Black composition, black coating composition, resin black matrix, color filter for liquid crystal display and liquid crystal display

A composition, black technology, applied in the direction of instruments, filters, coatings, etc., can solve the problems of increased manufacturing cost, insufficient adhesion, low adhesion of resin black matrix, etc., to prevent the reduction of yield, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] After putting titanium dioxide powder (4.0kg) with an average primary particle size of 40nm into the reaction furnace, flow ammonia gas at a linear velocity of 6cm / sec in the furnace, and react at a furnace temperature of 850°C for 9 hours to obtain titanate nitrogen Compound A (3.2 kg). The diffraction spectrum of the powder of titanate nitride A as a light-shielding agent was measured using an X-ray diffraction device manufactured by Rigaku, and the result was, I 1 , I 2 , I 3 36cps, 36cps, 818cps respectively, X-ray intensity ratio R 1 0.82, X-ray intensity ratio R 2 is 1.00.

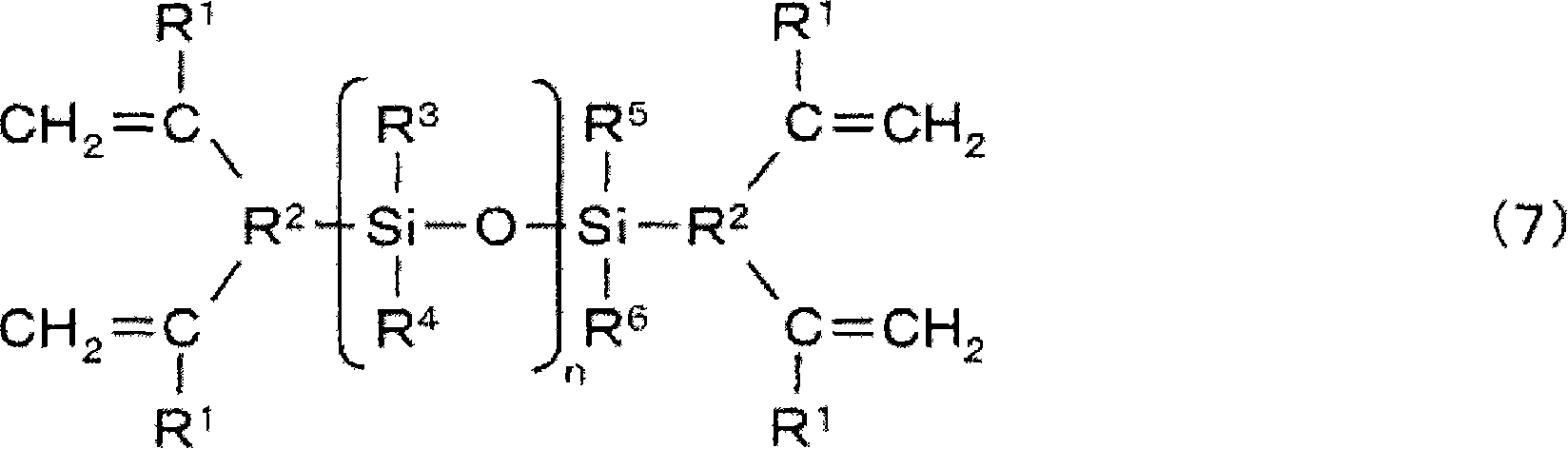

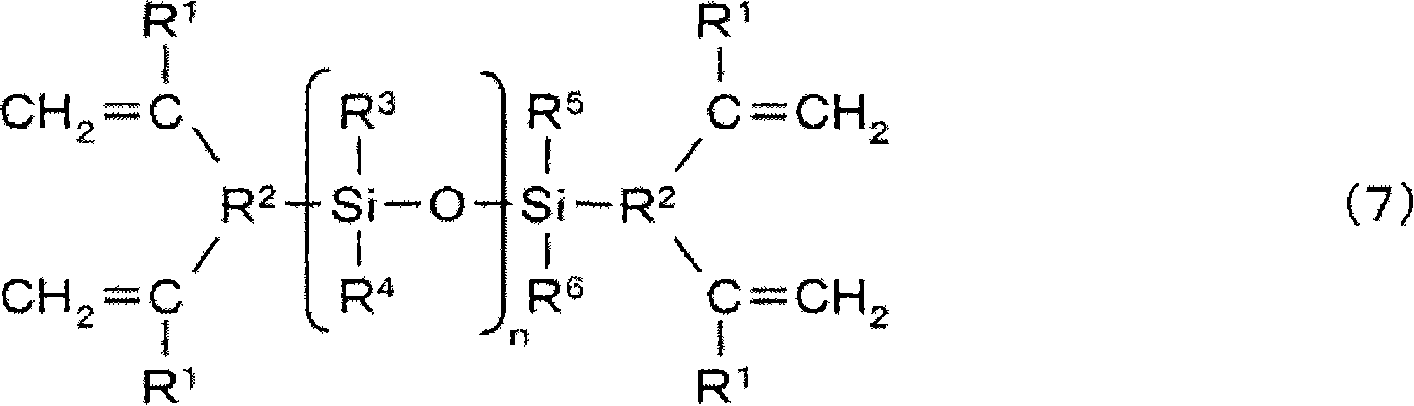

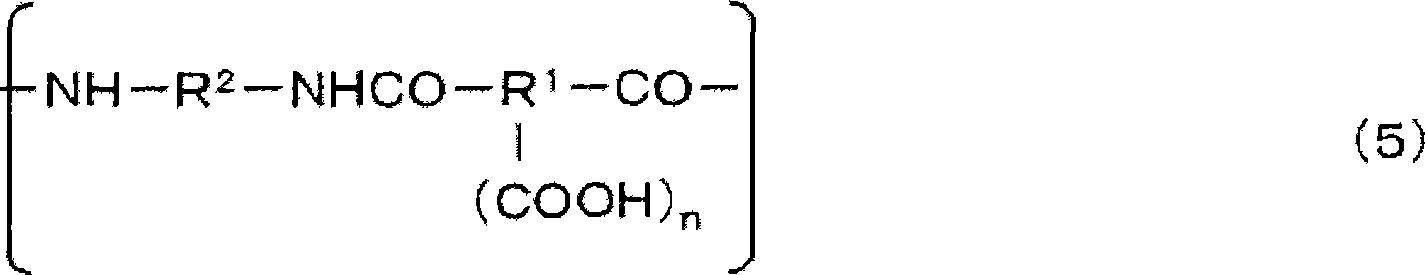

[0102] In γ-butyrolactone (3825g) solvent, pyromellitic dianhydride (149.6g), benzophenone tetracarboxylic dianhydride (225.5g), 3,3'-diaminodiphenyl sulfone (69.5 g), 4,4'-diaminodiphenyl ether (210.2g), and bis-3-(aminopropyl)tetramethylsiloxane (17.4g) reacted at a temperature of 60°C for 3 hours, Maleic anhydride (2.25g) was added, and it was made to react at the temperature of 60 de...

Embodiment 2

[0105]Put titanium dioxide powder (4.0kg) with an average primary particle size of 50nm into the reaction furnace, then circulate ammonia gas at a linear velocity of 5.5cm / sec in the furnace, and react at a furnace temperature of 850°C for 8 hours to obtain nitrogen titanate Compound B (3.1 kg). The diffraction spectrum of the powder of titanate nitride B was measured using an X-ray diffraction device manufactured by Rigaku, and the result was, I 1 , I 2 , I 3 Respectively 41cps, 73cps, 775cps, X-ray intensity ratio R 1 0.71, X-ray intensity ratio R 2 is 1.78. Except having used titanate nitride B as a light-shielding agent, it carried out similarly to Example 1, and formed the light-shielding film for resin black matrices. The film thickness of the obtained light-shielding film for resin black matrices was 0.8 micrometers, and OD value was 3.51. In addition, a cellophane cross-hatch peeling test was performed in the same manner as in Example 1, but no peeling site was f...

Embodiment 3

[0107] Put titanium dioxide powder (4.0kg) with an average primary particle size of 45nm into the reaction furnace, flow ammonia gas at a linear velocity of 6.5cm / sec in the furnace, and react at a furnace temperature of 800°C for 8 hours to obtain nitrogen titanate Compound C (3.2 kg). The diffraction spectrum of the powder of titanate nitride C was measured using an X-ray diffraction device manufactured by Rigaku, and the result was, I 1 , I 2 , I 3 Respectively 49cps, 42cps, 802cps, X-ray intensity ratio R 1 0.78, X-ray intensity ratio R 2 is 0.86. Except having used titanate nitride C as a light-shielding agent, it carried out similarly to Example 1, and formed the light-shielding film for resin black matrices. The film thickness of the obtained light-shielding film for resin black matrices was 0.8 micrometers, and OD value was 3.55. In addition, a cellophane cross-hatch peeling test was performed in the same manner as in Example 1, but no peeling site was found.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com