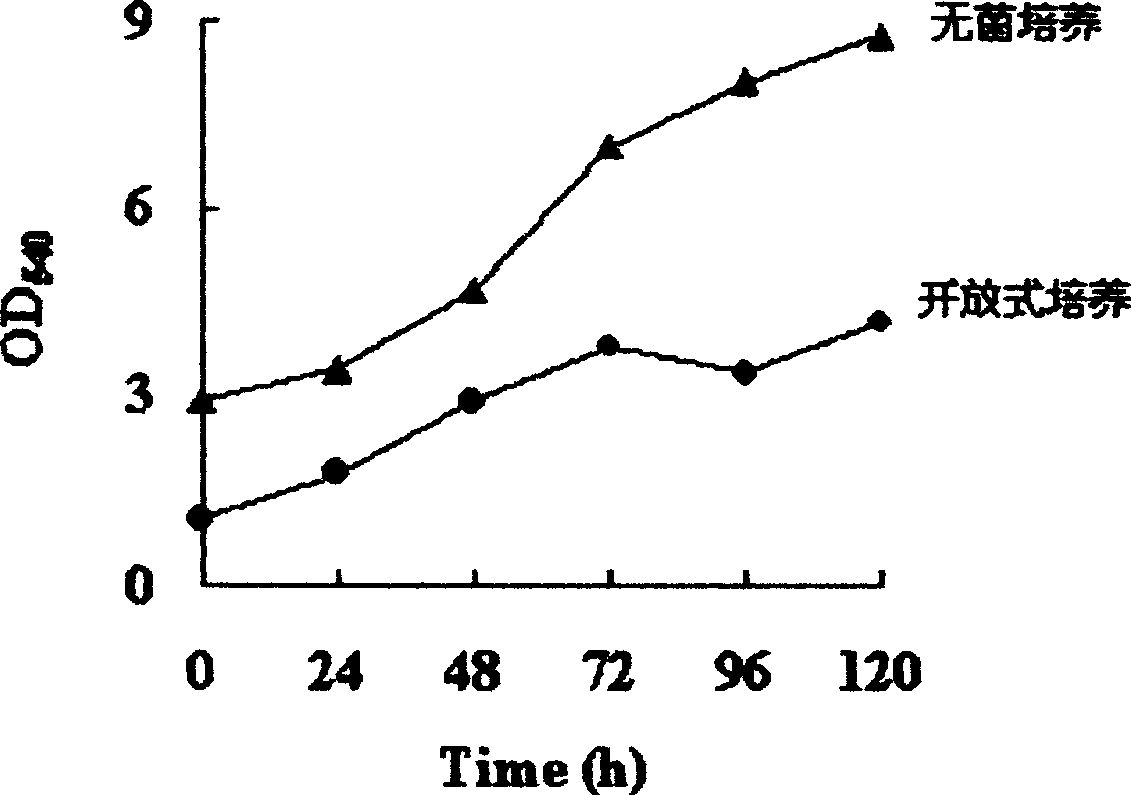

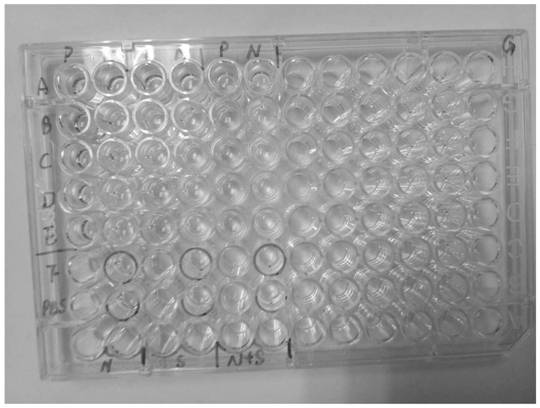

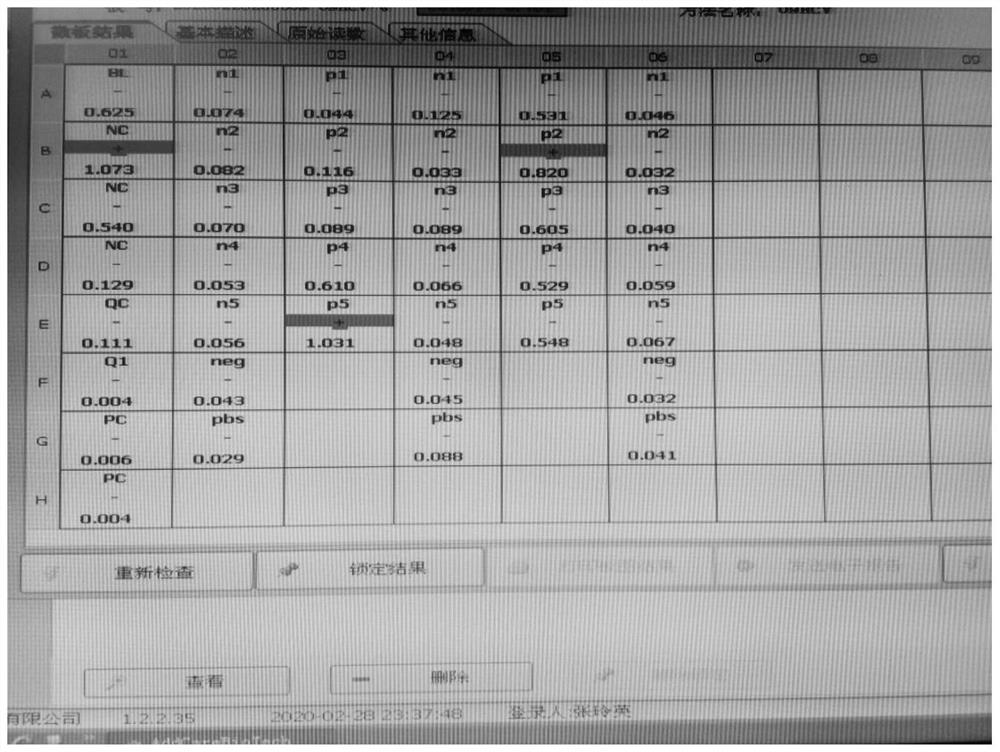

Kit of Mycobacterium tuberculosis and detection method thereof

InactiveCN102081091AEasy to synthesizeHigh OD valueMicrobiological testing/measurementColor/spectral properties measurementsBiotin-streptavidin complexSingle strand dna

The invention discloses a kit of Mycobacterium tuberculosis and a detection method thereof. The kit contains an enzyme-linked immunosorbent assay (ELISA) plate, a biotin-labeled single-stranded DNA adaptor, horseradish peroxidase-labeled streptavidin and a chromogenic substrate. In the detection method provided by the invention, the biotin-labeled single-stranded DNA adaptor of Mycobacterium tuberculosis H37Rv is used as a probe and a method which is similar to the indirect enzyme-linked immunosorbent assay (ELISA) method is adopted to detect Mycobacterium tuberculosis; and Mycobacterium tuberculosis or sputum to be detected or a body fluid sample, and a control sample are added in the ELISA plate for incubation, Mycobacterium tuberculosis combined with the plate is trapped by the biotin-labeled single-stranded DNA adaptor and then washed, the horseradish peroxidase-labeled streptavidin is added, the substrate is added for developing, and the optical density (OD) value is detected by a microplate reader after developing when the absorption wavelengh is 450nm. When the kit provided by the invention detects Mycobacterium tuberculosis or the Mycobacterium tuberculosis or somatic antigen in sputum, blood and body fluid, the detection speed is high, the detection is convenient and safe, the detection time can be saved, the efficiency is high, the cost is low, the detection sensitivity and accuracy are high, and the application prospect is wide.

Owner:WUHAN UNIV

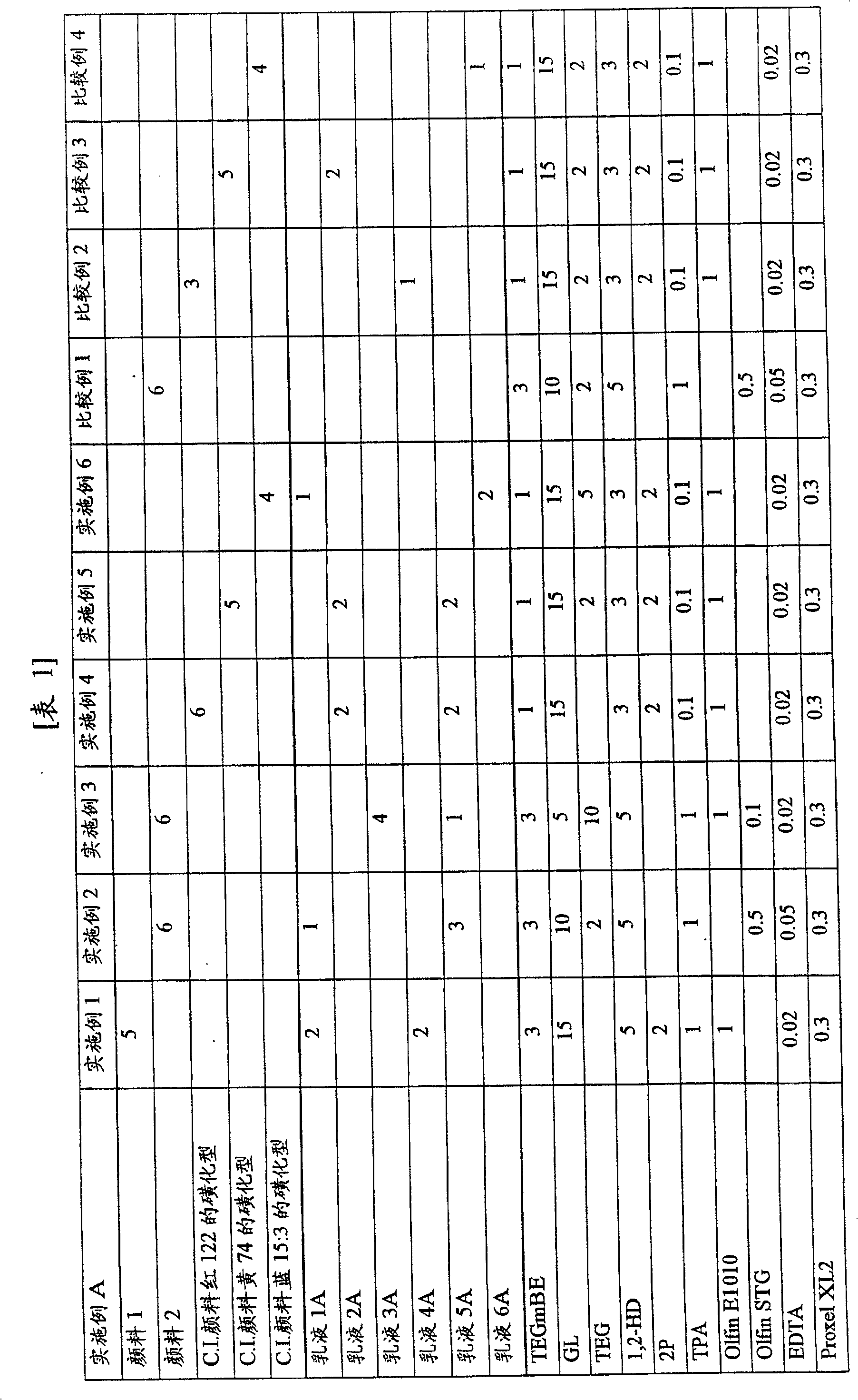

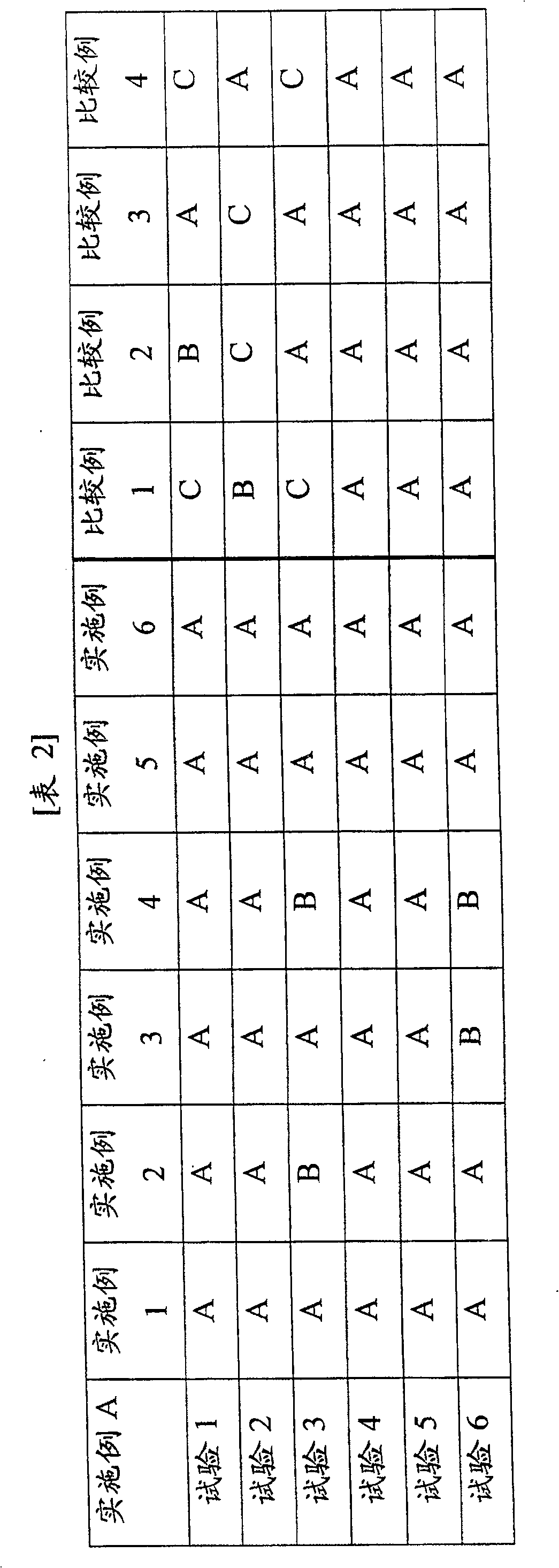

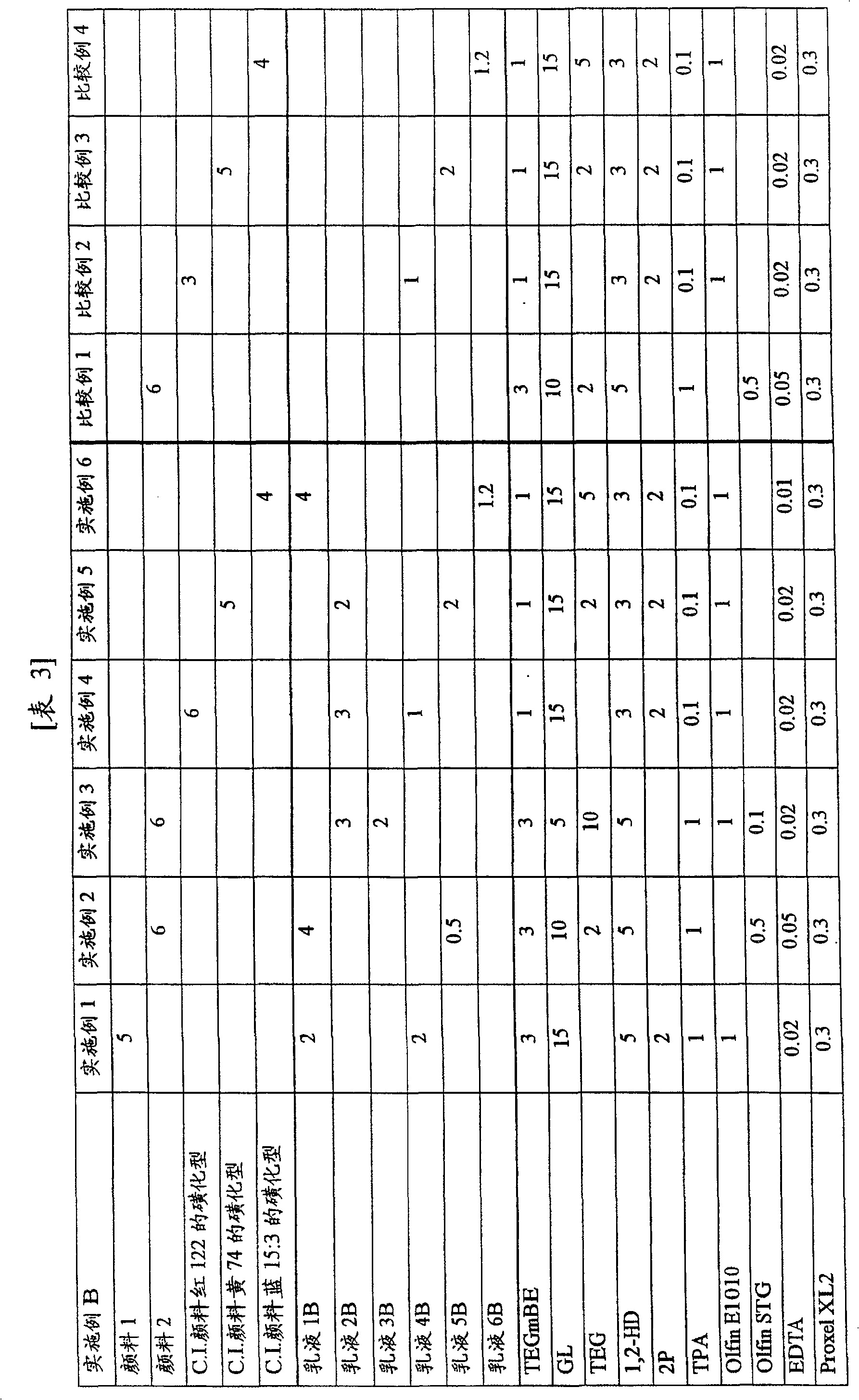

Ink composition for ink-jet recording, recording method using same, and record

InactiveCN1592775AImprove reliabilityImprove printing qualityDuplicating/marking methodsInksZeta potentialGlass transition point

It is an object of the present invention to provide an ink jet recording ink composition with good reliability and print quality, a high OD value, and good fixability that affords excellent smear resistance. This object is achieved with the present invention by providing ink jet recording ink composition comprising at least a self-dispersing pigment and two types of resin particles with mutually different properties. The above-mentioned two types of resin particles are two types of resin particles whose glass transition points, average sizes, minimum film-formation temperatures, zeta potentials, and other such properties are mutually different. The present invention also provides a recording method, wherein the above-mentioned ink composition is used to form an image on a recording medium, and provides recorded matter comprising an image formed on a recording medium using the above-mentioned ink composition.

Owner:SEIKO EPSON CORP +1

Ink composition for ink-jet recording, recording method using the same, and record

ActiveCN1831053AImprove reliabilityImprove printing qualityDuplicating/marking methodsInksZeta potentialGlass transition point

It is an object of the present invention to provide an ink jet recording ink composition with good reliability and print quality, a high OD value, and good fixability that affords excellent smear resistance. This object is achieved with the present invention by providing ink jet recording ink composition comprising at least a self-dispersing pigment and two types of resin particles with mutually different properties. The above-mentioned two types of resin particles are two types of resin particles whose glass transition points, average sizes, minimum film-formation temperatures, zeta potentials, and other such properties are mutually different. The present invention also provides a recording method, wherein the above-mentioned ink composition is used to form an image on a recording medium, and provides recorded matter comprising an image formed on a recording medium using the above-mentioned ink composition.

Owner:SEIKO EPSON CORP +1

High-temperature-resistant black exposure and development printing ink, method for preparing same and application

PendingCN108373655AImprove insulation performanceHigh OD valueInksPhotosensitive materials for photomechanical apparatusCyclohexanoneEpoxy

The invention provides high-temperature-resistant black exposure and development printing ink, a method for preparing the same and application. The high-temperature-resistant black exposure and development printing ink is applied to the field of decoration of different types of 3D (three-dimensional) curved glass and special-shaped glass. The high-temperature-resistant black exposure and development printing ink is double-component printing ink. A component A of the high-temperature-resistant black exposure and development printing ink comprises epoxy resin, polyester resin, fillers, carbon black, auxiliaries, photoinitiators and cyclohexanone. A component B of the high-temperature-resistant black exposure and development printing ink comprises closed curing agents and butyl acetate. Diluents comprise butanone, butyl acetate and MIBK (methyl isobutyl ketone). The high-temperature-resistant black exposure and development printing ink, the method and the application have the advantages that the curing agents and the diluents can be proportionally added, then the high-temperature-resistant black exposure and development printing ink can be sprayed, 1% sodium carbonate solution can besprayed for 30-90 seconds after the high-temperature-resistant black exposure and development printing ink is preliminarily baked and exposed, unexposed regions can be quickly faded, clear images canbe displayed, and the high-temperature-resistant black exposure and development printing ink is free of residues; the high-temperature-resistant black exposure and development printing ink can be ultimately baked at the temperatures of 150-180 DEG C for 30 minutes, the dried high-temperature-resistant black exposure and development printing ink is excellent in insulating property and good in adhesion, has a high OD (optical density) value and can resist high temperatures, and the problems of low yield and efficiency and high cost of the traditional decoration technologies for 3D curved glass and special-shaped glass can be effectively solved.

Owner:江西赐彩新材料股份有限公司

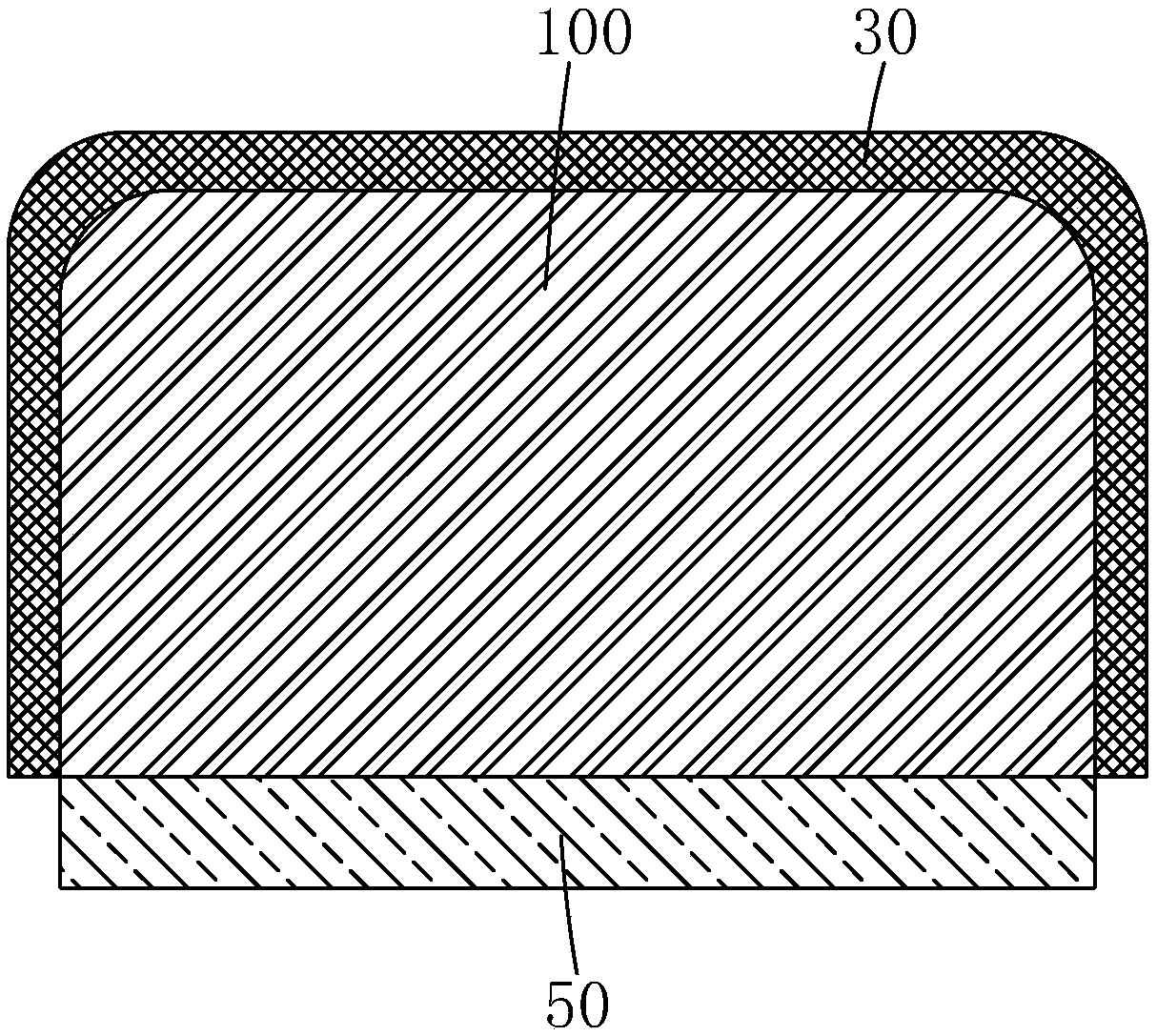

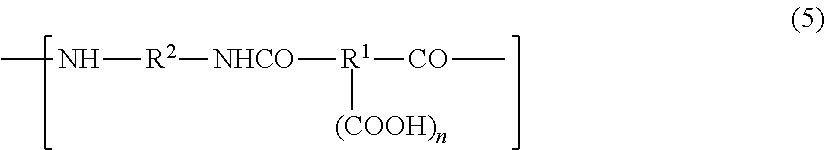

Reactive polyurethane hot melt adhesive for shading round hole of mobile phone and preparation method ofhot melt adhesive

ActiveCN112608705AHigh OD valueImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to the technical field of reactive polyurethane hot melt adhesives, in particular to a reactive polyurethane hot melt adhesive for shading a round hole of a mobile phone and a preparation method of the reactive polyurethane hot melt adhesive. The polyurethane hot melt adhesive is prepared from the following raw materials in parts by weight: 30 to 65 parts of polyhydric alcohol, 10 to 40 parts of tackifying resin, 0.1 to 1 part of antioxidant, 5 to 15 parts of opacifying agent, 10 to 35 parts of aromatic isocyanate, 0.01 to 0.1 part of a catalyst and 1 to 2 parts of a silane coupling agent. The hot melt adhesive provided by the invention has high shading property and aging resistance.

Owner:WUXI WANLI ADHESION MATERIALS

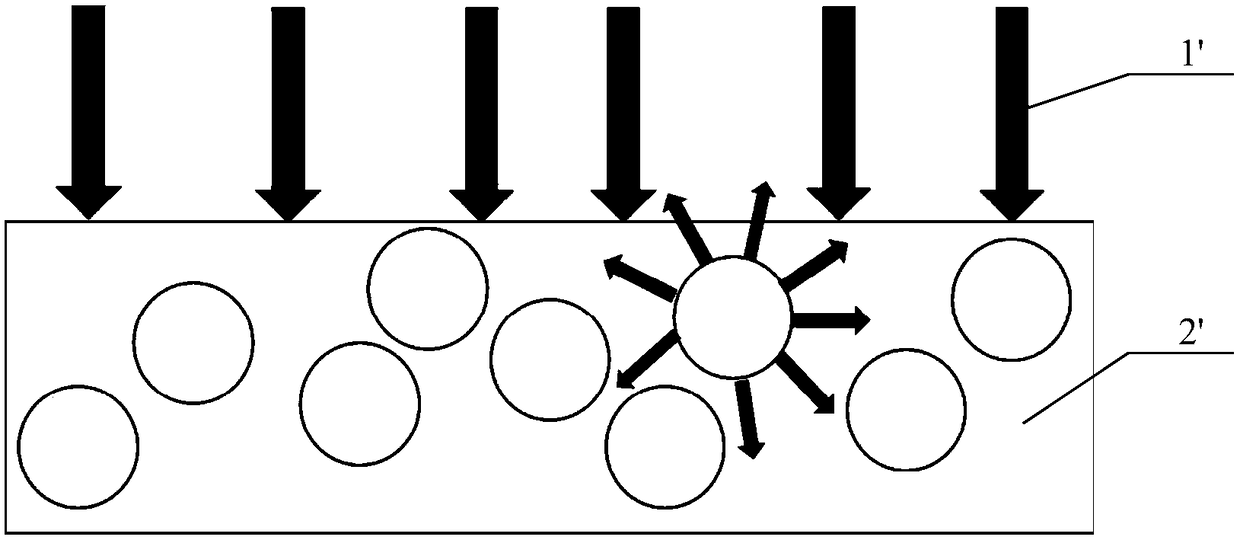

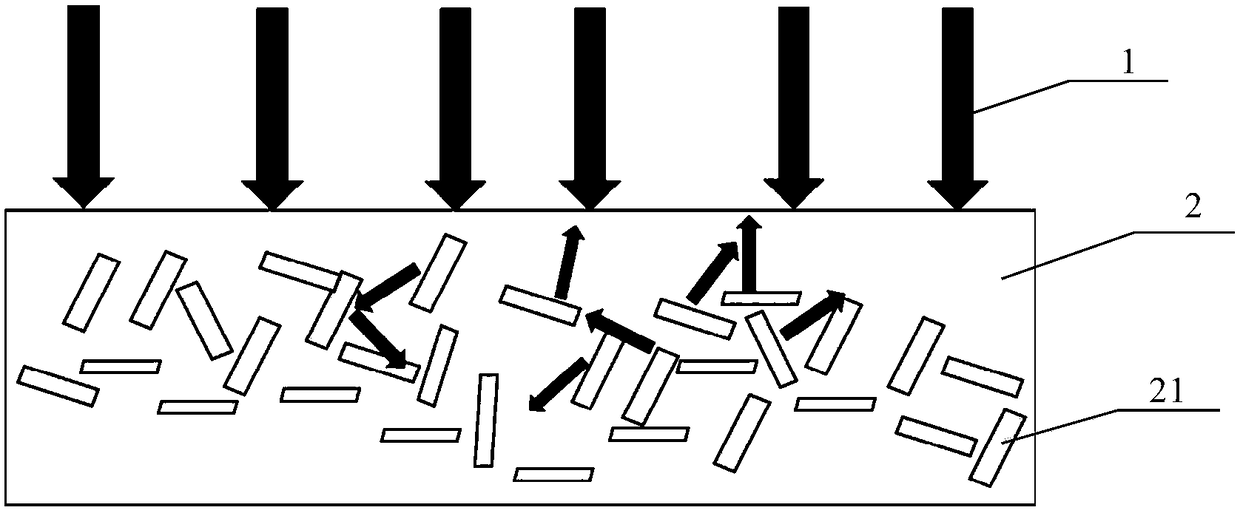

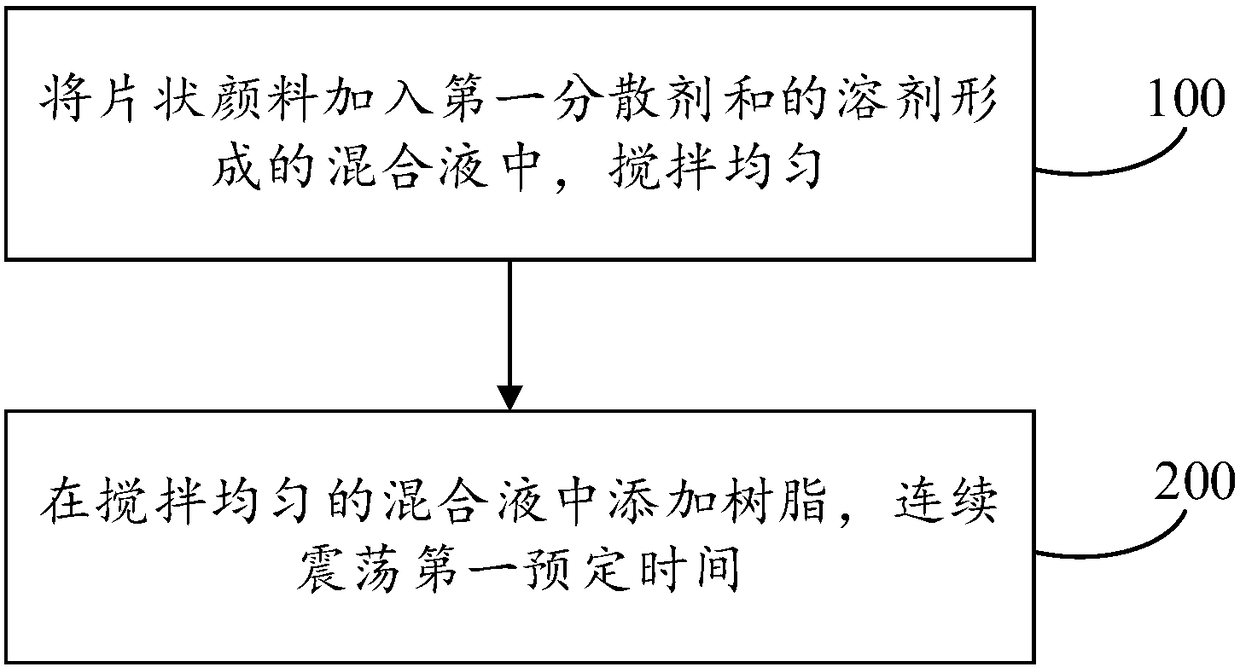

Pigment solution for black matrix, black matrix as well as preparation method of pigment solution, display panel

ActiveCN108329758AStrong entry abilityHigh OD valuePhotosensitive materials for photomechanical apparatusPigment pastesElectrical resistance and conductanceSolvent

The invention discloses a pigment solution for a black matrix, a black matrix as well as a preparation method of pigment solution and a display panel. The pigment solution for the black matrix is prepared from a first dispersion agent, a solvent, resin and flaky pigment for reflecting light. The pigment solution for the black matrix according to embodiments of the invention is prepared from the first dispersion agent, the solvent, the resin and the flaky pigment for reflecting light, the pigment solution for the black matrix is used for producing the black matrix, the flaky pigment is high incapability for insulating the entry of the light, the light can be completely reflected, an OD value is higher, the cost is low by adopting the resin material, and the resistivity is higher.

Owner:BOE TECH GRP CO LTD +1

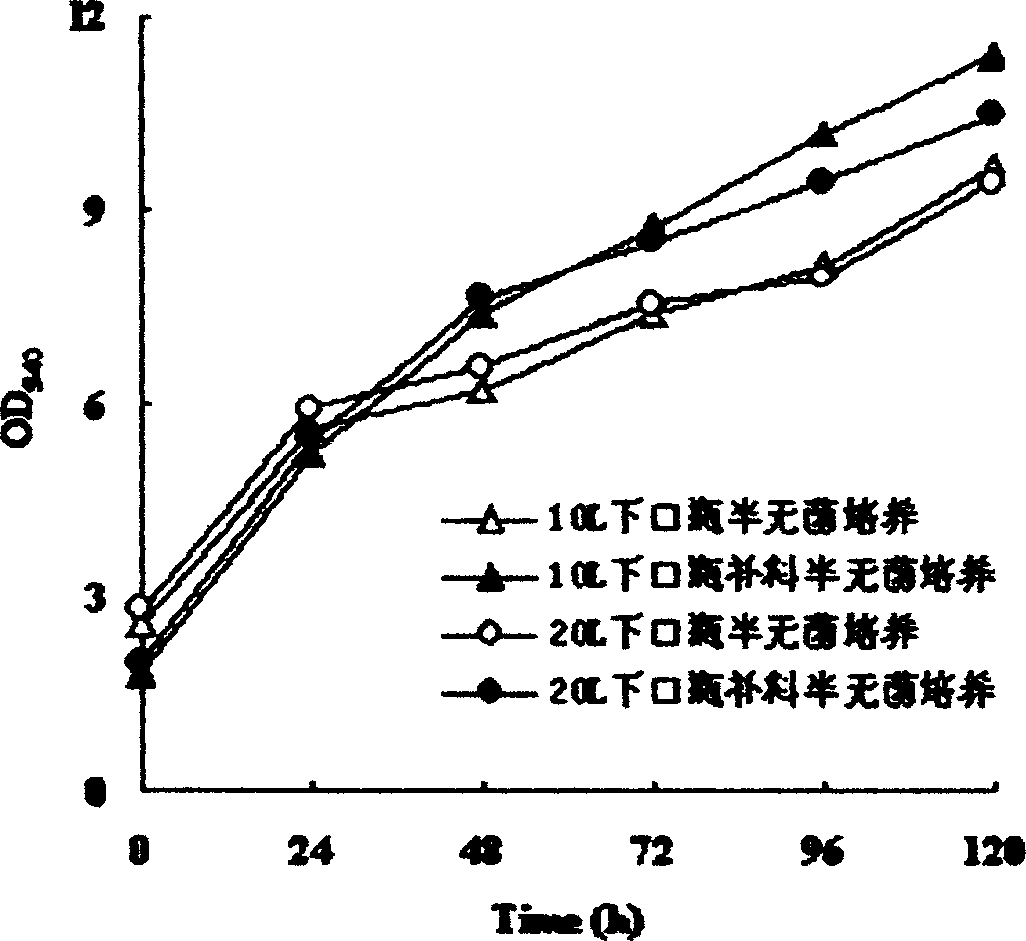

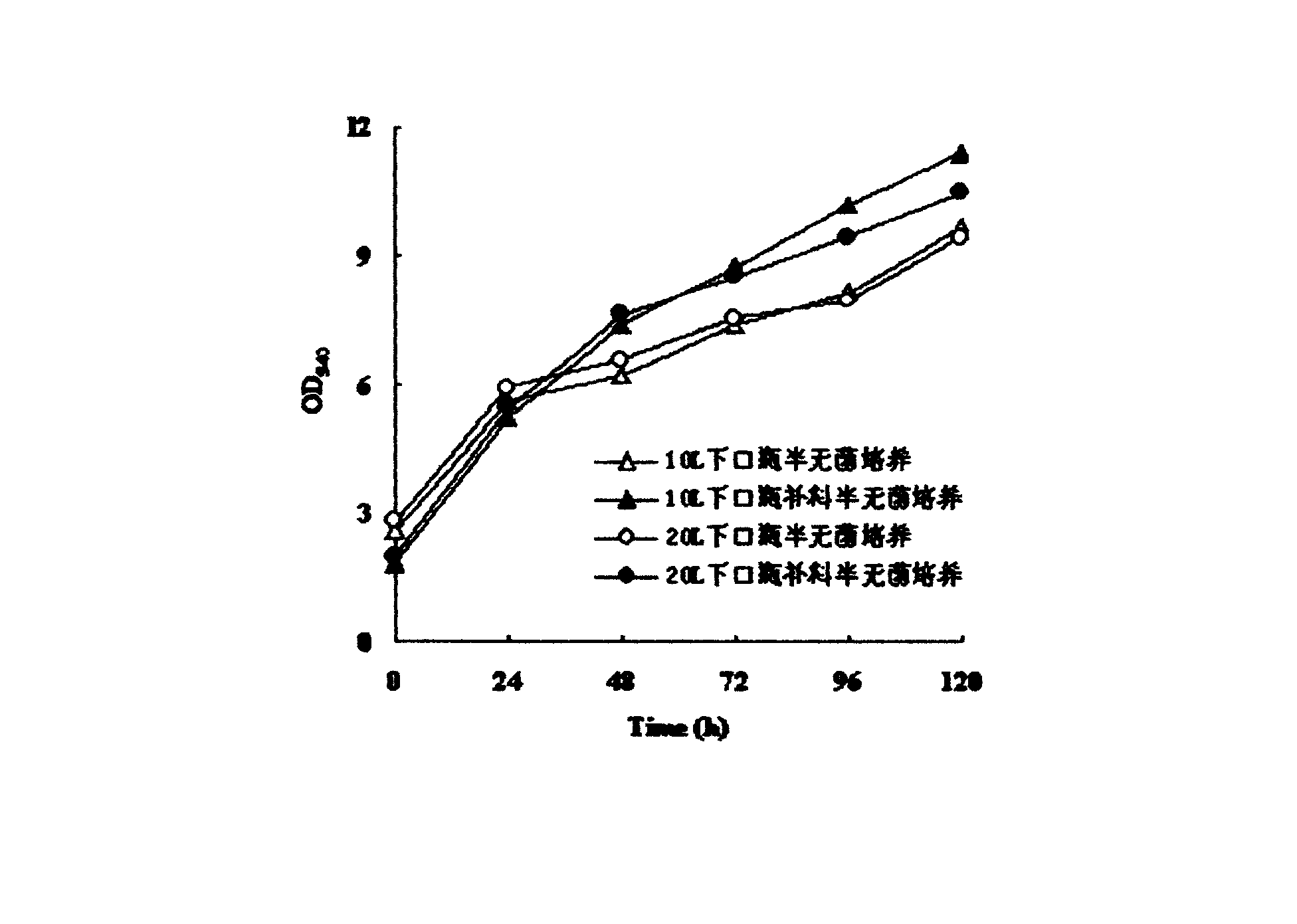

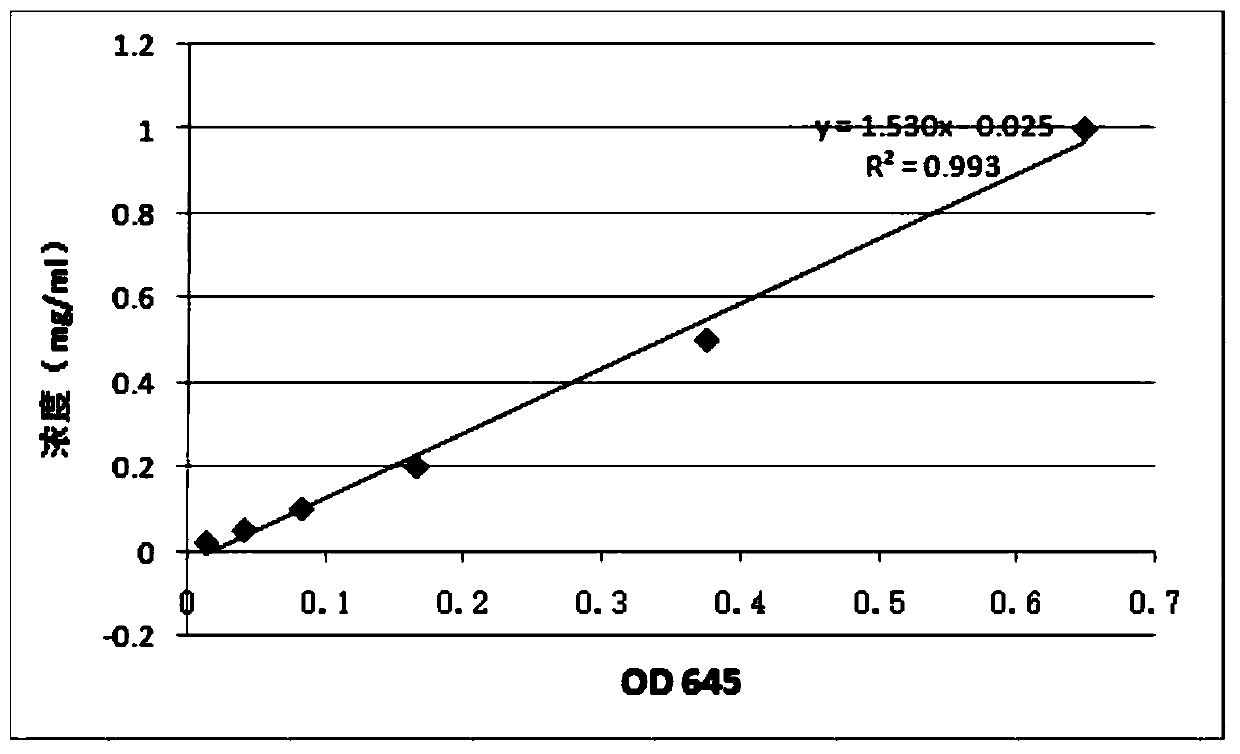

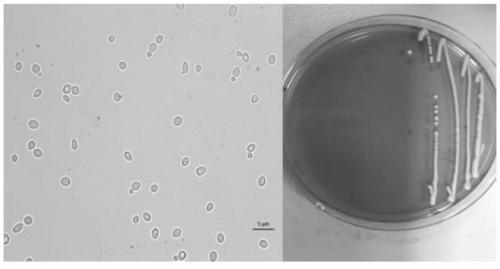

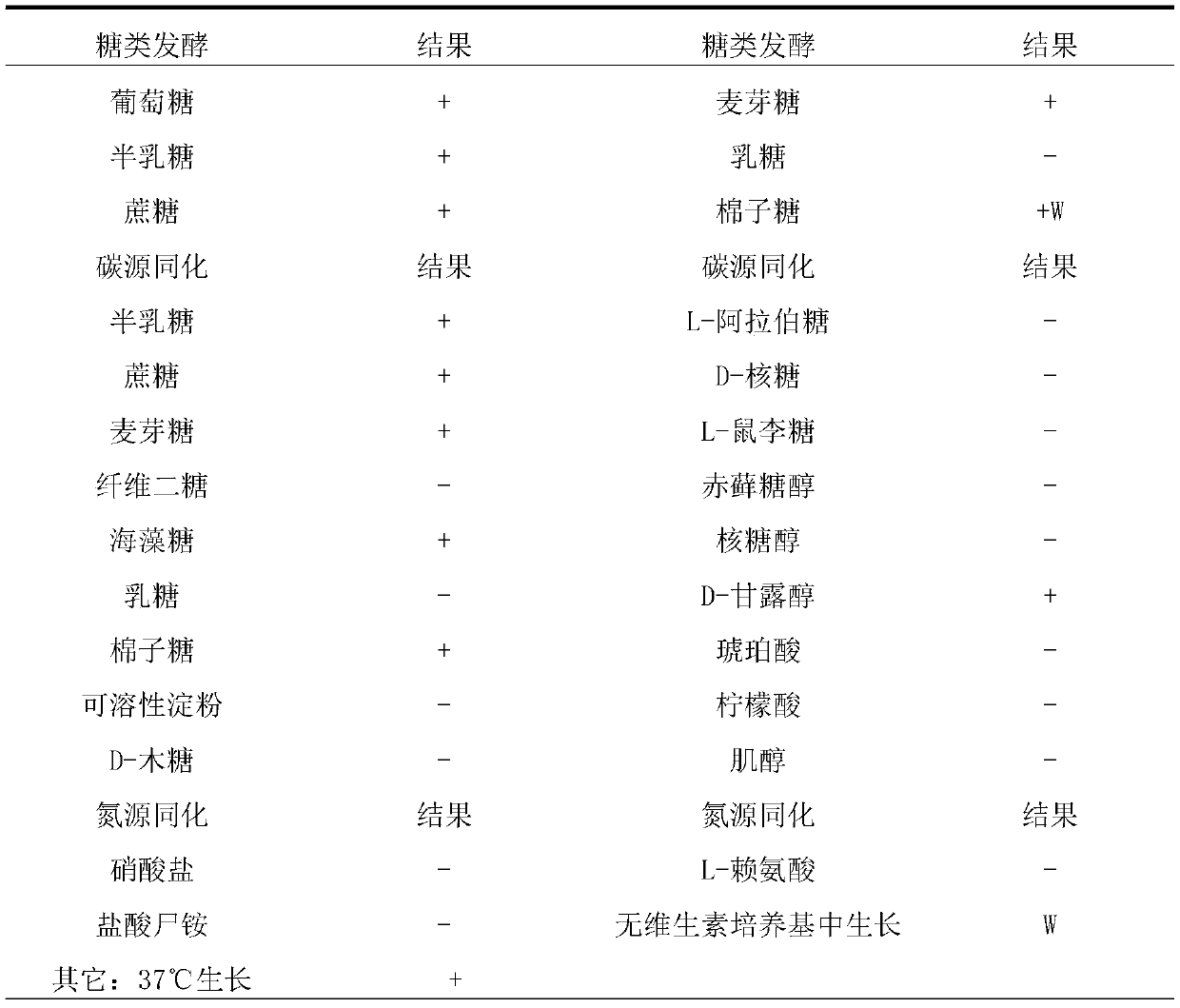

Saccharomyces cerevisiae strain rich in GABA and identification method thereof

InactiveCN109694830AGood acid toleranceHigh OD valueFungiMicrobiological testing/measurementMicroorganismExtracellular

The invention discloses a saccharomyces cerevisiae strain rich in GABA and an identification method thereof, and belongs to the technical field of microbes. The strain is named as SS-A-1 (saccharomyces cerevisiae SS-A-1), has been preserved in China Center for Type Culture Collection (CCTCC), and has a preservation number of CCTCC No.M201825. The 18SrDNA sequence of the strain is represented by the SEQ ID No.1. The intracellular SOD enzyme activity of the saccharomyces cerevisiae SS-A-1 is high and can reach 40.57 u / mL; the extracellular GABA content is high and can reach 1345.42 mg / mL; moreover, the saccharomyces cerevisiae SS-A-1 has a good acid resistant property and a good effect on inhibiting pathogenic bacteria, in particular, micrococcus luteus, and the safety coefficient of obtained fermentation product is high.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD +1

Ink composition for ink-jet recording, recording method using the same, and record

InactiveCN100569874CImprove reliabilityImprove printing qualityDuplicating/marking methodsInksZeta potentialGlass transition point

It is an object of the present invention to provide an ink jet recording ink composition with good reliability and print quality, a high OD value, and good fixability that affords excellent smear resistance. This object is achieved with the present invention by providing ink jet recording ink composition comprising at least a self-dispersing pigment and two types of resin particles with mutually different properties. The above-mentioned two types of resin particles are two types of resin particles whose glass transition points, average sizes, minimum film-formation temperatures, zeta potentials, and other such properties are mutually different. The present invention also provides a recording method, wherein the above-mentioned ink composition is used to form an image on a recording medium,and provides recorded matter comprising an image formed on a recording medium using the above-mentioned ink composition.

Owner:SEIKO EPSON CORP +1

Ink composition for ink-jet recording, recording method using the same, and record

ActiveCN1831056AImprove reliabilityImprove printing qualityDuplicating/marking methodsInksZeta potentialGlass transition point

It is an object of the present invention to provide an ink jet recording ink composition with good reliability and print quality, a high OD value, and good fixability that affords excellent smear resistance. This object is achieved with the present invention by providing ink jet recording ink composition comprising at least a self-dispersing pigment and two types of resin particles with mutually different properties. The above-mentioned two types of resin particles are two types of resin particles whose glass transition points, average sizes, minimum film-formation temperatures, zeta potentials, and other such properties are mutually different. The present invention also provides a recording method, wherein the above-mentioned ink composition is used to form an image on a recording medium, and provides recorded matter comprising an image formed on a recording medium using the above-mentioned ink composition.

Owner:SEIKO EPSON CORP +1

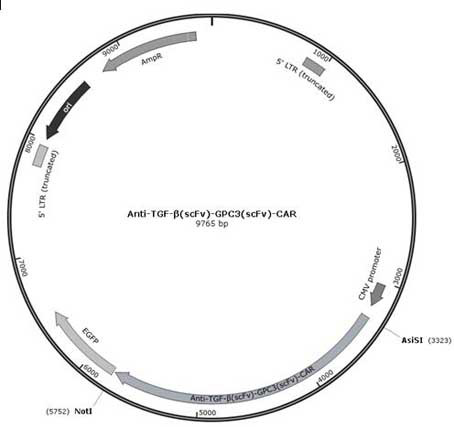

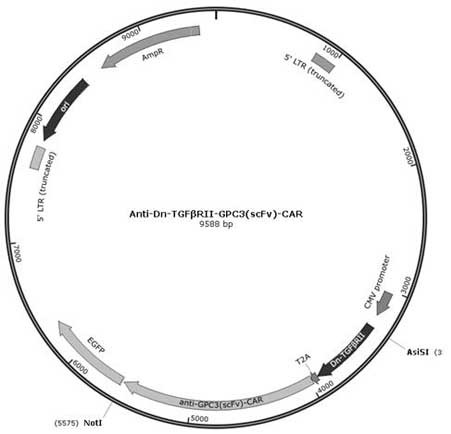

CAR-T cell for overcoming TGF-beta immunosuppression for solid tumor

ActiveCN112210543AIncrease lethalityImprove proliferative abilityPolypeptide with localisation/targeting motifImmunoglobulin superfamilyAntigenGenome editing

The invention provides a CAR-T cell for overcoming TGF-beta immunosuppression for a solid tumor. The CAR-T cell is a CAR-T cell for blocking a TGF-beta signal and targeting the solid tumor. The double-target CAR is adopted to increase the number of effective antigens on the surface of the solid tumor, wider immune response is carried out, the activation of the T cell is enhanced through the synergistic effect, the binding efficiency of the CAR-T and the tumor cell is improved, and the problems of relapse and metastasis caused by tumor immune escape are solved to a greater extent. The CAR capable of keeping activity in TME and resisting immunosuppressive cytokines is designed, the expression of corresponding immunosuppressive cytokines (TGF beta RII) on the surface of the T cell is reducedthrough a gene editing technology (CRISPR / CAS9), the tumor microenvironment is overcome, the activity of the CAR-T cell is improved, and the CAR-T cell is more effective in solid tumor treatment.

Owner:山东省成体细胞产业技术研究院有限公司

Ink for Ink-Jet Recording and Ink Set for Ink-Jet Recording

A black ink for ink-jet includes a pigment wherein an average particle diameter Da of the pigment is in the range of about 90 nm to about 130 nm. In addition, (D95−D5) / Da is about 1.4 or less, where D5 is the 5% cumulative particle diameter of the pigment and D95 is the 95% cumulative particle diameter of the pigment. A color ink for ink-jet recording also includes a pigment with the value Da of about 100 nm or less and (D95−D5) / Da of about 1.3 or less.

Owner:BROTHER KOGYO KK

Side shading glue and borderless display device

ActiveCN106554650BHigh OD valueGood flexibilityNon-linear opticsElectrically-conductive paintsCross-linkPolymer science

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Black composition, black coating composition, resin black matrix, color filter for liquid crystal display and liquid crystal display

ActiveUS8476351B2High OD valueImprove adhesionLiquid crystal compositionsPhotosensitive materialsCrystallographyDisplay device

A black coating composition which gives a highly adhesive resin black matrix that exhibits a high OD value which was able to be attained only by metal thin film black matrices is disclosed. The black coating composition comprises as indispensable components a titanium nitride oxide and a resin. The X-ray intensity ratios R1 and R2 of the titanium nitride oxide represented by the Equations (1) and (2) below, respectively, satisfy the relationships represented by Formulae (3) and (4) below:R1=I3 / {I3+1.8(I1+1.8I2)} (1)R2=I2 / I1 (2)R1>0.70 (3)0.85<R2<1.80 (4)wherein I1 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ, determined by using CuKα line as the X-ray source, is 25° to 26°, I2 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ is 27° to 28°, and I3 represents the maximum diffraction intensity of the titanium nitride oxide when the angle of diffraction 2θ is 36° to 38°.

Owner:TORAY IND INC

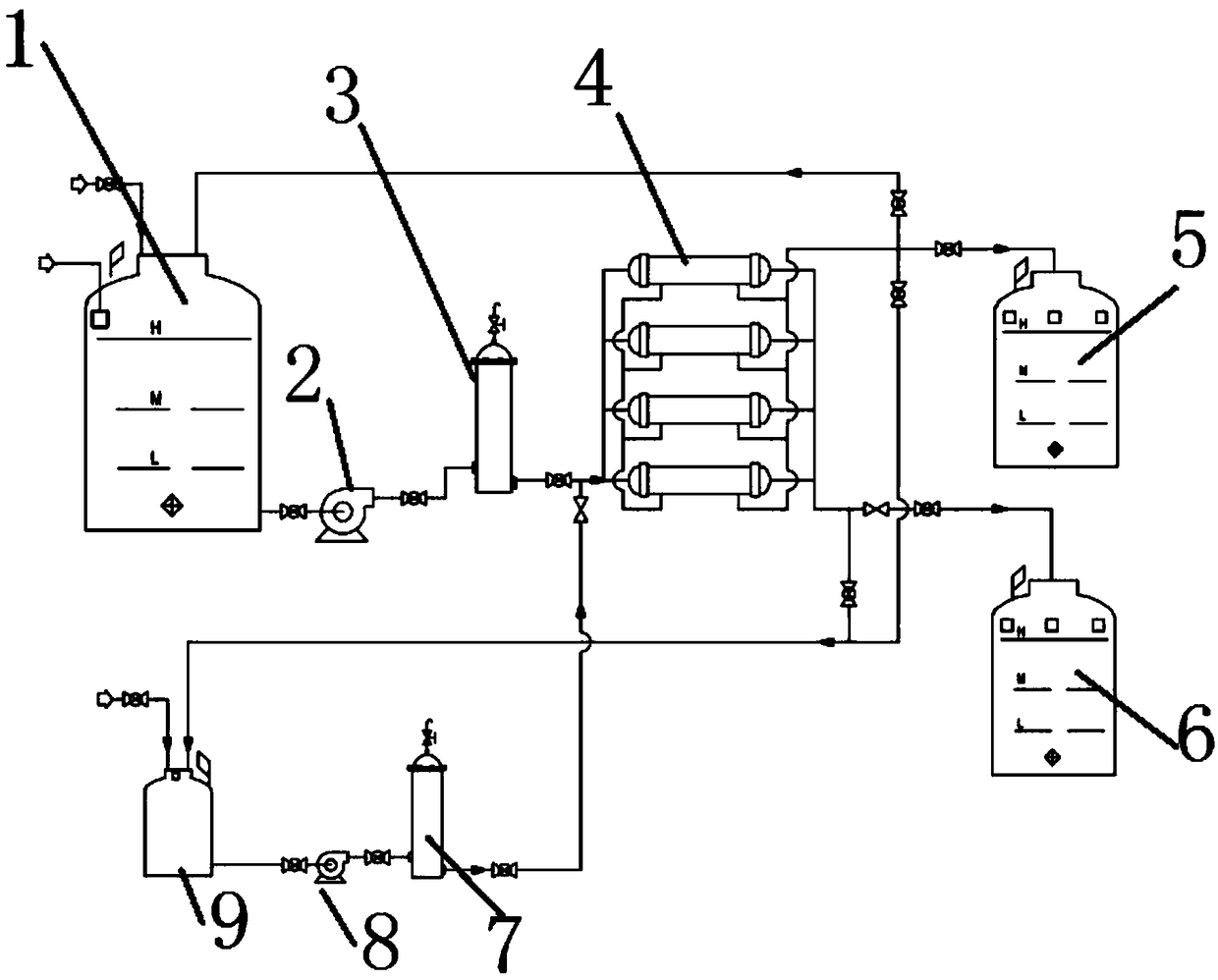

Escherichia coli fermentation liquor concentration process and system

InactiveCN108504612AKeep aliveHigh OD valueBioreactor/fermenter combinationsBiological substance pretreatmentsChemistryFermentation broth

The invention discloses an escherichia coli fermentation liquor concentration process, comprising the following steps: performing filter washing on escherichia coli fermentation liquor, and then performing concentrating and separating on the filtrate by a ceramic film under the condition of operation pressure of 0-6Bar. The invention also discloses an escherichia coli fermentation liquor concentration system, comprising a stock solution tank, a delivery pump, a self-cleaning filter and a ceramic film component which are connected in series, wherein the ceramic film component is internally connected with a concentrated liquor tank and a permeating liquor tank; and the operation pressure of the ceramic film component is 0-6Bar.

Owner:HANGZHOU RUINA MEMBRANE ENG

Optical filter and ambient light sensor

InactiveCN112437893AImprove detection accuracyEqual importPhotometryCamera filtersMaterials scienceLight scattering

The present invention addresses the problem in providing an optical filter that can improve the detection accuracy of an ambient light sensor even if a system for authenticating biometric features andthe ambient light sensor are arranged at close positions. The optical filter of the present invention has a substrate (i) and a light scattering layer formed on at least one surface of the substrate(i), and is characterized in that an OD value when measured at a wavelength of 940 nm from the direction perpendicular to the optical filter is 3 or more.

Owner:JSR CORPORATIOON

Liquid crystal display device

InactiveCN1322360CHigh OD valueReduce reflected lightNon-linear opticsOptical elementsLiquid-crystal displayEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

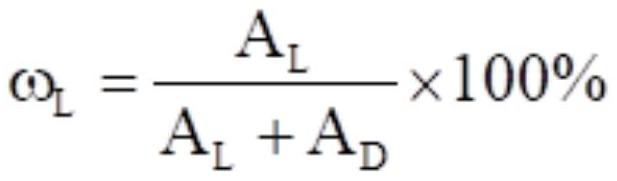

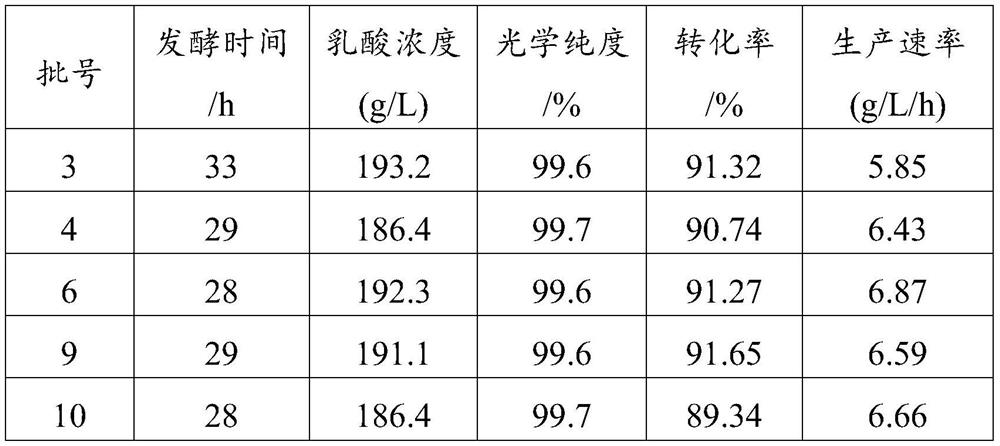

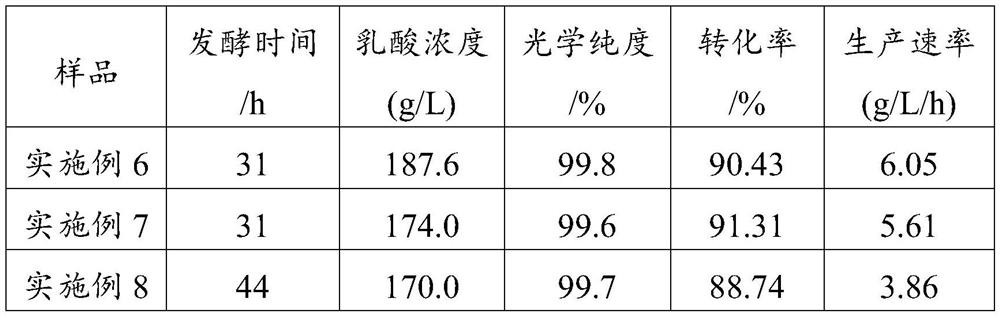

Fermentation medium for preparing hydroxyl-containing carboxylic acid and salt thereof by utilizing bacillus coagulans and fermentation method

ActiveCN112574926AHigh OD valueFast production rateBacteriaMicroorganism based processesBiotechnologyCarboxylic acid

The invention provides a fermentation medium for preparing hydroxyl-containing carboxylic acid and salt thereof by utilizing bacillus coagulans and a fermentation method. The fermentation medium contains an organic nitrogen source and an inorganic nitrogen source, and the mass ratio of the organic nitrogen source to the inorganic nitrogen source is 1:(1-6), preferably 1:(1.3-2.5). According to thefermentation medium provided by the invention, the OD value of the bacterial liquid is effectively controlled, meanwhile, the high conversion rate is realized by controlling the concentration of thecarbon source, the balance between the high OD value and the high conversion rate is achieved, and the yield of a fermentation product is not inhibited, so that the hydroxyl-containing carboxylic acidand the salt thereof prepared by utilizing the fermentation medium provided by the invention are high in production speed and high in conversion rate; besides, the finally obtained fermentation liquor is high in product concentration and high in optical purity.

Owner:ANHUI BBCA BIOCHEMICAL CO LTD

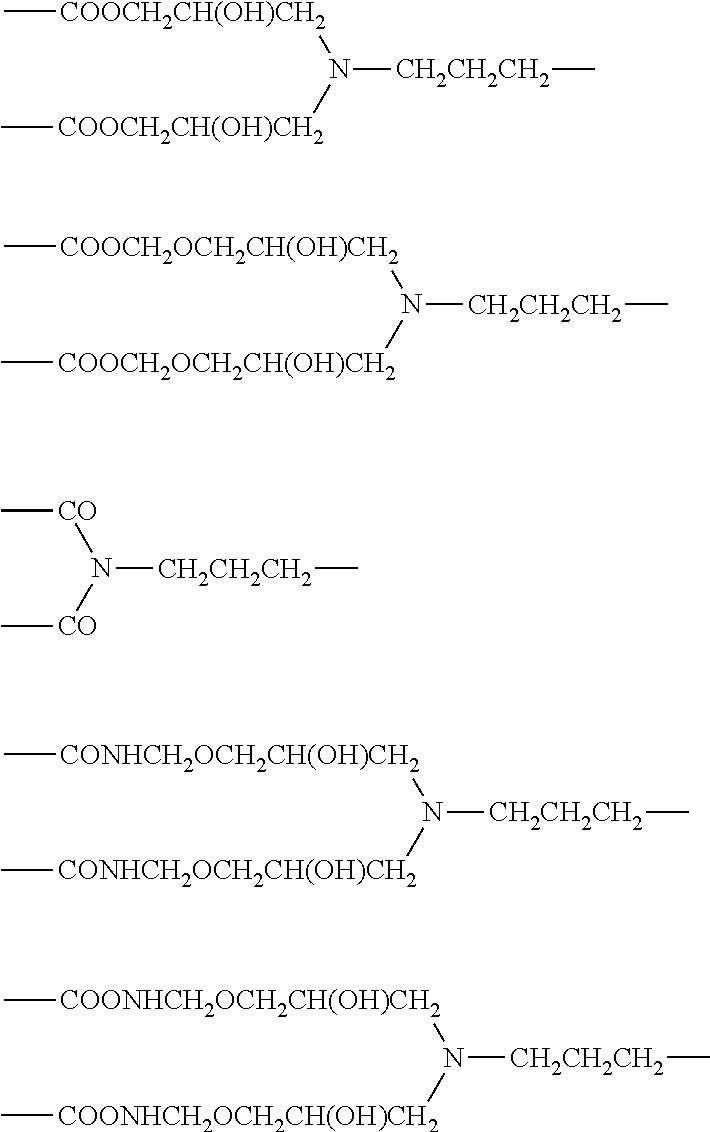

A kind of black frame glue and liquid crystal panel

ActiveCN113249042BReduce pollutionReduce contamination riskNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceNanoparticle

The embodiment of the present application discloses a black frame glue. The raw materials of the black frame glue include acrylate, epoxy resin, free radical initiator, curing agent, filler, coupling agent and bio-melanin. The application also discloses a liquid crystal panel. The bio-melanin nanoparticles are added to the black frame glue of the present application to improve the ability of the black frame glue to scavenge free radicals, and also improve the adhesion of the black frame glue. Applying the black frame glue of the present application to a liquid crystal panel can not only improve the contamination of the liquid crystal panel, but also improve the OD value and bonding performance.

Owner:SUZHOU CHINA STAR OPTOELECTRONICS TECH CO LTD

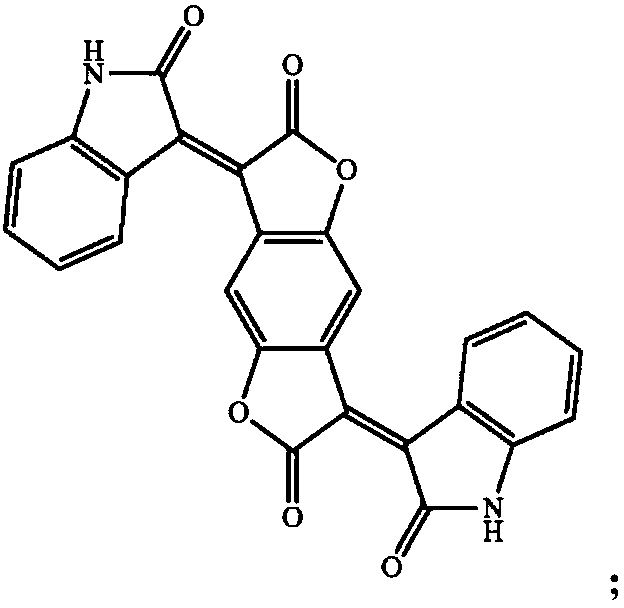

Composite white pigment, photoresist material containing same and application of composite white pigment

ActiveCN105093829AImprove absorption rateHigh shieldingPhotosensitive materials for photomechanical apparatusNon-linear opticsLithography processLiquid-crystal display

The invention relates to the field of liquid crystal display, in particular to a composite white pigment and a photoresist material. The composite white pigment comprises an inner core prepared from a non-white pigment, and an outer layer prepared from a white pigment, wherein the photoresist material provided by the invention is prepared from the following components in parts by weight: 5-15 parts of a photosensitizer, 5-15 parts of a dispersing agent, 50-80 parts of a solvent and 5-15 parts of a composite white pigment. Through a double-layer structure design with different colors in inner layer and outer layer, the defects of the original ordinary pure white pigment on a light absorption surface are improved with the nonwhite inner core; improvement of the light absorption properties of the traditional white photoresist material is facilitated; the absorption rate of the white color on the light can be increased; the screening capacity of the photoresist is improved; the color can be relatively uniform; the material can be ideally applied to a one-glass-solution (OGS) frame material; a few of manufacture procedures of a white lithography process can be reduced; and the OD value can be effectively increased.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

A rapid detection kit for novel coronavirus antibody based on mixed antigen

ActiveCN111239394BEasy to operateHigh detection sensitivitySsRNA viruses positive-senseAntibody mimetics/scaffoldsAntigenCoronavirus antibody

The invention discloses a kit for rapid detection of novel coronavirus antibody based on mixed antigens, comprising colloidal gold of colloidal gold antigen of nucleocapsid protein antigen of COVID-19 and colloidal gold of antigenic protein of COVID-19 spike protein. The kit is used for diagnosing novel coronavirus pneumonia, and it is easy to operate. It can directly mix the colloidal gold of the colloidal gold of the nucleocapsid protein antigen of COVID-19 and the colloidal gold of the spike protein antigen of the COVID-19 as a whole for detection, or directly mix the COVID-19 nucleocapsid protein antigen colloidal gold and COVID-19 spike protein antigen colloidal gold are mixed for detection, and the detection sensitivity is high, which is conducive to the effective control of the epidemic.

Owner:SICHUAN MACCURA BIOTECH CO LTD

Reactive polyurethane hot-melt adhesive for mobile phone round hole shading and preparation method thereof

ActiveCN112608705BHigh OD valueImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to the technical field of reactive polyurethane hot-melt adhesives, in particular to reactive-type polyurethane hot-melt adhesives for shading mobile phone round holes and a preparation method thereof. The raw materials of the polyurethane hot melt adhesive include, in parts by weight, 30-65 parts of polyol, 10-40 parts of tackifying resin, 0.1-1 part of antioxidant, 5-15 parts of sunscreen, and 10-15 parts of aromatic isocyanate. 35 parts, 0.01-0.1 parts of catalyst, 1-2 parts of silane coupling agent. The hot melt adhesive provided by the invention has good light-shielding property and aging resistance.

Owner:WUXI WANLI ADHESION MATERIALS

Color optical filter and liquid crystal display device

InactiveCN1292269CGood optical performanceReduce reflectionNon-linear opticsOptical elementsLight filterComputer science

The present invention relates to color optical filter and LCD device therewith. The color optical filter includes one first substrate, and one black matrix and coloring layer. The black matrix layer includes one anti-reflecting layer and one mask layer set on the first substrate layer successively; the coloring layer and the black matrix layer are set on the first substrate alternately; and the coloring layer covers the surface of the mask layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com