Ultraviolet light hybrid light curing waterborne polyurethane acrylate and preparation method and application thereof

A polyurethane acrylate, hybrid light curing technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow curing speed, high price, limited practical application, etc., and achieve fast curing reaction speed and prepolymer conversion. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

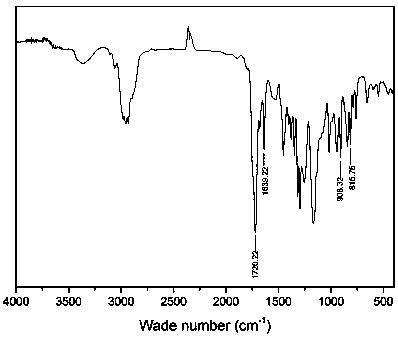

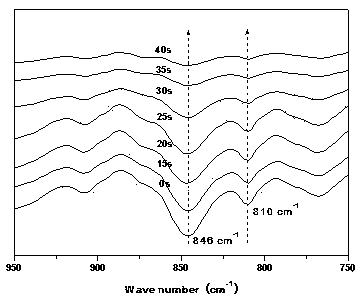

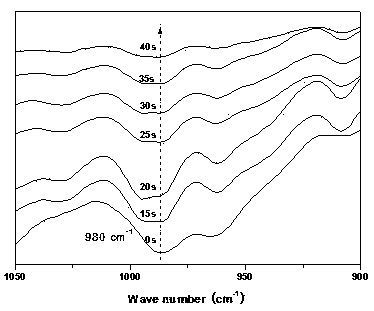

[0032] After dehydration of 100 parts by weight of polypropylene carbonate diol with a molecular weight of 2000 and an intramolecular carbonate group molar fraction of 0.25, add 5 parts by weight of hydrophilic chain extender dimethylol propionic acid, 30 parts by weight of Toluene diisocyanate, 0.5 parts by weight of catalyst dibutyltin dilaurate, react at 80°C for 4 hours, cool down to 60°C, add 5 parts by weight of functional monomer hydroxyethyl methacrylate, 5 parts by weight of functional monomer shrink Glycerin was partially capped, reacted for 1 hour, cooled to 30°C, added 3.76 parts by weight of salt-forming agent triethylamine to react for 0.1 hour, added 280 parts by weight of deionized water, and emulsified at 0°C for 2 hours, then added 5 parts by weight of the chain extender diethylamine were reacted for 1 hour to obtain an ultraviolet light-mixed light-curable aqueous polyurethane acrylate emulsion. Adopt the Magna360 type Fourier transform infrared spectrometer...

Embodiment 2

[0049] With 100 parts by weight of molecular weight 2000, after the polypropylene carbonate diol dehydration of intramolecular carbonate group molar fraction is 0.25, add 6 parts by weight of hydrophilic chain extender dimethylol propionic acid, 45 parts by weight of toluene Diisocyanate, 0.5 parts by weight of catalyst dibutyltin dilaurate, react at 80°C for 4 hours, cool down to 60°C, add 10 parts by weight of functional monomer hydroxyethyl methacrylate for partial capping, react for 1 hour, cool down to 30°C, add 3.76 parts by weight of salt-forming agent triethylamine to react for 0.1 hour, add 280 parts by weight of deionized water, emulsify and react at 0°C for 2 hours, then add 5 parts by weight of chain extender diethylamine to react After 1 hour, an ultraviolet light mixed photocurable aqueous polyurethane acrylate emulsion was obtained.

[0050] Mix 100 parts by weight of the above-mentioned UV-cured water-based polyurethane acrylate emulsion with 3.5 parts by weigh...

Embodiment 3

[0052] With 100 parts by weight of molecular weight 2000, after the polypropylene carbonate diol dehydration of intramolecular carbonate group molar fraction is 0.25, add 5 parts by weight of hydrophilic chain extender dimethylol propionic acid, 30 parts by weight of toluene Diisocyanate, 0.5 parts by weight of catalyst dibutyltin dilaurate, react at 80°C for 4 hours, cool down to 60°C, add 5 parts by weight of functional monomer hydroxyethyl methacrylate, 5 parts by weight of functional monomer glycidol Carry out partial capping, react for 1 hour, cool down to 30°C, add 3.76 parts by weight of salt-forming agent triethylamine to react for 0.1 hour, add 280 parts by weight of deionized water, emulsify and react at 0°C for 2 hours, then add 5 The weight part of the chain extender diethylamine was reacted for 1 hour to obtain the ultraviolet light mixed photocurable aqueous polyurethane acrylate emulsion.

[0053] Mix 100 parts by weight of the above-mentioned UV-curable water-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com