A kind of black frame glue and liquid crystal panel

A black frame and acrylate technology, applied in adhesives, instruments, optics, etc., can solve the problems of liquid crystal pollution, slow curing speed, etc., and achieve the effects of improving adhesion, increasing adhesion, good shaping ability and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

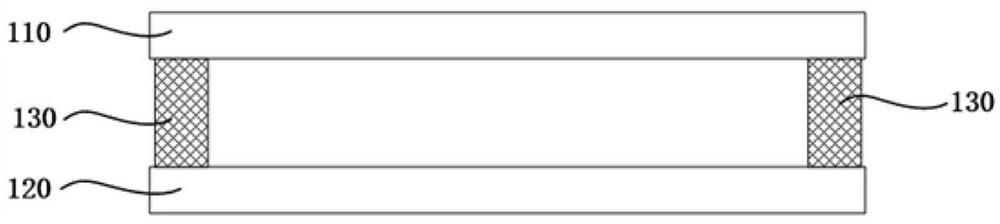

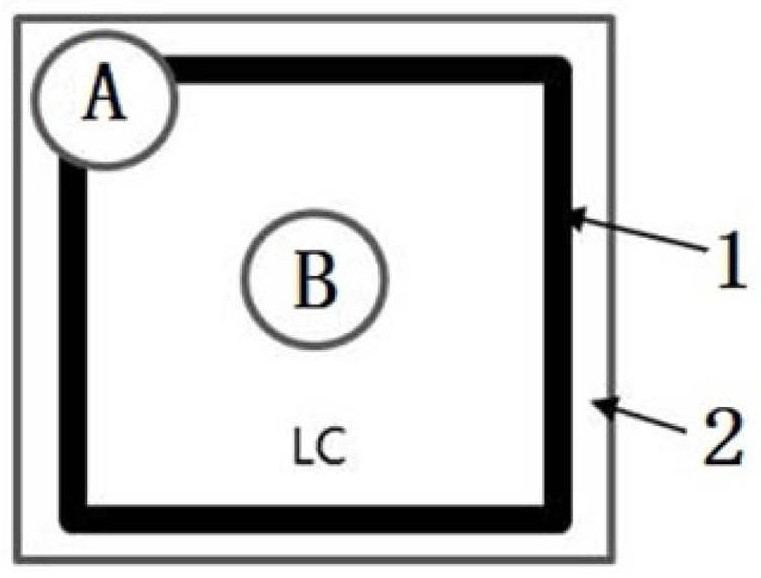

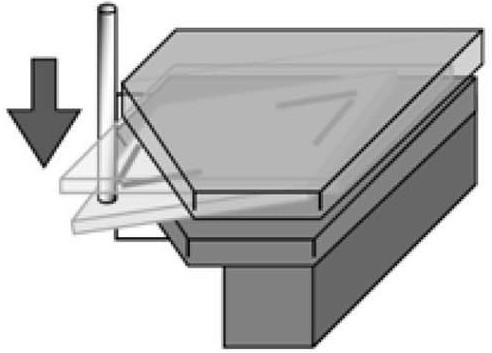

Image

Examples

Embodiment 1

[0040] This embodiment provides a black frame glue, which contains raw materials in parts by weight: 70 parts by weight of acrylate, 30 parts by weight of epoxy resin, 0.05 parts by weight of free radical initiator, 5 parts by weight of curing agent, filler 6 parts by weight, 5 parts by weight of coupling agent, 0.5 parts by weight of pigment and 5 parts by weight of bio-melanin.

[0041] The biological melanin is isomelanin nanoparticles, and the preparation method refers to Xuhao Zhou et al, Artificial Allomelanin Nanoparticles, ACS Nano.

[0042] The acrylate is a dicyclopentadiene-skeleton (meth)acrylate and an isocyanuryl-skeleton (meth)acrylate.

[0043] The epoxy resin adopts bisphenol A type epoxy resin.

[0044] The free radical initiator adopts benzophenone compound.

[0045] The curing agent adopts adipic acid dihydrazide.

[0046] The filler is spherical silica.

[0047] The coupling agent uses γ-aminopropyltrimethoxysilane.

Embodiment 2

[0050] This embodiment provides a black frame glue, which contains raw materials in parts by weight: 90 parts by weight of acrylate, 10 parts by weight of epoxy resin, 0.1 part by weight of free radical initiator, 0.5 parts by weight of curing agent, filler 10 parts by weight, 0.1 parts by weight of coupling agent, 5 parts by weight of pigment and 0.01 part by weight of bio-melanin.

[0051] The biological melanin is eumelanin nanoparticles, and the preparation method refers to: Ming Xiao et al, Bio-Inspired Structural Colors Produced via SelfAssembly of Synthetic MelaninNanoparticles, CS Nano, 9(5), 5454-5460.

[0052] The acrylate is a (meth)acrylate with a dicyclopentadiene skeleton.

[0053] The epoxy resin adopts bisphenol A type epoxy resin.

[0054] The free radical initiator uses an azo compound.

[0055] The curing agent adopts dihydrazide isophthalic acid.

[0056] The filler is calcium carbonate and aluminum oxide.

[0057] The coupling agent uses γ-glycidoxypro...

Embodiment 3

[0060] This embodiment provides a black frame glue, which contains raw materials in parts by weight: 50 parts by weight of acrylate, 50 parts by weight of epoxy resin, 0.01 parts by weight of free radical initiator, 10 parts by weight of curing agent, filler 1 part by weight, 10 parts by weight of coupling agent, 0.1 part by weight of pigment and 10 parts by weight of bio-melanin.

[0061] The bio-melanin is isomelanin nanoparticles, and the preparation method is the same as that in Example 1.

[0062] The acrylate is a (meth)acrylate with an isocyanuryl skeleton.

[0063] The epoxy resin adopts bisphenol F type epoxy resin.

[0064] The free radical initiator uses acyl phosphine oxide compounds, peroxides and azo compounds.

[0065] The curing agent adopts adipic acid dihydrazide.

[0066] The filler adopts spherical silica and alumina.

[0067] The coupling agent uses γ-isocyanate propyl trimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com