Carbon fiber cloth adhesive for underwater or humid environment reinforcement engineering and preparation method thereof

A carbon fiber cloth, wet environment technology, applied in the field of chemical building materials, can solve the problems of inability to meet the application requirements of hydraulic building reinforcement engineering, poor bonding performance, etc., and achieve excellent underwater curing and underwater bonding performance, solidification. Effects of long glue time, excellent underwater cure and wet side bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

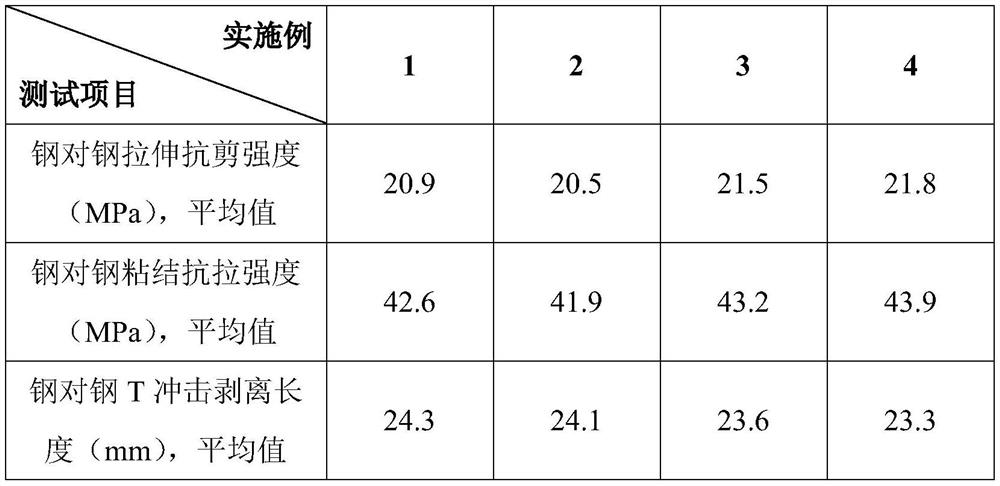

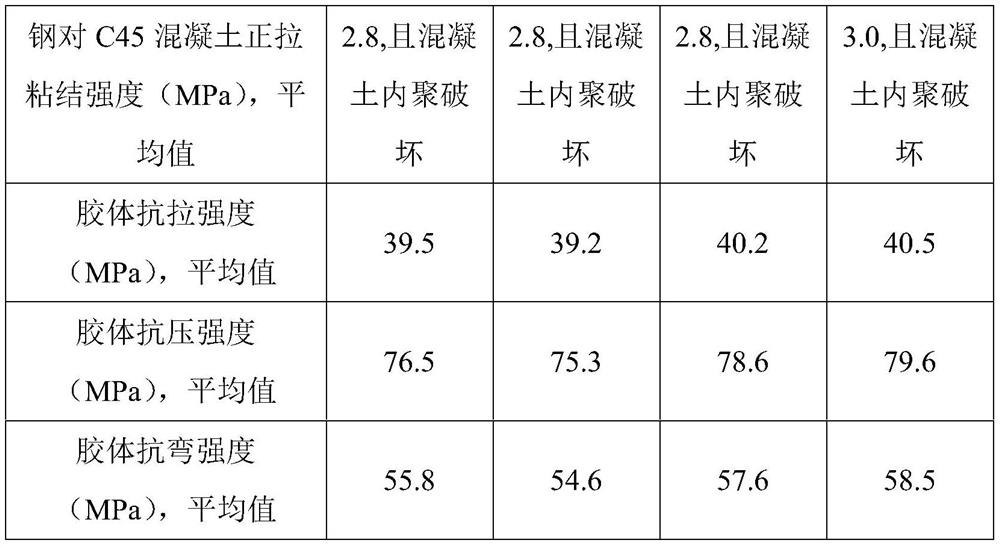

Embodiment 1

[0028] Carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering, it is composed of A and B two components, the mass ratio is A component: B component = 1:1. After component A and component B are accurately weighed according to the mass ratio, stir and mix evenly to obtain the carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering.

[0029]The formula of the A component in parts by mass is: 50 parts of fluorinated epoxy resin 1,3-bis(3-glycidyl ether tetrafluorophenoxy)-2-hydroxypropane; 20 parts of hydroxymethyl bis Phenol A type epoxy resin CEQ-45; bisphenol S type epoxy resin 30 parts; diglycidyl aniline 2 parts; trimethylolpropane triglycidyl ether 5 parts; 5 parts nano rubber toughening agent VP-501 ; 8 parts of nano-silica toughening agent; 0.5 parts of water-absorbing resin acrylamide-acrylate copolymer cross-linked product; 0.1 part of defoamer BYK-066N; 0.1 part of dispersant BYK-163; 100 parts of active s...

Embodiment 2

[0036] Carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering, it is composed of A and B two components, the mass ratio is A component: B component = 1:1. After component A and component B are accurately weighed according to the mass ratio, stir and mix evenly to obtain the carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering.

[0037] The formula of the A component in parts by mass is: 75 parts of fluorinated epoxy resin 1,3-bis(3-glycidyl ether tetrafluorophenoxy)-2-hydroxypropane; 10 parts of hydroxymethyl bis Phenol A type epoxy resin CEQ-45; bisphenol S type epoxy resin 15 parts; diglycidyl aniline 4 parts; trimethylolpropane triglycidyl ether 5 parts; 10 parts nano rubber toughening agent VP-501 ; 5 parts of nano-silica toughening agent; 1 part of water-absorbing resin acrylamide-acrylate copolymer cross-linked product; 0.2 parts of defoamer BYK-066N; 0.2 parts of dispersant BYK-163; 100 parts of active ...

Embodiment 3

[0044] Carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering, it is composed of A and B two components, the mass ratio is A component: B component = 2:1. After component A and component B are accurately weighed according to the mass ratio, stir and mix evenly to obtain the carbon fiber cloth adhesive for underwater or wet environment reinforcement engineering.

[0045] The formula of the A component in parts by mass is: 65 parts of fluorinated epoxy resin 1,3-bis(3-glycidyl ether tetrafluorophenoxy)-2-hydroxypropane; 15 parts of hydroxymethyl bis phenol A type epoxy resin CEQ-45; bisphenol S type epoxy resin 20 parts; diglycidyl aniline 3 parts; trimethylol propane triglycidyl ether 4 parts; 8 parts nano rubber toughening agent VP-501 ; 7 parts of nano-silica toughening agent; 0.8 parts of water-absorbing resin acrylamide-acrylate copolymer cross-linked product; 0.15 parts of defoamer BYK-066N; 0.18 parts of dispersant BYK-163; 120 parts of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com