Pigment solution for black matrix, black matrix as well as preparation method of pigment solution, display panel

A technology of black matrix and pigment liquid, which is applied in the direction of pigment slurry and photosensitive materials used in optical mechanical equipment, etc., can solve the problems of low resistance, high cost, and low shading density, and achieve high resistance, low cost, and high penetration ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

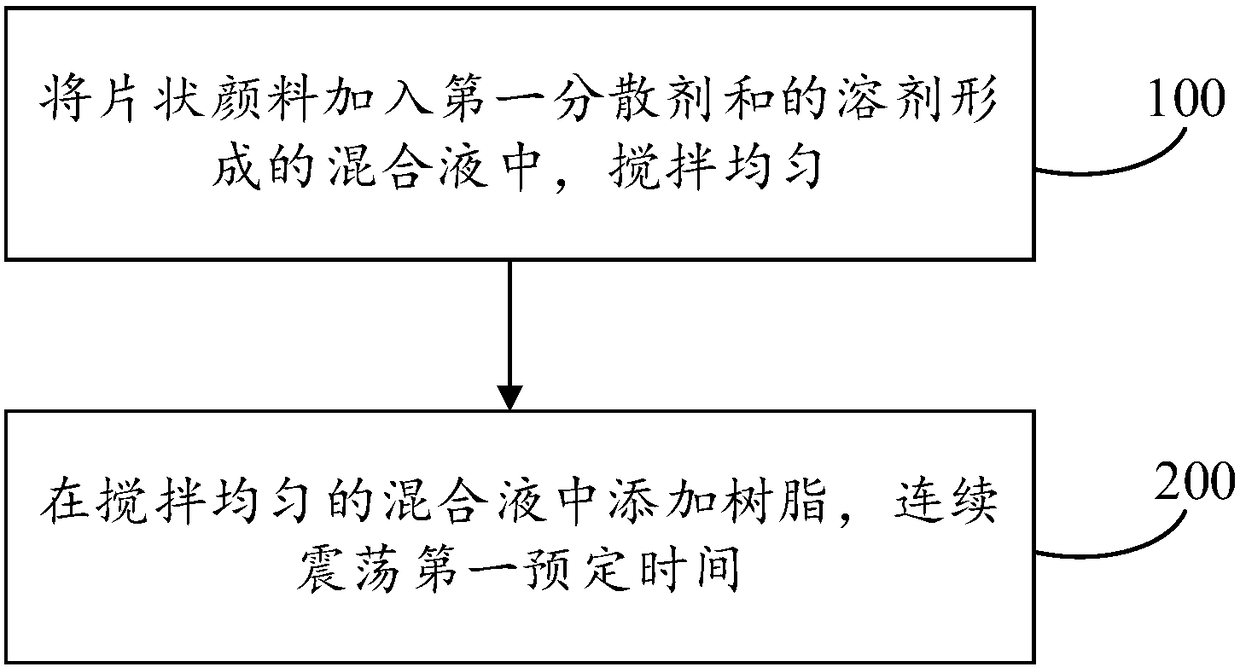

[0035] The present invention also provides a kind of preparation method of the black matrix pigment liquid of preparation above-mentioned embodiment, refer to image 3 shown, including the following steps:

[0036] Step 100, adding flake pigments into the mixed liquid formed by the first dispersant and solvent, and stirring evenly.

[0037] Step 200, adding resin to the homogeneously stirred mixture, and vibrating continuously for a first predetermined time.

[0038] In the preparation process of the above-mentioned pigment solution for black matrix, the mass parts of each component added are specifically: 15-35 parts of flake pigment, 1-5 parts of resin, 1-3 parts of first dispersant, 60-85 parts of solvent .

[0039] The above-mentioned first predetermined time may be 4h-7h, and the above-mentioned mixing process may be oscillating and mixing in a vibrating machine and / or sanding and mixing in a sand mill.

[0040] The present invention also provides a method for preparin...

Embodiment 1

[0046] Pigment solution preparation:

[0047] Add 15 to 25 parts of flaky titanium dioxide (150nm in length and width, and 20nm in thickness) to 1 to 3 parts of BYK dispersant and 60 to 85 parts of PMA (propylene glycol methyl ether acetic acid) in a shake bottle equipped with zirconium beads. ester) mixture, under the condition of uniform stirring, add 1 to 5 parts of 611 resin;

[0048] Vibrate continuously for 5 hours to prepare a pigment solution containing flake pigments.

[0049] Black matrix preparation:

[0050] Mix the above pigment liquid with soluble resin, monomer, initiator, leveling agent, etc.;

[0051] After coating, exposing and developing, a black matrix is produced.

[0052] After testing, the thickness of the black matrix is 0.75 μm, the OD value is 4.3, and the volume resistance is 3.2×10 6 Ω·cm.

Embodiment 2

[0054] Pigment solution preparation:

[0055] Add 20 to 30 parts of flaky titanium dioxide (150nm in length and width, and 20nm in thickness) to 1 to 3 parts of BYK dispersant and 60 to 85 parts of PMA (propylene glycol methyl ether acetic acid) in a shake bottle equipped with zirconium beads. ester) mixture, under the condition of uniform stirring, add 1 to 5 parts of 611 resin;

[0056] Vibrate continuously for 5 hours to prepare a pigment solution containing flake pigments.

[0057] Black matrix preparation:

[0058] Mix the above pigment liquid with soluble resin, monomer, initiator, leveling agent, etc.;

[0059] After coating, exposing and developing, a black matrix is produced.

[0060] After testing, the thickness of the black matrix is 0.8 μm, the OD value is 4.8, and the volume resistance is 2.5×10 6 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com