Method for preparing color filter and method for manufactring liquid crystal display

A technology of color filter and manufacturing method, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of high backlight reflectivity, achieve the effects of reducing backlight reflection, increasing OD value, and optimal optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

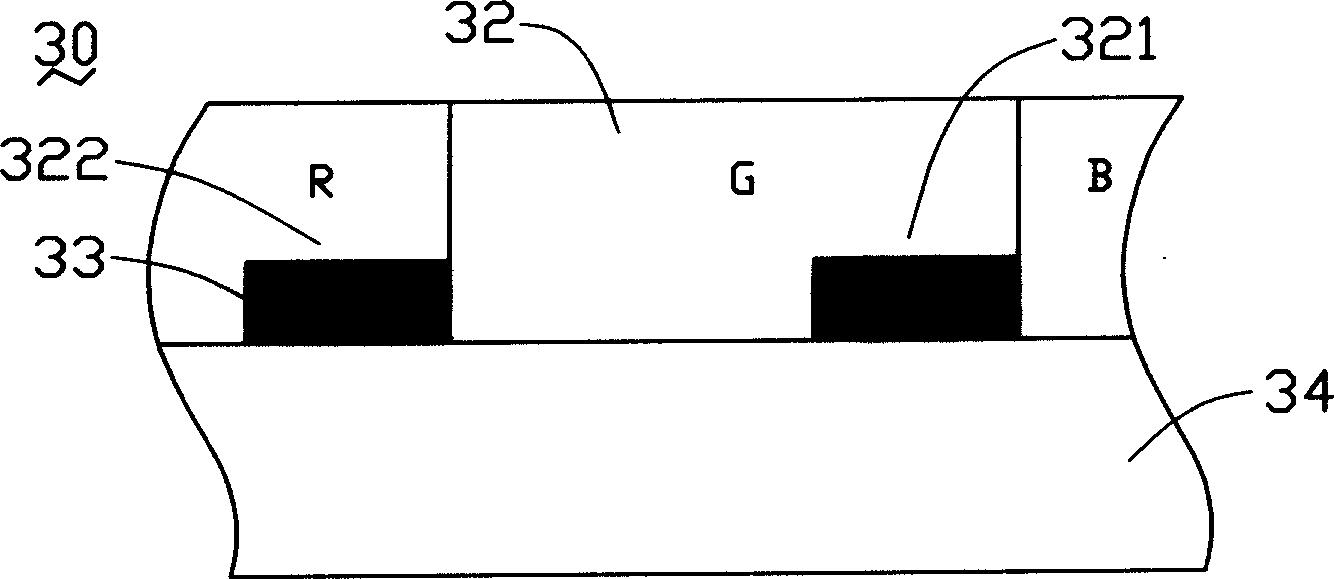

[0018] see image 3 , is a schematic diagram of the first embodiment of the manufacturing method of the color filter of the present invention. First, make a first base layer 34; then make a black resin matrix layer 33 on the surface of the first base layer 34, the material of this black resin matrix layer 33 is black photosensitive resin or black thermal resin, also available phenolic resin or acrylic Resin and black pigment are mixed; Then a coloring layer 32 is formed on the surface of the first base layer 34, and the coloring layer 32 includes three kinds of coloring units of red (R), green (G) and blue (B), and its function is The light is filtered so that it only passes through the light of the same color as the coloring unit; the coloring unit and the black resin matrix layer 33 are alternately distributed on the first base layer 34 . Parts 321 and 322 of the colored layer 32 extend to the entire surface of the black resin matrix layer 33 to cover the black resin matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com