Escherichia coli fermentation liquor concentration process and system

A technology of Escherichia coli and concentration system, which is applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, bacteria, etc., can solve the problems of low density of concentrated bacteria and high accumulation of organic acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

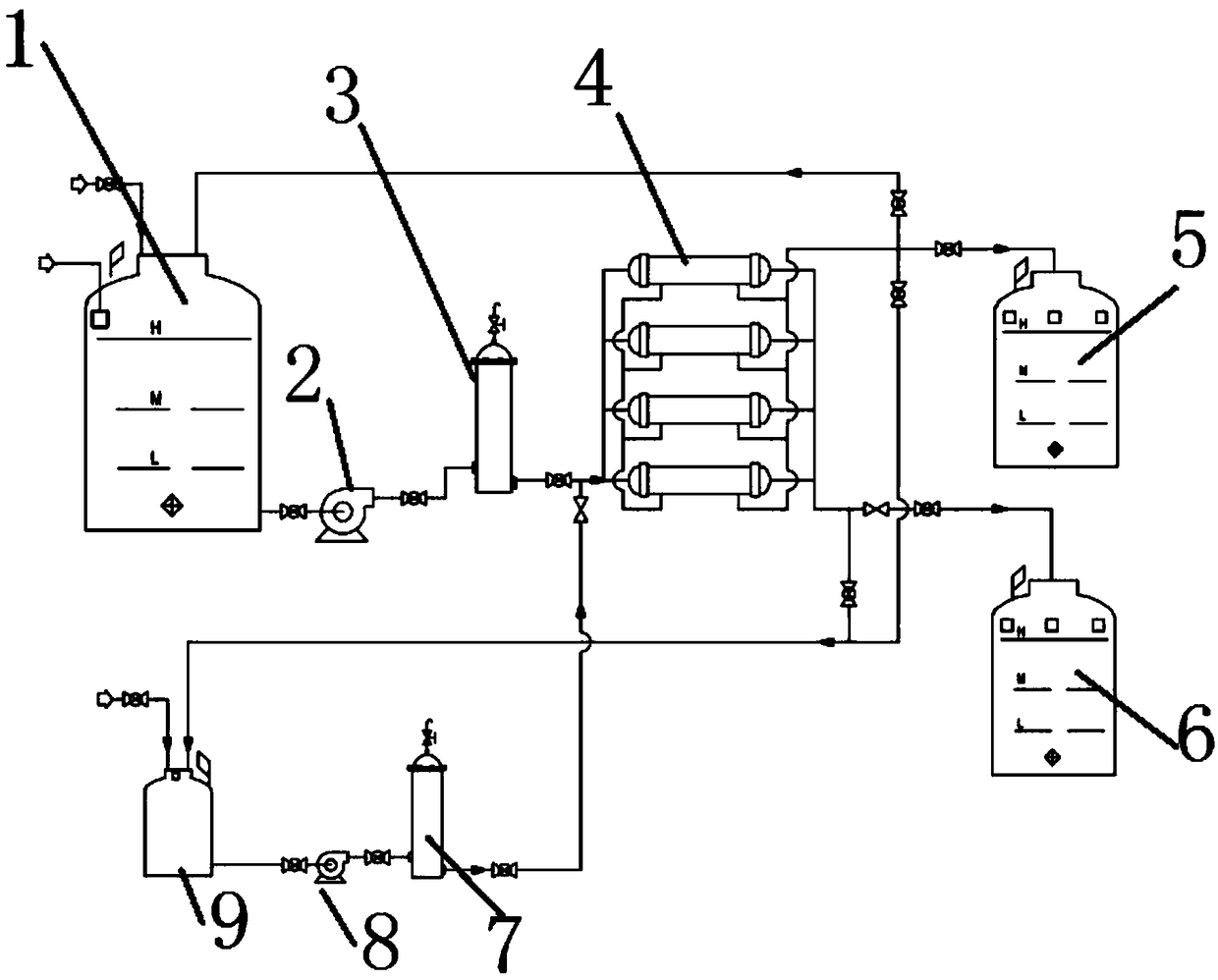

[0012] Such as figure 1 Shown, a kind of Escherichia coli fermented liquid concentrating process, comprises the following steps: carry out diafiltration to Escherichia coli fermented liquid, then the filtrate is carried out concentrating and separating by ceramic membrane under operating pressure under 0-6Bar condition; Also includes the ceramic membrane Cleaning steps.

[0013] The ceramic membrane is made of silicon carbide or aluminum oxide; the pore size of the ceramic membrane is 200nm.

[0014] A system for concentrating Escherichia coli fermentation liquid, comprising a raw liquid tank 1, a delivery pump 2, a self-cleaning filter 3, and a ceramic membrane module 4 connected in series in sequence, and the ceramic membrane module 4 is connected to a concentrated solution tank 5 and a permeate tank 6 ; The operating pressure of the ceramic membrane module 4 is 0-6 Bar.

[0015] It also includes an online cleaning device, which includes a cleaning medicine box 7, a flushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com